EPP Beads

Our high-quality EPP (Expanded Polypropylene) beads offer exceptional durability, lightweight properties, and excellent energy absorption. Ideal for various applications, including automotive parts, packaging, and sporting goods, our EPP beads provide superior cushioning and insulation. Available in customizable sizes and densities to meet your specific needs. Choose our reliable EPP beads for innovative and high-performance solutions.

Get EPP Beads Wholesale

- Exceptional Durability and Resilience: EPP beads offer outstanding resistance to repeated impacts and maintain their shape and performance over time, ensuring long-lasting product integrity.

- Superior Energy Absorption and Cushioning: Their closed-cell structure provides excellent shock absorption and vibration dampening, making them ideal for protective packaging and safety applications.

- Lightweight yet Strong: EPP is remarkably light, reducing overall product weight and transportation costs, while still providing significant structural strength and support.

- Versatile and Sustainable: EPP beads can be molded into complex shapes for diverse applications and are recyclable, contributing to environmentally conscious product design.

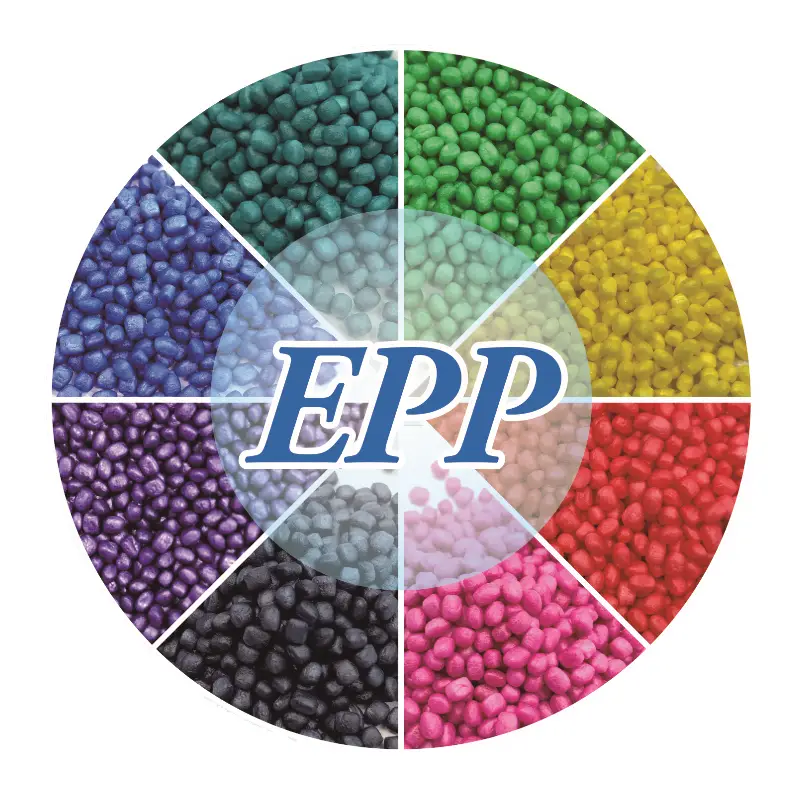

EPP Beads with different colors

We offer EPP (Expanded Polypropylene) beads in a vibrant spectrum of colors, including bright red, deep blue, light blue, rich green, and shiny yellow. These high-quality, pre-colored beads provide excellent design flexibility for various applications. Contact us to explore the colorful possibilities for your products!

wholesale EPP foam beads

We provide wholesale EPP foam beads for your requirements. We offer a wide variety of EPP foam beads at wholesale prices. You’ll find options for different densities, sizes, and even colors. It’s worth exploring these platforms to find the specific EPP foam beads that meet your needs.

EPP raw material

Our company proudly offers high-quality EPP (Expanded Polypropylene) raw material, ideal for diverse applications. Benefit from its excellent energy absorption, lightweight nature, and thermal insulation properties. Contact us today to discuss your specific needs and explore our reliable supply options for your production.

FAQs about EPP Beads

what is EPP?

Expanded Polypropylene (EPP) is a versatile, engineered plastic foam material.

It’s composed of polypropylene beads that are expanded using heat and pressure. This process results in a lightweight, yet highly durable material with excellent energy absorption, thermal insulation, and chemical resistance.

EPP is also known for its ability to withstand repeated impacts without damage, making it ideal for applications in automotive, packaging, and other industries where protection and durability are crucial.

can you customize EPP beads with different sizes?

Yes, EPP beads can indeed be customized with different sizes to meet specific application requirements. Our EPP manufacturer can control the size of the expanded polypropylene beads during the pre-expansion stage of the production process. This involves carefully managing factors like temperature, pressure, and the duration of the expansion to achieve the desired dimensions.

Customizing the bead size offers several advantages:

- Tailored Density: Smaller beads generally result in a higher density foam structure, offering increased rigidity and compression strength. Conversely, larger beads lead to lower density foam with enhanced energy absorption.

- Surface Finish: The size of the beads can influence the surface texture of the final molded part. Smaller beads can create a smoother surface, while larger beads might result in a more textured finish.

- Material Fill: In the molding process, the size of the beads affects how well the material fills intricate mold cavities. Smaller beads can navigate complex shapes more easily.

- Specific Performance: Different applications demand different performance characteristics. For instance, packaging might benefit from larger beads for cushioning, while automotive components could require smaller, denser beads for structural integrity.

what are uses of EPP beads?

EPP beads are incredibly versatile due to their unique properties, leading to a wide array of applications across various industries. Their lightweight nature, combined with excellent energy absorption and impact resistance, makes them ideal for protective purposes.

EPP foam beads thermal and sound insulation capabilities, chemical resistance, and buoyancy expand their usability significantly.

Here are some key uses of EPP beads:

- Automotive Industry: Used in bumper cores, door panels, headrests, seating components, and other safety-related parts due to their energy absorption properties, contributing to passenger safety and vehicle weight reduction.

- Packaging: Provides superior cushioning and protection for fragile and valuable goods like electronics, medical equipment, and instruments during shipping and handling.

- Sports and Leisure: Found in helmets, padding, flotation devices, and toys due to their impact resistance, durability, and lightweight nature.

- Construction: Utilized for thermal and acoustic insulation in walls, roofs, and flooring, as well as in HVAC systems for ducting and insulation.

- Consumer Goods: Integrated into furniture for comfort and lightweight construction, as well as in reusable containers and coolers for their insulation properties.

- Material Handling: Used in the creation of dunnage trays and reusable containers for protecting and transporting parts and products within manufacturing and logistics.

- Medical Industry: Employed in orthotic supports, positioning aids, and protective packaging for medical devices due to their biocompatibility and cushioning.

how to make EPP beads?

Creating Expanded Polypropylene (EPP) beads is a multi-stage process that transforms raw polypropylene resin into the lightweight, resilient material we know. This carefully controlled procedure involves expanding the polypropylene particles to many times their original volume using steam and pressure. The resulting beads possess a closed-cell structure, which contributes to their excellent energy absorption, insulation, and buoyancy.

Let’s delve into the key steps involved in manufacturing these versatile beads.

This initial stage involves taking small, solid polypropylene resin beads and exposing them to steam in a controlled environment, typically a pre-expander vessel. The heat from the steam softens the polypropylene, while a blowing agent, usually pentane or butane that was previously impregnated into the resin beads during polymerization, vaporizes and expands within the softened polymer.

This causes the beads to increase significantly in size, achieving a preliminary expansion to a specific density. The duration and intensity of the steam exposure are carefully regulated to achieve the desired pre-expansion ratio.

Stabilization (Aging):

After pre-expansion, the EPP beads contain residual blowing agent and are still relatively soft. To stabilize them and allow them to reach their final, stable size, they are transferred to large, ventilated silos or bags for an aging period. During this time, air gradually diffuses into the closed cells, replacing the remaining blowing agent.

This process increases the internal pressure within the beads, making them more rigid and dimensionally stable. The duration of the aging process can vary depending on the desired final properties of the beads.

Secondary (Final) Expansion:

In this crucial step, the pre-expanded and aged beads undergo a second exposure to steam in another controlled vessel, often referred to as a secondary expander. This further expands the beads to their final desired size and density.

The conditions in the secondary expander, such as steam pressure and cycle time, are precisely controlled to achieve the target expansion ratio and ensure uniform bead size and density. This stage is critical for achieving the final performance characteristics of the EPP material.

Drying and Cooling:

Once the final expansion is complete, the EPP beads are typically conveyed to a drying system where residual moisture from the steam is removed. This is important to prevent clumping and ensure the free flow of the beads for subsequent processing.

Following drying, the beads are cooled to ambient temperature before being packaged and stored for shipment or further processing into molded parts. Proper drying and cooling are essential for maintaining the quality and dimensional stability of the finished EPP beads.

why choose our EPP beads?

Choosing the right EPP bead supplier is crucial for the success of your products, and we believe our offerings stand out for several compelling reasons. We are committed to providing not just a material, but a partnership that ensures quality, reliability, and tailored solutions to meet your unique needs. Our focus on consistent quality, customization options, and dependable service makes us a preferred choice for businesses seeking high-performance EPP raw materials.

Uncompromising Quality: We adhere to stringent quality control measures throughout our entire production process, from raw material selection to the final product. This ensures that our EPP beads consistently meet the highest industry standards for density, size uniformity, and performance characteristics. You can rely on our beads to deliver consistent and predictable results in your manufacturing processes, minimizing waste and maximizing the quality of your end products.

Customization Capabilities: Recognizing that different applications have unique requirements, we offer a range of customization options for our EPP beads. This includes the ability to tailor bead sizes and densities to match your specific performance needs, whether you require enhanced energy absorption, increased rigidity, or a particular surface finish. Our team works closely with you to understand your exact specifications and deliver EPP beads that are optimally suited for your intended use.

Reliable Supply and Support: We understand the importance of a consistent and dependable supply chain for your operations. We maintain robust production capacities and efficient logistics to ensure timely delivery of your EPP bead orders. Beyond just providing the material, our experienced team offers comprehensive technical support and expertise to assist you with material selection, processing recommendations, and any other inquiries you may have. We are dedicated to building long-term relationships based on trust and mutual success.