Ever wondered what makes expanded polystyrene (EPS) foam so versatile? It all boils down to one critical characteristic: density. This guide will reveal how the mass packed into a given volume of EPS foam dictates its performance.

Understanding EPS density is key to unlocking its potential. From its insulating power to its strength in construction and packaging, density is the fundamental property that makes EPS foam suitable for a myriad of applications.

What is Expanded Polystyrene Density?

Expanded Polystyrene (EPS) density refers to the mass per unit volume of EPS foam. Essentially, it measures how much polystyrene material is packed into a given space within the foam.

This seemingly simple metric is profoundly important because it directly influences various key properties of the EPS, such as its strength, thermal insulation capabilities, compressive resistance, and ultimately, its suitability for diverse applications in construction, packaging, and more.

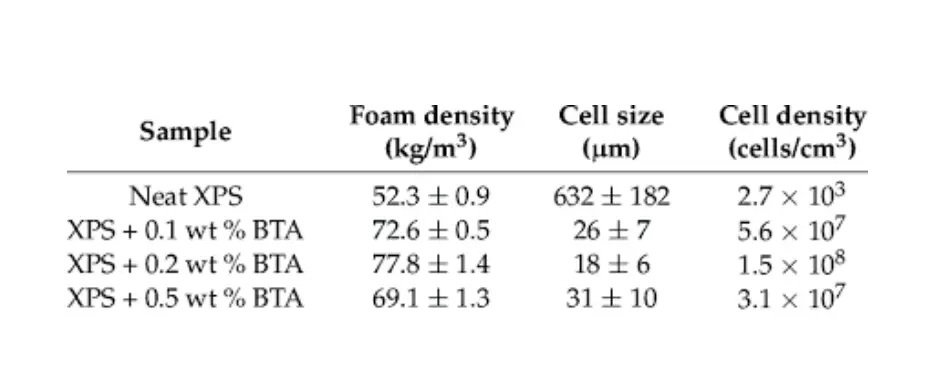

Here is the table showing you the average EPS foam density:

| Density (pcf) | Stress @ 10% Compression (psi) | Flexural Strength (psi) | Tensile Strength (psi) | Shear Strength (psi) |

| 1 | 13 | 29 | 31 | 31 |

| 1.5 | 24 | 43 | 51 | 53 |

| 2 | 30 | 58 | 62 | 70 |

| 2.5 | 42 | 75 | 74 | 92 |

| 3 | 64 | 88 | 88 | 118 |

| 3.3 | 67 | 105 | 98 | 140 |

| 4 | 80 | 125 | 108 | 175 |

Polystyrene Density kg/m³

The density of the EPS foam is 19.8 kg/m³. This value indicates that for every cubic meter of this particular Expanded Polystyrene foam, the mass contained within that volume is 19.8 kilograms. This specific density is a crucial characteristic, as it directly impacts other mechanical properties of the foam, such as its stiffness and resistance to deformation, which are also listed in the table.

The other properties presented in the table are directly influenced by this density. For instance:

- Tensile Cut off stress (0.10 MPa): This is the stress at which the material is expected to fail under tension.

- Young’s Modulus (4.32 MPa): This indicates the stiffness of the material; a higher density generally correlates with a higher Young’s Modulus, meaning a stiffer foam.

- Poisson’s Ratio (0.00): This value suggests that the material does not expand or contract perpendicular to the applied force when stretched or compressed. For typical foams, this value is often close to zero.

- Shear Modulus (2.16 MPa): This measures the material’s resistance to shear deformation, or twisting.

- Bulk Modulus (1.44 MPa): This represents the material’s resistance to compression in all directions.

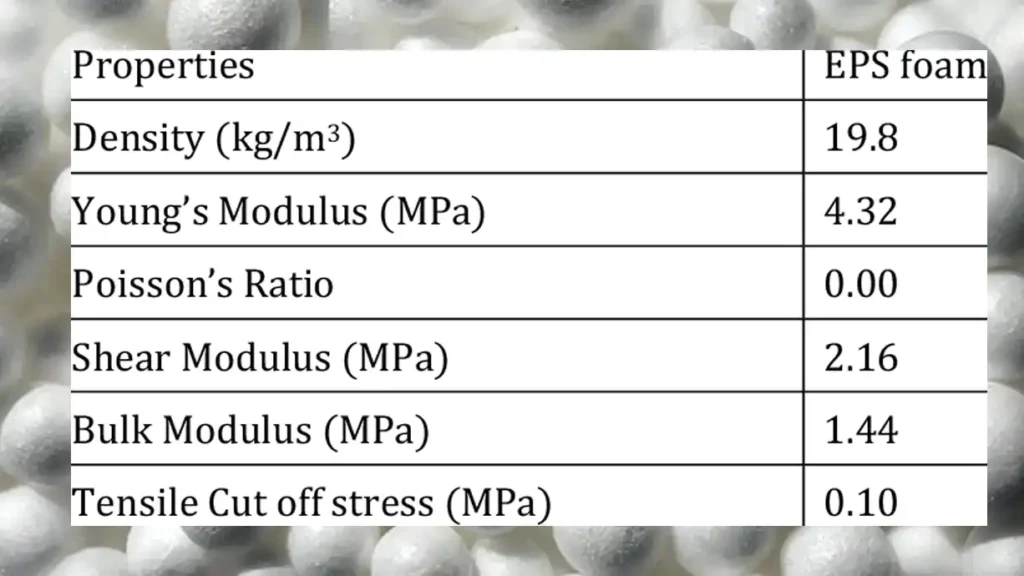

Expanded Polystyrene Density Formula

The formula for calculating the density of any material, including Expanded Polystyrene (EPS), is the fundamental physics formula for density:

ρ=m/V

Where:

- ρ (rho) is the density of the material.

- m is the mass (or weight) of the object.

- V is the volume of the object.

To determine the density of an EPS block, you would follow these steps:

Measure the mass: Use a scale to weigh the EPS block and record its mass.

Measure the volume:

- For a simple, regular shape (like a rectangular block), measure its length, width, and height. The volume is calculated as V = length × width × height.

- For an irregularly shaped piece, you might need to use a displacement method, such as submerging it in a fluid and measuring the volume of the displaced fluid.

Calculate the density: Divide the measured mass by the calculated volume.

The density of expanded polystyrene is a key characteristic that determines its physical properties, such as its compressive strength and thermal insulation capabilities. Different manufacturing processes and material grades result in a wide range of densities for EPS foam, typically ranging from about 10 kg/m³ to 35 kg/m³ (or 0.6 to 2.2 pounds per cubic foot).

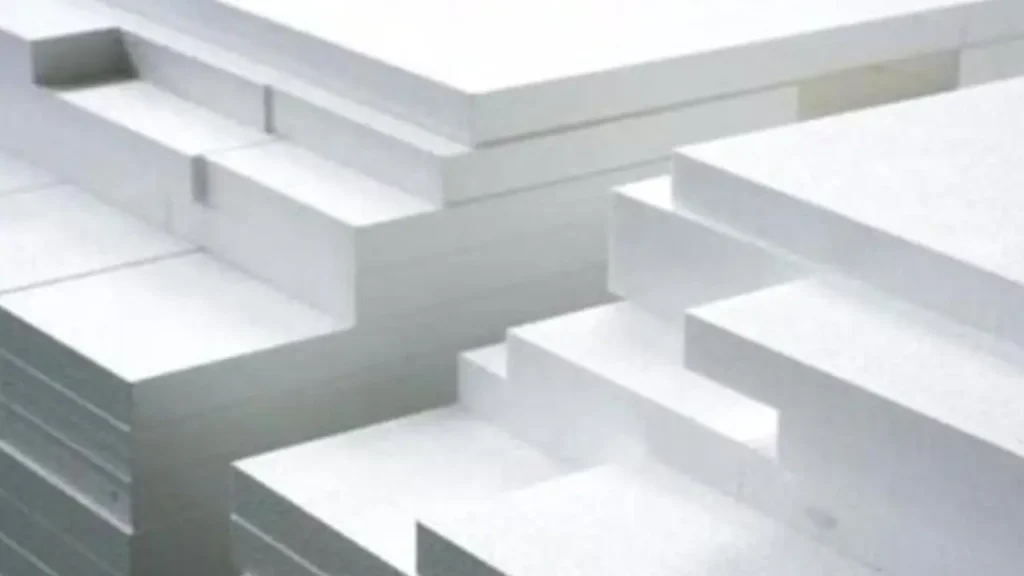

Expanded Polystyrene Production Process for Different Densities

| Density | Production Process |

| Low | Expandable polystyrene (EPS) beads are pre-expanded using steam, then placed in a mold and exposed to additional steam to fully expand and fuse the beads together. The molded EPS blocks are then cooled, trimmed, and stored for further processing. |

| Medium | Similar to low-density EPS production, but with adjustments in steam pressure and processing time to achieve the desired density. The pre-expanded beads are subjected to higher pressures and longer molding times to create a denser foam structure. |

| High | High-density EPS production involves a more controlled expansion process with precise steam conditions and mold temperatures. The pre-expanded beads undergo multiple stages of molding and cooling to achieve a tightly compacted foam structure with enhanced strength and durability. |

The production of Expanded Polystyrene (EPS) foam is a fascinating process where steam is the primary agent for expanding polystyrene beads. The key to achieving different EPS foam densities—low, medium, and high—lies in precise control over the steam conditions and molding parameters during manufacturing. This allows EPS manufacturers to tailor the final product’s characteristics to suit specific application requirements.

The table above illustrates how the production process is adjusted for various densities:

- High Density: Achieving high-density EPS requires a more controlled expansion process. This involves precise steam conditions and mold temperatures, with pre-expanded beads undergoing multiple stages of molding and cooling to yield a tightly compacted foam structure with enhanced strength and durability.

- Low Density: Expandable polystyrene (EPS) beads are pre-expanded with steam, then molded with additional steam to fuse them. The resulting blocks are cooled, trimmed, and stored.

- Medium Density: This process is similar to low-density production but involves adjustments in steam pressure and processing time. Higher pressures and longer molding times are used to create a denser foam structure.

High-Density EPS Foam

High-density EPS foam offers a range of significant benefits due to its tightly compacted cellular structure. This increased material per volume translates directly into superior mechanical performance, making it an ideal choice for demanding applications. Its robust nature means it can withstand considerable compressive forces and impacts without deforming or breaking down, offering enhanced durability and a longer lifespan compared to lower-density variants.

Beyond its mechanical strength, high-density EPS foam excels in other critical areas. Its denser composition typically results in improved thermal insulation properties, as the smaller, more numerous air pockets within the foam more effectively resist heat transfer.

Furthermore, its reduced porosity contributes to better resistance against moisture absorption, making it suitable for applications where exposure to water or humidity is a concern.

Key benefits of High-Density EPS foam include:

- Impact Resistance: Excellent for protecting fragile or heavy items during transport due to its ability to absorb shock.

- Increased Compressive Strength: Can support heavier loads without deforming, crucial for applications like foundation insulation or under-slab insulation.

- Enhanced Durability: More resistant to wear and tear, impacts, and compression, leading to a longer product lifespan.

- Superior Thermal Insulation: Denser structure generally means better R-value (thermal resistance), leading to greater energy efficiency.

- Improved Moisture Resistance: Less prone to water absorption, maintaining its performance even in damp environments.

- Dimensional Stability: Maintains its shape and size under varying environmental conditions, reducing the risk of warping or shrinkage.

High Density Expanded Polystyrene Foam Board Insulation

High-density expanded polystyrene (EPS) foam board is a type of rigid insulation known for its combination of thermal resistance, structural strength, and moisture resistance. The “high density” classification refers to a higher concentration of polystyrene per cubic foot, which gives the material its enhanced properties.

Key Characteristics

- Density: While standard EPS foam has a density around 1 pound per cubic foot (pcf), high-density EPS typically ranges from 1.5 pcf to 3.0 pcf or more. This increased density directly correlates with its improved performance.

- Compressive Strength: A defining feature of high-density EPS is its exceptional compressive strength. This allows it to withstand significant loads without deforming. This makes it ideal for applications where it will be subject to heavy weight, such as under-slab or below-grade foundation insulation. Compressive strengths for high-density EPS can range from 25 to 60 psi (pounds per square inch).

- R-value (Thermal Resistance): The R-value of EPS foam is a measure of its ability to resist heat flow. While EPS generally has an R-value of about R-4 per inch of thickness, the R-value of high-density EPS is slightly higher, often ranging from R-4.3 to R-5.0 per inch. The denser structure with more compacted air pockets results in better resistance to heat transfer.

- Moisture Resistance: High-density EPS has a lower water absorption rate compared to its lower-density counterparts. The closed-cell structure of the foam means that water can only penetrate through the tiny channels between the fused beads. The denser the foam, the fewer and smaller these channels are, improving its resistance to moisture.

- Dimensional Stability: High-density EPS maintains its shape and size under various environmental conditions, reducing the risk of warping or shrinkage. This is crucial for construction applications that require precise dimensional accuracy.

Common High Density EPS Applications

The unique properties of high-density EPS make it suitable for demanding applications in residential and commercial construction:

- Below-grade foundation and slab insulation: Its high compressive strength allows it to be used under concrete slabs and against foundation walls, where it must support heavy loads and resist moisture from the surrounding soil.

- Roofing systems: High-density EPS is a popular choice for commercial and residential roofs due to its lightweight nature, durability, and excellent insulation properties.

- Insulated Concrete Forms (ICFs) and Structural Insulated Panels (SIPs): It is a core component in these advanced building systems, providing a durable and highly efficient thermal envelope.

- Civil Engineering (Geofoam): Extremely high-density EPS is used as “geofoam” for applications like lightweight fill in road and railway construction to stabilize soil and reduce stress on underlying structures.

High-Density EPS vs XPS

It is important to note that while high-density EPS offers excellent performance, it is different from extruded polystyrene (XPS), which is another type of rigid foam insulation. XPS is typically blue, pink, or green and has a higher R-value per inch (around R-5) and better moisture resistance than standard EPS. However, high-density EPS is often more cost-effective and is praised for its long-term R-value stability, as it doesn’t use blowing agents that can leak over time and reduce its insulating power.

How Expanded Polystyrene Foam Density Affects Strength and Durability

Expanded Polystyrene (EPS) foam density plays a crucial role in determining the material’s structural strength, insulation performance, and durability. Higher-density EPS provides better load-bearing capacity and long-term stability, while lower-density foam is lighter and more cost-effective. Choosing the right density ensures optimal performance for walls, floors, roofs, and other construction applications.

Cost vs. Performance: Choosing EPS foam density involves balancing budget and functionality. Lower-density EPS is cheaper and lighter, suitable for non-load-bearing applications, while higher-density foam costs more but ensures superior strength, durability, and long-term energy efficiency, making it worth the investment.

Structural Strength: Higher-density EPS foam can withstand greater loads without deformation, making it ideal for flooring, roofing, and load-bearing walls. It provides consistent support over time, reducing the risk of cracks or settling, ensuring the building remains stable and safe for long-term use.

Durability: EPS density affects resistance to compression, moisture, and wear. Denser panels are less prone to sagging or damage from environmental stress, maintaining their performance in extreme conditions. This makes high-density EPS a reliable choice for industrial, residential, and commercial structures.

Thermal Insulation: While all EPS foams insulate well, density influences thermal efficiency. Higher-density EPS traps heat more effectively, improving energy savings in buildings. It balances insulation with structural requirements, ensuring both comfort and performance without compromising strength.

Soundproofing: Denser EPS foam absorbs and reduces sound transmission more effectively. In residential or commercial buildings, higher-density panels provide quieter interiors by minimizing noise from traffic, machinery, or neighboring spaces, enhancing comfort and usability.

Importance of Expanded Polystyrene Foam Density

Expanded Polystyrene (EPS) density plays a crucial role in determining the performance, functionality, and suitability of EPS products for various applications. Understanding the importance of EPS density is essential for making informed decisions in product design, manufacturing, and usage.

Here are some key reasons why EPS density matters:

1. Thermal Insulation Properties: The density of EPS directly affects its thermal insulation capabilities. Higher-density EPS typically offers better insulation performance due to its reduced porosity and increased material density. This makes high-density EPS ideal for applications requiring superior thermal insulation, such as building insulation and cold storage.

2. Compressive Strength: EPS density influences its compressive strength, which is crucial for supporting structural loads and withstanding external pressures. Higher-density EPS exhibits greater compressive strength, making it suitable for applications where durability and load-bearing capacity are essential, such as foundation insulation and civil engineering projects.

3. Dimensional Stability: EPS density impacts its dimensional stability, or the ability to maintain shape and size under varying environmental conditions. Higher-density EPS tends to have lower dimensional changes, making it more resistant to deformation and warping over time. This makes high-density EPS desirable for applications requiring precise dimensional accuracy, such as architectural molding and packaging.

4. Impact Resistance: The density of EPS also affects its impact resistance, with higher-density foams typically offering greater resistance to impact and mechanical stress. This makes high-density EPS ideal for protective packaging applications where shock absorption and product safety are paramount.

5. Water Absorption: EPS density influences its susceptibility to water absorption, with lower-density foams being more prone to moisture ingress. Higher-density EPS exhibits lower water absorption rates, making it suitable for outdoor applications or environments with high humidity levels.

6. Cost and Material Efficiency: The choice of EPS density can impact production costs and material efficiency. While higher-density EPS may offer superior performance, it often comes at a higher cost due to increased material usage and manufacturing complexity. Lower-density EPS, on the other hand, may provide a more cost-effective solution for less demanding applications.

The density of Expanded Polystyrene (EPS) is a critical parameter that influences its thermal insulation properties, compressive strength, dimensional stability, impact resistance, water absorption characteristics, and cost-effectiveness.

By understanding the importance of EPS density, manufacturers and end-users can make informed decisions to select the most suitable EPS products for their specific requirements.

Factors Affecting Expanded Polystyrene Density

Several factors influence the density of Expanded Polystyrene (EPS), affecting its properties and suitability for various applications. Understanding these factors is essential for optimizing EPS production and achieving desired material characteristics. Here are the key factors affecting EPS density:

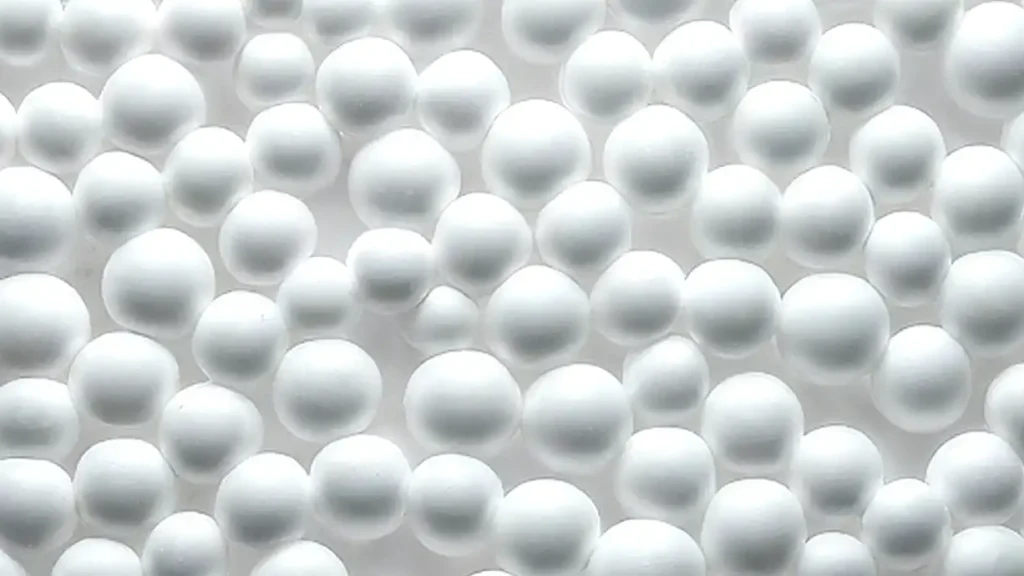

1. Raw Material Properties: The characteristics of the polystyrene resin used as the raw material for EPS production significantly impact the final foam density. Properties such as molecular weight, polymer distribution, and melt flow index of the resin influence the expansion and foaming behavior during the manufacturing process.

2. EPS Expansion Process Parameters: The parameters of the expansion process, including steam pressure, temperature, dwell time, and agitation, play a crucial role in determining EPS density. Higher steam pressures and temperatures lead to increased expansion and lower foam density, while lower pressures and temperatures result in denser foam with higher density.

3. Bead Size and Shape: The size and shape of the EPS beads used in production affect foam density. Smaller bead sizes tend to produce denser foam, as they pack more tightly together during the expansion process. Similarly, a uniform bead shape promotes uniform expansion and helps maintain consistent foam density.

4. Molding Conditions: The conditions during the molding stage, such as mold temperature, pressure, and cycle time, influence EPS density. Higher mold temperatures and pressures typically result in denser foam with reduced cell size and higher material density. Longer molding cycle times may also contribute to increased foam density by allowing for more complete fusion and consolidation of the beads.

5. Chemical Additives: The inclusion of chemical additives, such as blowing agents, nucleating agents, and flame retardants, can affect EPS density. Blowing agents generate gas bubbles during the expansion process, contributing to foam density reduction. Nucleating agents control cell size and distribution, impacting foam structure and density. Flame retardants may alter the foaming behavior and final density of EPS.

6. Ambient Conditions: Ambient conditions, such as humidity and air temperature, can influence EPS density during production. High humidity levels may affect the expansion and curing process, leading to variations in foam density. Control of ambient conditions is essential to ensure consistent foam quality and density.

7. Quality Control Measures: Implementation of quality control measures throughout the manufacturing process is critical for maintaining consistent EPS density. Monitoring and adjusting process parameters, conducting regular testing and inspection of raw materials and finished products, and adhering to strict quality standards help ensure uniform foam density and product performance.

Expanded Polystyrene Production Equipment

Expanded polystyrene (EPS) production involves several key machines and equipment that are essential for different stages of the manufacturing process.

Here are some of the machines commonly used in EPS production:

EPS Pre-expander: The pre-expander is a machine used to expand polystyrene beads by applying steam heat. It controls the temperature and steam pressure to achieve the desired expansion ratio and density of the beads.

EPS Aging Silos: After pre-expansion, the expanded beads are transferred to aging silos where they are stored for some time. Aging allows the expanded beads to stabilize and reach equilibrium moisture content before further processing.

EPS Molding Machine: Molding machines are used to shape the expanded beads into final products such as blocks, sheets, or custom molds. These machines apply heat and pressure to the beads to fuse them and form a solid structure.

EPS Steam Chest/Boiler: Steam chests or boilers are used to generate steam, which is an essential component of the EPS production process. Steam is used for the pre-expansion of the beads, molding, and shaping operations.

EPS Cutting Machine: Cutting machines are used to cut molded EPS blocks or sheets into specific dimensions and shapes. These machines can utilize hot wires, saw blades, or other cutting methods depending on the requirements of the final product.

EPS Shape Molding Machine: Shape molding machines are used to produce EPS products with complex shapes and contours. These machines use molds to shape the expanded beads under heat and pressure, resulting in detailed and precise finished products.

EPS Cooling System: After molding or shaping, EPS products need to be cooled down to solidify and stabilize their structure. Cooling systems, such as air or water cooling, are employed to rapidly reduce the temperature of the molded EPS products.

EPS Recycling Equipment: EPS production often generates waste materials that can be recycled and reused. Recycling equipment, such as shredders and compactors, are used to process EPS scrap into reusable pellets or materials for future production cycles.

Quality Control Equipment: Various quality control equipment, including density meters, thermal conductivity testers, and dimensional measurement tools, are used to ensure that the produced EPS foam meets the required specifications and standards.

High Density Expanded Polystyrene

High-density expanded polystyrene (EPS) refers to EPS foam with a higher density compared to standard EPS materials. It typically has a density of over 30 kg/m³, although specific densities may vary depending on the manufacturer and application requirements.

High-density EPS offers increased strength, durability, and insulation properties compared to lower density EPS materials, making it suitable for applications where greater structural integrity and thermal resistance are needed. Examples of applications for high-density EPS include insulation for buildings, thermal packaging for temperature-sensitive products, and structural components in construction and engineering projects.

Here’s a table illustrating the density ranges for different types of expanded polystyrene (EPS) foam:

| EPS Type | Density Range (kg/m³) |

|---|---|

| Very Lightweight EPS | 10 – 15 |

| Lightweight EPS | 15 – 20 |

| Standard EPS | 20 – 30 |

| High-Density EPS | 30 – 40+ |

This table provides an overview of the density ranges commonly found in various types of expanded polystyrene foam. Keep in mind that specific densities may vary depending on the manufacturer and application requirements.

Applications of Different Expanded Polystyrene Density

Low Density EPS

Medium Density EPS

High Density EPS

| Industry | Product | Low Density (0.5 – 1.0 lbs/ft³) | Medium Density (1.0 – 2.0 lbs/ft³) | High Density (2.0+ lbs/ft³) |

| Packaging | Protective Packaging | Fragile items, electronics, glassware | Moderate-weight products, consumer goods | Industrial equipment, automotive parts |

| Void Fill | Shipping boxes, containers | Packaging inserts, cushioning materials | Heavy-duty packaging | |

| Insulation | Refrigerator Insulation | Lightweight, thermal insulation | Energy-efficient, thermal comfort | Structural integrity, thermal stability |

| Wall Insulation | Lightweight, temporary structures | Residential, and commercial buildings | SIPs for energy-efficient construction | |

| Construction | Architectural Foam | Decorative elements, lightweight | Aesthetics, trim work | Lightweight fill material, facades |

| Formwork | Concrete casting, rapid construction | Labor reduction, cost-effective | Structural support, stability | |

| Specialty | Buoyancy Aids | Marine applications, flotation devices | Water sports equipment, impact resistance | Model making, prototyping |

| Stage Props | Event decorations, theatrical sets | Themed decorations, film production | Creative projects, entertainment venues |

This table outlines how EPS foam of different densities is utilized across various industries for specific products. Low-density foam is typically used for lightweight applications where cushioning is essential, medium-density foam offers a balance of strength and weight for insulation and construction purposes, while high-density foam provides structural integrity and durability for heavy-duty applications.

SL (Standard Light) Density EPS Foam

SL (Standard Light) Density EPS foam stands out for its exceptionally low density, specifically 13.5 kg/m³. This characteristic makes it remarkably lightweight, which is a significant advantage in applications where minimizing added mass is crucial. While its primary role isn’t structural support, its excellent insulation and cushioning capabilities make it highly valuable for a range of non-load-bearing uses.

This grade of EPS foam is particularly well-suited for scenarios where protection, thermal regulation, or space filling are the main objectives, rather than bearing heavy loads. Its versatility is evident across several industries, from safeguarding delicate products during transit to providing effective insulation in various building elements.

Key applications of SL Density EPS Foam include:

- Geofoam: The most popular choice for geofoam applications due to its lightweight nature, often used for embankment stabilization, lightweight fill, or reducing lateral earth pressures. (Note: For applications demanding higher compressive strength in geofoam, M, H, or VH grades would be more appropriate.)

- Packaging: Widely utilized for product cushioning, protecting goods during shipping without significantly increasing package weight.

- Insulation: An effective material for thermal insulation in areas where structural integrity is not a primary concern, contributing to energy efficiency.

- Void Filling: Employed in landscaping and construction to fill empty spaces where no structural support is required, such as behind retaining walls or under lightweight concrete slabs.

M (Medium) Density EPS Foam

M (Medium) Density EPS foam, characterized by a density of 19 kg/m³, represents an excellent middle ground, offering a harmonious blend of being relatively lightweight yet possessing sufficient strength. This makes it a highly versatile material suitable for a broad spectrum of general-purpose applications where a moderate level of structural integrity is necessary. Notably, it is often the recommended grade for external cladding systems due to this balanced performance.

This grade of EPS foam provides a more robust solution than its lighter counterparts while still maintaining ease of handling and installation. Its balanced properties make it a go-to material for construction, packaging, and even creative pursuits where a reliable, moderately strong, and insulating material is desired.

Key applications of M (Medium) Density EPS Foam include:

- Craft Projects: Valued by hobbyists and artists for its flexibility and ease of cutting, allowing for detailed shaping and design.

- Insulation for Walls and Roofs: Offers a strong combination of effective thermal insulation and moderate structural strength, making it a preferred choice for building envelopes.

- External Cladding Applications: Often the recommended grade for exterior wall insulation and finishing systems due to its balance of properties.

- Packaging for Delicate Items: Provides enhanced cushioning and protection for fragile goods, surpassing the performance of SL density foam for more critical packaging needs.

H (High) Density EPS Foam

H (High) Density EPS foam, at 24 kg/m³, is engineered for superior strength and durability, making it the go-to choice for applications that demand high compressive resistance and robust performance. Its denser cellular structure translates into an exceptional ability to bear loads and withstand significant stress, setting it apart from lighter EPS grades. This characteristic makes it indispensable in various demanding industries where structural integrity is paramount.

This grade of EPS foam is particularly valuable in scenarios where a material needs to provide both insulation and substantial support. Its enhanced resistance to deformation and impact ensures longevity and reliability in critical applications, often serving as a foundational element in complex projects.

Ideal applications for H (High) Density EPS Foam include:

- Geofoam: Employed in civil engineering as a lightweight fill material for bridge abutments, road construction over soft soils, and other applications requiring high compressive strength to prevent settlement.

- Construction: Widely utilized in concrete formwork, where it provides robust support and forms the desired shape for poured concrete. It’s also used as a reliable support material within walls and floors, particularly where structural loads are present.

- Architectural Models: Its inherent strength and ability to hold intricate detail make it perfect for creating durable and precise architectural models.

- Heavy-Duty Packaging: Offers superior protection for heavier or more valuable products, providing enhanced cushioning and structural support to prevent damage during transit and storage.

VH (Very High) Density EPS foam, with a density of 28 kg/m³, represents the pinnacle of strength and durability within the EPS range. It is specifically engineered for the most rigorous and demanding applications, where maximum compressive resistance and unyielding performance are absolutely critical. This grade offers unparalleled structural integrity, making it capable of withstanding extreme loads and impacts without compromise.

This highest density EPS foam is the material of choice when superior strength, long-term stability, and exceptional load-bearing capacity are paramount. Its robust nature makes it indispensable in advanced construction and industrial scenarios where the material must perform under the harshest conditions.

Ideal applications for VH (Very High) Density EPS Foam include:

- Heavy-Duty Floatation Devices: Used in marine applications or for large pontoons where high buoyancy combined with extreme durability and resistance to water absorption is necessary.

- Structural Insulation Panels (SIPs): A key component in SIPs, providing maximum structural support and superior insulation for highly energy-efficient and durable buildings.

- High-Impact Geofoam Applications: Perfectly suited for demanding civil engineering projects such as roadways, bridge foundations, or embankment stabilization, where a lightweight fill is required that can also offer substantial compressive strength to support significant loads.

- Industrial Packaging: Provides the highest level of protection for extremely heavy, valuable, or fragile industrial products, ensuring maximum shock absorption and load distribution during transit and storage.

How Can EPS Density Be Adjusted During Production?

EPS density is primarily adjusted by controlling the amount of steam applied during the pre-expansion and molding phases. More steam generally leads to greater expansion and thus lower density, while less steam results in a higher density. The processing time and temperature also play crucial roles in fusing the beads to achieve the desired final density.

How Can EPS Density Be Adjusted During Production?

EPS density is primarily controlled by manipulating the amount of steam used in both the pre-expansion and molding stages. More steam expands the beads further, creating a lower density.

Conversely, less steam results in less expansion and thus a higher density. Factors like temperature and processing time also play a role in achieving the desired final product.

Is EPS Density Directly Related to Its Insulation Performance?

Yes, EPS density is directly related to its insulation performance, typically measured by R-value.

Generally, higher density EPS tends to have a slightly better R-value per inch. This is because increased density means more trapped air pockets within the foam structure, which are excellent at resisting heat transfer. However, the gains in R-value become less significant at very high densities, and the primary benefit of higher density shifts more towards compressive strength.

Can EPS Density Affect Its Recyclability?

While all EPS is technically recyclable, its density significantly impacts the practicalities and economics of recycling. Lower density EPS, common in packaging, presents a challenge due to its high volume-to-weight ratio, making collection, transportation, and storage inefficient and costly. This often necessitates compaction or densification before processing.

Higher density EPS, such as that used in construction, is generally easier to handle for recycling due to its greater mass per volume, reducing transportation costs. Regardless of density, effective EPS recycling relies on clean, segregated material and the availability of specialized facilities that can process it mechanically (granulation, compaction) or chemically.

Conclusion

Understanding Expanded Polystyrene (EPS) density is crucial for unlocking its full potential. As we’ve explored, this single characteristic dictates the foam’s strength, insulation capabilities, and suitability for countless applications, from lightweight packaging to robust construction.

The production process carefully controls density, yielding grades like SL, M, H, and VH, each tailored for specific performance needs. Whether you prioritize supreme insulation, high compressive strength, or a balanced approach, there’s an EPS density perfectly suited for your project.

For all your wholesale EPS foam needs, no matter the density, look no further than Epsole. We provide high-quality EPS foam to meet diverse industrial and construction requirements.