EPS (Expanded Polystyrene) packaging is a cornerstone of modern logistics, offering unparalleled protection for a vast array of products. From delicate electronics to perishable goods, its lightweight yet robust nature ensures items arrive at their destination safe and sound. In this blog, we’ll explore the diverse world of EPS, highlighting how its adaptability makes it an ideal choice for businesses across various industries.

Whether you require a snug, custom-fit solution for a unique product or a readily available standard shape for general use, EPS delivers. This article will delve into the distinct advantages and applications of both custom-molded and standard EPS packaging, helping you understand which option best suits your specific needs for efficiency, protection, and cost-effectiveness.

What is EPS in Packaging?

Expanded Polystyrene (EPS) in packaging refers to a lightweight, rigid, closed-cell foam material that is widely used for protecting a diverse range of products during transport and storage. It’s essentially polystyrene beads that have been expanded using steam, creating a material that is approximately 98% air.

This unique composition gives EPS several key characteristics that make it highly effective for packaging:

- Versatile and Customizable: EPS can be easily molded into custom shapes to perfectly fit products, or produced in standard blocks and sheets for general cushioning.

- Exceptional Shock Absorption: Its cellular structure allows it to absorb significant impact energy, protecting fragile items from breakage and damage during transit.

- Excellent Thermal Insulation: The high air content provides superb insulation, making it ideal for packaging temperature-sensitive goods like food, pharmaceuticals, and medical supplies.

- Lightweight and Cost-Effective: Being mostly air, EPS is incredibly light, which helps reduce shipping costs and overall material usage.

- Moisture and Chemical Resistance: It is largely impervious to water and many chemicals, ensuring the integrity of packaged contents even in challenging environments.

EPS Packaging Solutions

When it comes to safeguarding products during shipping and handling, Expanded Polystyrene (EPS) packaging stands out as a highly effective and versatile choice. Its exceptional shock absorption, thermal insulation, and lightweight properties make it an ideal material for a diverse range of applications. From delicate electronics to fresh produce, EPS solutions are engineered to ensure items arrive at their destination intact and in optimal condition, minimizing costly damages and enhancing customer satisfaction.

The adaptability of EPS allows for a wide array of packaging designs, catering to virtually any product requirement. Whether you need custom-made protective inserts that perfectly cradle a fragile item or standard-sized blocks for general cushioning, EPS delivers reliable performance. This comprehensive list explores 15 distinct EPS packaging solutions, showcasing the breadth of its capabilities and how it contributes to secure and efficient logistics across various industries.

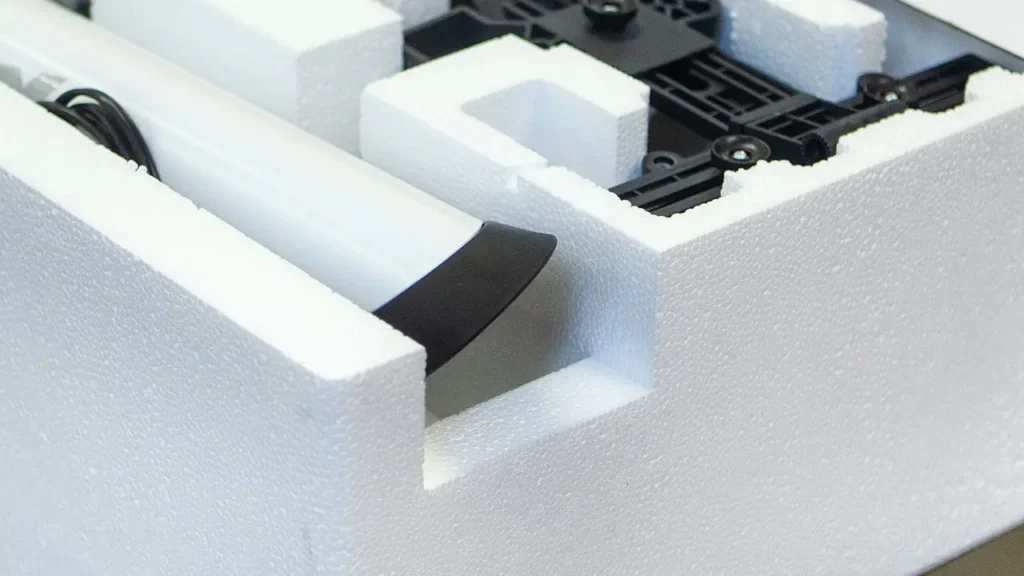

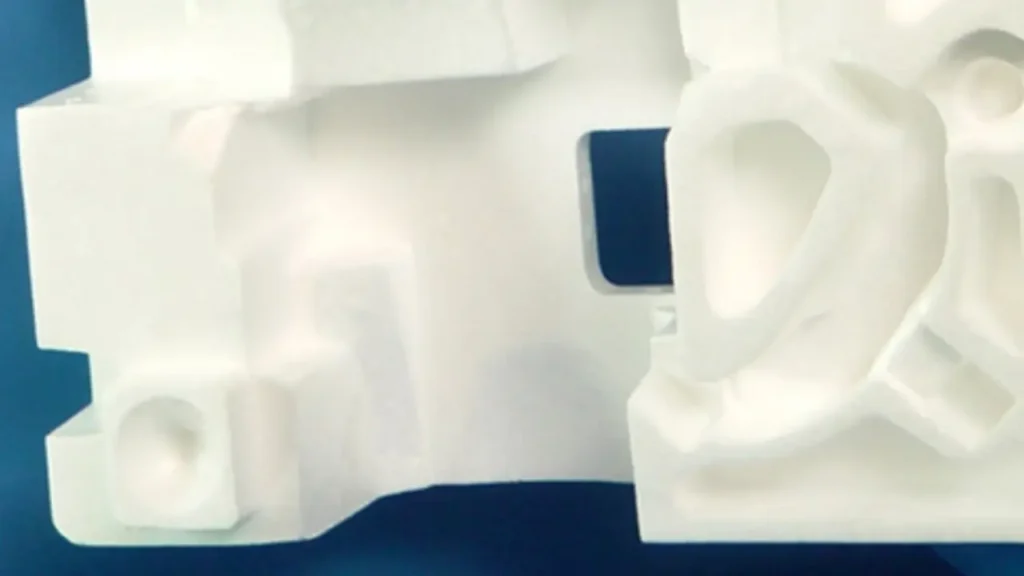

1. Custom Molded EPS Inserts

Custom molded EPS inserts are designed to precisely fit and cushion specific products, offering superior protection against impacts and vibrations. These inserts are created by molding EPS beads into a shape that perfectly matches the contours of the item being packaged. This snug fit ensures that the product remains stationary within the packaging, preventing movement that could lead to damage during transit.

Beyond just protection, custom molded inserts can also be designed with features like finger grips for easy removal or channels for cables, enhancing the overall user experience. This tailored approach makes them ideal for packaging delicate electronics, medical devices, glassware, and other high-value or fragile goods where a perfect fit is paramount for safety and presentation.

2. EPS Foam Corners

EPS foam corners provide robust protection for the vulnerable edges and corners of products, which are often the first points of impact during drops or bumps. These pre-formed corner pieces are easily applied to items like furniture, mirrors, picture frames, and appliances, offering a strong barrier against damage. They are a simple yet effective way to reinforce packaging without adding significant weight or bulk.

Their versatility allows them to be used in conjunction with other packaging materials like cardboard boxes or stretch film, creating a comprehensive protective solution. EPS foam corners are particularly useful for irregularly shaped items or products that require focused protection on their most susceptible areas, ensuring safe delivery from warehouse to customer.

3. EPS Coolers and Insulated Containers

EPS coolers and insulated containers are specifically designed for the safe transportation of temperature-sensitive goods. Their exceptional thermal insulation properties maintain consistent internal temperatures, keeping perishable items like food, pharmaceuticals, and biological samples cold or warm for extended periods. This makes them indispensable for industries requiring strict temperature control throughout the supply chain.

These containers come in various sizes and designs, from small personal coolers to large shipping boxes, and can be used with ice packs or dry ice for enhanced temperature regulation. Their lightweight nature also contributes to lower shipping costs, making them an efficient and reliable choice for maintaining product integrity during transit.

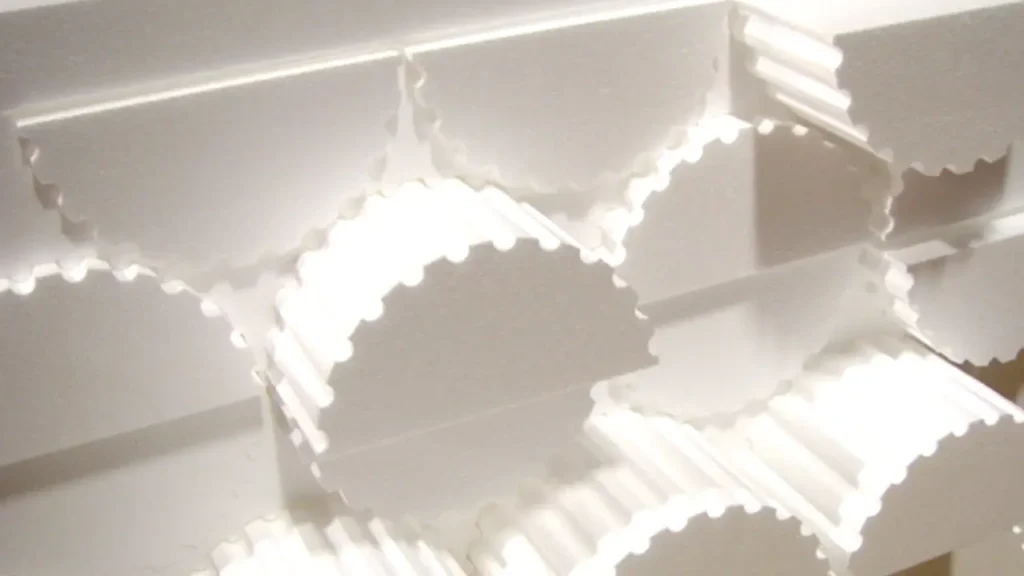

4. EPS Blocks and Sheets

EPS blocks and sheets are fundamental forms of EPS packaging, offering versatile cushioning and void filling solutions. These are large, solid pieces of EPS that can be easily cut, shaped, or layered to provide custom protection for a wide range of products. They are commonly used for general cushioning, bracing items within a larger box, or creating protective layers between stacked goods.

Their simplicity and adaptability make them a cost-effective choice for businesses needing flexible packaging solutions. Whether used as dunnage to fill empty spaces in a carton, as edge protectors, or as base layers for heavy items, EPS blocks and sheets provide dependable impact absorption and support for diverse shipping needs.

5. EPS End Caps

EPS end caps are specially designed protective pieces that fit securely over the ends of long or cylindrical products, offering crucial impact protection. They are commonly used for items such as pipes, rods, fluorescent light tubes, and furniture legs, safeguarding the most vulnerable parts during shipping and handling. Their snug fit prevents axial movement and provides a shock-absorbing buffer.

These end caps are often custom-molded to match specific product dimensions, ensuring a precise and effective protective barrier. They are an efficient solution for preventing dings, scratches, and more significant damage to the extremities of elongated items, making them an essential component in specialized packaging strategies.

6. EPS Panel Insulators

EPS panel insulators are utilized for applications where rigid, lightweight insulation is required, often integrated into larger packaging structures or even building components. While primarily known for construction, they are also used in packaging for products requiring substantial thermal control or structural support. They can form the walls or bases of highly insulated shipping containers.

These panels provide excellent R-value, making them ideal for creating custom insulated boxes or liners for delicate instruments, electronics, or other items sensitive to temperature fluctuations. Their rigidity also adds to the overall structural integrity of the packaging, offering both thermal and impact protection.

7. EPS Geofoam for Void Filling

EPS geofoam, while typically used in civil engineering for lightweight fill, also finds niche applications in packaging for large-scale void filling or as a stable base for very heavy or irregularly shaped items within large crates. It’s essentially very large blocks of EPS used to fill significant empty spaces, providing stable support and reducing the amount of other heavier dunnage materials needed.

In packaging contexts, especially for oversized or unusually shaped industrial components, EPS geofoam can be custom cut to provide a secure, lightweight foundation or brace. This ensures that massive items remain stable during transit, preventing shifting and potential damage, while keeping shipping weights manageable.

8. EPS Fish Boxes

EPS fish boxes are purpose-built containers specifically designed for the hygienic and temperature-controlled transportation of fresh seafood. Their superior insulation properties are crucial for maintaining the chill chain, keeping fish and other seafood fresh from the catch to the consumer. They are leak-proof and designed to prevent contamination, adhering to strict food safety standards.

These boxes are lightweight yet robust enough to withstand the rigors of transit, often featuring drainage holes to manage meltwater from ice. Their ability to preserve freshness and prevent spoilage makes them an indispensable tool for the fishing industry and seafood distributors worldwide.

9. EPS Wine Shippers

EPS wine shippers are specialized packaging solutions designed to securely transport wine bottles, protecting them from breakage and temperature fluctuations. These inserts typically hold individual bottles snugly, preventing movement and absorbing impacts. The excellent insulating properties of EPS also help maintain a stable temperature, crucial for preserving the quality of wine.

Available in various configurations, from single-bottle shippers to multi-bottle packs, these solutions are popular among wineries, distributors, and consumers sending wine as gifts. They offer a reliable and cost-effective way to ensure that delicate wine bottles arrive safely and in optimal condition, regardless of the journey.

10. EPS Fruit and Vegetable Trays

EPS fruit and vegetable trays are commonly used in the agricultural industry to protect produce during transport and display. These trays gently cradle delicate fruits and vegetables, preventing bruising and damage that can occur from direct contact or shifting during transit. Their lightweight nature also helps reduce overall shipping costs.

Beyond protection, EPS trays often provide a clean and appealing presentation for produce in retail settings. Their ability to maintain product integrity, coupled with their hygienic properties, makes them an essential packaging component for ensuring fresh produce reaches consumers in pristine condition.

11. EPS Returnable Packaging

EPS returnable packaging solutions are designed for multiple uses, promoting sustainability and cost efficiency in closed-loop supply chains. These durable containers, often custom-molded, are engineered to withstand repeated handling and transport, reducing the need for single-use packaging materials. They are particularly valuable for inter-company logistics or components within an assembly process.

By investing in returnable EPS packaging, businesses can significantly cut down on waste and long-term packaging expenses. Their robust protective qualities remain consistent over many cycles, making them an environmentally conscious and economically smart choice for businesses with recurring shipping needs.

12. EPS Protective Sleeves

EPS protective sleeves are flexible, expandable mesh-like structures made from EPS that slip over products to provide surface protection against scratches and minor impacts. They are particularly useful for protecting delicate finishes on items like glassware, bottles, machined parts, or painted components. The mesh design allows for breathability while offering a soft, protective layer.

These sleeves are easy to apply and remove, making them an efficient solution for both manufacturers and consumers. They offer a cost-effective way to add an extra layer of defense against superficial damage, ensuring products retain their aesthetic appeal and functional integrity.

13. EPS Display Packaging

EPS display packaging combines product protection with attractive presentation, often featuring custom-molded forms that showcase the item while keeping it secure. This type of packaging is frequently used for electronics, cosmetics, and other retail products where visual appeal is as important as safety during transit. The EPS can be shaped to highlight product features.

Beyond just holding the product, EPS display packaging can also be designed with cut-outs for accessories, product information, or branding elements. It offers a premium unboxing experience for consumers while ensuring the product remains well-protected from manufacturing to the retail shelf.

14. EPS Architectural (as packaging for art/sculptures)

While primarily known for construction, large, EPS architectural foam shapes can serve as highly specialized packaging for oversized or uniquely shaped valuable items, such as artwork, sculptures, or delicate museum exhibits. These are essentially bespoke protective crates or internal cushioning systems made entirely or predominantly of EPS, tailored to the exact dimensions and fragility of the object.

The lightweight nature of EPS significantly reduces shipping weight for massive pieces, while its excellent shock absorption provides unparalleled protection against impact and vibration. This application highlights the ultimate customization potential of EPS, offering a secure and cost-effective solution for transporting invaluable and irreplaceable items.

15. EPS Dunnage and Loose Fill

EPS dunnage, including loose fill peanuts, is a common solution for filling empty spaces within a box, preventing products from shifting during transit. These small, lightweight pieces conform around irregularly shaped items, providing cushioning and absorbing shocks from all directions. They are particularly useful for packaging multiple small items together or for products with unique contours.

While some concerns exist regarding environmental impact, many modern EPS loose fills are made from recycled content or are designed to be recyclable, offering a practical solution for void filling and basic product protection. They provide a cost-effective and efficient way to stabilize contents and prevent damage during shipping.

How to Choose Suitable EPS Packaging?

Choosing the suitable EPS packaging for your product involves carefully assessing several key factors to ensure optimal protection and cost-effectiveness. The right selection safeguards your goods throughout the supply chain, minimizing damage and enhancing customer satisfaction.

Here’s how to choose suitable EPS packaging:

- Cost-Effectiveness and Sustainability: Balance the upfront cost of EPS packaging with its long-term benefits in preventing damage and potential returns. Also, consider the availability of recycling infrastructure for EPS in your region and explore options made from recycled content for enhanced sustainability efforts.

- Product Fragility and Weight: Extremely fragile items, like glassware or sensitive electronics, demand higher-density EPS or custom-molded designs for superior shock absorption. Heavier products also necessitate denser EPS to withstand compression and provide adequate structural support during transit.

- Shipping Conditions and Duration: Consider the journey your product will undertake. If it’s exposed to extreme temperatures, moisture, or significant vibrations, packaging with enhanced thermal insulation and moisture resistance is crucial for maintaining product integrity and preventing spoilage or damage.

- Temperature Sensitivity: For perishable goods, pharmaceuticals, or items requiring strict temperature control, EPS’s excellent insulating properties are vital. Choose specific EPS coolers or insulated containers designed to maintain desired internal temperatures for the required shipping duration.

- Customization vs. Standard Shapes: Evaluate if your product requires a unique, form-fitting solution for maximum protection and presentation. While custom molds offer a perfect fit, standard EPS blocks or sheets can be a more cost-effective option for less delicate or general void-filling needs.

Conclusion

The versatility of EPS packaging, spanning from intricate custom molds to efficient standard shapes, truly underscores its critical role in safeguarding products across countless industries. By understanding the unique benefits of each type, businesses can make informed decisions that optimize protection, reduce transit damage, and ultimately enhance customer satisfaction. The right EPS solution is not just about packaging; it’s about peace of mind.

Ultimately, whether your demand leans towards tailor-made protection for specialized items or the practical utility of readily available forms, EPS offers a reliable, cost-effective answer. Its inherent shock absorption and insulation properties make it an indispensable asset in the supply chain, adapting to an ever-evolving market.

Ready to secure your products with high-quality, dependable EPS packaging? Look no further. You can get wholesale EPS packaging solutions designed to meet your precise requirements directly from our trusted source, Epsole. Partner with us for packaging excellence that ensures your goods arrive intact, every time.