Expanded Polystyrene (EPS) fire ratings are essential safety indicators that assess the material’s ability to resist fire and limit its spread. These ratings ensure that EPS products meet specific standards, enhancing fire safety in various applications such as construction, packaging, and insulation.

This article will help readers understand Expanded Polystyrene Fire Ratings.

What Is Expanded Polystyrene

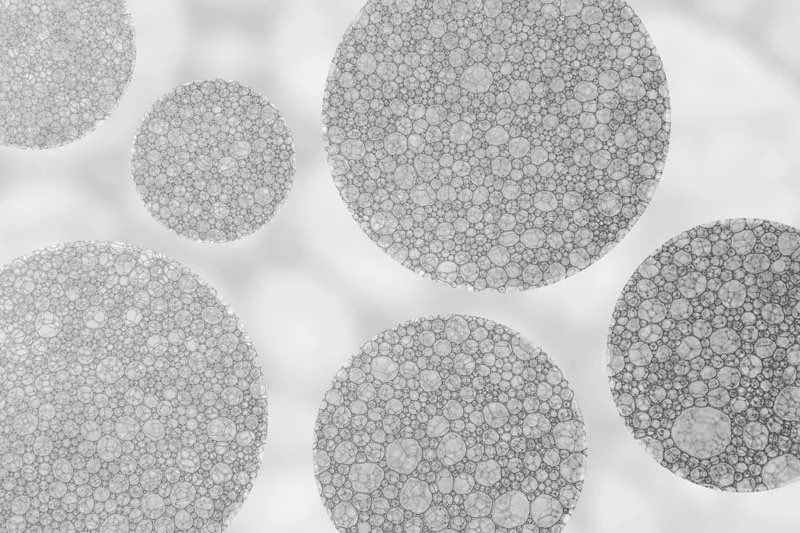

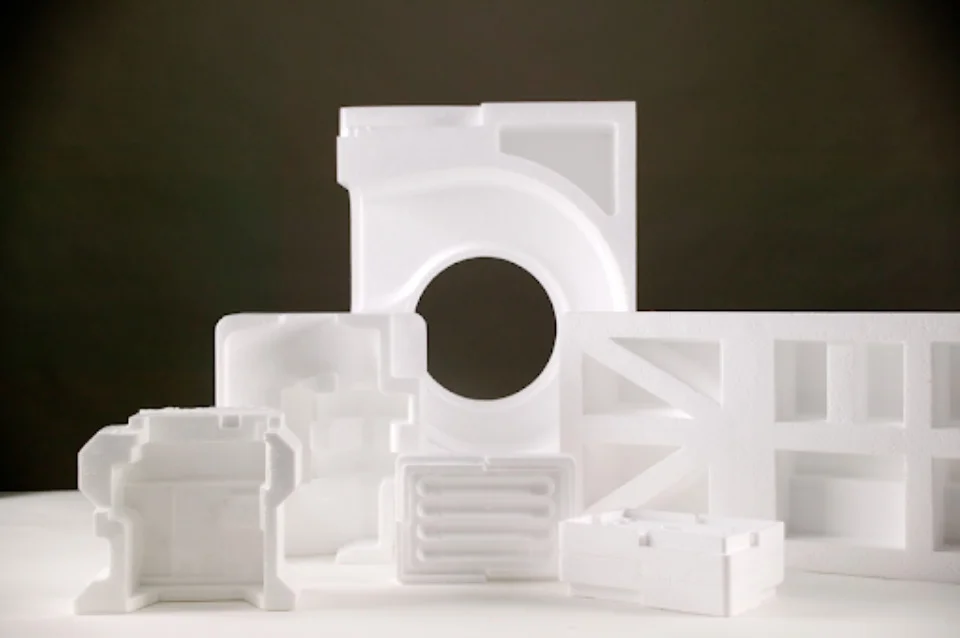

Expanded Polystyrene (EPS) is a lightweight, rigid, and versatile plastic material commonly used for insulation, packaging, and construction. It is characterized by its cellular structure, thermal insulation properties, and shock absorption capabilities.

What Is Expanded Polystyrene Fire Ratings

Expanded Polystyrene Fire Ratings refer to standardized assessments of the fire resistance and performance of Expanded Polystyrene (EPS) materials in the event of a fire. These ratings are determined through rigorous testing methods and standards established by regulatory bodies.

What Is Expanded Polystyrene Fire Ratings Key Characteristics

Low Combustibility

EPS has a low flammability, meaning it is less likely to ignite compared to other materials. This inherent property reduces the risk of flames spreading.

Flame Retardancy

Some EPS products are treated with flame-retardant additives during manufacturing. These additives help to inhibit the combustion process and slow down the spread of flames.

Limited Smoke Emission

When exposed to fire, EPS tends to produce relatively low levels of smoke compared to some other materials. This characteristic helps maintain visibility and reduces health risks associated with smoke inhalation during fire incidents.

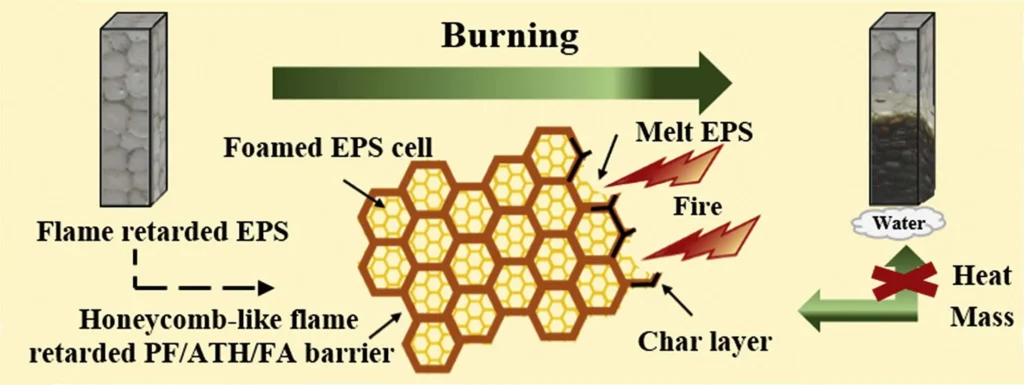

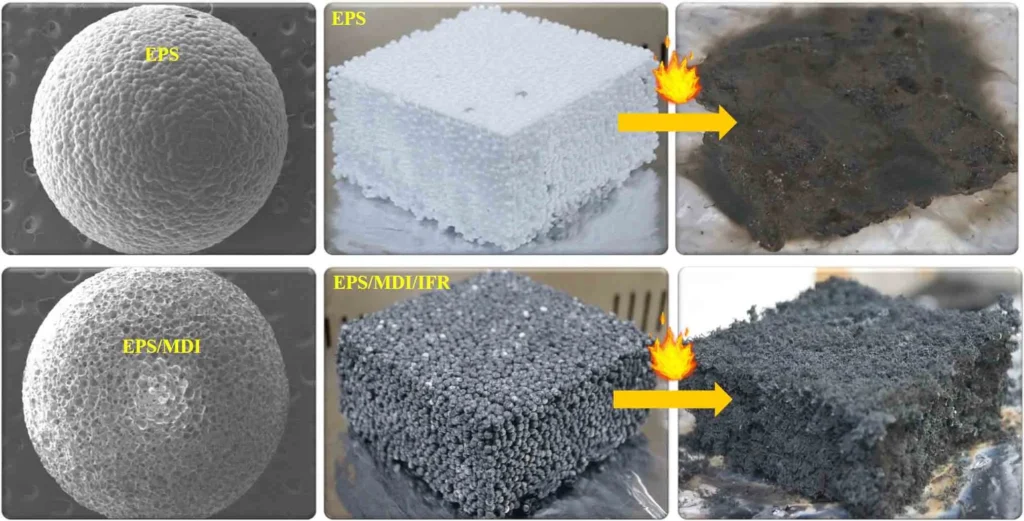

Formation of Char Layer

When exposed to fire, EPS may char rather than burn completely. This char layer acts as a protective barrier, insulating the underlying EPS material and slowing down the progression of flames.

Compliance with Standards

EPS products are subjected to rigorous testing and certification to ensure they meet specific fire safety standards and regulations. Compliance with these standards provides assurance of the material’s fire resistance and suitability for use in various applications.

Why Expanded Polystyrene Fire Ratings Are Important

Ensuring Fire Safety

Fire safety is paramount in any application involving EPS. Without proper precautions, EPS can pose significant fire hazards due to its combustible nature. Therefore, implementing effective fire safety measures is essential to mitigate risks and ensure the protection of both property and lives.

Understanding Expanded Polystyrene Fire Ratings

Expanded Polystyrene Fire Ratings assess fire resistance and performance, determined through rigorous testing methods and standards set by regulatory bodies. They evaluate factors like ignition resistance, flame spread, and smoke production, offering valuable insights into EPS behavior in fire scenarios.

Compliance with Regulations

Compliance with EPS fire safety regulations and standards is vital to ensure material suitability and safety. These regulations establish minimum fire performance criteria for EPS products, aiding in preventing fire incidents and ensuring legal compliance and liability protection.

Minimizing Fire Risks

Expanded Polystyrene Fire Ratings help stakeholders select materials for construction, packaging, and insulation. Choosing EPS with suitable ratings minimizes fire risks, protecting property and lives. Additionally, fire-rated EPS can lower insurance premiums and liability risks for building owners and contractors.

Enhancing Building Safety

Expanded Polystyrene Fire Ratings enhance building safety by ensuring structures have fire-resistant materials. Architects and engineers can create safer environments by incorporating fire-rated EPS into building designs, prioritizing the safety of occupants and emergency responders.

How to Test Expanded Polystyrene Fire Ratings

Testing methods for Expanded Polystyrene Fire Ratings involve standardized procedures to assess the material’s fire resistance. This includes controlled laboratory testing following specific standards like ASTM, UL, European (EN), and Chinese national standards.

Tests commonly used include the Cone Calorimeter Test, Flame Spread Test, and Smoke Density Test. These methods evaluate parameters like ignition time, flame spread rate, and smoke production to classify EPS materials into different fire resistance levels.

overview of global fire rating standards

| Standard | Region | Key Aspects |

|---|---|---|

| BS EN 13501-1 BS EN 13501-1 | Europe/UK | Classifies reaction to fire with ratings from A1 to F |

| BS 476 | UK | Includes tests for fire propagation and surface spread of flame |

| ASTM E119 | USA | Assesses the fire resistance of building elements |

| ISO 1182 | International | Determines non-combustibility of building materials |

The Relationship Between EPS Fire Ratings and Fire Performance

The relationship between Expanded Polystyrene fire ratings and actual fire performance is significant in determining the material’s effectiveness in fire scenarios. EPS fire ratings serve as standardized assessments of the material’s fire resistance based on laboratory testing, while fire performance refers to its behavior in real-world fire incidents. Understanding this relationship is crucial for ensuring fire safety in various applications.

Expanded Polystyrene fire ratings are determined through rigorous testing methods established by regulatory bodies. They provide valuable insights into the expected fire behavior of EPS under controlled conditions. However, the actual fire performance of EPS may vary based on several factors:

Environmental Conditions:

Real-world fire incidents may involve different environmental factors, such as temperature, humidity, and ventilation, which can influence EPS behavior during a fire.

Installation and Design:

The installation practices and design considerations of EPS in structures or products can impact its fire performance. Proper installation and integration are essential for maximizing fire resistance.

Exposure Time and Severity:

The duration and intensity of exposure to fire can significantly affect EPS performance. Prolonged exposure to high temperatures or severe fire conditions may exceed the capabilities indicated by expanded polystyrene fire ratings.

Compatibility with Adjacent Materials:

The interaction between EPS and other materials nearby during a fire can affect its behavior. Compatibility issues or improper material selection may impact fire spread and severity. Prolonged exposure to high temperatures or severe fire conditions may exceed the capabilities indicated by expanded polystyrene fire ratings.

Maintenance and Ageing:

The condition of EPS over time, including factors such as degradation, wear, and exposure to environmental elements, can influence its fire performance. Regular maintenance and inspection are necessary to ensure continued effectiveness.

Regulatory Compliance:

While Expanded Polystyrene fire ratings are based on standardized testing methods and criteria established by regulatory bodies, compliance with these standards does not guarantee absolute fire safety in all scenarios. Adherence to fire safety standards is essential for assessing expected performance.

The Factors Influencing Expanded Polystyrene Fire Ratings

Material density

Higher-density EPS typically exhibits better fire resistance as it contains more polymer and fewer voids, making it harder for flames to penetrate.

Flame retardant additives

Flame retardants can be added during EPS manufacturing to enhance its fire performance. These additives can slow down flame spread and reduce the severity of fires.

Structural design

The fire performance of EPS is also influenced by structural design. For example, in buildings, the design of walls and roofs can affect the speed and extent of flame spread.

Thickness and compression

Thicker and denser EPS generally have higher fire resistance as they provide more insulation and are more resistant to flame erosion.

Environmental conditions

Exposure to moist or humid environments may decrease the fire resistance of EPS. Wet EPS may absorb moisture, leading to decreased fire performance.

Expanded Polystyrene Fire Ratings are influenced by the factors mentioned above. Therefore, when selecting and using EPS, it is necessary to consider these factors comprehensively to ensure its safety performance in fire incidents.

How to Improve Expanded Polystyrene Fire Ratings

Expanded polystyrene (EPS) presents fire risks due to its combustible nature. When exposed to fire, EPS can ignite easily and release toxic fumes, contributing to fire spread and hindering evacuation efforts. To mitigate these risks, adequate fire protection measures are essential when using EPS materials.

Flame Retardant Additives: Incorporate flame retardant additives during manufacturing to slow down flame spread and reduce fire severity.

Coatings and Treatments: Applying fire-resistant coatings or intumescent treatments to EPS surfaces forms a protective barrier against heat and flames.

Structural Modifications: Implementing changes such as using thicker EPS layers or incorporating fire barriers can improve overall fire performance.

Oxygen Limitation: Designing EPS assemblies to restrict oxygen availability inhibits combustion and reduces fire spread.

Compliance with Standards: Ensuring EPS products meet relevant fire safety standards and regulations validates their effectiveness.

Fire Rating Requirements of EPS in Different Applications

Construction Applications

In the construction industry, EPS is commonly used in insulation boards, concrete forms, and architectural decorations. Fire rating requirements for EPS in construction applications typically adhere to building codes and regulations set by local authorities or international standards organizations.

These standards specify the minimum fire resistance performance criteria that EPS products must meet to ensure safety in buildings. Factors such as flame spread, smoke production, and ignition resistance are evaluated to determine the appropriate fire rating for EPS used in construction.

Packaging Applications

In packaging applications, EPS is valued for its lightweight and shock-absorbing properties, making it ideal for protecting fragile items during transportation and storage. Fire rating requirements for EPS packaging materials may vary depending on the contents being packaged and the mode of transportation.

Regulatory bodies may impose specific fire safety standards for packaging materials to ensure they meet minimum requirements for fire resistance and safety during transit.

Insulation Applications

EPS is extensively used as insulation material in residential, commercial, and industrial buildings to improve energy efficiency and indoor comfort. Fire rating requirements for EPS insulation typically focus on its ability to resist ignition, slow down flame spread, and limit smoke production in the event of a fire.

Building codes and standards specify the fire resistance performance criteria that EPS insulation products must meet to ensure compliance and safety in building applications.

How to Choose the Right Fire Rating for EPS Products?

Understand Requirements: Identify the specific fire safety standards and regulations applicable to your project or application.

Assess Risks: Evaluate potential fire hazards and risks in the environment where the EPS product will be used.

Consider Application: Take into account the intended use of the EPS product and its proximity to potential ignition sources.

Review Ratings: Compare available EPS products to ensure they meet or exceed the required fire resistance levels specified by regulations or project specifications.

Seek Expert Advice: Consult fire safety professionals or EPS manufacturers for guidance on selecting the most suitable EPS product with the appropriate fire rating for your application.

Innovation in Fire-resistant Expanded Polystyrene (EPS) Materials

Intumescent Coatings:

Intumescent coatings are applied to EPS surfaces to provide passive fire protection. These coatings expand when exposed to heat, forming a thick insulating char layer that slows down flame spread and protects the underlying EPS material from fire damage.

Flame Retardant Additives:

Researchers are developing new flame-retardant additives that can be incorporated into EPS during manufacturing. These additives suppress the combustion process, reduce flame spread, and decrease smoke production, improving the fire resistance of EPS products.

Nanostructured Materials:

Nanostructured materials, such as nanoparticles and nanocomposites, are being explored for their potential to enhance the fire resistance of EPS. These materials can be incorporated into EPS formulations to improve their thermal stability and reduce their flammability.

Hybrid Materials:

Hybrid materials, combining EPS with other fire-resistant materials such as mineral fibers or intumescent agents, are being developed to create composite materials with improved fire performance. These hybrid materials offer enhanced fire resistance while maintaining the lightweight and insulation properties of EPS.

Conclusion

Expanded Polystyrene Fire Ratings are crucial for assessing the material’s fire resistance and ensuring safety in various applications. These ratings provide standardized assessments based on rigorous testing methods, guiding the selection of suitable EPS products to mitigate fire risks effectively. By adhering to fire ratings, stakeholders can enhance fire safety measures and protect property and lives from fire hazards.