EPS panels are widely used in construction for their lightweight structure, excellent thermal insulation, and cost-effective installation. Understanding how EPS panels are made helps builders, manufacturers, and buyers appreciate the quality control, materials, and processes behind these essential building products, ensuring projects meet efficiency and performance standards.

The EPS panel manufacturing process involves multiple precise steps, including EPS core formation, lamination with surface materials, cutting, and quality inspection. Each stage ensures the panels provide consistent strength, insulation, and durability, making them ideal for walls, roofs, cold storage, and prefabricated structures, while supporting energy-efficient and sustainable construction practices.

EPS Panel Uses

EPS panels are versatile building materials used across industrial, commercial, and residential projects. Their lightweight structure, excellent thermal insulation, and durable surface make them suitable for walls, roofs, cold storage, and prefabricated buildings.

By offering energy efficiency, easy installation, and long-lasting performance, EPS panels are ideal for modern construction needs.

- Prefabricated Buildings – EPS panels are ideal for modular or prefabricated structures, providing easy assembly, lightweight handling, and excellent insulation. They support fast construction while maintaining structural integrity and long-lasting thermal performance for temporary or permanent buildings.

- Wall Insulation – EPS panels are widely used in walls to improve thermal efficiency, reduce energy consumption, and maintain comfortable indoor temperatures. They provide structural support while preventing heat loss and moisture penetration in both residential and commercial buildings.

- Roofing Applications – EPS panels offer lightweight and durable roof insulation, reducing structural load while protecting buildings from weather and temperature extremes. They enable quick installation and long-term energy savings for industrial, commercial, and prefabricated roofs.

- Cold Storage and Refrigeration – EPS panels maintain stable temperatures in cold rooms and refrigerated warehouses. Their superior insulation reduces energy usage, preserves stored goods, and ensures efficient, cost-effective climate control in food processing and storage facilities.

EPS Panel Manufacturing Process

EPS panels are widely used in construction due to their lightweight, durable, and insulating properties. Producing EPS panels requires a precise manufacturing process that includes core formation, lamination, cutting, and quality checks.

Understanding each step ensures panels meet structural, thermal, and performance standards for various applications.

Tools Needed

- EPS molding machine

- Lamination press

- Cutting saws or CNC cutters

- Conveyors and stacking equipment

- Measuring and inspection tools

- Protective gear

Step 1: EPS Core Formation

The first step involves expanding raw EPS beads using steam and heat to create a uniform foam block. The beads fuse together, forming a lightweight, insulating core. This stage determines the panel’s density, thermal performance, and stability. Proper expansion ensures consistent quality for cutting and lamination.

Once expanded, the foam blocks are cooled and stabilized. This prevents deformation during later processes and prepares the material for precise sizing. Operators monitor density and moisture content to guarantee panels meet project requirements, ensuring reliable thermal insulation and structural support for walls, roofs, and prefabricated structures.

Step 2: Cutting the EPS Core

After cooling, the EPS blocks are cut into specific panel dimensions using saws or CNC cutters. Accurate cutting ensures uniform thickness and size for easier lamination and installation. This step is critical to reduce material waste and maintain consistent panel quality across production batches.

The cutting process may include trimming edges or adjusting panel length and width based on customer specifications. Proper handling during this step prevents damage and ensures that panels are ready for lamination. Maintaining precise dimensions contributes to better insulation performance and smooth on-site assembly.

Step 3: Surface Lamination

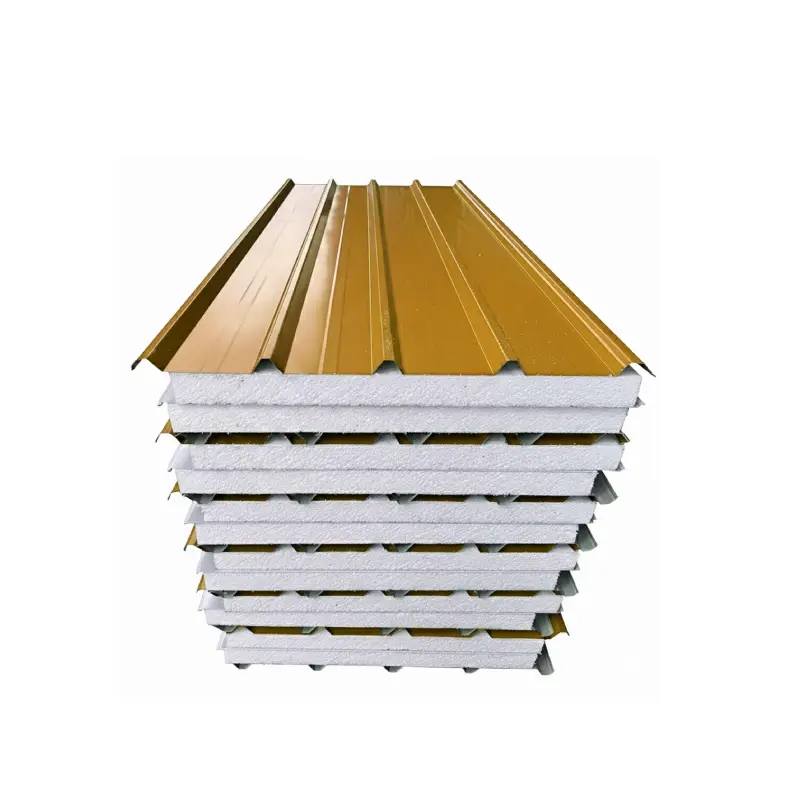

In this step, the EPS core is sandwiched between metal sheets or other surface materials using high-pressure lamination. The process bonds the surfaces securely, enhancing strength, durability, and resistance to moisture and environmental factors. Lamination ensures panels are rigid yet lightweight for easy handling.

The bonded panels are then inspected for uniform adhesion, smooth surfaces, and proper alignment. This step ensures structural integrity and long-term performance. Any irregularities are corrected to maintain high-quality insulation panels suitable for roofing, wall cladding, and cold storage applications.

Step 4: Edge Sealing and Finishing

Edges of the laminated panels are sealed and finished to prevent moisture penetration and improve durability. This step also smooths panel edges for easier installation. Proper finishing enhances aesthetics and protects the panel core from damage during transport and assembly.

Sealing may involve adhesives, protective coatings, or mechanical trimming. Consistent edge quality ensures panels fit precisely during construction, reducing gaps or thermal bridges. Finished edges also contribute to fire resistance and long-term performance, making panels reliable for industrial and commercial buildings.

Step 5: Quality Inspection

Every panel undergoes inspection for thickness, density, bonding strength, and surface integrity. This step ensures that all panels meet design specifications and performance standards before shipping. Quality control prevents defects that could affect thermal insulation or structural reliability.

Inspections may include visual checks, mechanical tests, or sample measurements. Panels failing standards are reprocessed or discarded to maintain product consistency. Rigorous quality control ensures customers receive durable, safe, and efficient EPS panels suitable for walls, roofs, and prefabricated structures.

Step 6: Packaging and Storage

Finished panels are stacked, packaged, and prepared for transport. Proper handling prevents deformation, moisture absorption, and surface damage during storage and shipping. Organized packaging also facilitates easy loading and unloading at construction sites.

Storage areas are kept clean, dry, and ventilated to preserve panel quality. Correct stacking prevents bending or crushing while maintaining the panels’ thermal performance. Well-packaged panels ensure safe delivery and a ready-to-install condition for industrial, commercial, and residential projects.

EPS Panel Production Line

EPS panel production lines are complete systems designed to efficiently produce high-quality EPS sandwich panels. They combine advanced machinery for EPS core forming, lamination, cutting, and quality control.

Using an integrated line ensures consistent panel size, density, and insulation performance, reducing labor, material waste, and production time for industrial, commercial, and prefabricated projects.

- Quality Control Stations – Integrated inspection systems check thickness, density, bonding strength, and surface quality. Panels failing standards are corrected or removed, ensuring consistent high performance and reliable insulation for a wide range of building applications.

- EPS Core Forming Machine – The EPS core forming machine expands raw beads into uniform foam blocks. We ensure consistent density and thermal insulation properties while preparing the material for precise cutting and lamination, which is critical for reliable panel performance and structural integrity.

- Cutting and Sizing Equipment – After forming, foam blocks are cut into panels with accurate thickness and dimensions. This equipment minimizes material waste, maintains uniformity, and ensures panels fit correctly during lamination and on-site installation.

- Lamination Press – The lamination press sandwiches EPS cores between surface materials under high pressure. We use this step to create strong, durable panels with excellent moisture resistance and surface smoothness for walls, roofs, and prefabricated structures.

- Edge Sealing and Trimming Tools – Panels pass through finishing equipment that seals edges and trims surfaces. This process prevents moisture penetration, improves aesthetics, and ensures panels are easy to install while maintaining long-term performance and insulation efficiency.

- Conveyor and Stacking Systems – Automated conveyors transport panels through production stages and stack them for storage. This reduces manual handling, prevents damage, and ensures smooth workflow, increasing overall production efficiency.

Conclusion

EPS panel manufacturing process combines careful material selection, precise core forming, and high-quality lamination to produce durable, thermally efficient panels. By following these steps, manufacturers ensure each panel meets performance standards, providing reliable insulation and long-lasting structural support for a wide range of construction projects.

For those looking to source EPS panels in bulk, we offer a wide selection of wholesale options. Our panels are produced with consistent quality and tailored to various insulation and structural requirements, making it easy for builders and distributors to find the right products for their projects.

Additionally, we provide complete EPS panel production lines, enabling manufacturers to produce panels efficiently with precise cutting, lamination, and quality control systems. Partnering with us ensures access to reliable machinery and materials, supporting smooth production and high-performance panels for diverse construction applications.

-300x300.webp)