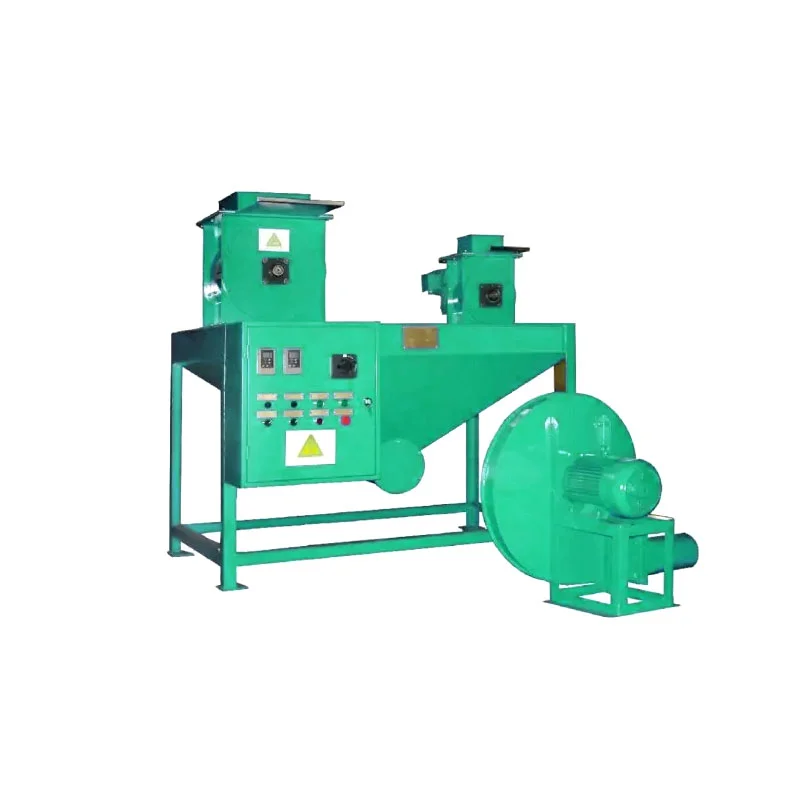

Our EPS recycling system consists of a crusher, dust collector and mixer. Being able to fully meet customers’ needs for EPS waste conversion and molding, the high technical content and stable performance make our EPS foam recycling system popular in many countries.

Environmental Sustainability: EPS recycling machines help in reducing the amount of expanded polystyrene(EPS)waste that ends up in landfills or oceans, contributing to a cleaner and healthier environment.

Resource Conservation: By recycling EPS materials, these machines help conserve valuable natural resources such as oil which is used in the production of virgin EPS, thus promoting

Cost Savings: Investing in an EPS recycling machine can lead to significant cost savings for businesses and municipalities by reducing waste disposal costs and potentially generating revenue from selling recycled EPS materials.

Energy Efficiency: Recycling EPS consumes much less energy compared to producing virgin EPS, making it an energy-efficient solution for waste management.

Versatility: EPS recycling machines are capable of processing various forms of EPS waste, including packaging materials, insulation boards, and foam products, making them versatile and adaptable to different recycling needs.

De-Duster With Automatic Dust Collector | |||

NO. | ITEM | UNIT | PSDR-25 |

1 | Capacity | m³/H | 25-30 |

2 | Power | KW | 8.4KW |

3 | Size | mm | 3500x1500x2050 |

4 | Duster Collector | mm | 840x840x3000 |

5 | Weight | kg | 700 |

6 | Mesh Size | mm | DN3 |

7 | Suction Suction | m³/H | 2000 |

8 | Air Bag | pecs | 16 |

EPS recycling machines are equipped with a high-efficiency crushing mechanism designed to break down expanded polystyrene(EPS)materials into smaller manageable pieces, This feature ensures optimal processing of EPS waste, maximizing recycling output.

We can not only efficiently remove impurities from the waste, but also reduce the energy consumption in the process. With excellent filtration efficiency and long-lasting stability, the waste can be kept highly clean, increasing the efficiency of recycling.

The EPS mixer system has two bins, corresponding to the fresh EPS bean bin and the recycled EPS bean bin, and the recommended mixing ratio is between 3-8%. Choose our mixer to streamline your production line, increase productivity, and achieve the best cost-effectiveness.

The mechanical recycling machine typically uses mechanical processes such as crushing, shredding, and compacting to break down EPS foam waste into smaller pieces. It may include equipment such as crushers, granulators, and densifiers to facilitate the recycling process.

Thermal recycling machine utilizes heat to melt and densify EPS foam waste, transforming it into denser blocks or pellets that can be reused in various applications. It often incorporates technologies such as hot melting and extrusion to process EPS waste thermally.

Chemical recycling machines employ chemical processes to break down EPS foam waste into its constituent molecules, which can then be used to produce new materials or products. They may utilize solvents, catalysts, or other chemical agents to depolymerize EPS foam and extract useful components.

EPS recycling machines are frequently used to recycle EPS packaging materials, such as foam packaging used for shipping fragile items. By recycling EPS packaging waste, these machines help reduce the environmental impact of packaging materials and promote sustainable packaging practices.

Expanded polystyrene (EPS) foam is commonly used as insulation material in construction projects. EPS recycling machines can process EPS insulation waste generated during construction and demolition activities, allowing for the efficient recycling of EPS foam into new insulation products.

Many electronic appliances come packaged in EPS foam to provide cushioning and protection during transportation. EPS recycling machines are utilized to recycle EPS foam packaging waste generated by electronic appliance manufacturers, contributing to the circular economy by reintroducing recycled EPS materials into new product packaging.

EPS foam is commonly used in the food service industry for packaging food and beverages, such as foam cups, containers, and trays. EPS recycling machines play a vital role in recycling EPS foam food packaging waste, helping restaurants, cafeterias, and food manufacturers minimize waste and reduce their environmental footprint.

EPS foam is widely used in retail and consumer product packaging, such as protective packaging for electronics, furniture, and household goods. EPS recycling machines enable the recycling of EPS foam packaging waste generated by retailers and consumers, supporting sustainable packaging initiatives and reducing landfill waste.

Various manufacturing processes generate EPS foam waste as a byproduct, such as the production of automotive parts, medical devices, and consumer goods. EPS recycling machines are utilized in manufacturing facilities to recycle EPS foam waste, diverting it from landfills and promoting resource conservation.

An EPS recycling machine is a specialized piece of equipment designed to process and recycle expanded polystyrene (EPS) foam waste into reusable materials. It typically involves crushing, melting, and densifying EPS foam to reduce its volume and facilitate recycling.

EPS recycling machines work by first breaking down EPS foam waste into smaller pieces through a crushing mechanism. The crushed EPS is then melted and densified using heat and pressure, transforming it into denser blocks or pellets that can be reused in various applications.

EPS recycling machines can process various types of EPS waste, including packaging materials, insulation boards, foam packaging, and manufacturing scraps. They are versatile and adaptable to different forms of EPS foam waste.

Using an EPS recycling machine offers several benefits, including reducing EPS waste sent to landfills, conserving natural resources, lowering carbon emissions, and promoting sustainability. It also helps businesses save on waste disposal costs and enhances their environmental stewardship.

Yes, EPS recycling is environmentally friendly because it diverts EPS waste from landfills, where it can take up valuable space and contribute to pollution. Recycling EPS reduces the need for virgin EPS production, conserving energy and resources in the process.

Most modern EPS recycling machines are designed with user-friendly interfaces and intuitive controls, making them relatively easy to operate. However, proper training and maintenance are essential to ensure optimal performance and safety.

Yes, recycled EPS materials produced by EPS recycling machines can be used in various applications, including packaging, insulation, construction materials, and consumer products. Recycled EPS offers similar performance characteristics to virgin EPS while reducing environmental impact.

The lifespan of an EPS recycling machine depends on factors such as usage, maintenance, and quality of components. With regular maintenance and proper care, EPS recycling machines can last for many years, providing a reliable and sustainable solution for EPS waste management.

Yes, EPS recycling can be economically viable, especially when considering the cost savings from reduced waste disposal fees and potential revenue generation from selling recycled EPS materials. Investing in an EPS recycling machine can lead to long-term financial benefits for businesses and municipalities.

Yes, many regions have regulations and standards in place to promote EPS recycling and reduce EPS waste. These may include mandates for recycling certain types of EPS materials, requirements for recycling facilities to meet certain environmental standards, and incentives for businesses to implement EPS recycling programs. It’s essential to be aware of and comply with relevant regulations and standards when engaging in EPS recycling activities.

Copyright © 2024 Hangzhou Epsole technologies Co.Ltd.