Expanded Polystyrene (EPS), commonly known as Styrofoam, is a lightweight and versatile material used in packaging, insulation, and construction.

However, its low density poses challenges for transportation, storage, and recycling. EPS densifier machines offer a solution by compacting EPS foam into dense blocks or logs, reducing its volume significantly.

In this guide, we’ll explore everything you need to know about EPS densifiers, from how they work to their benefits and applications.

What Is EPS Densifier

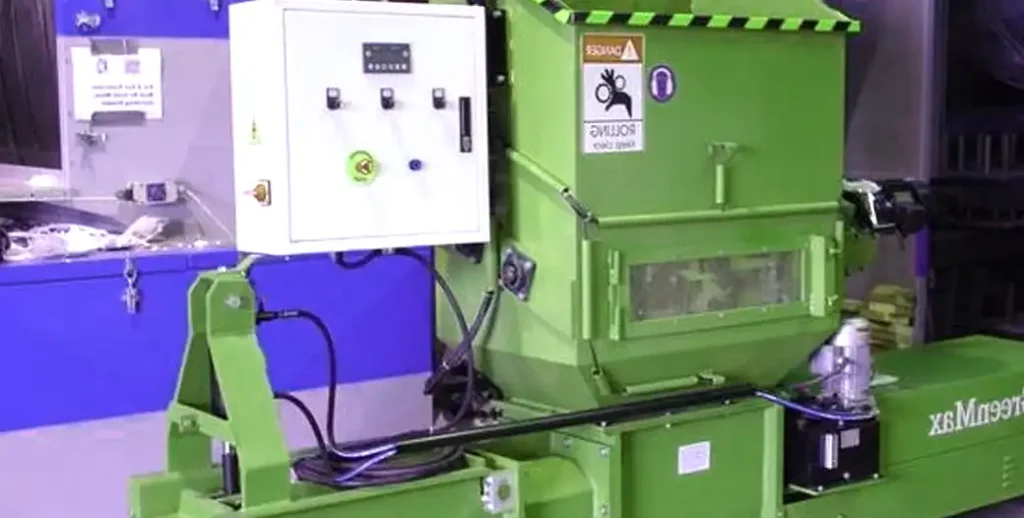

An EPS densifier, also EPS densifier machine, short for Expanded Polystyrene densifier, is a specialized machine designed to compact and reduce the volume of expanded polystyrene foam, commonly known as EPS or Styrofoam.

EPS foam is lightweight and widely used in packaging, insulation, and construction, but its low density makes it difficult to store, transport, and recycle efficiently.

EPS densifiers employ a combination of heat and pressure to compress EPS foam into denser forms, such as blocks or logs. The process involves feeding the EPS foam into the machine, where it undergoes compression, melting, extrusion, and cooling. The result is a significant reduction in volume, with densified EPS blocks or logs ready for storage, transportation, or recycling.

These machines are available in various sizes and configurations, suitable for small businesses, recycling facilities, or large industrial operations. EPS densifiers offer several benefits, including volume reduction, cost savings on waste disposal and transportation, and promoting environmental sustainability by diverting EPS foam from landfills and promoting recycling

How EPS Densifiers Work

EPS densifiers work by employing a combination of heat and pressure to compress expanded polystyrene (EPS) foam into denser forms, reducing its volume for easier storage, transportation, and recycling.

Here’s a breakdown of how EPS densifiers work:

Step 1: Collection and Preparation:

EPS foam waste, sourced from various sources such as packaging, electronics, or construction, is collected and prepared for densification. This may involve sorting and cleaning the foam to remove contaminants like dirt, tape, or labels, ensuring better compression and higher-quality output.

Step 2: Densification Process:

Compression: The prepared EPS foam is fed into the densifier machine, where it undergoes compression under controlled pressure.

Heating: Heat is applied to the EPS foam, causing it to soften and expand. This step facilitates the compression process by making the foam more pliable.

Extrusion: The softened EPS foam is forced through a die or chamber within the densifier, where it is compacted into denser forms such as blocks or logs. The pressure applied during extrusion further compresses the foam, reducing its volume significantly.

Cooling: Once compressed, the densified EPS foam is allowed to cool and solidify into its new shape, maintaining its denser form.

Step 3: Output:

The densified EPS blocks or logs are then ready for storage, transportation, or recycling. Depending on local recycling facilities, the densified EPS may be further processed into raw material for manufacturing new products.

EPS densifiers come in various sizes and configurations, ranging from small-scale units suitable for businesses to large industrial machines used by recycling facilities. They offer several benefits, including volume reduction, cost savings on waste disposal and transportation, and promoting environmental sustainability by diverting EPS foam from landfills and encouraging recycling.

What Is Densified EPS?

Densified EPS stands for Densified Expanded Polystyrene. Expanded Polystyrene (EPS) is a lightweight, rigid, cellular plastic material commonly used in packaging and insulation. Densified EPS is a form of EPS that has undergone a densification process, which compresses the material to increase its density.

This densification process involves applying heat and pressure to the EPS foam, causing the individual foam beads to fuse together more tightly. As a result, densified EPS has a higher density compared to standard EPS, making it stronger and more durable.

Densified EPS is often used in applications where higher strength and durability are required, such as in construction for insulation boards or in packaging for products that need extra protection during shipping and handling.

Benefits of EPS Densifier

EPS densifiers offer several benefits for businesses, recycling facilities, and the environment:

Volume Reduction: Densifiers can significantly reduce the volume of expanded polystyrene (EPS) foam waste, often by up to 98%. This reduction in volume makes the foam more manageable for storage, transportation, and recycling, saving valuable space and reducing logistics costs.

Cost Savings: By compacting EPS foam waste into denser forms, businesses can save money on waste disposal and transportation costs. Densified EPS can also be sold to recycling facilities as a valuable commodity, providing an additional revenue stream for businesses.

Environmental Impact: EPS densifiers play a crucial role in promoting environmental sustainability by diverting EPS foam from landfills and encouraging recycling. By reducing the volume of EPS foam waste and facilitating its recycling, densifiers help conserve natural resources and reduce the environmental impact of EPS production and disposal.

Versatility: Densifiers can process various types of EPS foam waste, including packaging materials, molded forms, and insulation boards. This versatility makes them suitable for a wide range of industries and applications, from manufacturing and construction to retail and logistics.

Energy Efficiency: Many modern EPS densifiers are designed to operate efficiently, minimizing energy consumption and reducing their carbon footprint. Some densifiers even utilize advanced technologies such as heat recovery systems to further improve energy efficiency and reduce operating costs.

EPS Densifier Applications

EPS densifiers have a variety of applications across different industries and sectors:

Manufacturing: Densified EPS foam can be used as raw material in manufacturing processes to produce a wide range of products. These include picture frames, crown molding, decorative trim, and other items where lightweight, rigid material is needed.

Construction: Densified EPS blocks can serve as lightweight fill material in construction projects. They can be used to fill voids or cavities in concrete structures, providing insulation and structural support while reducing overall weight. Densified EPS foam can also be used as insulation panels in walls, roofs, and floors to improve energy efficiency and thermal performance.

Packaging: Densified EPS foam blocks can be reused as protective packaging material for shipping fragile items. The dense nature of the material provides cushioning and shock absorption, helping to protect delicate products during transit.

Recycling: Densified EPS foam can be sold to recycling facilities for further processing. Once densified, EPS foam is easier to handle and transport, making it more cost-effective to recycle. Recycling densified EPS foam helps to conserve natural resources, reduce waste, and minimize environmental impact.

Art and Design: Densified EPS foam blocks can be used as a medium for artistic and creative projects. Artists and designers often use EPS foam as a sculpting material to create sculptures, props, and displays for exhibitions, events, and theatrical productions.

Horticulture: Densified EPS foam blocks can be used in horticulture and landscaping applications. They can serve as lightweight fill material in planters and garden beds, providing drainage and aeration for plant roots while reducing the overall weight of the container.

Conclusion

EPS densifier machines play a crucial role in managing EPS foam waste by compressing it into smaller, denser forms for storage, transportation, and recycling. With their ability to reduce volume, lower costs, and promote sustainability, densifiers offer an efficient solution for businesses and industries dealing with EPS foam waste. Whether used onsite or in recycling facilities, EPS densifiers contribute to a more environmentally friendly approach to waste management.