Welcome to our comprehensive guide on EPS helmets – your go-to resource for understanding everything there is to know about these critical pieces of safety gear. Whether you’re a seasoned rider or just starting your journey, ensuring the utmost protection for your head is paramount, and EPS helmets play a pivotal role in achieving that goal.

In this ultimate guide, we’ll delve into the intricate details of EPS foam helmets, uncovering their construction, functionality, safety standards, maintenance requirements, and much more. From understanding how EPS foam works to deciphering the significance of certifications like DOT, Snell, and ECE, we leave no stone unturned in providing you with the knowledge you need to make informed decisions about your helmet choices.

So, buckle up (or rather, helmet up!), as we embark on a journey through the world of EPS helmets, empowering you to ride with confidence and peace of mind. Let’s dive in!

What Is EPS Helmet?

EPS helmet meaning:

EPS foam helmets, short for Expanded Polystyrene foam helmets, are crucial protective gear designed to safeguard the head during various activities such as cycling, motorcycling, skiing, and snowboarding. EPS foam, the primary material used in these helmets, is renowned for its exceptional shock-absorbing properties.

When subjected to impact, EPS foam compresses, effectively absorbing and dispersing the kinetic energy generated, thus minimizing the force transmitted to the wearer’s head. This mechanism significantly reduces the risk of head injuries, making EPS foam helmets a cornerstone of safety equipment for enthusiasts and professionals alike across a wide range of recreational and sports activities.

How Does EPS Foam Work?

EPS foam works through a process of energy absorption and dissipation upon impact. When an external force is applied to the helmet, the EPS foam compresses, absorbing the kinetic energy generated by the impact. This compression action causes the foam cells to deform, effectively spreading the force over a larger surface area.

As a result, the energy is dissipated throughout the helmet, rather than concentrating on a single point of impact. By distributing the force, EPS foam helps to minimize the impact on the wearer’s head, reducing the risk of injury. This mechanism makes EPS foam helmets highly effective in protecting against head trauma during accidents or collisions.

Advantages of EPS Helmets

EPS helmets offer several advantages that make them the preferred choice for individuals seeking optimal head protection:

Exceptional Impact Absorption: EPS foam, the primary material used in these helmets, is renowned for its ability to absorb and dissipate impact energy effectively. This property helps minimize the force transmitted to the wearer’s head during accidents or collisions, reducing the risk of head injuries.

Lightweight Construction: Despite their superior impact-absorbing capabilities, EPS helmets are remarkably lightweight. This lightweight construction enhances comfort and reduces strain on the neck muscles during extended periods of wear, making them ideal for various recreational and sports activities.

Proven Effectiveness: EPS helmets have undergone rigorous testing and evaluation to ensure their effectiveness in protecting against head injuries. Their track record of success in real-world scenarios underscores their reliability and trustworthiness as a safety gear choice.

Wide Range of Applications: From cycling and motorcycling to skiing and snowboarding, EPS helmets are versatile protective gear suitable for a wide range of activities. Their adaptability makes them a go-to choice for enthusiasts and professionals across different sports and recreational pursuits.

Affordability: Despite their advanced technology and superior safety features, EPS helmets are often available at affordable price points, making them accessible to a broad audience. This affordability ensures that individuals can invest in high-quality head protection without breaking the bank.

Comfortable Fit: Many EPS helmets come equipped with adjustable straps and padding systems, allowing for a customized and comfortable fit. This snug fit not only enhances safety but also ensures a pleasant wearing experience for the user, even during prolonged use.

The advantages of EPS helmets make them an indispensable piece of safety equipment for anyone engaging in activities where head protection is paramount. Whether you’re hitting the trails on your bike or carving up the slopes on your skis, an EPS helmet provides peace of mind and confidence, knowing that your head is well-protected against potential impacts and injuries.

Construction of EPS Helmets

The construction of EPS helmets involves several key components designed to maximize safety and comfort for the wearer:

Inner Shell:

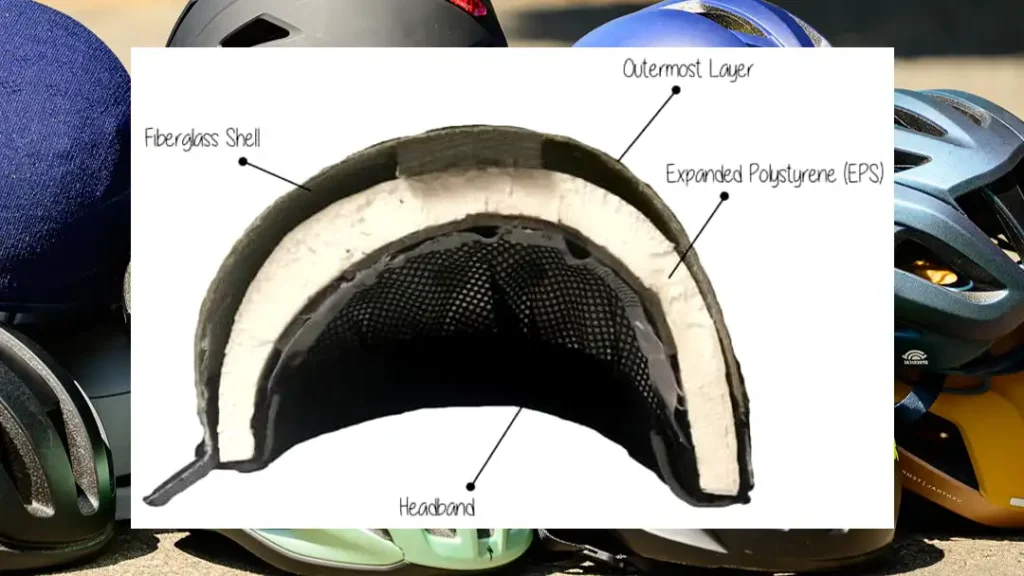

- Expanded Polystyrene (EPS) Foam: The inner shell of EPS helmets is primarily composed of EPS foam, a lightweight and impact-absorbing material. EPS foam is engineered with a cellular structure that compresses upon impact, effectively dissipating energy and reducing the force transmitted to the wearer’s head.

- Molded Shell: Surrounding the EPS foam inner shell is a molded outer shell, typically made from durable materials such as polycarbonate or fiberglass. This outer shell adds structural integrity to the helmet and provides additional protection against impacts and abrasions.

Outer Shell:

- Polycarbonate or Fiberglass: The outer shell of EPS helmets is constructed from tough and resilient materials like polycarbonate or fiberglass. These materials are chosen for their ability to withstand impacts and provide an additional layer of defense against external forces.

- Aerodynamic Design: Many EPS helmets feature an aerodynamically designed outer shell to minimize wind resistance and enhance overall performance. This streamlined design not only improves the helmet’s aesthetics but also contributes to a smoother and more comfortable riding experience.

The combination of EPS foam and a sturdy outer shell ensures that EPS helmets offer optimal protection against head injuries while maintaining a lightweight and comfortable design. By carefully engineering each component for maximum safety and functionality, EPS helmet manufacturers prioritize the well-being and confidence of riders in various recreational and professional settings.

How to Mould EPS Helmet

Molding an EPS helmet involves a precise process to shape Expanded Polystyrene (EPS) foam into the desired helmet design. Here’s a step-by-step guide on how to mold an EPS helmet:

Design Preparation:

Begin by creating a detailed design for the EPS helmet, considering factors such as size, shape, ventilation, and safety features. This design serves as a blueprint for the molding process.

Preparation of EPS Material:

EPS beads, the raw material for the helmet, are pre-expanded and stored in silos. Before molding, the EPS beads are further expanded and heated using steam, making them pliable for shaping.

Molding Machine Setup:

Set up the EPS molding machine according to the specifications of the helmet design. The machine consists of two mold halves that come together to form the helmet shape during molding.

Loading the Mold:

Pour the prepared EPS beads into the molding machine. The mold halves are heated to a precise temperature, ensuring proper fusion and shaping of the EPS material.

Molding Process:

Close the mold halves to encase the EPS beads and initiate the molding process. The combination of heat and pressure causes the EPS beads to fuse together and conform to the shape of the mold cavity, forming the helmet.

Cooling and Solidification:

After molding, allow the helmet to cool and solidify inside the mold. This step ensures that the EPS material retains its shape and structural integrity once removed from the mold.

Demolding:

Once cooled, open the mold to release the molded helmet. Carefully remove the helmet from the mold, taking care not to damage its shape or surface finish.

Trimming and Finishing:

Trim away any excess material or rough edges from the molded helmet to achieve the desired finish. Additional components, such as straps, buckles, and padding, may be added during this stage to complete the helmet assembly.

Quality Control:

Conduct thorough quality control inspections to ensure that the molded helmet meets the specified safety standards and manufacturing tolerances. This may include visual inspections, dimensional checks, and impact testing.

Packaging and Distribution:

Once approved, package the molded helmets securely for distribution to retailers or end-users. Proper packaging helps protect the helmets during transportation and storage, ensuring their quality upon arrival.

By following these steps meticulously, manufacturers can produce high-quality EPS helmets that offer excellent protection and comfort for riders across various sports and recreational activities.

Safety Standards and Testing

Safety standards and testing play a crucial role in ensuring the effectiveness and reliability of EPS helmets in protecting against head injuries. Various regulatory bodies and organizations establish stringent standards and protocols that manufacturers must adhere to when designing and testing helmets.

Here are some key aspects of safety standards and testing for EPS helmets:

DOT Certification:

The Department of Transportation (DOT) certification sets specific safety requirements for motorcycle helmets sold in the United States. Helmets that meet DOT standards undergo rigorous testing to assess their impact absorption, retention system effectiveness, peripheral vision, and other critical safety aspects.

Snell Certification:

Helmets with Snell certification have undergone additional testing beyond DOT standards to meet the stringent safety criteria established by the Snell Memorial Foundation. Snell-certified helmets undergo impact testing at higher velocities to ensure superior protection against severe head injuries.

ECE Certification:

The Economic Commission for Europe (ECE) certification signifies that helmets comply with safety standards mandated for use in European countries. ECE-certified helmets undergo comprehensive testing to evaluate their performance in various impact scenarios, including frontal, lateral, and rear impacts.

MIPS Technology:

Some EPS helmets incorporate MIPS (Multi-Directional Impact Protection System) technology, which aims to reduce rotational forces during oblique impacts. MIPS helmets feature a low-friction layer between the outer shell and the inner liner, allowing the helmet to slide slightly upon impact, thereby mitigating rotational forces transmitted to the brain.

By adhering to these safety standards and incorporating advanced technologies like MIPS, EPS helmet manufacturers ensure that their products offer the highest level of protection for riders across different activities and environments. Regular testing and certification processes help to maintain the integrity and effectiveness of EPS helmets, giving riders confidence in their safety gear’s ability to mitigate the risks associated with head injuries.

Maintenance and Care

Proper maintenance and care are essential to ensure the longevity and effectiveness of EPS helmets in providing optimal protection for riders. Here are some key maintenance procedures and care tips to keep your helmet in top condition:

Cleaning Procedures:

Regular cleaning of your EPS helmet is vital to remove dirt, sweat, and other contaminants that can compromise its integrity. Use mild soap and water to gently clean the outer shell and inner padding, taking care not to use harsh chemicals that may degrade the helmet’s materials.

Avoid submerging the helmet in water or using abrasive cleaners, as these can damage the EPS foam and other components.

Storage Tips:

Store your EPS helmet in a cool, dry place away from direct sunlight and extreme temperatures. Prolonged exposure to heat or sunlight can degrade the helmet’s materials and reduce its effectiveness in protecting against impacts.

Avoid storing the helmet in areas where it may be subjected to heavy weight or pressure, as this can deform the helmet and compromise its protective capabilities.

Replacement Guidelines:

Helmets should be replaced every five years, even if they appear to be in good condition. Over time, the materials used in the helmet may degrade, reducing its ability to absorb impacts effectively.

Additionally, helmets should be replaced after a significant impact or crash, as they may have sustained hidden damage that compromises their structural integrity.

By following these maintenance procedures and care tips, you can ensure that your EPS helmet remains in optimal condition, providing reliable protection for your head during various recreational and professional activities. Proper maintenance not only prolongs the lifespan of your helmet but also ensures that it performs as intended when you need it most.

Choosing the Right EPS Helmet

Choosing the right EPS helmet is crucial for ensuring maximum safety and comfort during your recreational or professional activities. Here are some key factors to consider when selecting an EPS helmet:

Fit and Comfort:

A properly fitting helmet is essential for optimal protection and comfort. Look for a helmet that snugly fits your head without being too tight. Many helmets come with adjustable fit systems, such as dial-in retention systems or interchangeable padding, allowing you to customize the fit to your specific head shape.

Ensure that the helmet sits level on your head and covers the forehead without tilting backward or forward. The chin strap should be securely fastened and snug, with no more than one or two fingers’ width of space between the strap and your chin.

Helmet Weight:

Lightweight helmets reduce fatigue and strain on the neck muscles during extended periods of wear. Choose a helmet that strikes a balance between weight and protection, ensuring that it provides adequate safety without compromising comfort.

Consider the type of activities you’ll be engaging in and opt for a helmet that meets the specific weight requirements for your needs. Whether you’re cycling, motorcycling, or skiing, a lightweight helmet can enhance your overall riding experience.

Ventilation System:

Effective ventilation is essential for keeping you cool and comfortable, especially during hot weather conditions. Look for helmets with strategically placed vents and airflow channels that promote air circulation and heat dissipation.

Ventilation systems vary between helmets, so consider your individual preferences and riding conditions when choosing a helmet with the right ventilation features for your needs.

Visor Options:

Different visor options cater to varying visibility needs and riding environments. Consider whether you’ll need a clear visor for low-light conditions, a tinted visor for bright sunlight, or an anti-fog visor for humid or rainy weather.

Some helmets come with interchangeable visors or built-in features like anti-fog coatings, allowing you to customize your visibility options based on the conditions you’ll be riding in.

By carefully considering these factors and choosing an EPS helmet that meets your specific needs and preferences, you can ensure that you ride with confidence and peace of mind, knowing that your head is well-protected against potential impacts and injuries.

FAQs about EPS Helmets

How long does an EPS helmet last?

On average, EPS helmets last around five years with proper care and maintenance. However, they should be replaced sooner if they suffer a significant impact or show signs of wear and tear.

Can I paint my EPS helmet?

While it’s possible to paint an EPS helmet, it’s not recommended, as certain paints and solvents can degrade the foam’s protective properties. Consult the manufacturer for approved painting methods.

Are EPS helmets recyclable?

Yes, EPS helmets are recyclable. Many manufacturers offer recycling programs to properly dispose of old helmets and recycle the materials for other purposes.

How do I know if my EPS helmet is damaged?

Inspect the helmet regularly for any signs of cracks, dents, or deformation. If you’re unsure, consult a qualified professional for a thorough inspection.

Can I customize the fit of my EPS helmet?

Yes, many helmets come with adjustable fit systems, such as dial-in retention systems or interchangeable padding, allowing you to customize the fit for maximum comfort and safety.

Are EPS helmets suitable for all types of riding?

While EPS helmets offer excellent protection for a wide range of activities, including cycling, motorcycling, and snow sports, it’s essential to choose a helmet specifically designed for your intended use.

Conclusion

In conclusion, EPS helmets represent a pinnacle of safety technology, offering superior protection against head injuries in various recreational and professional activities. Understanding the construction, safety standards, and maintenance requirements of EPS helmets is crucial for ensuring optimal safety and performance on the road or in any adventure.