Welcome to the comprehensive guide on shaping EPS foam. Whether you’re a beginner or an experienced artisan, mastering the art of sculpting foam opens endless creative possibilities. From crafting props for theater productions to creating stunning sculptures, EPS foam is a versatile material.

In this guide, we’ll delve into the intricacies of shaping EPS foam, exploring various techniques and tools to help you unleash your creativity.

What is EPS Foam?

EPS foam, short for Expanded Polystyrene foam, is a lightweight and rigid material commonly used in packaging, insulation, and crafting. Composed of polystyrene beads expanded with steam, EPS foam exhibits excellent thermal insulation properties.

Properties of EPS Foam

EPS foam boasts several desirable properties, including lightweight, durability, and thermal insulation. Its closed-cell structure makes it resistant to moisture, mold, and mildew, ensuring longevity in various applications.

Benefits of Shaping EPS Foam

Shaping EPS foam offers a myriad of benefits that make it a preferred choice for various applications:

Versatility: EPS foam is highly versatile, lending itself to a wide range of projects and applications. Whether you’re crafting intricate sculptures, architectural models, or lightweight props for theater productions, EPS foam provides a versatile canvas for creativity.

Lightweight: One of the most significant advantages of EPS foam is its lightweight nature. Unlike traditional materials like wood or metal, EPS foam allows for the creation of large-scale structures without adding significant weight. This makes it ideal for projects where weight is a concern, such as stage sets or event decorations.

Ease of Manipulation: EPS foam is easy to manipulate, making it suitable for artists and craftsmen of all skill levels. Whether you’re a beginner or an experienced artisan, shaping EPS foam requires minimal effort and expertise. Its lightweight and forgiving nature allow for easy cutting, carving, and shaping to achieve desired designs.

Cost-Effectiveness: Compared to other materials like wood or metal, EPS foam is highly cost-effective. It’s readily available and affordable, making it an economical choice for both hobbyists and professionals alike. Additionally, its lightweight properties can result in cost savings during transportation and installation.

Insulation Properties: In addition to its creative benefits, EPS foam also boasts excellent thermal insulation properties. Its closed-cell structure provides effective insulation against heat transfer, making it ideal for use in packaging and construction applications where thermal efficiency is essential.

Durability: Despite its lightweight and airy appearance, EPS foam is surprisingly durable. It can withstand a wide range of environmental conditions, including moisture, mold, and mildew, ensuring longevity in various applications. Additionally, EPS foam is resistant to rot and decay, making it suitable for both indoor and outdoor use.

Tools for Shaping EPS Foam

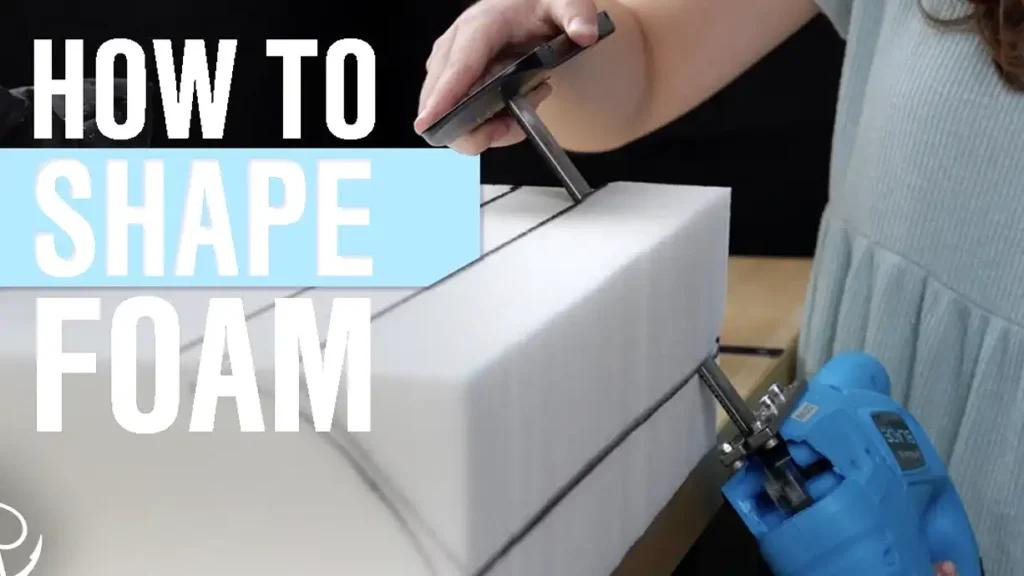

Hot Wire Cutter

A hot wire cutter is a must-have tool for shaping EPS foam. Utilizing heat, the wire effortlessly slices through the foam, enabling precise cuts and intricate designs.

How to Cut Expanded Polystyrene? (3 Cutting Methods)

Foam Rasp

A foam rasp is ideal for refining rough edges and shaping intricate details. With its coarse surface, it allows for effortless sculpting and smoothing of EPS foam surfaces.

Sanding Blocks

Sanding blocks are essential for achieving smooth and polished finishes on EPS foam projects. Available in various grits, they help refine surfaces and eliminate imperfections.

How to Shape EPS Foam?

Safety Precautions: Always wear safety goggles and a dust mask when working with EPS foam to protect yourself from airborne particles and fumes generated during cutting and shaping processes. Additionally, work in a well-ventilated area to minimize exposure to fumes.

Shaping EPS foam involves several techniques and tools to achieve desired designs effectively.

Here’s a step-by-step guide on how to shape EPS foam:

Prepare Your Workspace: Start by setting up a clean and well-ventilated workspace. Ensure you have ample room to maneuver and work comfortably.

Gather Your Tools: Collect the necessary tools for shaping EPS foam, including a hot wire cutter, foam rasp, sanding blocks, heat gun or oven (for heat molding), and safety equipment such as safety goggles and a dust mask.

Design Your Project: Before you begin shaping the EPS foam, have a clear idea of the design or shape you want to create. Sketch out your design on paper or create a digital mockup to serve as a reference.

Cutting with a Hot Wire Cutter: If you need to make straight cuts or shape large pieces of EPS foam, use a hot wire cutter. Turn on the cutter and carefully guide it along the lines of your design, allowing the heat to melt through the foam smoothly.

Carving with a Foam Rasp: For more intricate details or shaping curved surfaces, use a foam rasp. Gently carve away excess foam, working in small, controlled movements to achieve the desired shape and texture.

Sculpting: Sculpting involves shaping EPS foam into three-dimensional objects. Use a combination of cutting, carving, and shaping techniques to bring your design to life, focusing on creating smooth transitions and realistic textures.

Heat Molding (Optional): If you need to reshape or bend the foam, you can use heat molding. Apply heat to the desired area using a heat gun or by placing the foam in a preheated oven. Once the foam becomes pliable, carefully mold it into the desired shape and hold it in place until it cools and sets.

Refine and Smooth: After shaping the EPS foam, use sanding blocks to refine rough edges and smooth out any imperfections. Start with coarse sandpaper to remove any large bumps or uneven areas, then gradually switch to finer grits for a polished finish.

Finishing Touches: Once you’re satisfied with the shape and texture of the EPS foam, you can add finishing touches such as painting, sealing, or embellishing with other materials to enhance the appearance and durability of your project.

Techniques for Shaping EPS Foam

Carving

Carving is a fundamental technique for shaping EPS foam. Using a hot wire cutter or foam rasp, carve away excess foam to create desired shapes and forms.

Sculpting

Sculpting involves shaping EPS foam into three-dimensional objects. Whether crafting figurines or architectural models, sculpting allows for intricate detailing and realistic textures.

Heat Molding

Heat molding is a technique that involves applying heat to EPS foam to reshape it. By heating the foam with a heat gun or oven, it becomes malleable, allowing for bending and shaping into desired forms.

Tips for Working with EPS Foam

Work in a Well-Ventilated Area

When shaping EPS foam, ensure adequate ventilation to prevent inhalation of fumes produced during cutting and shaping processes.

Use Safety Equipment

Wear safety goggles and a dust mask to protect yourself from airborne particles and fumes generated during foam sculpting.

Practice Patience

Mastering the art of shaping EPS foam takes time and practice. Be patient with yourself and embrace the learning process.

Common Mistakes to Avoid

Applying Too Much Heat

Excessive heat can cause EPS foam to melt or deform irreversibly. Use caution when heat molding and ensure even distribution of heat.

Neglecting Surface Preparation

Failing to properly prepare the surface of EPS foam can result in adhesion issues when painting or applying finishes. Always sand and prime the foam before adding decorative elements.

Overcomplicating Designs

Keep designs simple and manageable, especially when starting out. Overly intricate designs can be challenging to execute with EPS foam.

FAQs

How do I shape EPS foam without a hot wire cutter?

You can use handheld tools like utility knives or serrated blades to carve EPS foam manually. While it may require more effort, it’s still achievable with patience and precision.

Can EPS foam be recycled?

Yes, EPS foam is recyclable. Many recycling facilities accept EPS foam for processing into new products, reducing environmental impact.

What types of projects can I create with shaped EPS foam?

The possibilities are endless! You can create anything from cosplay costumes and props to architectural models and themed décor.

Is EPS foam suitable for outdoor use?

While EPS foam is not inherently weatherproof, it can be coated with sealants or paints to enhance durability and weather resistance.

How do I achieve smooth finishes on EPS foam?

Sanding is key to achieving smooth finishes on EPS foam. Start with coarse sandpaper to remove rough edges, then gradually switch to finer grits for a polished surface.

Can EPS foam be painted?

Yes, EPS foam can be painted with acrylic or latex paints. However, it’s essential to prime the foam beforehand to ensure proper adhesion and prevent paint from being absorbed unevenly.

Conclusion

Mastering the art of shaping EPS foam opens a world of creative possibilities. Armed with the right tools, techniques, and tips, you can bring your imagination to life and create stunning works of art. Whether you’re a hobbyist or a professional crafter, shaping EPS foam allows you to unleash your creativity and craft intricate designs with ease.