Importing EPS Molding Machine from China

Are you feeling tired of finding an excellent EPS molding machine? Here we are EPS machine supplier to provide all EPS moulding machine to meet your requirement, for more, please feel free to contact us at any time.

Our EPS Molding Machine

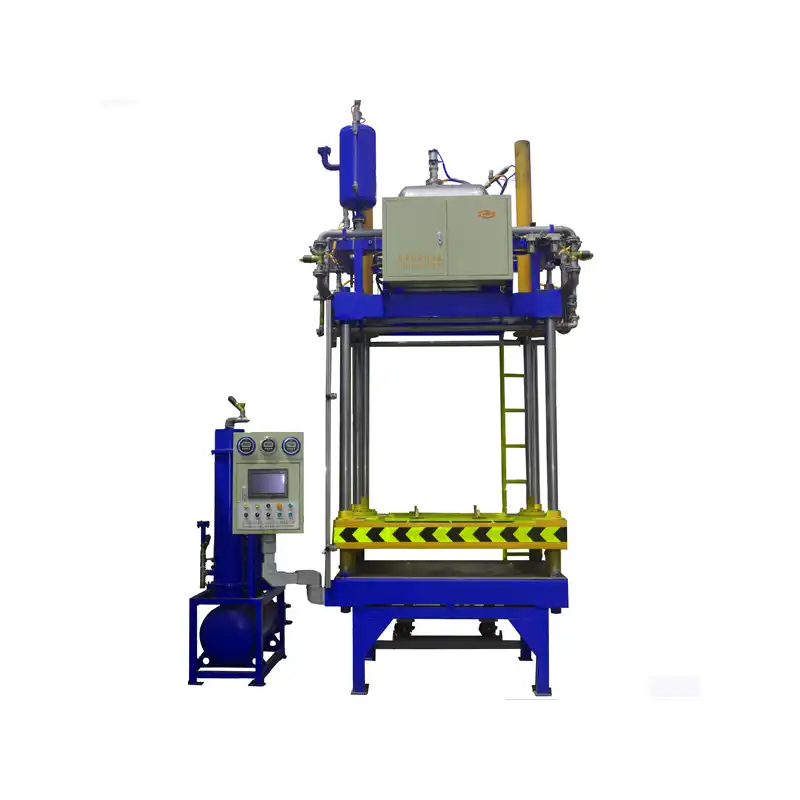

EPS molding machine, also named EPS moulding machine. An EPS molding machine is a type of equipment used in the production of expanded polystyrene (EPS) foam products.

-

Precise Temperature Control: Advanced temperature control systems ensure accurate heating of polystyrene beads for optimal expansion and molding.

-

Automatic Feeding: Automated feeding systems facilitate the consistent supply of polystyrene beads to the machine, improving productivity and reducing manual labor.

-

Mold Customization: Many EPS molding machines allow for the customization of molds to produce a variety of shapes and sizes according to specific product requirements.

-

Fast Cycle Times: Efficient molding processes and rapid cooling systems enable fast cycle times, increasing production throughput and efficiency.

-

Energy Efficiency: Modern EPS molding machines are designed to minimize energy consumption through efficient heating and cooling systems, reducing operational costs and environmental impact.

Types of EPS Molding Machines

Block molding machines are used to produce large blocks or sheets of EPS foam. These machines typically involve the pre-expansion of polystyrene beads followed by molding and cutting processes to create blocks of various sizes.

Shape molding machines are versatile and can produce EPS foam products in a wide range of shapes and sizes, including packaging inserts, architectural elements, and custom designs. They use molds to shape the expanded polystyrene into the desired form.

Continuous molding machines are designed for high-volume production of EPS foam products with consistent shapes and sizes. They feature constant production lines where polystyrene beads are continuously fed into the machine, molded, cooled, and cut into finished products.

Batch molding machines are suitable for smaller-scale production runs or custom projects where flexibility and customization are essential. They operate in batches, allowing for greater control over production parameters and mold customization.

Recycling molding machines are designed to process recycled EPS material, such as post-consumer or post-industrial waste, into new EPS foam products. They contribute to sustainability efforts by reducing waste and promoting the circular economy for EPS materials.

Foam packaging molding machines specialize in producing EPS foam packaging solutions, such as protective packaging inserts, cushioning materials, and foam trays. They are optimized for efficient production of lightweight and protective packaging solutions for shipping and handling purposes.

EPS Molding Machine Applications

Packaging

EPS foam is widely used for packaging purposes due to its lightweight, shock-absorbing properties. EPS molding machines produce foam packaging inserts, protective packaging materials, shipping containers, and custom packaging solutions for fragile items, electronics, appliances, and more.

Construction

In the construction industry, EPS foam is utilized for insulation, lightweight fill, and architectural elements. EPS molding machines manufacture insulation boards, thermal panels, insulated concrete forms (ICFs), decorative moldings, and structural components used in residential, commercial, and industrial buildings.

Automotive

EPS foam is employed in automotive applications for its sound-dampening and impact-resistant properties. EPS molding machines produce automotive components such as seat cushions, headrests, door panels, bumper cores, and packaging for automotive parts during shipping and storage.

Why Choose Our EPS Molding Machine

-

Advanced Technology: Our EPS molding machines are equipped with advanced technology and innovative features to ensure efficient and high-quality production processes. From precise temperature control to automation capabilities, our machines are designed to meet the demands of modern manufacturing.

-

Customization Options: We offer customization options to tailor the EPS molding machine to your specific production needs. Whether you require specialized molds, unique configurations, or integration with existing production lines, we can accommodate your requirements to optimize efficiency and productivity.

-

Reliability and Durability: Our EPS molding machines are built to last, featuring robust construction and high-quality components. With proper maintenance and support, our machines deliver reliable performance over the long term, minimizing downtime and maximizing production uptime.

-

Energy Efficiency: We prioritize energy efficiency in our EPS molding machines, implementing technologies and design principles to minimize energy consumption without compromising performance. By reducing energy costs, our machines contribute to cost savings and environmental sustainability.

FAQs about EPS molding machine

What is an EPS molding machine?

An EPS molding machine is a type of equipment used to produce expanded polystyrene (EPS) foam products. It heats and expands polystyrene beads, then molds them into various shapes and sizes according to specific product requirements.

What are the different types of EPS molding machines?

EPS molding machines come in various types, including block molding machines, shape molding machines, continuous molding machines, batch molding machines, and more. Each type serves different production needs and requirements.

What are the main applications of EPS molding machines?

EPS molding machines are used across industries for applications such as packaging, construction insulation, automotive components, marine and aerospace parts, consumer products, medical packaging, horticulture, and artistic projects.

What factors should be considered when choosing an EPS molding machine?

Factors to consider include production volume, product specifications, customization requirements, available space, energy efficiency, reliability, support services, and budget considerations.

How does an EPS molding machine work?

An EPS molding machine typically involves processes such as pre-expansion, molding, and cooling. Polystyrene beads are heated and expanded, then injected into molds where they take the desired shape. After cooling, the molded EPS foam products are ejected from the molds.

What are the benefits of using EPS foam products?

EPS foam products offer benefits such as lightweight, thermal insulation, shock absorption, buoyancy, sound dampening, moisture resistance, and recyclability, making them suitable for a wide range of applications.

How can I maintain an EPS molding machine for optimal performance?

Maintenance tasks may include cleaning, lubricating moving parts, checking temperature and pressure settings, inspecting molds for wear or damage, and performing routine calibration and adjustments as needed.

Can EPS molding machines be automated?

Yes, many EPS molding machines offer automation options such as robotic handling systems, inline trimming, packaging solutions, and integration with computerized control systems for improved efficiency and productivity.

Are EPS foam products environmentally friendly?

EPS foam products can be recycled, and many manufacturers offer recycling programs to reuse EPS materials. Additionally, EPS foam has a relatively low environmental impact compared to alternative materials due to its lightweight nature and energy-saving properties.

Where can I purchase an EPS molding machine?

EPS molding machines are available from various manufacturers and suppliers worldwide. It’s essential to research different options, compare features and prices, and choose a reputable provider that meets your specific needs and requirements.