Expanded Polypropylene (EPP) foam is an incredibly versatile, high-performance material that is transforming numerous industries. Known for its exceptional ability to absorb multiple impacts, high strength-to-weight ratio, and thermal insulation, EPP is essential where durability and safety are paramount.

This guide explores the key applications where EPP foam excels. From protecting passengers in automobiles to insulating sensitive goods during transit, you’ll discover why this lightweight, resilient foam is the preferred choice for engineers seeking reliable, long-lasting material solutions.

EPP Benefits

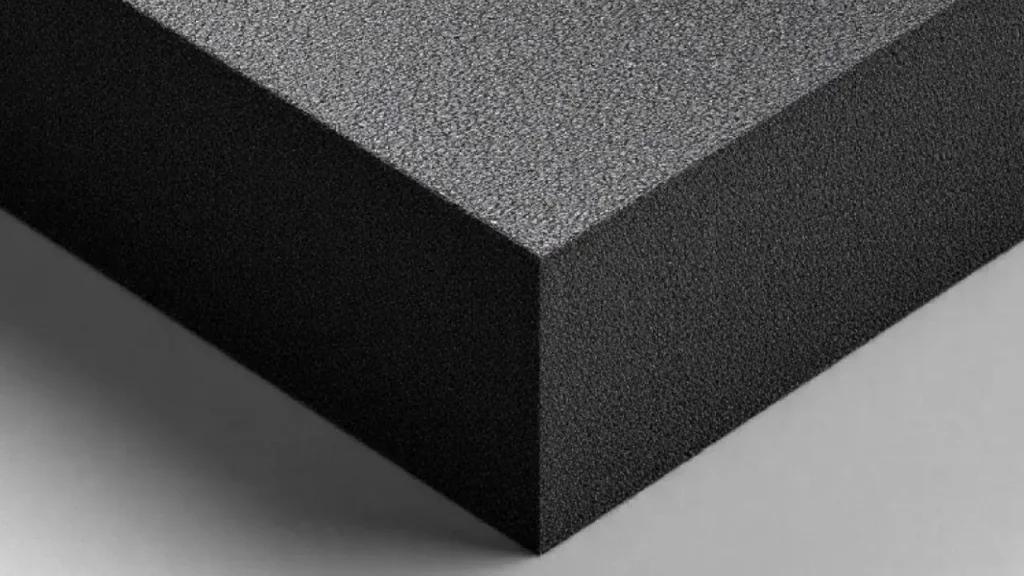

Expanded Polypropylene (EPP) foam is a cutting-edge material valued for its exceptional performance characteristics across multiple sectors. Its closed-cell structure and polymer composition provide an ideal balance of strength, low density, and resilience, which is unmatched by conventional foam materials.

This unique combination of properties makes EPP an indispensable choice for engineers and designers. It allows for the creation of lightweight, highly durable components that contribute to enhanced safety, improved energy efficiency, and better product protection across the automotive, packaging, and construction industries.

- Outstanding Multi-Impact Resistance EPP foam has remarkable resilience, meaning it can absorb significant energy from repeated impacts without experiencing permanent structural deformation. This crucial property makes it the ideal material for automotive bumper cores and headrests, as well as high-value, reusable industrial dunnage that protects components over countless shipping cycles.

- Exceptional Strength-to-Weight Ratio Composed of over 90% air, EPP is incredibly lightweight, which is vital for applications where mass reduction is critical. Its light weight drastically improves vehicle fuel efficiency and reduces emissions, minimizes freight costs in packaging, and simplifies the handling and installation of HVAC components and construction materials.

- Superior Thermal and Acoustic Insulation The closed-cell nature of EPP provides excellent thermal insulation, effectively preventing heat transfer and making it perfect for temperature-controlled packaging for pharmaceuticals and food. Furthermore, its structure offers significant sound dampening qualities, enhancing noise reduction in vehicle interiors and HVAC systems.

- High Chemical and Water Resistance EPP foam is biologically neutral and highly resistant to a wide range of chemicals, including oils, solvents, and most acids. This resistance ensures the material’s integrity is maintained in harsh environments, making it a reliable choice for marine applications (buoyancy aids) and robust, easily sanitized medical equipment cases.

EPP Applications

Expanded Polypropylene (EPP) foam is a highly versatile, resilient, and lightweight closed-cell bead foam used across many sectors for its superior energy absorption, thermal insulation, and multi-impact resistance. Its durability, chemical inertness, and 100% recyclability make it a sustainable choice for safety and efficiency-critical applications, replacing heavier materials and enhancing product performance.

Automotive Safety Components

EPP is critical in automotive safety, used for energy absorption in crashes. This includes bumper cores to manage collision energy, headrests and knee bolsters for occupant protection, door panels to absorb side impact force, and various pillar fillers to reduce structural weight while maintaining high safety standards and improving fuel efficiency.

Packaging and Logistics Solutions

The foam’s high resilience and shock absorption make it ideal for protecting sensitive goods. Applications include reusable dunnage trays for industrial parts, protective packaging for electronics and medical devices, and insulated food boxes and pharmaceutical cool boxes for reliable temperature-controlled logistics, ensuring product integrity during transport and handling.

HVAC and Insulation

EPP’s excellent thermal insulation and acoustic dampening properties are leveraged in Heating, Ventilation, and Air Conditioning (HVAC) systems. It’s used for HVAC housings, ductwork insulation, and components within air conditioning units and boilers. This improves energy efficiency, reduces operational noise, and makes the system lighter for easier assembly and maintenance access.

Sports and Leisure Equipment

Due to its lightweight nature and superior impact resistance, EPP is frequently used in sports and leisure. Key applications include liners in bicycle helmets to absorb impact, drone/UAV bodies for durable and lightweight flight, fascia rollers for fitness, and protective padding in various sports equipment, offering both safety and longevity in active use.

Construction and Other Industries

In construction, EPP serves as effective insulation panels and in ground floor insulation for thermal performance. Other unique uses include buoyant pontoons, durable and lightweight modular furniture systems, orthotic supports in the medical field, and various void fillers to reduce overall product weight and provide structural support.

Industrial and Material Handling

The foam’s durability and load-bearing capacity make it perfect for industrial use. Specific applications include material handling systems, returnable packaging for inter-factory transport, ESD (Electrostatic Discharge) foam for sensitive electronics, and high-strength load bearing applications in temporary or modular structures.

Medical and Pharmaceutical Logistics

Its hygienic, temperature-resistant, and shock-absorbing qualities are essential for critical transport. This sector uses EPP for human organ transportation containers, components for medical devices, insulated shipping container liners, chemical bottle packs, and medical supports like head bracing for patient stabilization and protection.

Food and Catering Services

EPP is food-contact safe and offers superior thermal performance, essential for the food chain. Applications include hot & cold catering boxes for meal delivery, insulated fulfilment centre tote tray liners, cool boxes for picnics, fish boxes for fresh produce transport, and even synthetic corks and specialised cake rings.

Consumer and Miscellaneous Products

The foam’s versatility allows for numerous consumer products that benefit from being lightweight and robust. This includes components for child car seats, modular toy systems, acoustic tiles for sound deadening in rooms, floatation aids like swimming noodles or buoys, and lightweight, durable exhibition or modular platform systems.

Civil Engineering and Landscaping

EPP is utilized in large-scale civil projects for its lightweight strength. Applications include road construction infill material to reduce ground pressure, lightweight blocks for train station platform extensions, and landscaping elements where a lightweight, yet durable filler is required to manage soil pressure or drainage effectively.

Specialized Appliance Packaging

Due to its exceptional cushioning and thermal properties, EPP is ideal for protecting large, sensitive household items. This covers cooker packaging, white goods appliance packaging, and specialized inserts for small appliances packaging, ensuring items like refrigerators and washing machines arrive undamaged from shocks or temperature changes.

Aerospace and Interior Components

In the aerospace industry, EPP’s lightweight and flame-retardant grades are beneficial. It is used for aircraft interior components to reduce fuel consumption, luggage compartments, and as a lightweight core material in composite panels to achieve high stiffness with minimal added mass.

Agriculture and Horticulture

EPP’s insulation, water resistance, and inertness are valuable for growing and preserving produce. Uses include insulated beehives to regulate temperature and protect colonies, HOTBIN compost bins that use EPP’s insulation to accelerate decomposition, and seedling trays that offer superior thermal stability for plant growth.

Educational and Safety Aids

The material’s durability and buoyancy make it excellent for specialized aids. This includes Mani swimming aids and various flotation devices for learning and safety, and playground floor surfacing where its multi-impact absorbing properties are essential for reducing injury risks for children.

Design and Prototyping

EPP’s ease of molding and structural integrity make it a choice for development and aesthetic components. It is used for prototyping automotive seating and other large parts, creating grade ‘A’ surface finishes on visible automotive components, and forming complex, durable designer furniture pieces.

Noise and Vibration Reduction

EPP’s unique cellular structure provides excellent acoustic dampening, making it effective for reducing noise, vibration, and harshness (NVH). This is specifically utilized in automotive acoustic barriers, sound deadening foam for machinery, HVAC noise isolation pads, and porous EPP components designed to absorb sound within vehicle interiors.

Marine and Buoyancy Aids

Beyond pontoons, EPP’s hydrophobic, closed-cell nature is perfect for water-based applications requiring reliable floatation. Applications include buoys and markers for navigation and safety, marine safety equipment components, surfboards and wakeboards (as a lightweight core), and various life-saving floatation collars and rings.

Energy and Electrical Applications

EPP is used where light weight, insulation, and fire resistance are key for electrical and power systems. This covers thermal covers or jackets for heating system components, cable management components in electric vehicles, and insulating blocks around electrical devices to maintain stable operating temperatures and provide shock protection.

Specialized Protection and Buffering

The material’s ability to recover after multiple impacts is crucial for long-term protective uses. This includes side impact protection elements in vehicles, pedestrian impact absorbers in front-end designs, corner protectors for sharp edges on goods, and cushion packaging for fragile glassware or ceramics during shipping.

Furniture and Display Systems

EPP is used in the creation of lightweight, durable, and easily transportable furniture and retail elements. This involves movable lightweight furniture (like stools or tables), retail display systems that require easy assembly and robustness, and as a comfortable core material for ergonomic office seating parts.

Horticulture and Garden Products

EPP’s properties are beneficial for maintaining optimal growing conditions and outdoor product longevity. Applications include thermal boxes to deliver fresh pet food, durable and insulated garden planters, specialized grow-beds for hydroponics that resist moisture, and highly durable landscape borders that withstand environmental exposure.

Chemical and Lab Transport

EPP’s chemical resistance and durability are critical for safe handling of aggressive or sensitive substances. This is applied in lab specimen transport boxes, specialized chemical sample holders for testing facilities, and sterile packaging for medical components that must remain pristine during transit and storage.

Security and Defense Equipment

The material’s combination of low weight and high energy absorption is valuable in protective gear and equipment housing. Uses include equipment padding for military or security cases, lightweight armor backing or energy dissipators, and custom-molded weapon cases to protect firearms from impact and moisture.

Personal Mobility Devices

EPP is used in various products that require a balance of structural support, light weight, and impact safety for personal transport. This includes core components for scooters and electric bikes, lightweight wheel-chair seating components, and internal housing for battery packs in mobility devices.

Arts and Entertainment

The ease of molding and light weight of EPP make it useful for temporary installations and props. Applications cover theatrical stage props for easy handling, event signage and displays that are robust and portable, and exhibition stand components for trade shows that are quick to assemble and dismantle.

Sporting Protective Gear

EPP is integral to high-impact protective wear for athletes, going beyond helmets. This includes shoulder pads and chest protectors for contact sports, shin guards and forearm guards, and protective inserts for specialized athletic footwear, ensuring superior, non-brittle impact energy management.

Construction Forms and Infill

In building, EPP is used for temporary and permanent structure elements. This involves insulating door inserts to improve energy ratings, insulating concrete forms (ICFs) for lightweight and thermally efficient walls, and swimming pool infill materials to stabilize and insulate surrounding areas.

White Goods and Appliance Internal Parts

EPP is incorporated inside appliances for insulation and sound dampening. Applications cover internal packaging blocks for vibration isolation during use, thermal insulation parts in dishwashers and ovens, and housing brackets for delicate internal components to secure them.

Educational Tools and Toys

The material is safe, durable, and lightweight, making it excellent for educational products. Uses include building blocks and construction kits for children, large foam geometric shapes for teaching, and soft, safe projectiles or components for physics demonstration kits in schools.

Footwear Components

EPP is utilized in the footwear industry to enhance comfort, support, and durability. This involves lightweight midsole components for sports shoes, orthopedic insoles for specialized support, and protective toe cap inserts in safety boots, all benefiting from the material’s resilienc

Conclusion

EPP foam is undeniably a game-changer across modern manufacturing, offering a unique blend of multi-impact resistance, thermal performance, and lightweight design. We have explored its crucial role in automotive safety components, reusable protective packaging, and specialized construction. This closed-cell material delivers sustainable, high-value performance that other foams simply cannot match.

The durability and resilience of EPP directly translate into long-term cost savings and enhanced product quality for your business. Utilizing EPP allows you to create lighter, safer, and more robust products capable of withstanding the rigors of repeated use and harsh environments. It’s the smart choice for future-proofing your designs.

If you are ready to benefit from the superior properties of EPP, trust Epsole as your wholesale partner. We provide high-quality EPP beads and custom-molded parts tailored to your specifications. Contact Epsole today to discuss your project needs and secure the best wholesale EPP foam solutions!