The journey from tiny EPP beads to high-performance products is a fascinating one, at the heart of which lies the EPP molding process. This innovative manufacturing technique harnesses the unique properties of expanded polypropylene to create components that are not only incredibly lightweight but also exceptionally durable and resilient.

This blog post will delve into the intricacies of how these seemingly simple beads are transformed into the brilliant EPP products we encounter daily. We’ll explore the steps involved in the molding process, highlighting how precision and specialized equipment are crucial in shaping these versatile materials into their final, functional forms.

What is EPP?

EPP (Expanded Polypropylene) is a lightweight, closed-cell bead foam. It’s known for excellent energy absorption, high resilience, chemical resistance, and thermal insulation. EPP is also 100% recyclable, making it an environmentally friendly material used in automotive, packaging, and sports equipment.

- Exceptional Energy Absorption/Impact Resistance: EPP excels at absorbing and dissipating energy from impacts, making it ideal for crash-relevant components in automotive, protective packaging, and sports equipment (e.g., bumpers, headrests, helmets). It can undergo multiple impacts without significant deformation.

- Lightweight: Composed of over 90% air, EPP has a very low density, leading to extremely lightweight products. This is crucial for applications where weight reduction is vital, such as improving fuel efficiency in vehicles or reducing shipping costs for packaged goods.

- High Strength-to-Weight Ratio: Despite its lightness, EPP boasts impressive structural strength and durability, allowing it to withstand heavy loads and repeated stresses without compromising its integrity.

- High Resilience/Shape Recovery: EPP exhibits excellent elastic properties, allowing it to deform under pressure or impact and then return to its original shape. This “memory” makes it highly durable and suitable for reuse in various applications.

- Thermal Insulation: Its closed-cell structure provides excellent thermal insulation, making EPP suitable for temperature-sensitive applications like insulated food containers and HVAC components.

- Chemical Resistance: EPP is resistant to water, oils, and most chemicals, enhancing its longevity and suitability for diverse environments.

- Water Resistance/Buoyancy: Due to its closed-cell structure, EPP absorbs very little water and is buoyant, making it ideal for marine applications and moisture-prone environments.

- Recyclability: EPP is 100% recyclable, contributing to a more sustainable manufacturing cycle and reducing landfill waste.

- Hygienic and Non-Toxic: EPP is food-safe, chemically inert, and resistant to microbial growth, making it suitable for medical and food contact applications.

EPP Injection Molding

- EPP Injection Molding is a highly efficient manufacturing process used to create lightweight, durable, and recyclable expanded polypropylene (EPP) parts. This method ensures precision, consistency, and excellent impact resistance, making it ideal for automotive, packaging, and consumer goods industries.

- Eco-friendly and recyclable: EPP material is fully recyclable and environmentally friendly, reducing waste and promoting sustainable production practices.

- Lightweight yet strong: EPP injection molding produces components that are extremely light but maintain high structural integrity, reducing product weight while ensuring durability in automotive and packaging applications.

- Excellent impact resistance: Parts created with EPP molding effectively absorb shocks, providing superior protection for both products and users, making it ideal for safety and energy absorption applications.

- Precision and repeatability: The injection molding process allows precise control over part dimensions and shapes, ensuring consistent quality across large production runs.

Machines Used in the EPP Molding Process

The journey of transforming expanded polypropylene (EPP) beads into intricate and functional products is a marvel of modern manufacturing. This process, known as EPP molding, relies on highly specialized machinery designed to leverage EPP’s unique characteristics. It’s here that raw material truly comes to life, taking on forms vital for countless applications.

- Mold Cavity: This is where the EPP beads are shaped, with the cavity defining the final product’s precise dimensions and form.

- Steam Chambers: Integrated into the machine, these chambers use steam to heat and further expand the EPP beads within the mold, fusing them.

- Filling System/Injectors: These components precisely fill the mold cavity with the pre-expanded EPP beads.

- Hydraulic or Electric Clamping System: This mechanism applies a significant force to keep the mold halves securely closed during the molding process.

- Cooling System: After molding, the product must be cooled to solidify and retain its shape, typically involving the circulation of water.

- Vacuum System: Many modern EPP molding machines incorporate a vacuum system to aid in faster filling, better fusion, and quicker cooling cycles.

- Control System (PLC & HMI): An advanced computer-controlled system with a programmable logic controller (PLC) and human-machine interface (HMI) allows for precise control over temperature, pressure, steam flow, and cycle times, ensuring consistent product quality.

EPP Molding Process

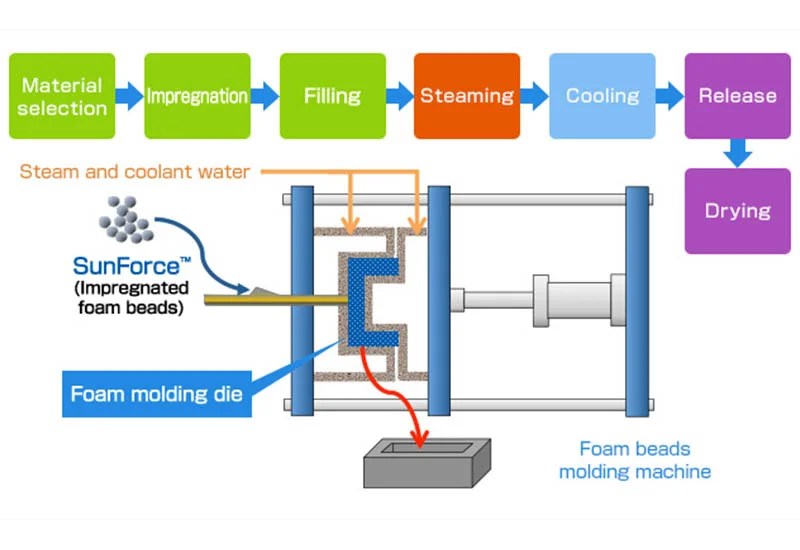

The journey of transforming expanded polypropylene (EPP) beads into intricate and functional products is a marvel of modern manufacturing. This precise and highly controlled process, known as EPP molding, relies on highly specialized machinery designed to leverage EPP’s unique characteristics. It’s here that raw material truly comes to life, taking on forms vital for countless applications across diverse industries, from automotive safety components to protective packaging solutions.

This detailed process involves several critical stages, each contributing significantly to the final product’s quality, integrity, and performance. From the initial preparation of the raw EPP material to the final cooling and demolding of the finished part, precision and strictly controlled conditions are paramount.

Understanding these steps is essential to fully appreciate how EPP achieves its superior properties and complex geometries.

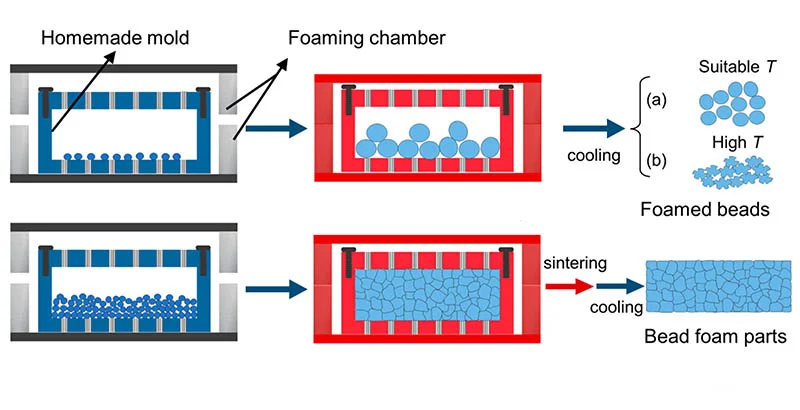

Step 1: Pre-Expansion

The very first stage in the EPP molding process involves the pre-expansion of raw EPP beads. These small, solid polypropylene pellets are introduced into a pre-expander, a specialized vessel where they are exposed to steam. The heat from the steam causes the trapped blowing agent within the beads to expand, effectively “popping” them much like popcorn. This process dramatically increases their volume and reduces their density, transforming them into uniform, closed-cell structures.

Precise control of steam temperature, pressure, and residence time within the pre-expander is absolutely critical during this phase. This meticulous regulation ensures that the beads expand to the exact target density required for the final product, which directly influences the part’s energy absorption capabilities, lightweight properties, and overall performance.

Following pre-expansion, the beads are typically aged in large silos for a period. This allows the internal pressure within the expanded beads to equalize with the ambient air, stabilizing them and preparing them for the subsequent, more intensive molding stage. Proper aging is crucial for preventing collapse during molding and ensuring consistent, high-quality results.

Step 2: EPP Mold Filling

Once the pre-expanded EPP beads have been adequately aged and stabilized, they are ready for the mold filling stage. The beads are pneumatically transported from the aging silos through a series of hoses and feeding mechanisms directly into the mold cavity of the EPP shape molding machine. The mold itself is a meticulously engineered tool, custom-designed to the exact dimensions and intricate geometry of the final product.

The efficiency and uniformity of this filling process are paramount. Advanced filling systems utilize precise air pressure and vibration to ensure that the pre-expanded beads evenly distribute themselves throughout the entire mold cavity, including complex sections, thin-walled areas, and intricate undercuts. Any inconsistencies in filling can lead to voids, uneven density, or structural weaknesses in the finished part, compromising its integrity and performance.

Therefore, automated sensors and feedback loops often monitor the filling process to ensure complete and consistent bead distribution before the next stage begins.

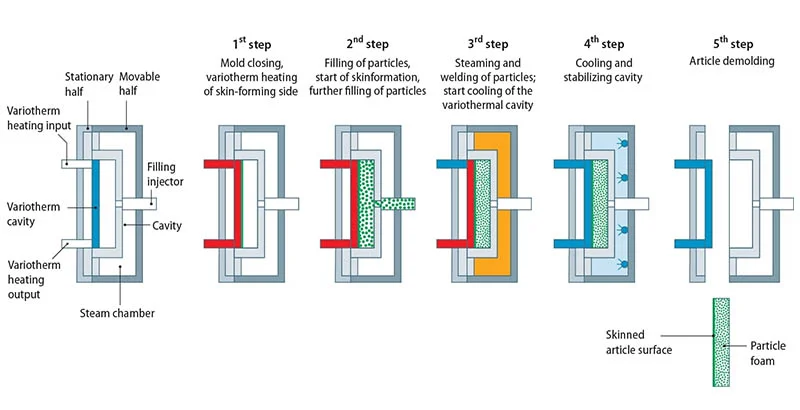

Step 3: Steam Chest Molding

With the mold precisely filled with pre-expanded EPP beads, the critical steam chest molding stage commences. High-pressure steam is rapidly injected directly into the mold cavity, typically through multiple strategically placed nozzles. The intense heat from the steam causes the surface of the pre-expanded beads to soften and become tacky, while simultaneously causing a slight, final expansion of the beads.

Under the influence of the steam’s heat and pressure, these softened EPP beads are forced to further expand against each other and against the mold walls, fusing together to form a solid, homogeneous structure. This fusion process effectively welds the individual beads into a single, cohesive EPP product that perfectly replicates the shape of the mold interior.

Precise control over steam temperature, pressure, and injection duration is absolutely vital during this phase, as these parameters directly determine the final part’s density, structural integrity, dimensional stability, and surface finish. Over-steaming can lead to material degradation, while under-steaming can result in poor fusion and weak parts.

Step 4: Cooling

Immediately following the steam chest molding, the newly formed EPP part undergoes a crucial cooling phase while still contained within the mold. This step is essential to solidify the EPP material and “set” its shape, preventing any deformation or shrinkage once it’s removed from the mold. Cooling is typically achieved by circulating cold water through integrated channels within the mold plates, effectively drawing heat away from the EPP part.

Many modern EPP molding machines also incorporate a vacuum system during cooling. This vacuum helps to accelerate the cooling process by drawing out the steam and hot air from within the mold, and also helps to stabilize the internal pressure within the EPP cells, preventing the part from collapsing or distorting. Rapid and uniform cooling is paramount to achieving consistent product dimensions, minimizing cycle times, and ensuring that the final part maintains its structural integrity and resilience without internal stresses or warping.

Step 5: Demolding and Post-Processing

Once the EPP part has been sufficiently cooled and solidified, it is carefully demolded from the machine. Automated ejector pins or robotic arms typically assist in this process, gently pushing or pulling the finished part from the mold cavity to prevent any damage. The demolded parts are then ready for any necessary post-processing steps, which vary depending on the product’s final application.

Post-processing can include various operations such as trimming excess material (often referred to as “flash” or “sprue” that might be present along the mold parting lines), precision drilling of holes, routing or cutting specific contours, or the integration of additional components like metal inserts, fasteners, or fabric coverings.

Some EPP parts may also undergo a final conditioning period in a controlled environment to ensure complete dimensional stability and to allow any residual moisture to evaporate, optimizing their long-term performance and ensuring they meet all quality specifications before packaging and shipment.

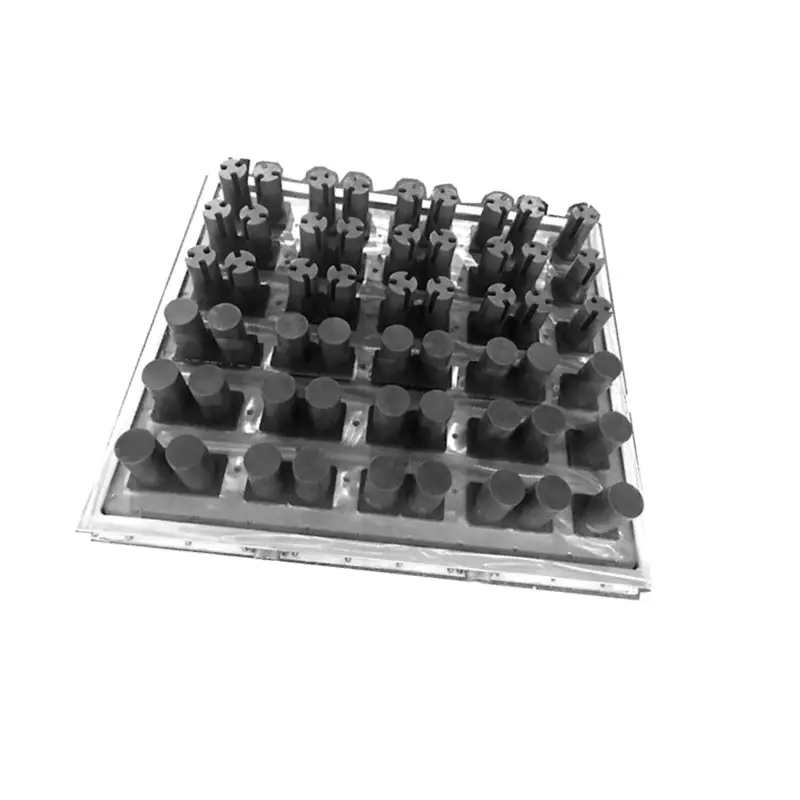

How to Manufacture EPP Molds?

Producing EPP (Expanded Polypropylene) molds involves a precise and multi-stage manufacturing process to create durable and high-quality tools for molding EPP foam parts. This complex procedure ensures the resulting molds can withstand high temperatures and pressures.

Step 1: Design and Engineering

The process begins with the creation of a digital 3D model of the desired EPP part. This model is used to design the mold, taking into account factors like shrinkage, draft angles, and wall thickness. Engineers use specialized software to simulate the molding process and refine the mold’s design.

The design phase is crucial for ensuring the final part meets all specifications and is free from defects. The engineers meticulously plan the placement of heating and cooling channels within the mold to guarantee a consistent temperature throughout the molding cycle. This careful planning prevents warping and ensures the part’s structural integrity.

Step 2: CNC Machining of the Mold Cavities

Once the digital design is complete, the mold cavities are machined from a solid block of aluminum. Computer Numerical Control (CNC) machines are used to precisely cut the intricate shapes and features of the mold. Aluminum is the preferred material due to its excellent thermal conductivity and machinability.

The CNC machining process is a critical step that dictates the final part’s surface finish and dimensional accuracy. The machines follow the digital model with extreme precision, ensuring that the finished mold perfectly replicates the designed part. This guarantees that all details and tolerances are maintained, resulting in high-quality molded products.

Step 3: Integration of Heating and Cooling Systems

After machining, channels for heating and cooling are incorporated into the mold. These channels are essential for controlling the temperature during the molding process. Steam is often used to heat the EPP beads and fuse them, while cooling water solidifies the foam.

Properly designed and integrated temperature control systems are vital for a consistent and efficient molding process. The precise control of temperature and pressure is necessary to ensure the EPP beads expand and fuse uniformly, creating a high-quality part with consistent density and mechanical properties.

Step 4: Assembly of the Mold

The machined mold cavities, along with the heating and cooling plates, are carefully assembled. Ejector pins and other moving components are installed to ensure the finished EPP part can be easily and cleanly removed from the mold after the cycle is complete. All parts are securely fastened.

This step involves putting all the individual components together to form a functional mold. Proper alignment and secure assembly are paramount to the mold’s performance and longevity. A well-assembled mold ensures smooth operation, reduces wear on the components, and minimizes the risk of production issues.

Step 5: Surface Finishing and Treatment

The final step in mold manufacturing involves polishing the mold’s surfaces to achieve the desired finish on the final EPP part. A non-stick coating or other surface treatments may be applied to facilitate easier part removal. The mold is then thoroughly inspected for any imperfections before being put into production.

The surface finish of the mold directly impacts the appearance and quality of the finished EPP product. A smooth and well-treated surface prevents the EPP foam from sticking, ensuring a clean and efficient demolding process. This final treatment prepares the mold for its intended use in high-volume manufacturing.

How Many EPP Products Can be Made?

EPP (Expanded Polypropylene) is a versatile, lightweight, and durable material widely used in protective, packaging, and structural applications. Its shock absorption, insulation, and resilience properties make it ideal for manufacturing a wide range of products across automotive, sports, electronics, and consumer goods industries.

EPP Tool Handles: EPP tool handles are ergonomic, lightweight, durable, reduce user fatigue, improve grip comfort, and withstand repeated impacts for hand tools, sports equipment, and industrial applications.

EPP Car Bumpers: We manufacture EPP car bumpers that are lightweight yet durable, providing excellent energy absorption in collisions, improving vehicle safety, reducing overall weight, enhancing fuel efficiency, and contributing to better performance in modern automotive design.

EPP Helmets: EPP helmets offer superior shock absorption for cycling, motorbiking, and sports, absorbing multiple impacts without cracking, keeping users safer during high-risk activities, and extending helmet life while remaining lightweight and comfortable.

EPP Packaging Trays: EPP packaging trays protect delicate electronics, medical devices, and fragile products during transport, cushioning items, minimizing damage, being reusable, eco-friendly, and reducing costs for logistics and storage operations.

EPP Furniture Components: EPP furniture parts are lightweight and resilient, providing structural strength, supporting weight, reducing transport costs, and making them ideal for modern modular furniture, office setups, and eco-friendly interior solutions.

EPP Sports Equipment: EPP sports equipment like pads, mats, and protective gear is durable, light, and cushioning, enhancing player safety, comfort, and performance during intense physical activities while ensuring long-lasting reliability.

EPP Acoustic Panels: EPP acoustic panels reduce noise while remaining lightweight, offering effective sound absorption for studios, offices, and industrial environments, combining sustainability, durability, and aesthetic versatility without adding excess weight.

EPP Guitar Cases: EPP guitar cases are shock-resistant, lightweight, and durable, protecting valuable instruments from impact and vibration during transport, ensuring safety and convenience for musicians on the move.

EPP Drone Shells: EPP drone shells are lightweight, impact-resistant, and enhance flight stability, protecting delicate electronics from collisions while maintaining overall drone performance even after minor crashes.

EPP Helmet Liners: EPP helmet liners provide additional cushioning inside helmets, are lightweight, highly durable, absorb multiple impacts, and offer extra protection for motorbike, cycling, or extreme sports helmets.

EPP Automotive Parts: EPP automotive parts like seat cores and door panels reduce vehicle weight, maintain structural strength, improve fuel efficiency, reduce emissions, and provide energy-absorbing safety advantages.

EPP Cooler Boxes: EPP cooler boxes are lightweight, durable, and thermally insulating, maintaining internal temperatures, resisting impact, and providing long-lasting performance for outdoor activities, transport, or food delivery.

EPP Toy Blocks: EPP toy blocks are lightweight, durable, safe for children, resist breakage, absorb impacts, offer educational play, and are eco-friendly and reusable for long-term enjoyment.

EPP Luggage: EPP luggage is durable, lightweight, and impact-resistant, protecting contents during travel, reducing transport effort, and providing a long-lasting alternative to conventional hard-shell luggage materials.

EPP Protective Cases: EPP protective cases safeguard tools, electronics, and sensitive equipment, with lightweight cushioning absorbing shocks during drops, minimizing damage, and improving equipment longevity.

EPP Medical Equipment Components: EPP medical device components are lightweight, hygienic, impact-resistant, reduce transport weight, protect sensitive devices, and can be molded into complex shapes for customized applications.

EPP Insulation Panels: EPP insulation panels provide thermal and acoustic insulation for buildings and vehicles, are lightweight, durable, easy to install, enhance energy efficiency, and reduce maintenance costs.

EPP Drone Landing Pads: EPP landing pads are lightweight, shock-absorbing, and portable, protecting drones during takeoff and landing on uneven terrain while minimizing the risk of damage to delicate components.

EPP Seat Cushions: EPP seat cushions are lightweight, resilient, ergonomic, reduce fatigue, provide support, and maintain shape over time, ideal for automotive, office, or public seating applications.

EPP Electronic Housings: EPP electronic housings are lightweight, durable, and impact-resistant, protecting devices from shocks, reducing transport weight, and customizable for different electronic components.

What are the key properties of EPP that make it suitable for various applications?

EPP exhibits lightweight, durability, energy absorption, and recyclability, making it an ideal choice for applications ranging from automotive parts to protective packaging.

How does the EPP molding process contribute to environmental sustainability?

The EPP molding process utilizes recyclable materials and energy-efficient manufacturing techniques, aligning with the principles of environmental sustainability and circular economy practices.

Can EPP products be customized to meet specific requirements?

Yes, manufacturers can customize EPP properties by incorporating additives during the molding process, allowing for tailored solutions to suit diverse application needs.

What are some common post-molding operations performed on EPP products?

Post-molding operations may include trimming, assembly, surface treatment, and printing, enhancing the functionality and aesthetics of EPP products.

Conclusion

The EPP molding process stands as a testament to material science and engineering, consistently delivering products that meet demanding performance requirements across diverse sectors. From critical automotive components to protective packaging and innovative consumer goods, EPP’s unique combination of properties, enabled by this precise manufacturing method, ensures its continued relevance and growth.

As industries increasingly seek lightweighting solutions, superior impact absorption, and sustainable manufacturing practices, the role of EPP products becomes even more pronounced. The transformative journey from raw beads to highly engineered parts underscores the material’s versatility and the molding process’s efficiency in meeting these evolving demands.

For businesses looking to leverage the advantages of EPP, sourcing high-quality materials and expertly crafted products is paramount. You can unlock the full potential of this exceptional material and achieve your design and performance goals. Get wholesale EPP foam products from our Sinodrills.