Extruded Polystyrene (XPS) Styrofoam is a key material in modern construction and insulation. It’s a closed-cell, rigid foam known for its superior thermal resistance and high compressive strength. This structure makes it ideal for challenging applications where moisture and heavy loads are concerns. Understanding XPS is essential for effective, energy-efficient building.

XPS Styrofoam’s versatility allows it to be used in various parts of a structure, including roofing, wall sheathing, and foundation insulation. Its consistent R-value and excellent water resistance contribute significantly to reducing energy consumption and preventing moisture-related damage in buildings. This blog will explore its characteristics and diverse uses.

What is XPS Styrofoam?

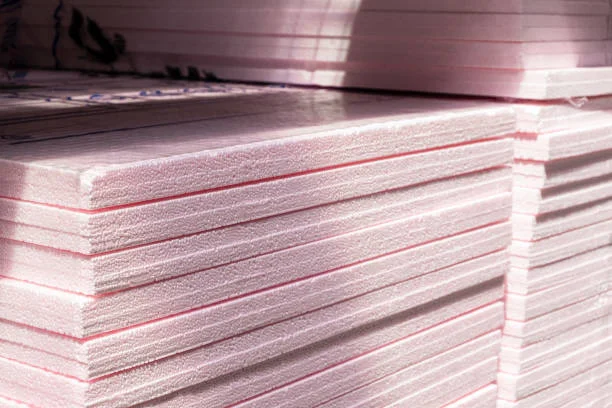

XPS polystyrene foam, full name Extruded Polystyrene Styrofoam, is a rigid foam plastic made from polystyrene resin through an extrusion process.

Its main component is polystyrene, and a foaming agent such as carbon dioxide or hydrofluorocarbons is added during the manufacturing process to form a uniform closed-cell structure.

XPS Styrofoam vs EPS Styrofoam

XPS and EPS Styrofoam are both excellent rigid foam insulators made from polystyrene, but their manufacturing processes create significant differences in key performance characteristics for building applications. XPS is extruded for a denser, closed-cell structure, whereas EPS is molded from expanded beads, resulting in a less uniform, often lighter product.

These structural variances directly influence their suitability for various construction environments, particularly concerning moisture handling and long-term stability. While both resist water to some degree, one is generally preferred for below-grade uses, while the other might offer better R-value retention over decades in certain scenarios. Understanding these nuances is crucial for selecting the most cost-effective and reliable insulation.

Manufacturing Process

XPS foam is created through an extrusion process where polystyrene resin and blowing agents are continuously pushed through a die and cooled, forming smooth-surfaced boards. This method creates a uniform, closed-cell structure where cells are tightly packed without significant voids between them. This consistent structure is key to its high performance in strength and moisture resistance.

EPS foam, conversely, is manufactured by introducing a blowing agent (like steam) to small polystyrene beads, causing them to expand and fuse within a mold. This results in an open-cell-like structure where tiny, irregular gaps or voids exist between the fused beads. While this keeps the material lightweight, the structure is inherently less uniform and can allow for greater moisture ingress compared to XPS.

Moisture Resistance

XPS boasts superior moisture resistance due to its fully closed-cell structure. The tight packing of the cells physically blocks the movement of water into the foam body. Laboratory tests often show XPS absorbing significantly less water by volume than EPS, making it the preferred choice for applications directly exposed to soil or standing water, like below-grade foundations.

While EPS is also naturally water-resistant, the interstitial spaces between the fused beads can absorb moisture over time, especially with prolonged immersion. Although some studies show EPS can dry out effectively, its moisture absorption can lead to a temporary or long-term reduction in its R-value when consistently wet, unlike XPS which maintains its thermal rating better under damp conditions.

Compressive Strength

Because of its dense, uniform, closed-cell structure achieved during extrusion, XPS possesses high compressive strength. This means it can withstand significant load and pressure without crushing or deforming. XPS products are often rated for specific psi (pounds per square inch) capacities, making them ideal for load-bearing applications like under concrete slabs, roadways, or parking lots.

EPS has lower compressive strength than XPS for a comparable thickness and density, making it generally unsuitable for areas that will bear heavy, sustained structural loads. While EPS can be manufactured in higher densities for more strength, XPS typically offers superior load-bearing capability right out of the box for demanding structural insulation uses.

R-Value and Thermal Performance

XPS typically offers a higher R-value per inch than standard EPS foam. XPS commonly achieves an R-value of about R-5.0 per inch. This is attributed to its homogenous structure which traps the blowing agent gas, which is a better insulator than the trapped air in EPS. This allows for thinner insulation layers to meet the same thermal code requirements.

While EPS has a slightly lower starting R-value (often R-3.8 to R-4.5 per inch depending on density), some research suggests that its R-value is more stable over the long term because it relies on trapped air rather than blowing agents that can slowly dissipate (thermal drift), which can cause XPS’s R-value to slightly decrease over many years.

Cost and Eco-Friendliness

EPS foam is generally more cost-effective than XPS, often being 10% to 30% cheaper per R-value equivalent. This lower cost, combined with its lightweight nature, makes it a favored choice for high-volume applications like general wall/roof insulation and packaging, where extreme compressive strength isn’t the primary requirement.

XPS is the more expensive option due to the more complex and energy-intensive extrusion manufacturing process. Environmentally, both are petroleum-based, but XPS traditionally uses blowing agents with higher Global Warming Potential (GWP), though manufacturers are shifting away from these. EPS is often cited as being less energy-intensive to produce.

Comparison chart of XPS Styrofoam vs. EPS Styrofoam

| Aspect | XPS Styrofoam (Extruded) | EPS Styrofoam (Expanded) |

| Manufacturing | Continuous extrusion process | Molding expanded beads with steam |

| Cell Structure | Uniform, dense Closed-Cell | Fused beads with interstitial voids |

| Moisture Resistance | Excellent; very low water absorption | Moderate; can absorb moisture in voids |

| Compressive Strength | High; ideal for load-bearing areas | Lower; best for lower-load applications |

| R-Value (per inch) | Generally Higher (e.g., R-5.0) | Generally Lower (e.g., R-3.8 to R-4.5) |

| Long-Term R-Value | Can slightly degrade due to gas loss | Considered stable over time |

| Relative Cost | More Expensive | More Cost-Effective |

Advantages of XPS Polystyrene Foam

XPS polystyrene foam offers superior moisture resistance compared to many other insulation types, making it excellent for below-grade applications or areas prone to dampness. Its closed-cell structure locks out water vapor, helping to maintain its insulating value over time, which is a significant benefit for long-term building performance and preventing mold growth.

Excellent Thermal Insulation Performance

XPS polystyrene foam has extremely low thermal conductivity, a property that gives it excellent insulation capabilities. Thermal conductivity is a key measure of a material’s effectiveness at preventing the transfer of heat, and XPS foam’s value is significantly lower than that of many traditional insulation materials. Its unique molecular structure and closed-cell cell morphology effectively limit the occurrence of heat convection and heat conduction.

High Strength and Pressure Resistance

XPS polystyrene foam exhibits superior compressive strength compared to other common foam materials. This is mainly due to its uniform and dense closed-pore structure, as well as the unique molecular chain arrangement formed during the production process. This high strength allows XPS to withstand large loads without deformation, performing well in a variety of practical application scenarios.

In terms of ground insulation, it can withstand the daily activities of people and furniture and the placement of heavy objects without significant compression and dents. For roof load-bearing, XPS can serve as an effective insulation layer while providing additional support to the roof structure, enhancing the overall stability of the roof and resisting the pressure caused by natural factors such as wind, rain and snow.

Excellent Moisture-proof Performance

The closed-cell structure of XPS polystyrene foam is key to its excellent moisture resistance. The closed-cell structure makes it difficult for moisture to penetrate into the foam, effectively preventing moisture absorption. This feature is a great advantage in applications with higher humidity or in contact with water.

In buildings, good moisture resistance is essential to maintain insulation. If the insulation material absorbs moisture, its thermal conductivity will increase, resulting in a decrease in insulation performance. XPS foam effectively avoids this problem, maintaining good insulation and structural stability over the long term, even in damp basements or near water sources.

Chemical Stability

XPS polystyrene foam exhibits good resistance to most chemicals. This is due to the chemical structure of polystyrene itself and the stabilizers and antioxidants added during the production process. It is not susceptible to erosion and degradation by common chemicals such as acids, alkalis, salts and organic solvents.

This chemical stability enables XPS to maintain stable performance under a variety of complex environmental conditions. Whether exposed to industrial waste gases, acid rain, or chemical leaks, it maintains its physical and chemical properties. This makes XPS widely used in industries that require high chemical stability of materials, such as chemical industry and electronics.

XPS Manufacturing Process

The manufacturing process of XPS includes the following key steps:

Raw Material Preparation

polystyrene resin particles are mixed with additives such as foaming agents, flame retardants, antioxidants, etc. in precise proportions. Ensuring the quality and proportion of the raw materials is accurate is the basis for the subsequent production of high-quality XPS sheets.

Extrusion Molding

The mixed raw materials are fed into the extruder. The inside of the extruder is in a high temperature and high pressure environment, and the raw materials are extruded under strong mechanical pressure and thermal force to form a continuous plate or tube shape.

Foaming and Curing

During the extrusion process, the foaming agent is decomposed by heat to produce gas, causing the material to expand to form a uniform closed-cell foam structure. Subsequently, it is quickly cooled by a cooling device to solidify and shape the foam to maintain a stable shape and size.

Cutting and Trimming

The cured XPS sheet is cut according to the predetermined length and width. At the same time, the edges and surfaces of the sheet are trimmed to ensure dimensional accuracy and appearance quality.

Quality Inspection

The XPS sheets produced are tested for various performance indicators, such as density, compressive strength, thermal conductivity, water absorption, etc., to ensure that the products meet relevant standards and customer requirements.

Packaging and Storage

Qualified XPS sheets are packaged to protect the products from damage during transportation and storage, and are properly stored in a dry and ventilated warehouse waiting for shipment and use.

The fine control and coordinated operation of these key steps ensure the performance and quality of XPS products.

XPS Styrofoam Application

The application of XPS (Extruded Polystyrene) foam is widespread across the construction industry due to its robust, closed-cell nature. It’s a favorite choice for demanding environments where moisture resistance and structural support are key requirements. Its versatility allows it to be specified for numerous building envelope components, ensuring long-term energy efficiency and building integrity in various climates.

Common XPS Insulation Applications

Exterior Wall Insulation: Applied continuously on the exterior of wall framing, XPS acts as an effective thermal break, minimizing heat loss through structural elements like studs and providing a durable, moisture-resistant layer under exterior cladding systems.

Below-Grade Applications (Foundations & Basements): XPS is ideal for insulating foundations, basements, and below-slab areas because its low water absorption rate prevents moisture intrusion, safeguarding against mold and maintaining thermal performance in damp, underground settings.

Roof Systems (Especially Flat and Inverted): Its high compressive strength allows XPS to be installed above the waterproofing membrane on flat or “inverted” roofs, where it withstands foot traffic, ballast loads, and freeze-thaw cycles without significant degradation.

Conclusion

We’ve explored XPS Styrofoam’s superior performance in demanding applications, highlighting its moisture resistance and thermal efficiency.

Similarly, Expanded Polystyrene (EPS), another valuable foam, offers lightweight, cost-effective insulation for packaging and construction. Both materials are critical for enhancing energy savings and durability in modern projects, making them indispensable choices for builders and developers.

For your construction, packaging, or insulation needs, secure the highest quality Expanded Polystyrene (EPS) materials for the best value. We are a trusted supplier, offering competitive wholesale prices and reliable service. Get wholesale EPS materials from our Epsole and ensure your projects benefit from durable, high-performance, and cost-effective insulation solutions. Contact us today for a quote!