Expanded Polystyrene R-Value plays a crucial role in enhancing insulation efficiency, whether in construction projects or packaging solutions. Understanding its significance, benefits, and applications can lead to more sustainable and energy-efficient outcomes.

What is Expanded Polystyrene?

Expanded Polystyrene (EPS) is a lightweight, rigid, cellular plastic material derived from petroleum and natural gas. Through a process of expansion, polystyrene beads are expanded to form a multitude of tiny cells, resulting in the versatile material known as EPS.

What Is EPS Insulation

EPS insulation refers to insulation material made from Expanded Polystyrene (EPS). EPS insulation is a lightweight, rigid, and versatile material commonly used in construction and packaging industries for its excellent thermal insulation properties.

During the manufacturing process, polystyrene beads are expanded and fused together to form a closed-cell structure, creating EPS insulation boards or blocks. These boards or blocks are available in various thicknesses and densities to suit different insulation requirements.

EPS insulation is valued for its high R-Value, which measures its thermal resistance. It effectively slows down the transfer of heat, helping to maintain comfortable indoor temperatures and reduce energy consumption for heating and cooling.

In construction, EPS insulation is commonly used in walls, roofs, and foundations to improve energy efficiency and thermal comfort in buildings. It can also be used in packaging to protect fragile items during transportation, as EPS’s cushioning properties help absorb shock and vibrations.

Expanded Polystyrene R-Value

R-value measures the thermal resistance of a material, indicating its effectiveness in resisting heat flow. A higher R-value signifies better insulation capability.

Factors influencing the R-value include material density, thickness, and the presence of air pockets within the material.

Expanded Polystyrene Insulation R Value

Expanded Polystyrene (EPS) insulation is valued for its thermal resistance, commonly referred to as the R-value. The R-value measures how well a material resists the transfer of heat.

EPS insulation achieves its R-value due to its structure: it consists of a cellular matrix of trapped air pockets. These pockets of air hinder the movement of heat through the material, thereby reducing heat transfer. The thicker the EPS insulation, the greater its R-value, as there is more material through which heat must pass.

The R-value of EPS insulation is determined by factors such as its density, thickness, and the efficiency of its manufacturing process. Higher-density EPS typically has a higher R-value because it contains more material and air pockets to resist heat flow.

When selecting EPS insulation for a project, it’s essential to consider the desired level of thermal resistance needed to meet energy efficiency requirements. Higher R-values are often required for regions with more extreme climates to provide sufficient insulation and reduce heating and cooling costs.

Expanded Polystyrene R Value Chart

Here’s an Expanded Polystyrene R-Value chart:

| Thickness (inches) | R-Value |

|---|---|

| 1 | 3.6 |

| 1.5 | 5.4 |

| 2 | 7.2 |

| 2.5 | 9.0 |

| 3 | 10.8 |

| 3.5 | 12.6 |

| 4 | 14.4 |

This chart showcases the R-Value of Expanded Polystyrene (EPS) insulation at various thicknesses. As the thickness increases, so does the R-Value, indicating improved insulation efficiency. Builders and contractors can use this chart to select the appropriate EPS thickness for their insulation needs, ensuring optimal energy efficiency and comfort in buildings.

Expanded Polystyrene R Value Calculator

Here is the expanded polystyrene R-value calculator.

Expanded Polystyrene R-Value Calculator

R-Value of EPS Rigid Insulation

The R-value of EPS (Expanded Polystyrene) rigid insulation varies depending on factors such as thickness and density. On average, EPS rigid insulation typically has an R-value ranging from R-3.6 to R-4.2 per inch of thickness. This means that every inch of EPS insulation provides thermal resistance equivalent to R-3.6 to R-4.2.

It’s important to note that thicker EPS insulation will have a higher R-value, indicating greater insulation efficiency. Builders and contractors often select EPS rigid insulation with an appropriate thickness to meet specific energy efficiency requirements for their projects.

Benefits of Expanded Polystyrene R-Value

EPS boasts excellent insulation properties, offering superior thermal performance compared to traditional materials. Its lightweight nature contributes to energy efficiency, reducing heating and cooling costs in buildings. Additionally, EPS is moisture-resistant, mold-resistant, and durable, ensuring long-term effectiveness.

Applications

Expanded Polystyrene R-Value finds extensive applications in various industries. In construction, it serves as insulation in walls, roofs, and foundations, enhancing energy efficiency and comfort. In packaging, EPS protects goods during transportation, minimizing damage and ensuring product integrity.

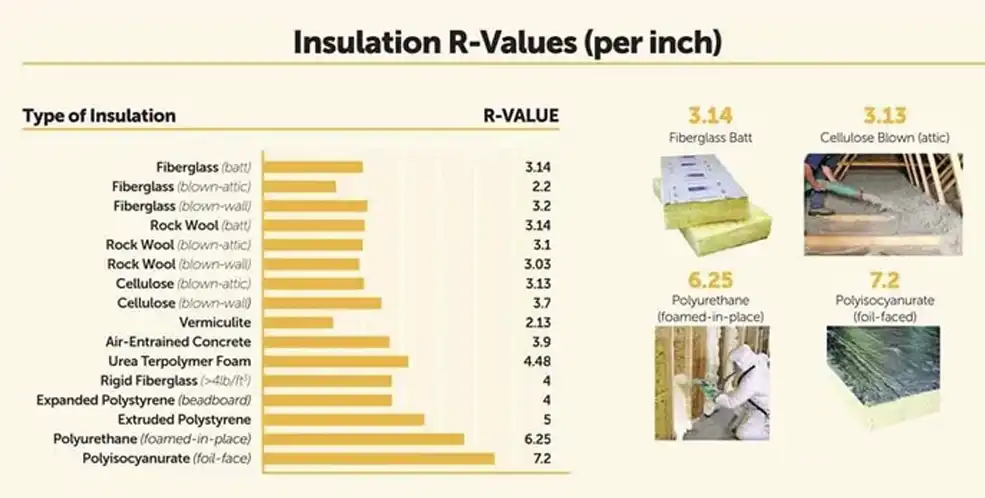

Comparative Analysis

Compared to other insulation materials like fiberglass and cellulose, Expanded Polystyrene R-Value demonstrates superior thermal performance. Its closed-cell structure prevents heat transfer effectively, making it an optimal choice for insulation projects.

Installation Techniques

Proper installation techniques are crucial for maximizing the benefits of Expanded Polystyrene R-Value. Ensuring uniform coverage and sealing gaps can significantly improve energy efficiency. Despite its initial cost, EPS proves to be cost-effective in the long run due to reduced energy consumption.

Environmental Impact

From a sustainability perspective, Expanded Polystyrene R-Value offers several advantages. It is 100% recyclable, with numerous facilities worldwide dedicated to recycling EPS waste. Moreover, its lightweight nature reduces transportation emissions, contributing to overall environmental conservation efforts.

Common FAQs

How does Expanded Polystyrene R-Value compare with other materials?

Expanded Polystyrene (EPS) R-Value compares favorably with other insulation materials due to its excellent thermal performance. EPS has a high R-Value, indicating its ability to resist heat flow effectively. Compared to materials like fiberglass and cellulose, EPS offers superior insulation, maintaining consistent indoor temperatures and reducing energy consumption. Its closed-cell structure prevents heat transfer efficiently, making it an optimal choice for insulation projects.

Is Expanded Polystyrene R-Value suitable for all climates?

Expanded Polystyrene R-Value is versatile and suitable for various climates. Its insulation properties remain effective in both hot and cold climates, helping to regulate indoor temperatures and improve energy efficiency. However, it’s essential to consider factors such as humidity levels and specific climate conditions when selecting insulation materials for optimal performance.

What are the long-term benefits of using Expanded Polystyrene R-Value?

The long-term benefits of using Expanded Polystyrene R-Value include energy savings, increased comfort, and durability. By providing efficient insulation, EPS helps reduce heating and cooling costs over time, leading to significant long-term savings on energy bills. Additionally, its moisture-resistant and mold-resistant properties ensure durability, maintaining insulation performance for years to come.

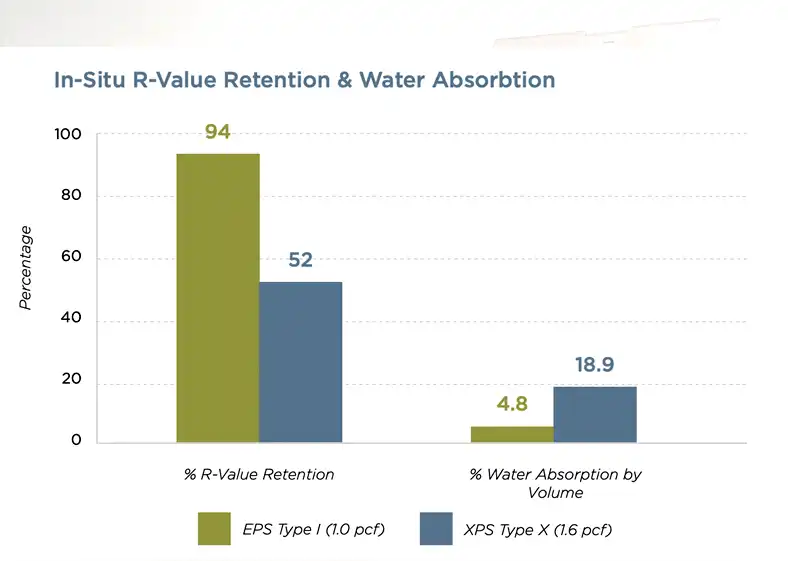

How does humidity affect the performance of Expanded Polystyrene R-Value?

Humidity can impact the performance of Expanded Polystyrene R-Value to some extent. While EPS itself is resistant to moisture, excessive humidity levels can affect its insulation properties over time. High humidity may lead to condensation within the insulation material, reducing its effectiveness in resisting heat flow. Proper installation techniques and moisture barriers can help mitigate these effects and maintain optimal performance.

Can Expanded Polystyrene R-Value be recycled?

Yes, Expanded Polystyrene R-Value is 100% recyclable. EPS waste can be recycled into various products, including new insulation materials, packaging, and construction materials. Recycling EPS not only reduces waste sent to landfills but also conserves natural resources and minimizes environmental impact. Many recycling facilities worldwide accept EPS waste, contributing to a more sustainable waste management system.

Are there any health concerns associated with using Expanded Polystyrene R-Value?

Expanded Polystyrene R-Value is generally considered safe for use in insulation and packaging applications. However, during manufacturing and installation, some concerns may arise regarding the release of volatile organic compounds (VOCs) and potential respiratory irritation. Proper ventilation and adherence to safety guidelines can help minimize exposure to any potential health risks associated with EPS insulation materials.

Conclusion

Expanded Polystyrene R-Value offers a myriad of benefits in terms of insulation efficiency, energy savings, and environmental sustainability. By leveraging its superior thermal performance and versatility, EPS contributes to creating more comfortable and sustainable living and working environments.