Styrofoam is a material that has become ubiquitous in everyday life, from food containers and packaging materials to insulation panels in construction. Despite its widespread use, many people are unaware of what Styrofoam actually is, how it’s made, and why it is so versatile. Understanding its properties and applications can help consumers and businesses make informed decisions.

In this ultimate guide, we’ll explore everything you need to know about Styrofoam, including its composition, types, benefits, environmental impact, and practical uses. Whether you’re curious about its role in packaging or considering sustainable alternatives, this guide will provide clear insights into one of the most common yet often misunderstood materials in modern life.

What is Styrofoam?

“Styrofoam” is often used colloquially to refer to various types of lightweight, white foam packaging or disposable cups. However, this is a common misconception. Styrofoam is actually a specific brand name of closed-cell extruded polystyrene foam (XPS), a product owned and manufactured by DuPont (formerly Dow Chemical Company).

This true Styrofoam is distinct from expanded polystyrene (EPS) foam, which is the white, beaded material typically found in packaging peanuts and coffee cups. Styrofoam (XPS) is primarily designed and used for its superior insulation properties in construction, characterized by its unique blue or pink color and smoother surface.

Styrofoam (XPS) is produced through an extrusion process where molten polystyrene is forced through a die while a blowing agent is injected. This creates a uniform, closed-cell structure, giving it distinct properties:

- Distinctive Colors: Typically blue or pink for insulation, though craft versions can be white or green.

- Closed-Cell Structure: This makes it highly resistant to water absorption and water vapor transmission, crucial for consistent insulation performance in damp environments.

- Higher Compressive Strength: It can withstand more pressure without deforming compared to EPS.

- Excellent Thermal Insulation: Provides stable R-value, even in wet conditions.

- Smooth Surface: Unlike the beaded appearance of EPS, XPS has a uniform, smooth finish.

Origins of Styrofoam

Here are the key points of the styrofoam origins

- Styrofoam was first developed by researchers at The Dow Chemical Company in the mid-20th century.

- In 1941, scientists led by chemist Ray McIntire discovered a method for extruding polystyrene foam, laying the foundation for Styrofoam.

- Initially created for military applications, Styrofoam’s buoyancy and insulation properties made it ideal for use in flotation devices during World War II.

- Dow Chemical obtained a patent for Styrofoam in 1944, marking the beginning of its commercial production.

- Over the years, Styrofoam gained popularity across various industries due to its versatility, durability, and insulating capabilities.

- Despite its widespread use, Styrofoam has faced criticism for its environmental impact, particularly its non-biodegradable nature and contribution to pollution.

- The origins of Styrofoam represent a significant milestone in materials science, showcasing innovation in creating lightweight and functional materials for diverse applications.

What is Styrofoam Made Out Of?

Styrofoam is primarily made out of expanded polystyrene (EPS), which is a type of plastic derived from petroleum.

Styrofoam is primarily made from a type of plastic called polystyrene. This lightweight material is expanded using a blowing agent, creating tiny air-filled cells that give Styrofoam its characteristic insulation and cushioning properties. Its unique composition makes it durable, versatile, and widely used in packaging and construction.

- Polystyrene Resin: The base material is a solid plastic polymer derived from petroleum. It provides the structure and rigidity needed for Styrofoam products, ensuring they maintain shape under pressure and temperature variations.

- Blowing Agents: Chemicals or gases are used to expand polystyrene beads, forming the foam structure. These agents create tiny bubbles within the material, making it lightweight yet resilient.

- Additives: Stabilizers, colorants, and flame retardants may be included to enhance the foam’s durability, appearance, and safety for specific applications like food containers or insulation panels.

Expanded: Styrofoam’s composition starts with polystyrene resin, a solid polymer derived from petroleum, providing the essential structural backbone for the foam. When combined with blowing agents, the resin expands into millions of air-filled cells, giving Styrofoam its light weight and excellent insulation properties, making it ideal for packaging and building applications.

Blowing agents are key to Styrofoam’s form, creating tiny bubbles that fill the material and reduce density. This process allows the foam to absorb shocks, insulate against temperature changes, and maintain rigidity without adding significant weight. Different types of blowing agents influence the foam’s texture, strength, and environmental impact.

Additives further improve Styrofoam’s performance. Stabilizers prevent degradation during processing, colorants give the foam its appearance, and flame retardants enhance safety for household and industrial uses. These small components make Styrofoam more durable, functional, and suited for a variety of applications beyond simple packaging, such as insulation and craft materials.

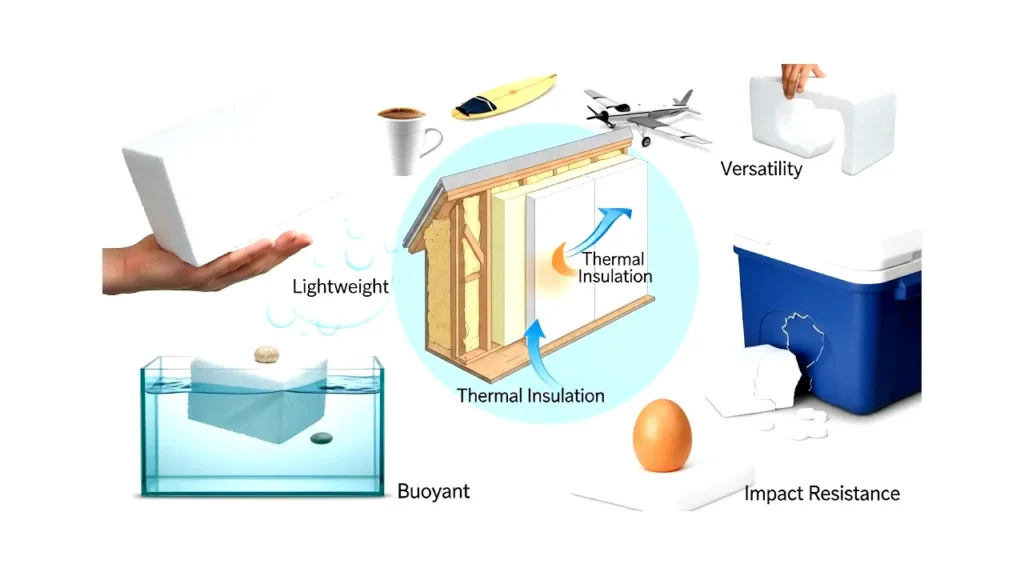

Properties of Styrofoam

The properties of Styrofoam are diverse and contribute to its widespread use in various industries. Here’s a more detailed explanation:

Insulation Efficiency:

Styrofoam is renowned for its exceptional thermal insulation properties. Its cellular structure traps pockets of air, which serve as barriers to heat transfer. This insulation efficiency makes Styrofoam an excellent choice for applications where temperature regulation is crucial, such as in buildings, refrigerators, and packaging for perishable goods. By preventing the exchange of heat between two environments, Styrofoam helps to maintain desired temperatures and reduce energy consumption.

Lightweight Nature:

One of the standout features of Styrofoam is its lightweight nature. Despite its low density, Styrofoam exhibits remarkable strength and durability, making it suitable for a wide range of applications. Its lightness is particularly advantageous in the packaging industry, where it helps to minimize shipping costs and reduce the overall weight of packaged goods. Additionally, its lightweight nature makes it easy to handle and manipulate, contributing to its popularity in construction and crafting.

Buoyancy:

Styrofoam’s buoyant properties make it invaluable in applications where flotation is required. Due to its closed-cell structure and low density, Styrofoam is exceptionally buoyant and can support heavy loads without sinking. This makes it ideal for use in flotation devices, marine buoys, and other water-related applications. Its buoyancy also extends to the construction industry, where Styrofoam is used as lightweight fill material in floating docks and pontoons.

Impact Resistance:

Despite its lightweight and airy composition, Styrofoam exhibits impressive impact resistance. Its closed-cell structure absorbs and disperses energy upon impact, helping to prevent damage to fragile items during shipping and handling. This property makes Styrofoam an excellent choice for protective packaging materials, where it provides cushioning and shock absorption to delicate products. Additionally, its impact resistance contributes to its durability in construction applications, where it can withstand external forces without deforming or breaking.

Versatility:

One of the most notable aspects of Styrofoam is its versatility. It can be molded, cut, and shaped into virtually any form or size, making it adaptable to a wide range of applications. From insulation boards and packaging inserts to decorative ornaments and craft materials, Styrofoam’s versatility knows no bounds. Its ability to be customized to specific shapes and dimensions makes it a preferred choice for designers, builders, and manufacturers seeking practical and cost-effective solutions.

Styrofoam Applications

Styrofoam, with its unique properties, finds diverse applications across various industries. Here’s a detailed explanation of some of its key applications:

Packaging Industry:

Styrofoam is widely used in the packaging industry due to its lightweight nature and excellent protective properties. It is commonly employed as cushioning material for fragile items during shipping and transportation. Whether it’s delicate electronics, glassware, or perishable goods, Styrofoam packaging provides a reliable barrier against impact and vibration, ensuring that products reach their destination intact and undamaged.

Food and Beverage Sector:

In the food and beverage sector, Styrofoam plays a crucial role in preserving the freshness and temperature of products. Its insulating properties make it an ideal choice for food containers, cups, and trays, keeping hot foods hot and cold foods cold. From takeout containers to disposable coffee cups, Styrofoam packaging helps maintain the desired temperature of food and beverages, prolonging their shelf life and enhancing the dining experience for consumers.

Construction and Building Materials:

Styrofoam is a staple in the construction industry, where it is used for insulation, structural support, and architectural elements. As insulation boards, Styrofoam helps regulate indoor temperatures, reduce energy consumption, and improve building efficiency. It is also utilized in concrete forms, providing lightweight and easy-to-handle molds for pouring concrete. Additionally, Styrofoam is employed in decorative architectural elements such as moldings, columns, and trim, adding aesthetic appeal to buildings and structures.

Arts and Crafts:

Styrofoam’s versatility and ease of manipulation make it a favorite material among artists, crafters, and DIY enthusiasts. Its lightweight and moldable nature make it suitable for sculpting, carving, and crafting intricate designs. Whether it’s creating props for theater productions, sculpting model landscapes, or crafting decorative ornaments, Styrofoam provides a versatile canvas for creative expression. Its affordability and availability in various shapes and sizes make it an accessible medium for artists of all skill levels.

Floral and Event Decor:

Styrofoam is widely used in floral arrangements and event decor due to its lightweight and porous structure. It serves as a stable base for arranging artificial or fresh flowers, providing support and stability for elaborate centerpieces and bouquets. Additionally, Styrofoam balls, cones, and shapes are popular choices for creating custom decorations for weddings, parties, and special events. Its ability to be painted, glued, and decorated makes it a versatile material for bringing creative visions to life in event design.

Environmental Impact of Styrofoam

Styrofoam, officially extruded polystyrene (XPS) foam, poses several significant environmental challenges throughout its lifecycle, from production to disposal. While it offers excellent performance, its widespread use and persistent nature contribute to various ecological concerns.

Its most notable environmental impact stems from its non-biodegradability. Styrofoam does not naturally decompose in landfills or natural environments, often persisting for hundreds, or even thousands, of years. This leads to massive accumulation in landfills, consuming valuable space, and contributing to visual pollution in natural ecosystems.

Here are some key aspects of Styrofoam’s environmental impact:

The recycling process is also complex and expensive, requiring specialized machinery and often thorough cleaning to remove contaminants (especially from food service items). As a result, very few recycling facilities accept it, leading to low recycling rates globally.

Non-Biodegradability and Persistence:

Styrofoam is highly resistant to natural decomposition by microorganisms. It can remain intact in landfills for centuries, essentially never biodegrading in the conventional sense.

Over time, particularly with exposure to sunlight (photodegradation), it can break down into smaller and smaller pieces, becoming microplastics. These microplastics then infiltrate soil, water, and air, posing long-term threats to ecosystems and potentially entering the food chain.

Landfill Burden:

Due to its lightweight and bulky nature, Styrofoam takes up a disproportionately large amount of space in landfills. Even though it’s light by weight, its volume contributes significantly to landfill capacity issues, accelerating the need for new landfill sites.

This issue is exacerbated by limited recycling options, meaning a vast majority of discarded Styrofoam ends up in these already strained waste facilities.

Pollution and Wildlife Harm:

Its lightweight and buoyant properties mean that Styrofoam readily gets carried by wind and water, leading to widespread environmental pollution, particularly in marine environments.

Animals, especially marine life, often mistake Styrofoam fragments for food, leading to ingestion that can cause internal blockages, starvation, and ultimately death. It can also cause entanglement and habitat disruption.

Production and Blowing Agents:

The production of Styrofoam (XPS) requires petroleum-based raw materials, a non-renewable resource, contributing to the demand for fossil fuels and associated greenhouse gas emissions.

Historically, some XPS products used hydrochlorofluorocarbons (HCFCs) as blowing agents, which are potent greenhouse gases and ozone-depleting substances. While the industry has largely transitioned to more environmentally friendly alternatives like hydrofluorocarbons (HFCs), and increasingly to very low Global Warming Potential (GWP) alternatives like hydrofluoroolefins (HFOs) or CO2, some legacy products and regional variations may still pose concerns regarding GWP.

Limited Recycling Infrastructure:

While technically recyclable, Styrofoam (XPS) faces significant recycling challenges. It’s difficult to collect economically due to its bulkiness and low weight.

Sustainable Alternatives to Styrofoam

Biodegradable Packaging Materials

Discover innovative alternatives to styrofoam, such as biodegradable packaging materials derived from renewable sources like cornstarch, sugarcane, and mushroom mycelium.

Eco-Friendly Insulation Options

Explore eco-friendly insulation alternatives, including cellulose insulation made from recycled paper and soy-based spray foam, offering sustainable solutions for energy-efficient buildings.

Promoting Circular Economy Practices

Learn about initiatives promoting a circular economy, where materials are reused, recycled, or repurposed, reducing reliance on single-use plastics like styrofoam.

Is Styrofoam Recyclable?

Despite misconceptions, traditional styrofoam is not easily recyclable due to its low market value and limited recycling infrastructure.

What Are the Environmental Risks of Styrofoam?

Styrofoam poses significant environmental risks, including pollution, wildlife ingestion, and long-term persistence in landfills and marine environments.

Can Styrofoam Be Reused?

While reusing styrofoam may seem like a viable option, its fragility and potential for contamination often limit its reusability.

Are There Biodegradable Alternatives to Styrofoam?

Yes, biodegradable alternatives to styrofoam exist, offering a more sustainable choice for packaging, insulation, and other applications.

What Steps Can Individuals Take to Reduce Styrofoam Use?

Individuals can reduce styrofoam consumption by opting for reusable containers, supporting businesses that use eco-friendly packaging, and advocating for waste reduction initiatives.

How Does Styrofoam Impact Marine Life?

Styrofoam pollution poses grave threats to marine life, with marine animals often mistaking it for food, leading to ingestion, entanglement, and death.

Is Styrofoam Paper or Plastic?

Styrofoam is plastic, specifically a brand name for extruded polystyrene (XPS) foam. It is derived from petroleum, a fossil fuel, and belongs to the polymer family. Despite common confusion with paper products, its chemical composition and properties firmly place it within the plastic category.

Is Styrofoam Eco-Friendly?

Generally, no, Styrofoam is not considered eco-friendly. While it offers energy efficiency in insulation applications, its non-biodegradable nature means it persists in the environment for centuries, contributing to landfill burden and plastic pollution. Its production also involves non-renewable resources and historically used potent greenhouse gases. Recycling infrastructure for Styrofoam (XPS) is also limited.

Is Styrofoam Toxic to Humans?

Under normal use, Styrofoam (XPS) is generally considered safe. However, concerns arise because it contains styrene, which the EPA and IARC classify as a probable human carcinogen. Heating Styrofoam, like microwaving food in it, can cause styrene to leach into food or release toxic fumes. Ingesting small solid pieces is usually not toxic, but the persistence of microplastics derived from it in the environment poses long-term health and ecological risks.

Does Styrofoam Absorb Water?

Styrofoam (XPS) has a closed-cell structure, making it highly resistant to water absorption. Its individual cells are sealed, preventing liquid water from penetrating easily. This property is why it’s favored for applications where moisture exposure is a concern, such as below-grade insulation.

Conclusion

In conclusion, understanding what is styrofoam goes beyond its surface-level properties and applications. It entails grappling with its environmental ramifications, exploring sustainable alternatives, and fostering a collective commitment to responsible consumption and waste management practices.

As we navigate the complexities of modern packaging solutions, let us strive for innovation, awareness, and a steadfast dedication to preserving our planet for future generations.

Request a Quote for Styrofoam Today!

Are you in need of high-quality Styrofoam packaging or insulation solutions? Look no further! Contact us now to request a quote and discover how our Styrofoam products can meet your packaging, construction, or creative needs. Our team of experts is ready to assist you with personalized solutions tailored to your requirements. Don’t compromise on quality and reliability – quote Styrofoam from us today and experience the difference firsthand!

Contact us now to get started!