To make you clear about expanded polystyrene applications and uses, here we put together a definitive list of expanded polystyrene applications for your reference.

Here we go.

What is Expanded Polystyrene Used For?

Expanded Polystyrene (EPS) is a versatile material with a wide range of applications across various industries. Some common uses of expanded polystyrene include:

- Building Insulation: EPS is extensively used as thermal insulation in residential, commercial, and industrial buildings. It is installed in walls, roofs, floors, and foundations to reduce heat transfer and improve energy efficiency.

- Packaging: EPS foam is commonly used for packaging fragile items such as electronics, appliances, and food products. Its lightweight, shock-absorbing properties help protect delicate items during transportation and storage.

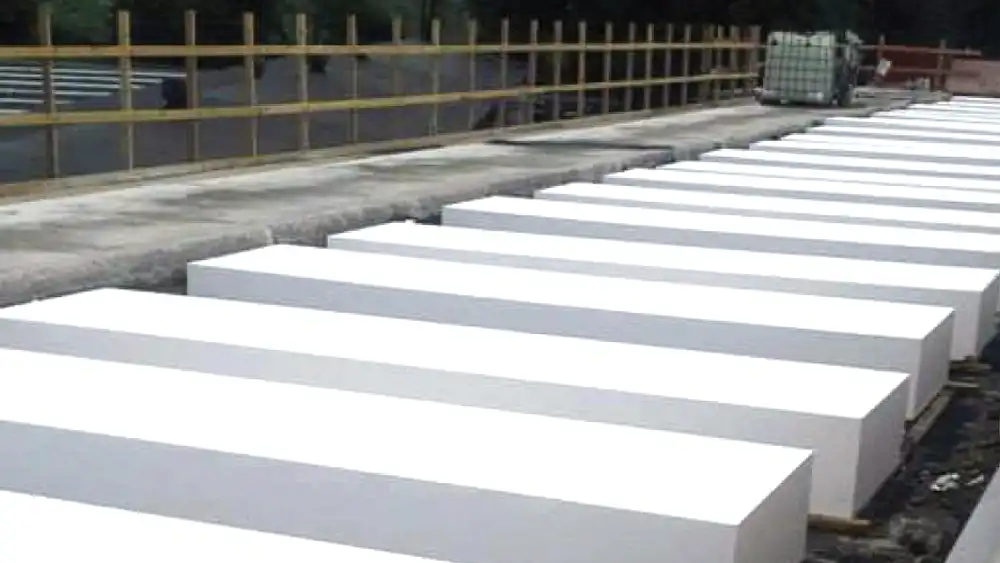

- Construction and Civil Engineering: EPS is used in construction for applications such as void fillers, lightweight fill material, and geofoam blocks for road embankments and bridge abutments. It offers structural support while minimizing overall weight.

- Horticulture and Agriculture: EPS is utilized in horticulture for seedling trays, plant pots, and protective packaging for plants during transportation. In agriculture, it is used as insulation in greenhouses to maintain consistent temperatures.

- Floatation Devices: EPS foam is used to manufacture buoyancy aids, life jackets, and flotation devices for water sports, marine activities, and personal safety applications.

- Art and Craft Projects: EPS foam is popular among artists and hobbyists for sculpting, model making, and other creative projects due to its lightweight and easy-to-carve properties.

- Stage and Set Design: EPS foam is used in the entertainment industry for creating stage sets, props, and themed environments for theaters, film productions, amusement parks, and events.

- Cold Chain Packaging: EPS is used in the transportation of temperature-sensitive goods, such as pharmaceuticals, vaccines, and perishable foods, where maintaining a specific temperature range is critical.

- Sound Insulation: EPS foam panels are sometimes used for soundproofing applications in recording studios, theaters, and residential buildings to reduce noise transmission between rooms.

- Craftsmanship and DIY Projects: EPS foam sheets and blocks are popular materials for DIY enthusiasts and craftsmen for creating custom decorations, architectural elements, and signage.

These are just a few examples of the many applications of Expanded Polystyrene. Its lightweight, insulating properties, and ease of shaping make it a versatile material suitable for diverse industries and creative endeavors.

Automotive Parts

Expanded Polystyrene is widely applied in the automotive industry, and it can be made into various kinds of automotive parts. Because EPS is lightweight, it can offer outstanding performance to ensure the automotive machinery can work well.

Expanded Polystyrene (EPS) is a lightweight and versatile material that has found applications in various industries, including the automotive sector. In the automotive industry, EPS is commonly used for manufacturing a variety of parts due to its advantageous properties.

Insulation: Expanded Polystyrene is known for its excellent insulation properties. In automotive applications, it is often used as insulation material in different components. For instance, EPS can be found in door panels to provide thermal and acoustic insulation, contributing to a quieter and more comfortable interior environment.

Bumpers: EPS is used in the manufacturing of automotive bumpers. Its lightweight nature makes it an ideal choice for this application, contributing to fuel efficiency by reducing the overall weight of the vehicle. Additionally, the energy-absorbing properties of EPS enhance safety by mitigating the impact during collisions.

Interior Components: Various interior components, such as seat cushions, headrests, and armrests, can be made using EPS. Its cushioning and shock-absorbing characteristics make it suitable for enhancing the comfort and safety of vehicle occupants.

Packaging for Parts: EPS is often used in the automotive industry for packaging delicate and sensitive parts. Its ability to provide cushioning and protection helps prevent damage during transportation and handling.

Void Fillers: In some cases, EPS is used as a void filler in the automotive manufacturing process. It can be inserted between different parts to provide structural support and stability.

Sound Deadening: EPS is valued for its acoustic insulation properties. It is employed in the automotive industry to reduce noise and vibrations within the vehicle, leading to a quieter and more pleasant driving experience.

Molded Components: EPS can be molded into various shapes and sizes, making it adaptable for a wide range of automotive components. From air ducts to structural support elements, its versatility allows for the creation of complex and customized parts.

Fuel Efficiency: Due to its lightweight nature, EPS contributes to improving fuel efficiency in vehicles. By incorporating EPS in certain components, automakers can reduce the overall weight of the vehicle, resulting in better fuel economy.

EPS for HVAC

Expanded Polystyrene (EPS) finds diverse applications in the Heating, Ventilation, and Air Conditioning (HVAC) industry, contributing to energy efficiency, thermal insulation, and structural support. Here are several ways EPS is utilized in HVAC systems:

Duct Insulation: EPS is used as insulation material for HVAC ductwork. The lightweight and insulating properties of EPS help in reducing heat transfer and maintaining the desired temperature within the ducts. This contributes to energy efficiency by minimizing heat loss or gain during the distribution of conditioned air.

Air Handler Units: Components of air handler units, such as panels and housing, can be constructed using EPS. Its insulation capabilities assist in maintaining consistent temperatures within the unit, enhancing the overall efficiency of the HVAC system.

Pipe Insulation: EPS is used to insulate pipes in HVAC systems. This insulation helps prevent heat loss or gain, ensuring that the transported fluids remain at the desired temperature. EPS pipe insulation is lightweight, easy to install, and provides an effective thermal barrier.

Equipment Packaging: EPS is utilized in packaging HVAC equipment during transportation. It acts as a protective material, cushioning components like compressors and fans, ensuring they arrive at their destination without damage.

Vibration Isolation Pads: In HVAC systems, especially for heavy equipment like chillers and air handling units, EPS is employed in the manufacturing of vibration isolation pads. These pads help dampen vibrations and reduce noise generated by the equipment, contributing to a quieter operation.

Roof Insulation: For HVAC systems that incorporate rooftop units, EPS is used as part of the roof insulation. The foam provides thermal resistance, helping to regulate temperatures within the building and improving energy efficiency.

Cooling Tower Fill Material: EPS can be used as fill material in the construction of cooling towers. Its lightweight nature and moisture resistance make it a suitable choice for creating the fill material that facilitates the exchange of heat in cooling tower systems.

Access Panels and Housings: EPS is often used to manufacture access panels and housings for HVAC components. Its versatility allows for the creation of custom-fit, lightweight, and durable enclosures that protect sensitive equipment.

Thermal Breaks: EPS is employed as a thermal break in HVAC systems to prevent thermal bridging. By placing EPS between materials with different thermal conductivity, it helps improve the overall thermal performance of the system and reduces energy loss.

Dampers and Louvers: Some HVAC components, such as dampers and louvers, can incorporate EPS for insulation and structural support. This enhances the efficiency of these components by minimizing heat transfer and improving overall system performance.

In summary, EPS plays a crucial role in the HVAC industry, contributing to energy efficiency, thermal insulation, and protection of components. Its lightweight and insulating properties make it a versatile material for various applications within HVAC systems.

EPS Applications for Construction

Expanded Polystyrene (EPS) is widely used in the construction industry for a variety of applications due to its lightweight, insulating, and versatile properties. Here are some common applications of EPS in construction:

Insulation: EPS is extensively used as insulation material in construction. It is available in the form of rigid foam boards or panels, which can be easily installed in walls, roofs, and floors. The excellent thermal insulation properties of EPS help in maintaining indoor temperatures, improving energy efficiency, and reducing heating and cooling costs.

Exterior Insulation and Finish Systems (EIFS): EPS is a key component in Exterior Insulation and Finish Systems, commonly known as EIFS. EIFS involves attaching EPS panels to the exterior of buildings, followed by a reinforcing mesh and a durable finish coat. This system provides both insulation and a decorative exterior finish.

Void Formers: EPS is used as void formers in construction applications. It is often placed beneath concrete slabs to create a lightweight void, reducing the overall weight of the structure. This not only conserves resources but also facilitates easier installation and minimizes the risk of soil settlement.

Geofoam: EPS is employed as geofoam in civil engineering and construction projects. Geofoam is a lightweight fill material used to reduce the load on underlying soils. It is particularly useful in areas where traditional, heavier fill materials could lead to settlement issues.

Roofing Systems: EPS is used in roofing systems for insulation purposes. It can be installed in the form of insulation boards or as part of a composite roofing system. EPS helps regulate temperature, prevents heat loss, and contributes to the overall energy efficiency of buildings.

Foundation Insulation: EPS is utilized for insulating building foundations. Placing EPS panels around the foundation perimeter helps prevent heat loss through the ground and minimizes the risk of frost heave, particularly in colder climates.

Stucco and Plastering: EPS can be used as a substrate for stucco and plaster applications. Its lightweight nature makes it easy to handle, and it provides a stable surface for the application of decorative finishes.

Lightweight Concrete: EPS beads are sometimes added to concrete mixes to create lightweight concrete. This type of concrete is used in various construction applications where reduced weight is a critical factor, such as in precast concrete elements.

Formwork for Concrete: EPS panels are used as formwork for casting concrete structures. The lightweight nature of EPS makes it easy to handle and transport, and it can be customized to create specific shapes and sizes for different construction projects.

EPS continues to be a preferred material in construction due to its cost-effectiveness, versatility, and environmentally friendly characteristics. Its applications contribute to energy-efficient buildings, reduced construction weight, and simplified installation processes.

EPS Applications for Pharmaceutical & Medical

Expanded Polystyrene (EPS) finds several valuable applications in the pharmaceutical and medical industries due to its favorable characteristics, including insulation properties, lightweight nature, and cost-effectiveness. Here are some common applications of EPS in these sectors:

Temperature-Sensitive Product Packaging: EPS is widely used for the packaging of temperature-sensitive pharmaceutical and medical products, such as vaccines, medications, and diagnostic kits. Its excellent insulation properties help maintain the required temperature during storage and transportation, ensuring the integrity and efficacy of the products.

Cooling Shippers and Containers: EPS is employed in the construction of cooling shippers and containers for the transportation of medical specimens, organs for transplant, and other temperature-sensitive materials. These containers are designed to provide thermal insulation and protect the contents from temperature fluctuations.

Insulated Cold Storage: EPS is used to insulate cold storage units and refrigerators in pharmaceutical and medical facilities. This helps to create a controlled environment for storing medications, vaccines, and other perishable medical supplies, ensuring their stability and effectiveness.

Pharmaceutical Packaging Inserts: EPS is often utilized as packaging inserts to provide cushioning and protection for fragile pharmaceutical products. It helps prevent breakage or damage during shipping and handling, ensuring the quality of the medication upon reaching the end-user.

Medical Device Packaging: EPS is used in the packaging of various medical devices, including diagnostic equipment, laboratory instruments, and delicate medical tools. Its shock-absorbing properties protect these devices from mechanical stresses during transportation.

Insulating Blood and Tissue Containers: EPS is employed in the manufacturing of containers used for the transportation of blood, tissues, and other biological materials. The insulation helps maintain the required temperature for the safe transport of these critical medical components.

Pharmaceutical Display and Presentation Materials: EPS is used to create lightweight and visually appealing display materials for pharmaceutical products in pharmacies and medical facilities. These materials can include product stands, promotional displays, and signage.

Disposable Medical Products: In some cases, EPS is used in the production of disposable medical products, such as specimen containers and packaging for single-use medical devices. Its cost-effectiveness and moldability make it a suitable material for such applications.

Orthopedic Supports and Cushions: EPS can be molded into orthopedic supports and cushions, providing comfortable and customized solutions for patients with orthopedic conditions. These supports can be used in various medical settings, including hospitals and rehabilitation centers.

Dental Model Packaging: EPS is used for packaging dental models and impressions. Its lightweight and protective properties help prevent damage to these delicate dental materials during transportation.

In summary, EPS plays a crucial role in the pharmaceutical and medical industries by providing solutions for packaging, transportation, insulation, and product protection, contributing to the safety and efficacy of medical and pharmaceutical products.

EPS Applications for Appliance Packaging

Expanded Polystyrene (EPS) is widely utilized in the appliance industry for packaging due to its excellent protective and insulating properties. Here are several applications of EPS in appliance packaging:

Protection for Fragile Components: EPS is commonly used to create custom-fit protective packaging for fragile components within appliances, such as glass panels, electronic circuits, or delicate mechanisms. Its ability to absorb and distribute impact energy helps prevent damage during transportation and handling.

Insulation for Temperature-Sensitive Appliances: Appliances that are sensitive to temperature variations, such as refrigerators and freezers, often require insulation during transportation. EPS serves as an effective thermal insulator, helping to maintain the desired temperature and protect the appliance from temperature fluctuations.

Cushioning for Large Appliances: Large appliances like washing machines, dishwashers, or ovens often have heavy and irregularly shaped parts. EPS can be molded or cut to create protective cushions that conform to the shape of these components, providing reliable shock absorption during shipping.

Void Filling and Structural Support: EPS can be used as void fillers to prevent movement within the packaging, ensuring that the appliance remains securely in place. Additionally, it can provide structural support to distribute the weight evenly and prevent any stress on vulnerable points during transportation.

Custom Molded Packaging: EPS is versatile in terms of molding, allowing for the creation of custom packaging solutions tailored to the specific shape and dimensions of individual appliances. This customization enhances the protection offered during transit.

Reducing Packaging Weight: As a lightweight material, EPS helps to keep the overall packaging weight low. This not only contributes to cost-effective shipping but also reduces the environmental impact associated with transportation.

Shock Absorption for Electronics: Appliances with electronic components, such as televisions, computers, or audio equipment, benefit from EPS’s shock-absorbing properties. It provides a cushion against impacts and vibrations, preventing potential damage to sensitive electronic parts.

Moisture Resistance: EPS has inherent moisture resistance, making it suitable for appliances that may be susceptible to damage from humidity or moisture during transportation or storage.

Recyclability and Sustainability: EPS can be recycled, contributing to sustainable packaging practices. Many appliance manufacturers are adopting eco-friendly packaging solutions, and EPS aligns with these efforts by being recyclable and having a lower environmental impact compared to some alternatives.

In summary, EPS is a preferred material for appliance packaging due to its ability to offer customized protection, insulation, and shock absorption. Its versatility and eco-friendly characteristics make it a practical choice for ensuring the safe and secure transportation of various appliances.

EPS Applications for Consumer Products

Expanded Polystyrene (EPS) is a versatile material widely used in the manufacturing of consumer products due to its lightweight, insulating, and protective properties. Here are some common applications of EPS in consumer products:

Packaging: EPS is extensively used for packaging fragile and delicate items such as electronics, appliances, glassware, and other sensitive products. Its excellent shock-absorbing capabilities help protect goods during transportation, reducing the risk of damage.

Food Packaging: EPS is commonly employed in the food industry for packaging perishable items. Its insulating properties make it suitable for containers and trays to keep food products fresh and maintain the desired temperature during storage and transport.

Coolers and Insulated Boxes: EPS foam is a popular choice for manufacturing coolers and insulated boxes. Its thermal insulation properties help keep beverages, food, and pharmaceutical products cold or hot for an extended period, making it ideal for outdoor activities and transportation.

Protective Packaging Inserts: EPS can be molded into custom shapes to create protective inserts for items like electronics, tools, and delicate equipment. These inserts securely hold the product in place during transit, minimizing the risk of damage.

Home Appliance Components: EPS is used in the production of various components for home appliances, such as refrigerator insulation, air conditioner housings, and protective casings. Its lightweight nature contributes to the overall efficiency of these appliances.

Toys and Games: EPS is utilized in the toy industry for manufacturing lightweight and durable toys. The material’s versatility allows for the creation of complex shapes, providing designers with flexibility in creating safe and enjoyable play items.

Disposable Plates and Cups: In the foodservice industry, EPS is often used to manufacture disposable plates, cups, and food containers. Its insulating properties help keep hot foods hot and cold foods cold, providing convenience for consumers.

Arts and Crafts Materials: EPS foam sheets and shapes are popular materials for arts and crafts projects. Their lightweight and easy-to-cut nature make them suitable for creating sculptures, models, and other creative endeavors.

Cushioning for Furniture: EPS can be used as cushioning material in furniture, providing a lightweight and comfortable padding for items like seat cushions and pillows.

Medical Packaging: EPS is employed in the medical industry for packaging sensitive medical equipment and supplies. Its shock-absorbing properties help protect delicate instruments during transportation.

Construction Forms and Shapes: EPS is used in the construction industry to create forms and shapes for architectural elements, such as decorative moldings, columns, and facades. Its lightweight and moldable characteristics make it a cost-effective solution for various design applications.

In summary, EPS finds widespread use in consumer products due to its versatility, insulating properties, and ability to provide protection and cushioning. Its applications range from packaging solutions to various everyday items that enhance convenience, safety, and functionality for consumers.

EPS Applications for Horticulture

Expanded Polystyrene (EPS) has several applications in horticulture, offering practical and efficient solutions for various aspects of plant cultivation. Here are some common uses of EPS in horticulture:

Seed Trays and Germination Trays: EPS is often used to manufacture seed trays and germination trays. Its lightweight nature makes it easy to handle, and the insulation properties of EPS help maintain consistent temperatures for seed germination.

Plant Propagation: EPS foam can be shaped into rooting cubes or blocks for plant propagation. These cubes provide a stable environment for the early stages of plant growth and can be easily transplanted into larger containers or directly into the ground.

Hydroponic Systems: Hydroponic systems, which involve growing plants without soil, often use EPS components. Floating rafts and containers made from EPS can provide buoyancy and support for plants while allowing for efficient nutrient delivery in hydroponic setups.

Insulation for Greenhouses: EPS panels are used for insulation in greenhouse construction. These panels help regulate temperature and conserve energy by minimizing heat loss during colder seasons and reducing heat gain in warmer weather, creating an optimal environment for plant growth.

Mulching: EPS sheets or beads can be used as a mulching material around plants. This helps in retaining soil moisture, suppressing weed growth, and providing insulation to the soil, especially in regions with extreme temperatures.

Protective Packaging for Plants: EPS is utilized in the packaging of delicate plants during transportation. Its cushioning properties help prevent damage to plants during transit, ensuring they arrive at their destination in good condition.

Pots and Containers: EPS containers are lightweight and can be used as plant pots. They are particularly useful for large plants where weight may be a concern. EPS pots also provide insulation to the roots, protecting plants from extreme temperature variations.

Landscaping and Topography: Shaped EPS foam can be used for creating artificial landscapes, such as hills and contours, in garden designs. It is a lightweight alternative to traditional materials and allows for creative and flexible landscaping solutions.

Aquaponics: In aquaponic systems, EPS can be used in the construction of floating rafts that support plants. These rafts float on water, allowing plants to absorb nutrients from the aquatic environment while helping to purify the water for fish.

Cold Storage for Harvested Produce: EPS coolers and containers are used for storing harvested fruits and vegetables. The insulation properties of EPS help maintain the required temperature, extending the shelf life of perishable produce.

In horticulture, EPS proves to be a versatile material, contributing to the efficiency, sustainability, and protection of plants throughout various stages of cultivation and distribution.

EPS Applications for Packaging

Expanded Polystyrene (EPS) is widely used in the packaging industry due to its excellent protective and insulating properties. Its versatility makes it suitable for a range of packaging applications, offering benefits such as lightweight construction, shock absorption, and thermal insulation. Here are some common applications of EPS in packaging:

Protective Packaging: EPS is commonly used as protective packaging material for fragile and delicate items. It is molded or cut into custom shapes to securely cradle and protect items during shipping and handling. This is particularly crucial for products like electronics, glassware, and sensitive equipment.

Food Packaging: EPS is used in the food industry for packaging perishable goods. Its insulating properties help maintain temperature, keeping food items cool or warm during transportation. EPS coolers are often used for shipping temperature-sensitive items like fresh produce, seafood, and pharmaceuticals.

Insulated Shipping Containers: EPS foam is utilized in the construction of insulated shipping containers. These containers are employed for transporting goods that require temperature control, such as pharmaceuticals, vaccines, and certain food products. The insulating nature of EPS helps maintain the desired temperature inside the container.

Consumer Electronics Packaging: Many consumer electronics, including TVs, computers, and appliances, are packaged using EPS. The foam provides a cushioning effect, protecting the products from impact and vibrations during transit. Additionally, its lightweight nature minimizes the overall package weight.

Automotive Parts Packaging: EPS is used to protect and package automotive parts during shipping. Its shock-absorbing capabilities ensure that delicate components reach their destination without damage. It is often used as custom-fit inserts to secure specific parts within packaging.

Medical Equipment Packaging: The medical industry utilizes EPS for packaging sensitive and expensive medical equipment. The foam’s ability to absorb shocks and vibrations helps safeguard delicate instruments during transportation, ensuring they arrive in proper working condition.

Construction Material Packaging: EPS is used for packaging and protecting construction materials such as glass panels, ceramic tiles, and other breakable items. Its lightweight nature reduces the overall weight of the packaging while providing effective protection.

Wine and Beverage Packaging: EPS is employed in the packaging of wine and other beverages. It acts as an insulating material in bottle shippers, helping to regulate temperature during transportation and prevent breakage.

E-commerce Packaging: With the rise of online shopping, EPS has become a popular choice for packaging fragile items sold through e-commerce platforms. Its customizable and protective nature ensures that products reach customers in optimal condition.

In summary, EPS is a versatile material widely used in packaging applications, offering protective and insulating qualities that make it valuable across various industries. Its ability to be molded into different shapes and sizes makes it suitable for creating tailored packaging solutions for a wide range of products.

EPS for Panel Applications

Expanded Polystyrene (EPS) is commonly used in panel applications across various industries due to its lightweight, insulating, and cost-effective properties. These panels, often molded or fabricated to specific dimensions, find applications in different sectors for diverse purposes. Here are some common uses of EPS in panel applications:

Building and Construction Panels: EPS panels are widely employed in the construction industry for insulation purposes. These panels, known as EPS insulation boards, are used in walls, roofs, and floors to enhance thermal insulation. They contribute to energy efficiency in buildings by reducing heat transfer.

Structural Insulated Panels (SIPs): EPS is a key component in Structural Insulated Panels, which are prefabricated panels used in building construction. SIPs consist of an EPS core sandwiched between oriented strand board (OSB) or other rigid facing materials. These panels offer excellent insulation and structural strength, making them popular for residential and commercial construction.

Cold Storage Panels: EPS panels are used in the construction of cold storage facilities, such as refrigerated warehouses and walk-in freezers. The insulating properties of EPS help maintain low temperatures, ensuring the preservation of perishable goods.

Roofing Panels: EPS panels are utilized as roofing materials, providing insulation and structural support. These panels are lightweight, making them easy to handle during installation, and they contribute to energy efficiency by reducing heat transfer.

Facade and Cladding Panels: EPS panels are employed in the construction of building facades and cladding systems. These panels enhance the aesthetic appeal of structures while also providing insulation. The lightweight nature of EPS makes it a convenient choice for exterior applications.

Automotive Panels: In the automotive industry, EPS panels are used for various purposes. They can be part of interior panels, contributing to sound insulation and overall comfort. Additionally, EPS is utilized in the construction of lightweight panels for certain vehicle components.

Stage and Set Design Panels: EPS panels are popular in the entertainment industry for creating lightweight and easily customizable stage and set designs. The panels can be carved or shaped to achieve specific artistic and structural requirements.

Exhibition and Display Panels: EPS panels are used in the creation of exhibition booths, display walls, and signage. Their lightweight nature makes them easy to transport and set up, while also providing a versatile surface for graphics and branding.

Marine Panels: Due to its buoyancy and resistance to water absorption, EPS is used in marine applications. It is integrated into panels for boat construction, providing both structural support and flotation.

Packaging Inserts for Panels: EPS is often used as packaging material for protecting delicate and sensitive panels during transportation. Custom-fit EPS inserts provide cushioning and prevent damage during shipping.

In summary, EPS panels are utilized in a wide range of applications, spanning construction, automotive, entertainment, and other industries, owing to their lightweight, insulating, and versatile characteristics.

Final Thoughts

Expanded Polystyrene (EPS) stands out as a well-established insulation material, finding diverse applications such as in lightweight concrete (LWC), decorative molding, backfilling, and as a core in building panels. Its versatility extends to use with both combustible and noncombustible materials.

This lightweight yet robust foam exhibits commendable thermal insulation, impact resistance, and load-bearing capacity at minimal weight. It serves as an effective water and vapor barrier, ensures air tightness for controlled environments, and boasts a lengthy lifespan with low maintenance requirements, facilitating fast and cost-effective construction.

This article underscores the practicality and advantages of employing EPS as an insulator that fulfills various insulation needs in the building design process, including addressing concerns related to fire safety. The incorporation of flame retardant grade EPS becomes crucial to adhere to fire safety regulations and mitigate flammability and flame spread risks on the EPS surface.

Consequently, EPS is integrated into building designs in collaboration with other fire-resistant materials, ensuring a comprehensive approach to meeting safety standards.