EPS (Expandable Polystyrene) is a kind of insulation material, which is light-weight, rigid, and which is produced from solid polystyrene particles.

Expansion is achieved by the small amounts of pentane gas, dissolved into the polystyrene material during the production process.

E.P.S. (Expandable Poly Styrene) is a lightweight, rigid, plastic foam insulation material produced from solid particles of polystyrene. Expansion is achieved by virtue of small amounts of pentane gas dissolved into the polystyrene base material during production. The gas expands under the action of heat, applied as steam, to form perfectly closed cells of EPS. These cells occupy approximately 40 times the volume of the original polystyrene bead. The EPS beads are then molded into appropriate forms suited to their application. Products made from foamed polystyrene are nearly ubiquitous, for example packing materials, insulation, and foam drink cups.

Here’s a simple table outlining some key material properties of EPS (Expanded Polystyrene):

| Property | Description |

|---|---|

| Density | Low density, lightweight material. |

| Thermal Insulation | Excellent thermal insulation properties. |

| Shock Absorption | High shock-absorbing capability. |

| Versatility | Can be molded into various shapes and sizes. |

| Cost-Effectiveness | Economical material for diverse applications. |

| Durability | Durable despite being lightweight. |

| Flame Retardancy | Generally flame-retardant with additives. |

| Chemical Inertness | Chemically inert, resistant to many chemicals. |

| Recyclability | Recyclable, contributing to sustainability. |

Please note that the specifics of these properties can vary based on the exact composition and manufacturing processes used for a particular EPS product.

EPS, expandable polystyrene is made of 98% air and only 2% material, so EPS is super lightweight, and easy to mould, or cut, you can use EPS materials to design many products.

Here are some widely used EPS raw materials that you can get to know in the following. You can choose any types you desire from the eps raw material manufacturer.

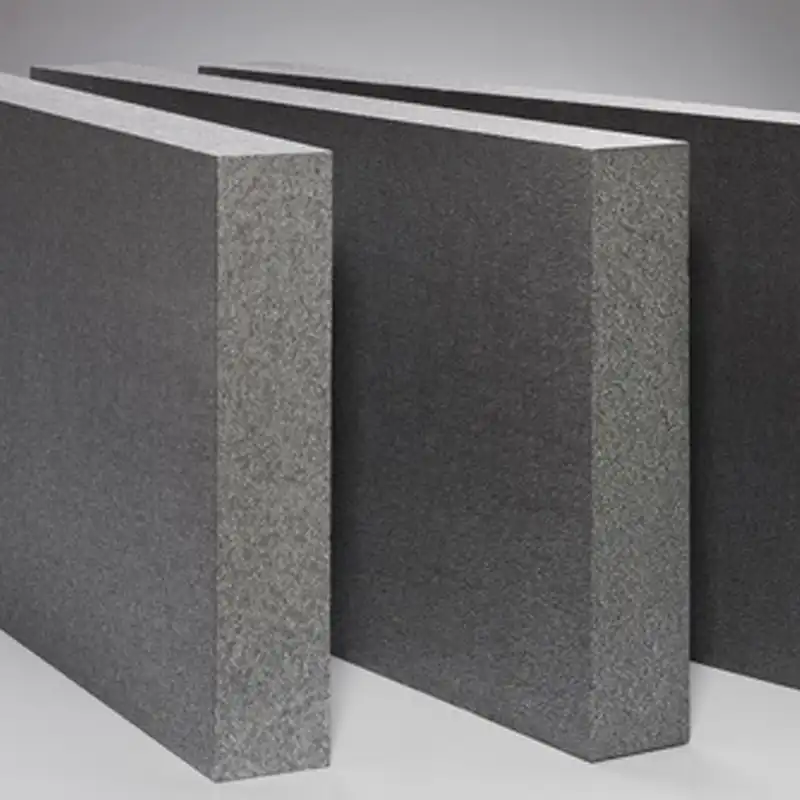

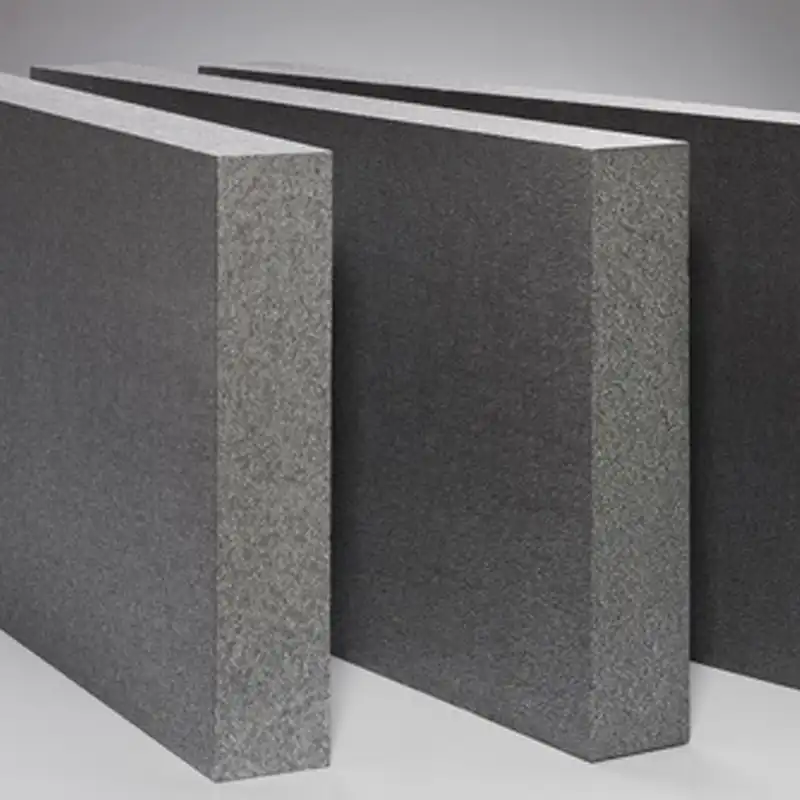

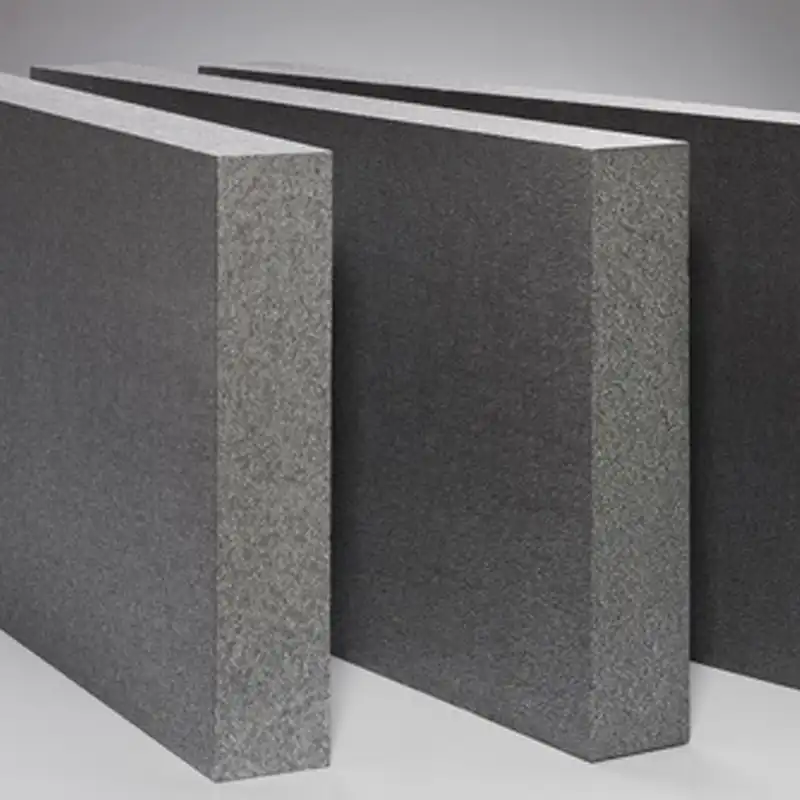

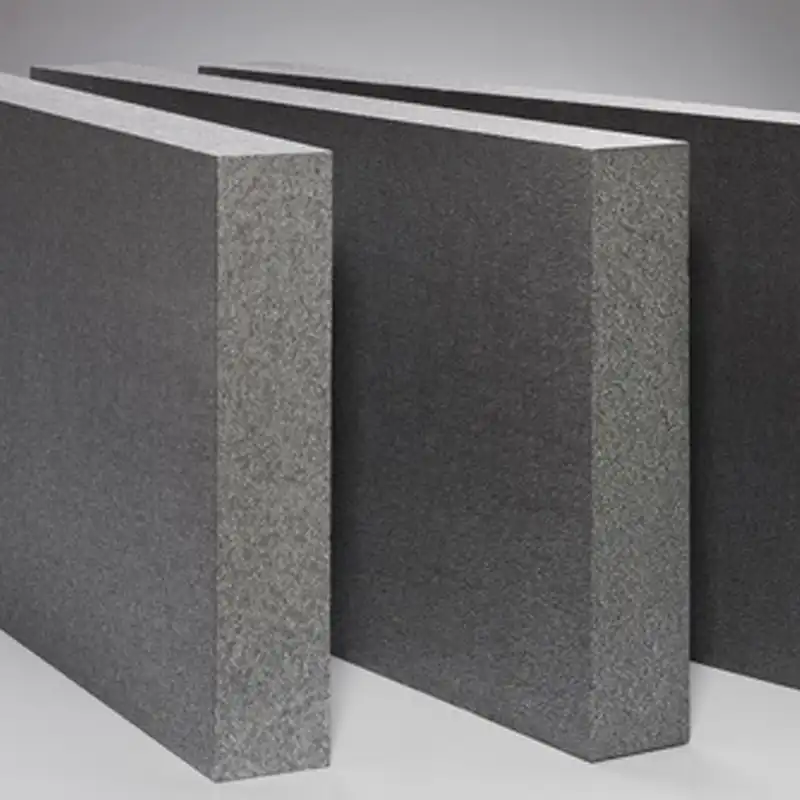

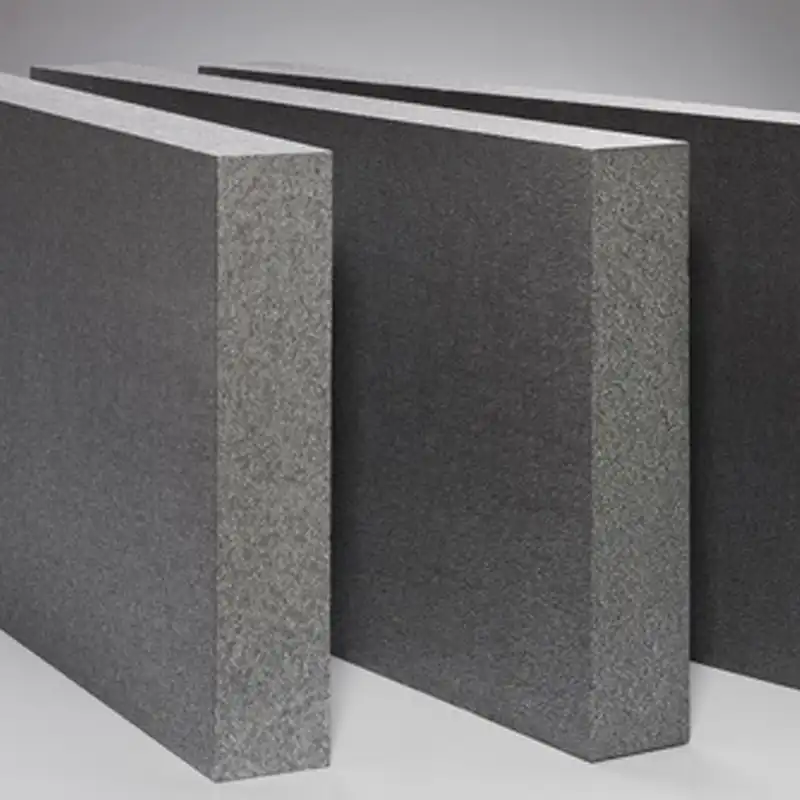

Graphite EPS, or Expanded Polystyrene infused with graphite particles, enhances insulation properties beyond traditional EPS. The addition of graphite enhances thermal resistance, making it a superior choice for energy-efficient construction.

Biodegradable EPS, or Expandable Polystyrene, represents an environmentally conscious alternative to traditional EPS. Composed of eco-friendly materials, it is designed to naturally break down over time, reducing environmental impact.

EPS with recycled content is an environmentally conscious choice, retaining the versatile properties of Expandable Polystyrene while promoting sustainability. Crafted from post-consumer or post-industrial recycled materials, it reduces waste and conserves resources. Choose EPS with recycled content for eco-friendly packaging, insulation, and construction needs.

Expanded Polyethylene (EPE) is a lightweight, flexible, and resilient foam material. Known for its excellent shock absorption and cushioning properties, EPE is commonly used in packaging for fragile items. It provides insulation against impact and vibrations, making it ideal for protecting goods during transit.

Elastomers are resilient polymers known for their elastic properties. These materials can undergo significant deformation and return to their original shape upon release of stress. Widely used for their flexibility and durability, elastomers find applications in diverse industries, including automotive tires, seals, gaskets, and various consumer goods.

Antistatic Polypropylene is a specialized material designed to dissipate static electricity, making it ideal for environments where electrostatic discharge could be detrimental. This form of polypropylene incorporates additives that reduce the buildup of static charges, safeguarding sensitive electronic components during manufacturing and transportation.

Antistatic Polypropylene is a specialized material designed to prevent static electricity buildup. With inherent antistatic properties, it inhibits the accumulation of electric charges, making it ideal for applications where electrostatic discharge could be damaging. This material is commonly used in the manufacturing of sensitive electronic components, packaging materials, and environments where static control is crucial.

Hybrid Polypropylene combines Expanded Polypropylene (EPP) and Expanded Polyethylene (EPE), offering a lightweight and resilient material. EPP provides structural strength and impact resistance, while EPE contributes to cushioning and flexibility. This combination results in a versatile solution for diverse applications, such as automotive components, protective packaging, and insulation.

Ethylene-Vinyl Acetate (EVA) is a versatile copolymer known for its flexibility, durability, and impact resistance. Comprising ethylene and vinyl acetate, it finds widespread use in industries such as footwear, packaging, and sports equipment. EVA's soft and rubber-like texture, combined with its excellent shock absorption, makes it a popular choice for shoe soles and padding materials.

EPS, or Expandable Polystyrene, is a lightweight, rigid, and closed-cell plastic foam utilized in various applications such as insulation, packaging, and cushioning.

The primary raw material for manufacturing EPS foam is typically polystyrene beads derived from a petrochemical known as styrene. These beads undergo a process where they are heated and expanded using steam, causing them to fuse together and create the foam material.

Subsequently, the resulting EPS foam is molded into diverse shapes and sizes to cater to specific application requirements.

The production of EPS foam demands specialized equipment and a controlled manufacturing process to ensure consistent quality and performance. This foam is extensively employed in the packaging industry owing to its exceptional cushioning and insulating properties, along with its recyclability.

Here are some advantages of EPS (Expandable Polystyrene) raw materials:

Lightweight: EPS is known for its low density, making it exceptionally lightweight. This characteristic is advantageous in various applications, especially in industries where weight is a critical factor.

Excellent Insulation: EPS exhibits excellent thermal insulation properties. Its closed-cell structure helps to trap air, providing effective insulation against heat transfer. This makes it widely used in construction for insulating walls, roofs, and floors.

Shock Absorption: The cushioning properties of EPS make it an ideal material for shock absorption. This quality is particularly beneficial in packaging, where it can protect delicate items from impact during transportation.

Versatile: EPS is a versatile material that can be molded into a wide range of shapes and sizes. This versatility allows it to be adapted for various applications, from packaging and construction to artistic and design purposes.

Cost-Effective: The production of EPS is relatively cost-effective, making it an economical choice for various industries. Its affordability, combined with its other beneficial properties, contributes to its widespread use.

Durable: Despite being lightweight, EPS is durable and can withstand significant stress and pressure. This durability enhances its suitability for applications where a combination of strength and low weight is essential.

These advantages collectively contribute to the popularity of EPS raw materials in numerous industries, offering a balance of lightweight construction, insulation efficiency, shock protection, versatility, cost-effectiveness, and durability.

EPS (Expandable Polystyrene) raw materials find applications in various industries.

Here are some examples:

Building and Construction:

Insulation: EPS is widely used for insulation in walls, roofs, and floors due to its excellent thermal insulation properties.

Void Formers: Used as void formers in construction to create lightweight structures and reduce overall building weight.

Lightweight Concrete: Added to concrete to create lightweight concrete blocks or panels.

Packaging:

Protective Packaging: Commonly used for packaging fragile items due to its shock-absorbing properties.

Coolers and Insulated Containers: Used to manufacture coolers and insulated containers for the transportation of temperature-sensitive goods.

Arts and Crafts:

Sculpting Material: EPS is often used as a sculpting material in artistic projects due to its ease of carving and shaping.

Marine Industry:

Buoyancy Aids: EPS is used in the production of flotation devices and buoyancy aids for boats and marine applications.

Horticulture:

Plant Nurseries: EPS is used in the horticultural industry for seed trays and as a material for hydroponic systems.

Automotive Industry:

Component Packaging: Used for protective packaging of automotive components during shipping.

Consumer Products:

Disposable Coolers: EPS is used in the production of disposable coolers for picnics and outdoor events.

Custom Shapes and Designs:

Architectural Molding: EPS is employed in creating decorative architectural moldings and elements for buildings.

Medical Industry:

Temperature-Sensitive Shipments: Used in the packaging of medical supplies and pharmaceuticals that require temperature control during transit.

Soundproofing:

Acoustic Panels: EPS is utilized in the production of acoustic panels for soundproofing applications.

These applications highlight the versatility of EPS raw materials in meeting diverse needs across different industries.

We are leading EPS manufacturer to provide all-in-one EPS solutions for your EPS project. Welcome to contact us at any time if you are looking for EPS machine, EPS material and many other EPS related product, please feel free to contact us now to get instant help.

Copyright © 2024 Hangzhou Epsole technologies Co.Ltd.

WhatsApp us