Expanded Polystyrene (EPS) is a lightweight, rigid foam material. It is the preferred choice in the packaging and construction industries, offering cost-effective solutions and energy-efficient insulation. It also serves as a cushioning transport packaging material for vibration-sensitive goods.

Let’s delve into the versatility of this material.

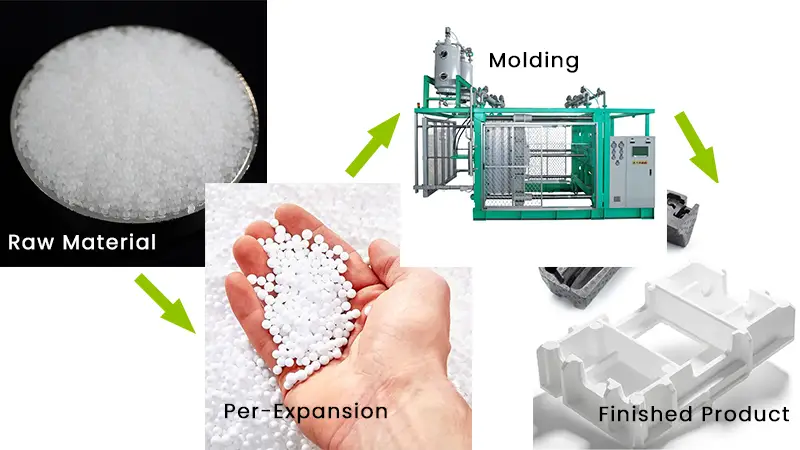

How is Expanded Polystyrene Manufactured?

Expanded polystyrene (EPS) is a lightweight, rigid, cellular plastic material widely used in packaging, insulation, and construction. The manufacturing process involves several steps:

Raw Material Preparation:

The primary raw material for EPS production is styrene, which is derived from petroleum or natural gas. Styrene monomers are polymerized to form polystyrene beads, which are small, spherical particles.

Pre-expansion:

The polystyrene beads are loaded into a pre-expander machine, where they are exposed to steam under pressure. This causes the beads to expand and fuse together, forming closed-cell structures filled with air. During this process, the beads increase in volume by around 20 to 50 times their original size.

Molding: The expanded beads are then molded into the desired shape using molds or forms. The molds are typically made of metal and can have various shapes and sizes depending on the final product.

Steam Chest Molding: In this step, the molded EPS is subjected to high-pressure steam inside a mold or a steam chest. The heat from the steam causes the expanded beads to soften and fuse together, resulting in a solid, uniform structure.

Cooling and Shaping: After molding, the EPS products are cooled to set their shape. They may also undergo additional cutting or shaping processes to achieve the desired dimensions and surface finish.

Final Processing: Once cooled and shaped, the EPS products may undergo further processing such as trimming excess material, surface coating, or printing for branding and labeling purposes.

Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the EPS products meet the required standards for density, strength, and dimensional accuracy.

Packaging and Distribution: The finished EPS products are packaged and prepared for distribution to customers across various industries.

Benefits of Expanded Polystyrene(EPS)

What is the benefit of using expanded polystyrene package?

- Lightweight: EPS is lightweight, reducing shipping costs and making handling easier.

- Insulation: Its cellular structure provides excellent thermal insulation, keeping products protected from temperature fluctuations.

- Shock Absorption: EPS absorbs shocks and impacts, protecting fragile items during transit.

- Versatility: It can be molded into various shapes and sizes, accommodating different packaging needs.

- Cost-Effective: EPS is cost-effective compared to alternatives like molded pulp or foam.

- Recyclability: It is recyclable, contributing to sustainability efforts in packaging.

- Fire Resistance: EPS is flammable. Modifying it with flame retardants can significantly reduce the foam’s flammability and the spread of flames.

Applications of EPS in the Packaging Industry

Here are some expanded polystyrene packaging ideas to know what expanded polystyrene used for in the following:

Food Packaging: EPS is widely used for packaging perishable goods like fruits, vegetables, and seafood due to its excellent insulation properties. Its ability to maintain consistent temperatures during transport helps preserve the freshness of these products, ensuring they reach consumers in optimal condition.

Electronics: EPS provides superior cushioning and protection for electronic products such as computers, TVs, and appliances. Its lightweight yet durable nature absorbs shocks and vibrations, safeguarding delicate electronic components from damage during shipping and handling.

Medical Supplies: EPS packaging material is crucial for the safe delivery of delicate medical equipment and supplies. Its shock-absorbing properties ensure that sensitive medical instruments and devices remain intact and sterile during transit, maintaining their efficacy and reliability.

Insulated Shipping Containers: EPS is an ideal material for insulated shipping containers designed to transport temperature-sensitive items like pharmaceuticals and vaccines. Its thermal insulation capabilities help maintain consistent temperature levels, protecting the integrity and effectiveness of these sensitive products throughout the shipping process.

Protective Packaging: EPS is commonly used as void fillers and protective inserts in shipping boxes to prevent damage to contents. Its ability to conform to various shapes and sizes allows it to create custom-fit protective barriers, minimizing the risk of product breakage or deformation during transit.

Beverage Packaging: EPS is commonly employed in the packaging of beverages, including both hot and cold drinks. Its thermal insulation properties help maintain the desired temperature of beverages, ensuring that hot drinks stay hot and cold drinks stay cold during transportation and storage. Additionally, EPS’s lightweight nature reduces shipping costs and its shock-absorbing capabilities protect glass bottles from breakage.

Fragile Item Packaging: EPS is an excellent choice for packaging fragile items such as ceramics, glassware, and artworks. Its ability to cushion and absorb shocks minimizes the risk of breakage or damage during transit. By providing a protective barrier around delicate items, EPS foam ensures that they arrive at their destination in pristine condition.

Automotive Parts Packaging: EPS is utilized in the packaging of automotive parts and components due to its impact resistance and ability to conform to complex shapes. It provides cushioning and protection during transit, preventing damage to critical automotive parts like engines, bumpers, and headlights. Additionally, its lightweight nature helps reduce overall packaging weight, contributing to fuel efficiency and cost savings in transportation.

Sustainability Advantages of Expanded Polystyrene

- Recyclability: EPS can be recycled into new products or used as raw material for other applications.

- Resource Efficiency: It requires less material compared to alternatives like paper-based packaging, reducing resource consumption.

- Durability: Its durability extends product lifespan, reducing the need for frequent replacements.

- Energy Efficiency: The lightweight nature of EPS reduces fuel consumption during transportation.

- Reusable: EPS packaging can be reused multiple times, further reducing waste.

Final Thoughts

Expanded Polystyrene (EPS) stands out as an invaluable material in packaging, offering a myriad of benefits derived from its lightweight composition, exceptional insulation capabilities, versatility, and recyclability. Its utilization across diverse industries underscores its efficacy in safeguarding products during transit, ensuring their integrity and quality upon arrival.

Moreover, EPS contributes to sustainability initiatives by optimizing resource utilization and facilitating recyclability, thereby aligning with the growing emphasis on environmental responsibility in packaging practices.