EPP foam has very wide applications in various industries, and today we are going to know more details about EPP.

In this blog post, let’s dive into the world of EPP foam.

What Is EPP?

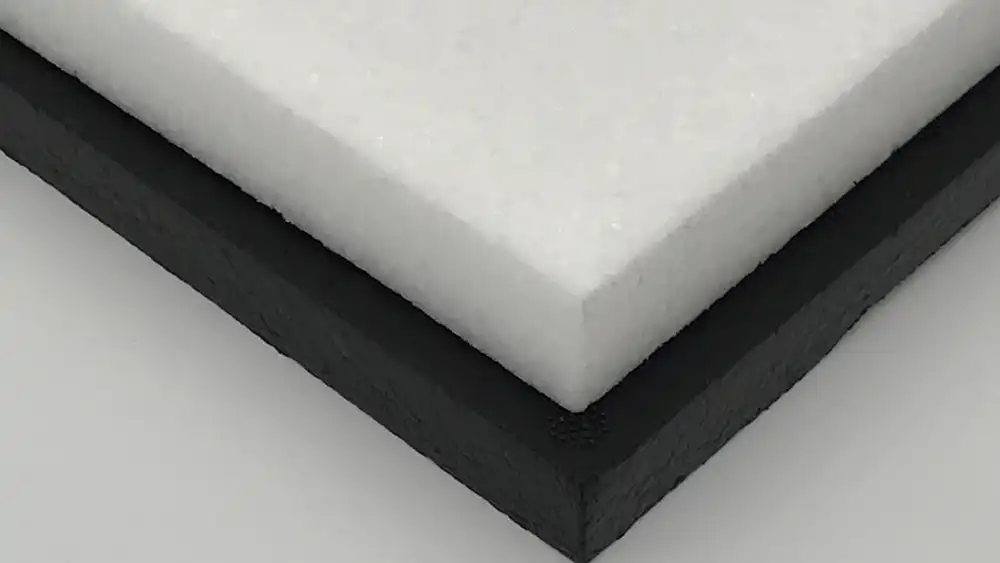

EPP Foam, short for Expanded Polypropylene Foam, is a versatile material known for its exceptional properties and wide range of applications.

It is a type of foam characterized by its cellular structure, which is achieved through the expansion of polypropylene beads. EPP Foam finds extensive use in various industries due to its lightweight nature, durability, and unique mechanical properties.

EPP Foam Material Properties

Here are some EPP Foam Material Properties that you can get.

Lightweight: EPP Foam is renowned for its lightweight nature, making it an ideal choice for applications where weight is a critical factor. Despite its low density, EPP Foam exhibits exceptional strength and durability, allowing for the creation of lightweight yet sturdy products.

Durable: One of the key properties of EPP Foam is its durability. It is capable of withstanding repeated impacts and compressions without undergoing deformation or damage, making it suitable for long-term use in demanding environments.

Impact Resistance: EPP Foam is highly resistant to impacts, making it valuable for applications requiring protection against shocks and collisions. Whether used in automotive bumpers, sports equipment, or protective packaging, EPP Foam provides reliable impact absorption, safeguarding both products and users.

Thermal Insulation: EPP Foam possesses excellent thermal insulation properties, allowing it to effectively regulate temperature and provide insulation against heat and cold. This makes it suitable for applications where temperature control is essential, such as insulated packaging and construction insulation.

Chemical Resistance: EPP Foam exhibits resistance to a wide range of chemicals, including oils, solvents, and acids. This property ensures that EPP Foam remains unaffected by exposure to various substances, enhancing its longevity and reliability in diverse environments.

Water Resistance: EPP Foam is inherently resistant to water and moisture, making it suitable for use in wet or humid conditions without compromising its structural integrity. This property prevents water absorption and mold growth, further enhancing the material’s durability.

Buoyancy: Due to its closed-cell structure, EPP Foam is buoyant, meaning it floats on water. This property makes it ideal for applications where flotation is required, such as in floating docks, life jackets, and marine buoys.

Resilience: EPP Foam exhibits high resilience, allowing it to return to its original shape after being subjected to deformation or compression. This resilience ensures that EPP Foam products maintain their structural integrity and performance over time.

Chemical Inertness: EPP Foam is chemically inert, meaning it does not react with or leach chemicals into its surroundings. This property makes it safe for use in sensitive applications such as food packaging and medical devices, where product contamination must be avoided.

Recyclability: EPP Foam is recyclable and can be reused to manufacture new products, reducing waste and promoting sustainability. Its recyclability makes it an environmentally friendly material choice compared to non-recyclable alternatives.

These properties collectively contribute to the versatility, reliability, and widespread use of EPP Foam across various industries, showcasing its value as a preferred material for numerous applications.

EPP Foam Density

Expanded polypropylene (EPP) foam density refers to the mass of the foam material per unit volume. In simpler terms, it indicates how much mass is packed into a given volume of EPP foam.

Density is typically measured in kilograms per cubic meter (kg/m³) or pounds per cubic foot (lb/ft³), depending on the unit system being used. Higher density EPP foam will have more mass packed into a given volume, while lower density foam will have less mass.

The density of EPP foam can have significant implications for its properties and performance. Generally, higher density foam tends to be stronger, more rigid, and have better impact resistance compared to lower density foam. It can withstand greater forces and is often used in applications where durability and structural integrity are important, such as in automotive components, protective packaging, or sporting equipment.

On the other hand, lower density EPP foam is typically softer, more flexible, and lighter in weight. It may be preferred in applications where cushioning or shock absorption is crucial, such as in helmet liners, protective padding, or in the packaging of fragile items.

Choosing the appropriate density of EPP foam depends on the specific requirements of the intended application, considering factors such as the level of impact protection needed, weight constraints, cost considerations, and desired flexibility or rigidity.

Applications of EPP Foam

EPP foam has wide applications, and here are some common applications of EPP Foam:

Automotive Components: EPP Foam is extensively used in the automotive industry for manufacturing various components such as bumpers, door panels, headrests, and parcel shelves. Its lightweight nature and excellent impact resistance make it ideal for enhancing vehicle safety and reducing overall weight, thus improving fuel efficiency.

Protective Packaging: EPP Foam is widely employed in protective packaging for fragile and sensitive items such as electronics, glassware, and medical equipment. Its ability to absorb shocks and vibrations ensures that the packaged items remain safe during transit, reducing the risk of damage.

Insulation: Due to its thermal insulation properties, EPP Foam is utilized in construction applications for insulation purposes. It helps in maintaining indoor temperatures, thereby reducing energy consumption for heating and cooling. Additionally, it serves as an effective sound insulator, minimizing noise transmission within buildings.

Sports Equipment: EPP Foam finds applications in the manufacturing of sports equipment such as helmets, knee pads, and body protectors. Its lightweight yet sturdy nature provides athletes with adequate protection against impacts and injuries during sports activities.

Toy Manufacturing: EPP Foam is a popular choice for producing children’s toys and recreational items due to its safety features and durability. From foam puzzles and building blocks to toy swords and balls, EPP Foam is used to create a wide range of toys that are both fun and safe for children to play with.

Medical Devices: In the medical industry, EPP Foam is utilized for creating cushioning and support components in various medical devices such as prosthetics, orthotics, and wheelchair cushions. Its ability to conform to body contours and provide comfort makes it suitable for medical applications requiring prolonged use.

Aerospace Components: EPP Foam is also employed in the aerospace industry for manufacturing lightweight yet robust components for aircraft interiors. From seating cushions and tray tables to overhead bins and insulation panels, EPP Foam contributes to enhancing passenger comfort and aircraft efficiency.

Floating Devices: Due to its buoyancy and water resistance, EPP Foam is used in the production of floating devices such as life jackets, buoys, and floating docks. These devices ensure safety in water-related activities by providing flotation support and buoyancy to users.

Consumer Electronics: EPP Foam is commonly used in the packaging of consumer electronics products such as laptops, smartphones, and appliances. Its shock-absorbing properties protect delicate electronic components from damage during shipping and handling, ensuring that the products reach consumers in pristine condition.

Cold Chain Packaging: EPP Foam’s thermal insulation capabilities make it suitable for cold chain packaging applications, where temperature-sensitive products such as pharmaceuticals, vaccines, and perishable goods need to be transported and stored at controlled temperatures to maintain their integrity and efficacy.

These diverse applications demonstrate the versatility and effectiveness of EPP Foam across various industries, highlighting its importance as a preferred material choice for numerous purposes.

EPP Foam Benefits

Here are some EPP foam benefits that you have to know about.

Lightweight and Durable

One of the primary characteristics of EPP Foam is its lightweight nature. Despite being lightweight, it offers exceptional durability, making it suitable for applications where both strength and weight are crucial factors.

Impact Resistance

EPP Foam exhibits remarkable impact resistance, making it ideal for products that require protection against shocks and impacts. This property finds extensive use in automotive safety components and protective packaging.

Thermal Insulation

Another notable property of EPP Foam is its excellent thermal insulation capabilities. This makes it suitable for applications where temperature control is essential, such as in the construction of insulated containers and packaging for perishable goods.

Chemical Resistance

EPP Foam is resistant to various chemicals, making it suitable for use in harsh environments where exposure to chemicals is a concern. This property enhances its longevity and reliability in demanding applications.

Manufacturing Process of EPP Foam

The production of EPP Foam involves several stages, each crucial for achieving the desired properties and quality of the final product.

Expanded Polypropylene (EPP) Beads

The manufacturing process begins with the production of EPP beads, which are small granules of polypropylene. These beads serve as the raw material for creating EPP Foam.

Molding and Expansion

The EPP beads are then subjected to high temperatures and pressure inside a mold, causing them to expand and fuse together. This process results in the formation of the characteristic cellular structure of EPP Foam.

Cooling and Finishing

After molding and expansion, the newly formed EPP Foam undergoes a cooling process to stabilize its structure. Once cooled, the foam is trimmed and finished to meet specific dimensional and quality requirements.

Advantages of EPP Foam

EPP Foam offers several advantages over other materials, making it a preferred choice for various applications.

Versatility

One of the significant advantages of EPP Foam is its versatility. It can be easily molded into complex shapes and designs, making it suitable for a wide range of applications across different industries.

Environmental Friendliness

EPP Foam is recyclable and reusable, making it an environmentally friendly choice compared to other foam materials. Its long lifespan and recyclability contribute to reducing waste and minimizing environmental impact.

Cost-Effectiveness

Despite its exceptional properties, EPP Foam is cost-effective compared to alternative materials with similar characteristics. Its durability and longevity translate to cost savings over time, making it an economically viable option for businesses.

Common Uses of EPP Foam

EPP Foam finds widespread use in various industries and applications due to its versatility and excellent properties.

Automotive Industry

In the automotive sector, EPP Foam is used for manufacturing lightweight yet durable components such as bumpers, interior trims, and protective padding.

Packaging

EPP Foam is extensively utilized in protective packaging for fragile items due to its cushioning properties and ability to absorb impacts.

Sports Equipment

The lightweight and impact-resistant nature of EPP Foam make it ideal for the production of sports equipment such as helmets, padding, and protective gear.

Toy Manufacturing

EPP Foam is commonly used in the manufacturing of toys and recreational products due to its safety features and ability to withstand rough handling.

Comparison with Other Foam Materials

EPP Foam differs from other foam materials in terms of properties and applications.

EPP vs. EPS Foam

While both EPP (Expanded Polypropylene) Foam and EPS (Expanded Polystyrene) Foam are lightweight and offer thermal insulation, EPP Foam has superior impact resistance and durability compared to EPS Foam.

EPP vs. EPE Foam

EPP Foam and EPE (Expanded Polyethylene) Foam share similar lightweight properties but differ in terms of durability and impact resistance. EPP Foam offers higher durability and better mechanical properties compared to EPE Foam.

Maintenance and Care Tips for EPP Foam Products

To ensure the longevity and optimal performance of EPP Foam products, proper maintenance and care are essential.

- Regularly clean EPP Foam products using mild soap and water to remove dirt and debris.

- Avoid exposing EPP Foam to harsh chemicals or solvents, as they may damage the material.

- Store EPP Foam products in a cool, dry place away from direct sunlight to prevent degradation over time.

- Inspect EPP Foam products periodically for any signs of wear or damage and replace as needed to maintain safety and functionality.

Conclusion

In conclusion, EPP Foam is a versatile and durable material with a wide range of applications across various industries. Its lightweight nature, combined with excellent mechanical properties such as impact resistance and thermal insulation, makes it an ideal choice for automotive components, packaging, sports equipment, and more. With proper care and maintenance, EPP Foam products can offer long-lasting performance and contribute to sustainable practices through recycling and reusability.

FAQs (Frequently Asked Questions)

Is EPP Foam recyclable?

Yes, EPP Foam is recyclable and can be reused to produce new products, making it an environmentally friendly material choice.

What are some common automotive applications of EPP Foam?

EPP Foam is used in automotive applications such as bumpers, interior trims, and protective padding due to its lightweight and impact-resistant properties.

How does EPP Foam compare to other foam materials like EPS and EPE?

EPP Foam offers superior impact resistance and durability compared to EPS (Expanded Polystyrene) Foam and EPE (Expanded Polyethylene) Foam, making it suitable for a wider range of applications.

Can EPP Foam be used for packaging fragile items?

Yes, EPP Foam is commonly used in packaging fragile items due to its cushioning properties and ability to absorb impacts effectively.

Is EPP Foam suitable for outdoor applications?

Yes, EPP Foam is suitable for outdoor applications as it is resistant to environmental factors such as moisture, chemicals, and UV radiation, making it ideal for use in various outdoor settings.