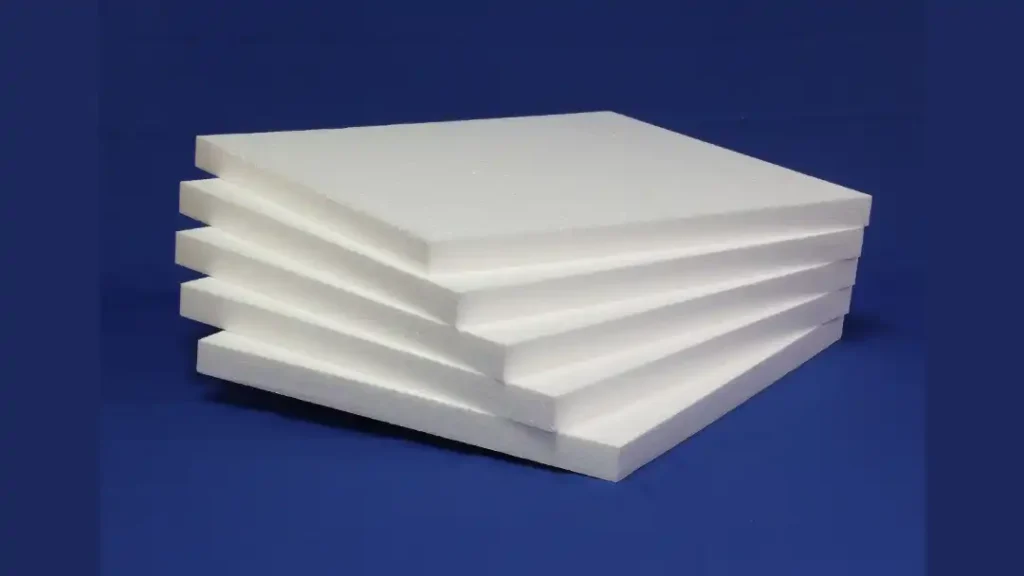

Closed cell expanded polystyrene (EPS) is a versatile and widely used material known for its excellent insulation properties, light weight, and durability.

Commonly referred to as “styrofoam,” EPS is prevalent in packaging, construction, and various industrial applications.

This article delves into the intricate details of closed-cell EPS, exploring its properties, benefits, applications, and more.

What Is Closed Cell Expanded Polystyrene

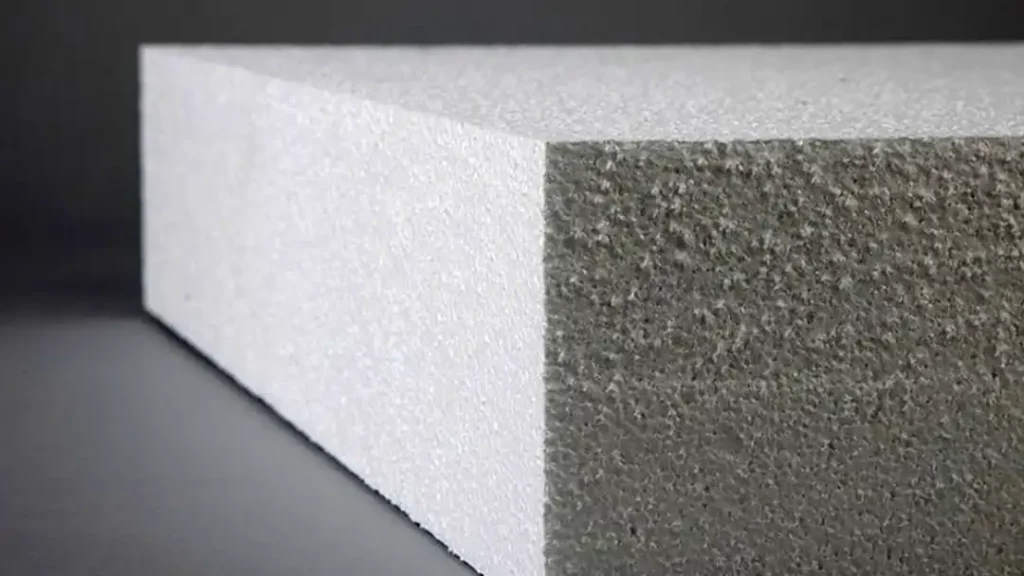

Closed cell expanded polystyrene (EPS) is a type of foam plastic material created from polystyrene, a synthetic aromatic hydrocarbon polymer made from the monomer styrene. EPS is characterized by its structure, which consists of tiny, closed, airtight cells.

This closed cell structure distinguishes it from other types of foam plastics and contributes to its unique properties.

Importance of Closed Cell Expanded Polystyrene

Closed-cell expanded polystyrene (EPS) is a versatile and widely used material with a range of important applications due to its unique properties. Here are some key points highlighting its importance:

Insulation Properties

- Thermal Insulation: EPS has excellent thermal insulation properties, making it an ideal material for use in building and construction. It helps maintain temperature stability in buildings, reducing energy consumption for heating and cooling.

- Moisture Resistance: The closed-cell structure of EPS makes it highly resistant to water absorption, preventing moisture from penetrating and compromising its insulation efficiency.

Structural Integrity and Durability

- Lightweight and Strong: Despite being lightweight, EPS is strong and durable, providing structural integrity without adding significant weight. This makes it useful in a variety of construction applications, including roofing, wall insulation, and underfloor insulation.

- Long Lifespan: EPS does not degrade over time when used in typical conditions, ensuring long-term performance and reliability.

Versatility and Customization

- Custom Shapes and Sizes: EPS can be easily molded into various shapes and sizes, catering to specific design requirements. This flexibility is advantageous in packaging, construction, and other industrial applications.

- Compatibility with Other Materials: It can be used in conjunction with other materials, enhancing its utility in composite applications and multi-layered systems.

Environmental Impact and Sustainability

- Recyclability: EPS is recyclable, and there are established processes for its collection and reprocessing. This contributes to waste reduction and the circular economy.

- Resource Efficiency: The production of EPS requires relatively low energy and raw material input compared to its insulating performance, making it an energy-efficient material choice.

Safety and Protection

- Shock Absorption: EPS is widely used in packaging for its excellent shock absorption properties, protecting sensitive and fragile items during transportation.

- Fire Resistance: EPS can be treated with flame retardants to enhance its fire resistance, making it safer for use in various applications.

Cost-Effectiveness

- Affordable: EPS is generally more affordable than other insulating materials, providing cost-effective solutions without compromising on performance.

- Easy Installation: Its lightweight nature makes EPS easy to handle and install, reducing labor costs and time in construction projects.

Technical Specifications of Closed Cell Expanded Polystyrene

Closed-cell expanded polystyrene (EPS) is a material characterized by a specific set of technical specifications that make it suitable for a variety of applications. Below are the detailed technical specifications of EPS:

Physical Properties

- Density: EPS typically has a density range of 10 to 50 kg/m³ (0.6 to 3.1 lb/ft³), with most applications using densities between 15 and 30 kg/m³ (0.9 to 1.9 lb/ft³).

- Cell Structure: The material features a closed-cell structure, meaning each cell is enclosed and does not allow air or moisture to pass through.

- Thermal Conductivity: The thermal conductivity (k-value) ranges from 0.030 to 0.038 W/m·K, making it an excellent thermal insulator.

- Water Absorption: EPS has low water absorption, typically less than 1% by volume when submerged, thanks to its closed-cell structure.

Mechanical Properties

- Compressive Strength: Depending on the density, the compressive strength of EPS ranges from 70 to 700 kPa (10 to 100 psi). Higher density EPS provides greater compressive strength.

- Flexural Strength: EPS exhibits flexural strength between 100 and 200 kPa (15 to 30 psi), again varying with density.

- Tensile Strength: The tensile strength of EPS ranges from 200 to 700 kPa (30 to 100 psi), suitable for applications requiring material resilience.

- Elastic Modulus: The modulus of elasticity for EPS typically ranges from 2,000 to 4,000 kPa (290 to 580 psi).

Thermal Properties

- R-value: The R-value, a measure of thermal resistance, is approximately 4 to 5 per inch of thickness (ft²·°F·hr/BTU), depending on density and specific formulation.

- Service Temperature Range: EPS can generally be used within a temperature range of -50°C to +75°C (-58°F to +167°F) without significant degradation of properties.

Fire and Safety

- Flame Retardancy: EPS can be manufactured with flame retardant additives to meet various fire safety standards. Flame-retardant EPS typically achieves a UL 94 rating of HB or V-2.

- Smoke Development: When exposed to fire, EPS may generate smoke, but the incorporation of flame retardants can help mitigate this.

Environmental and Chemical Resistance

- Chemical Resistance: EPS is resistant to many chemicals, including dilute acids and bases, but can be dissolved by organic solvents such as acetone, benzene, and gasoline.

- Biological Resistance: EPS does not support mold or mildew growth and is resistant to biological degradation.

Dimensional Stability

- Creep Resistance: EPS demonstrates good creep resistance, meaning it can maintain its shape and size under long-term loading conditions.

- Thermal Expansion: EPS has a low coefficient of thermal expansion, ensuring dimensional stability across a range of temperatures.

Acoustic Properties

- Sound Insulation: EPS provides some level of sound insulation, with its effectiveness increasing with thickness and density. It is often used in combination with other materials to enhance acoustic performance.

Manufacturing and Processing

- Formability: EPS can be easily cut, shaped, and molded into a variety of forms, making it highly versatile for different applications.

- Recyclability: EPS is recyclable, and waste EPS can be reprocessed into new EPS products or other materials.

These technical specifications highlight the versatility and suitability of closed-cell expanded polystyrene for a wide range of industrial, commercial, and residential applications, especially where thermal insulation, lightweight, and structural integrity are required.

Applications of Closed Cell Expanded Polystyrene

Closed-cell expanded polystyrene (EPS) is utilized in a wide array of applications due to its advantageous properties, such as excellent thermal insulation, lightweight, durability, and cost-effectiveness.

Here are detailed explanations of its key applications:

Building and Construction

- Insulation: EPS is extensively used for insulating walls, roofs, and floors in residential, commercial, and industrial buildings. Its thermal insulation properties help reduce energy consumption by maintaining indoor temperatures.

- Structural Insulated Panels (SIPs): EPS is a core material in SIPs, which are used for constructing energy-efficient buildings. These panels provide high structural strength and excellent insulation.

- Concrete Formwork: EPS is used as a formwork material for concrete structures. It is lightweight, easy to handle, and can be shaped to fit complex designs. After the concrete sets, the EPS formwork can be left in place for additional insulation.

- Geofoam: EPS geofoam is used in civil engineering projects as a lightweight fill material for embankments, retaining walls, and foundations. It reduces the load on underlying soils and minimizes settlement issues.

Packaging

- Protective Packaging: EPS is widely used for packaging fragile and sensitive items such as electronics, appliances, and medical equipment. Its shock-absorbing properties protect products from damage during shipping and handling.

- Food Packaging: EPS is used to make food containers, such as cups, trays, and coolers. It provides excellent thermal insulation, keeping hot foods hot and cold foods cold during transportation and storage.

Transportation

- Vehicle Insulation: EPS is used in the automotive industry for insulating components and providing soundproofing. It is also used in car seats and other interior components to reduce weight and improve fuel efficiency.

- Marine Buoys and Floating Docks: EPS is used to manufacture buoys and floating docks due to its buoyancy and resistance to water absorption. It ensures long-term durability in marine environments.

Consumer Goods

- Sporting Equipment: EPS is used in the cores of surfboards, bodyboards, and snowboards. Its lightweight and high strength make it ideal for performance equipment.

- Safety Gear: EPS is a critical component in helmets for cycling, motorcycling, and other sports. It provides impact absorption, protecting users from head injuries.

Industrial Applications

- Refrigeration and Cold Storage: EPS is used to insulate refrigeration units, coolers, and cold storage facilities. Its high thermal resistance helps maintain low temperatures efficiently.

- HVAC Systems: EPS is used in HVAC ducting and components for its insulating properties, which help improve energy efficiency in heating and cooling systems.

Landscaping and Gardening

- Green Roofs: EPS is used in green roof systems to provide lightweight, efficient drainage and insulation. It supports plant growth while reducing the load on the building structure.

- Hydroponic Systems: EPS panels are used in hydroponic systems as floating rafts for growing plants. Its resistance to water and chemicals makes it suitable for these applications.

Arts and Crafts

- Model Making: EPS is popular in model making and prototyping because it is easy to cut, shape, and mold. It is used for creating architectural models, theater props, and custom sculptures.

- Event Displays: EPS is used to create large-scale displays and decorations for events, exhibitions, and trade shows due to its lightweight and ease of handling.

Environmental and Green Applications

- Energy-Efficient Buildings: By providing superior insulation, EPS contributes to the construction of energy-efficient buildings, reducing overall energy consumption and greenhouse gas emissions.

- Sustainable Practices: EPS is recyclable, and efforts are increasing to collect and reprocess EPS waste into new products, supporting a circular economy.

Benefits of Closed Cell Expanded Polystyrene

Closed-cell expanded polystyrene (EPS) offers a range of benefits that make it a valuable material across numerous industries. Here are the key benefits:

Excellent Insulation Properties

- Thermal Insulation: EPS provides superior thermal insulation, which helps in maintaining temperature stability in buildings and reducing energy consumption for heating and cooling.

- Moisture Resistance: The closed-cell structure of EPS prevents water absorption, maintaining its insulation properties even in humid or wet conditions.

Lightweight and Strong

- Low Density: EPS is very lightweight, making it easy to handle and transport, yet it offers impressive strength and durability for its weight.

- High Strength-to-Weight Ratio: Despite its low density, EPS provides excellent structural integrity, making it suitable for load-bearing applications in construction and packaging.

Versatility

- Customizable: EPS can be easily molded, cut, and shaped into various forms, accommodating a wide range of design and application requirements.

- Wide Range of Applications: Its properties make EPS suitable for use in construction, packaging, insulation, and more, demonstrating its adaptability across different industries.

Cost-Effectiveness

- Affordable Material: EPS is generally less expensive than other insulation and packaging materials, providing cost-effective solutions for many applications.

- Easy Installation: Its lightweight nature and ease of handling reduce labor costs and installation time, further enhancing its cost-effectiveness.

Environmental Benefits

- Energy Efficiency: By providing effective insulation, EPS contributes to energy savings in buildings, leading to lower greenhouse gas emissions.

- Recyclability: EPS is recyclable, and there are established processes for collecting and recycling EPS waste, supporting sustainable practices.

Safety and Protection

- Shock Absorption: EPS’s ability to absorb impacts makes it ideal for protective packaging, ensuring that delicate and sensitive items are safeguarded during transportation.

- Fire Resistance: EPS can be manufactured with flame retardant additives to enhance its fire resistance, making it a safer choice for various applications.

Durability

- Long Lifespan: EPS does not degrade over time when used in typical conditions, providing long-lasting performance in insulation, packaging, and structural applications.

- Resistant to Biological Growth: EPS does not support mold, mildew, or bacterial growth, making it suitable for use in environments where hygiene is critical.

Acoustic Insulation

- Sound Dampening: EPS provides some level of sound insulation, which can be enhanced when used in combination with other materials, helping to reduce noise pollution.

Chemical Resistance

- Resistant to Many Substances: EPS is resistant to a wide range of chemicals, including acids and bases, making it suitable for various industrial applications.

Ease of Use

- Simple Handling: EPS is easy to cut, shape, and install, allowing for quick adaptation to different project requirements and reducing the need for specialized tools or skills.

Applications in Innovative Designs

- Creative Uses: EPS’s versatility allows for creative and innovative uses in arts, crafts, and design projects, from model making to large-scale event displays.

Conclusion

Closed cell expanded polystyrene (EPS) is a versatile material with numerous applications across various industries. Its unique properties make it a valuable resource for insulation, packaging, and beyond.

While it presents some environmental challenges, ongoing innovations and recycling efforts hold promise for a more sustainable future. Understanding the benefits and limitations of EPS can help users make informed decisions about its use in their projects.