In the industry of sustainable construction, ICF (Insulated Concrete Forms) block construction stands out as a beacon of innovation, marrying eco-consciousness with structural integrity.

This article delves into the nuances of ICF foam block construction, exploring its techniques, benefits, and environmental impacts. From energy efficiency to design versatility, discover why ICF Block Construction is heralded as a game-changer in the realm of sustainable building solutions.

What Is ICF Block Construction

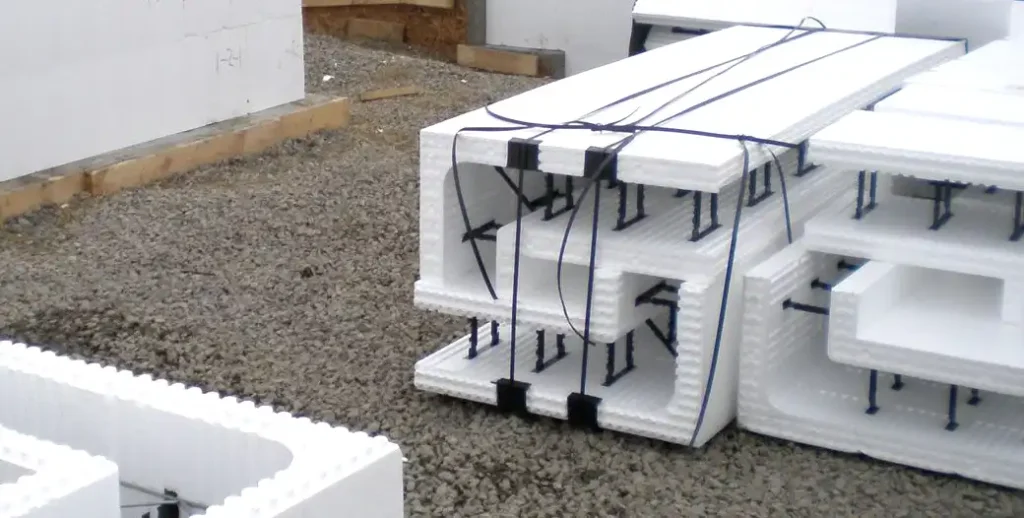

ICF Block Construction, or Insulated Concrete Forms Block Construction, is a method used in building construction that involves the use of interlocking hollow blocks made of insulating foam, typically expanded polystyrene (EPS), which are then filled with concrete. These blocks are stacked together like bricks to form the walls of a structure. The resulting walls are strong, durable, and well-insulated, providing a range of benefits for both residential and commercial buildings.

The process begins with the placement of the ICF blocks, which are then filled with concrete, creating solid walls that are highly resistant to fire, wind, and moisture. Once the concrete has cured, additional construction elements such as windows, doors, and finishes can be added as needed.

ICF Block Construction offers several advantages over traditional building methods. Firstly, it provides excellent thermal insulation, helping to regulate indoor temperatures and reduce energy consumption for heating and cooling. Additionally, the solid concrete core provides strength and durability, making buildings constructed with ICF blocks resilient to damage from natural disasters such as hurricanes and earthquakes. CF foam block constructionis known for its superior sound insulation properties, creating quieter and more comfortable indoor environments.

Origins of ICF Block Construction

The origins of ICF Block Construction can be traced back to the mid-20th century when the concept of using insulated concrete forms began to gain traction in the construction industry. The initial idea stemmed from the need for more efficient and durable building materials that could withstand the challenges posed by changing environmental conditions.

The first patented insulated concrete form system was introduced in the late 1960s, marking the beginning of modern ICF foam block construction. However, it wasn’t until the 1970s and 1980s that ICF technology began to see widespread adoption, particularly in regions prone to extreme weather conditions.

During this period, advancements in materials science and construction techniques led to the development of more sophisticated ICF systems, offering improved insulation properties, structural strength, and ease of installation. Builders and architects began to recognize the potential of ICF Block Construction to address key challenges in the construction industry, such as energy efficiency, durability, and environmental sustainability.

Modern Applications of ICF Block Construction

In contemporary times, ICF Block Construction has found diverse applications across the construction industry, showcasing its versatility and adaptability to various building projects. From residential dwellings to commercial complexes and industrial facilities, modern applications of ICF Block Construction continue to expand, driven by its numerous benefits and sustainable features.

- Residential Construction: One of the most common applications of ICF Block Construction is in the construction of residential homes. Builders and homeowners alike are drawn to the energy efficiency, durability, and comfort offered by ICF construction methods. From single-family residences to multi-unit developments, ICF blocks provide a solid foundation for structurally sound and environmentally sustainable housing.

- Commercial Buildings: ICF Block Construction has also gained popularity in the commercial construction sector. From office buildings to retail centers and educational facilities, ICF blocks offer a reliable and cost-effective solution for creating durable and energy-efficient structures. The ability to customize designs and achieve high-performance building envelopes makes ICF construction particularly attractive for commercial projects.

- Industrial Facilities: In industrial construction, where durability and resilience are paramount, ICF Block Construction is increasingly being utilized. Warehouses, manufacturing plants, and distribution centers benefit from the superior strength and thermal performance of ICF walls, ensuring optimal working conditions and long-term operational efficiency.

- Institutional Buildings: Institutions such as schools, hospitals, and government buildings are also embracing ICF Block Construction for its ability to meet stringent building codes and sustainability requirements. Enhanced fire resistance, sound insulation, and thermal stability make ICF construction an ideal choice for creating safe and comfortable environments in institutional settings.

- High-Rise Structures: While traditionally associated with low-rise construction, ICF Block Construction is now making inroads into high-rise buildings. With advancements in engineering and construction techniques, ICF systems can be adapted to meet the unique challenges of tall buildings, offering a viable alternative to conventional construction methods.

- Custom Homes and Architectural Projects: Beyond standard building applications, ICF Block Construction is valued for its design flexibility and versatility. Architects and designers appreciate the freedom to create custom homes and architectural landmarks using ICF blocks, resulting in visually striking structures that prioritize sustainability and innovation.

Benefits of ICF Block Construction

ICF Block Construction offers a plethora of benefits that make it a preferred choice for builders, architects, and homeowners alike. From energy efficiency to durability and comfort, the advantages of ICF construction extend across various aspects of building performance and sustainability.

Here are some key benefits of ICF Block Construction:

Energy Efficiency:

One of the most significant benefits of ICF Block Construction is its exceptional energy efficiency. The insulating properties of the foam cores in ICF blocks create a continuous thermal barrier, reducing heat loss in winter and heat gain in summer. This results in lower energy consumption for heating and cooling, leading to substantial cost savings over the lifespan of the building.

Structural Integrity:

ICF blocks provide robust structural support, creating buildings that are exceptionally strong and resilient. The solid concrete core, reinforced with steel rebar, offers superior resistance to impacts, wind loads, and seismic forces, ensuring long-term durability and stability even in extreme weather conditions.

Sound Insulation:

ICF Block Construction excels in sound insulation, creating quieter indoor environments with reduced noise transmission from external sources. The dense concrete walls effectively dampen sound vibrations, resulting in enhanced acoustic comfort for occupants. This makes ICF construction ideal for residential, commercial, and institutional buildings where noise control is essential.

Fire Resistance:

Another advantage of ICF Block Construction is its inherent fire resistance. The non-combustible materials used in ICF blocks, combined with the high thermal mass of concrete, provide effective protection against fire spread. As a result, buildings constructed with ICF blocks are safer and more resilient in the event of a fire, minimizing property damage and ensuring occupant safety.

Improved Indoor Air Quality:

ICF construction promotes healthier indoor environments by reducing air infiltration and minimizing the entry of pollutants, allergens, and outdoor contaminants. The airtight seals created by ICF walls help maintain consistent indoor temperatures and humidity levels, preventing the growth of mold and mildew and promoting better indoor air quality.

Environmental Sustainability:

ICF Block Construction is inherently sustainable, offering several environmental benefits. The use of recycled materials in ICF blocks, such as expanded polystyrene foam, reduces the demand for virgin resources and minimizes waste. Additionally, the energy efficiency of ICF buildings reduces greenhouse gas emissions and mitigates the environmental impact of heating and cooling systems.

Cost Savings:

While the initial cost of ICF Block Construction may be slightly higher than traditional construction methods, the long-term cost savings are significant. Lower energy bills, reduced maintenance requirements, and enhanced durability contribute to overall savings over the lifespan of the building, making ICF construction a sound investment for the future.

ICF Block Construction offers a host of benefits that address key concerns in building design and construction. From energy efficiency and structural integrity to sound insulation and environmental sustainability, ICF construction delivers superior performance and comfort for occupants while minimizing environmental impact and long-term costs.

ICF vs Block Construction

When it comes to building construction, two popular methods stand out: ICF (Insulated Concrete Forms) and traditional block construction. While both techniques involve the use of blocks to create walls, there are distinct differences between them that can impact factors such as energy efficiency, durability, and cost. Let’s explore the key differences between ICF and traditional block construction:

ICF Construction:

- Insulation: ICF construction incorporates insulated concrete forms made of materials like expanded polystyrene (EPS) or extruded polystyrene (XPS), providing excellent thermal insulation. The foam blocks create a continuous insulation layer, reducing energy consumption for heating and cooling.

- Strength: ICF walls are reinforced with steel rebar and filled with concrete, resulting in robust structures with high structural integrity. These walls offer superior resistance to impacts, wind loads, and seismic forces compared to traditional block walls.

- Energy Efficiency: Due to their insulation properties, ICF walls significantly reduce heat transfer, resulting in lower energy bills and improved indoor comfort. Buildings constructed with ICF blocks maintain more consistent temperatures year-round, leading to enhanced energy efficiency.

- Installation: ICF construction typically involves faster installation compared to traditional block construction, as the interlocking foam blocks are lightweight and easy to maneuver. Additionally, the stacking of blocks and pouring of concrete can be completed in fewer steps, saving time and labor costs.

Traditional Block Construction:

- Materials: Traditional block construction utilizes materials such as concrete blocks or clay bricks, which may not offer the same level of insulation as ICF blocks. While additional insulation can be added, it often requires extra materials and labor.

- Strength: Block walls constructed with concrete blocks or bricks are sturdy and durable but may not provide the same level of structural strength as ICF walls. Reinforcement with steel rebar is typically not as extensive in traditional block construction.

- Energy Efficiency: Without additional insulation, traditional block walls may have higher thermal conductivity, leading to increased heat transfer and energy loss. However, with proper insulation measures, the energy efficiency of block construction can be improved.

- Installation: Traditional block construction involves laying individual blocks or bricks and mortar, which can be more time-consuming and labor-intensive compared to ICF construction. Additionally, the need for skilled masons to achieve precise alignment and mortar joints adds to the overall cost.

Both ICF and traditional block construction methods have their advantages and drawbacks. While ICF construction offers superior insulation, strength, and energy efficiency, traditional block construction may be more familiar and cost-effective in certain scenarios. Ultimately, the choice between the two methods depends on factors such as project requirements, budget constraints, and desired performance outcomes. Consulting with a qualified contractor or architect can help determine the best approach for your specific building project.

Here’s a comparison table highlighting the key differences between ICF and traditional block construction:

| Feature | ICF Construction | Traditional Block Construction |

|---|---|---|

| Insulation | Excellent thermal insulation with foam blocks | Limited insulation; additional materials required |

| Strength | High structural integrity with reinforced concrete | Sturdy but may lack same level of reinforcement |

| Energy Efficiency | Reduced energy consumption and improved comfort | Potential for higher energy loss without proper insulation |

| Installation | Faster installation with interlocking foam blocks | More labor-intensive; requires skilled masons |

| Cost | Initial costs may be higher but long-term savings | Lower initial costs but potential for higher energy bills |

This table provides a concise overview of the key differences between ICF and traditional block construction methods, helping you make an informed decision based on your project needs and priorities.

Techniques of ICF Block Construction

Insulated Concrete Form (ICF) block construction combines strength, energy efficiency, and ease of installation. Using interlocking foam blocks filled with concrete, this method enhances insulation, durability, and structural performance. Proper techniques ensure stability, accurate alignment, and long-lasting results for residential, commercial, and industrial projects.

Finishing and Sealing: After concrete cures, walls may require surface finishing or sealing. We apply plaster, coatings, or waterproofing layers as needed to protect the structure, enhance thermal efficiency, and create a smooth, aesthetically appealing finish.

Block Alignment: Properly aligning ICF blocks ensures walls are straight, level, and structurally sound. We carefully place each block, checking horizontal and vertical alignment, which minimizes gaps, reduces material waste, and ensures uniform wall thickness throughout the construction process.

Reinforcement Placement: Reinforcing steel (rebar) is inserted into ICF blocks before pouring concrete. We strategically position rebar to strengthen the wall, improve load-bearing capacity, and enhance resistance against seismic, wind, and other structural stresses for long-term durability.

Concrete Pouring: Concrete is poured carefully into the ICF blocks, filling cavities evenly. We monitor pour speed, vibration, and consistency to prevent voids, maintain block integrity, and ensure a strong, stable, and durable wall structure.

Environmental Impact of ICF Block Construction

Insulated Concrete Form (ICF) block construction offers an eco-friendly alternative to traditional building methods. By improving energy efficiency, reducing material waste, and using recyclable components, ICF construction minimizes environmental impact while supporting sustainable building practices for residential, commercial, and industrial projects.

- Lower Carbon Footprint: By combining insulation, durability, and energy savings, ICF buildings reduce overall greenhouse gas emissions. We focus on efficient construction techniques to ensure a smaller carbon footprint without compromising structural integrity or performance.

- Energy Efficiency: ICF blocks provide superior insulation, reducing heating and cooling energy consumption. We design and install walls to optimize thermal performance, lowering carbon emissions and utility costs over the building’s lifecycle.

- Reduced Material Waste: ICF construction generates minimal waste due to precise block sizing and interlocking design. We efficiently use materials, recycle scrap foam, and minimize excess concrete, contributing to environmentally responsible building practices.

- Recyclable Materials: Many ICF blocks use recyclable or reusable foam and concrete components. We select sustainable materials to reduce landfill impact, promote circular construction practices, and support long-term environmental stewardship.

Conclusion

In conclusion, ICF Block Construction emerges as a paradigm shift in sustainable building practices, offering a harmonious blend of environmental stewardship and structural excellence. With its myriad benefits and versatile applications, ICF Block Construction is poised to redefine the future of the construction industry, one eco-friendly structure at a time.

Ready to experience the benefits of ICF Block Construction firsthand? Contact us today for a personalized quote and discover how ICF construction can transform your next building project. Build better, build sustainably with ICF Block Construction.

Get in touch now to request your quote and take the first step towards a more efficient, durable, and environmentally friendly building solution. Let’s make your vision a reality with ICF Block Construction.