Importing EPS Injection Machine from China

Are you looking for a premium EPS Injection Machine from China? Here we can provide the EPS injection molding machine with high-efficiency and competitive pricing. For more, please feel free to contact us at any time.

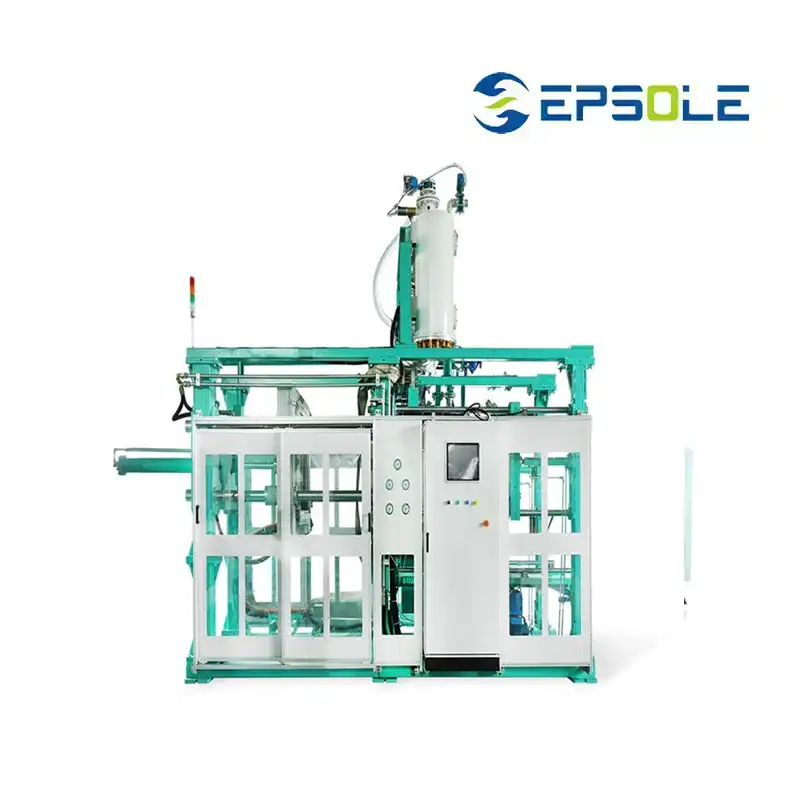

Our EPS Injection Machine

Introducing Our EPS Injection Machine: Precision, Efficiency, and Quality Combined!

Our cutting-edge EPS Injection Machine is engineered to deliver unmatched performance, ensuring precise molding, maximum efficiency, and superior product quality. From intricate designs to large-scale production, our machine is equipped to meet your EPS molding needs with excellence.

Precision Molding: Our EPS injection machine offers precise control over the injection process, ensuring accurate molding of intricate designs and complex shapes with minimal material wastage.

Temperature Regulation: With advanced temperature regulation systems, the machine maintains optimal temperatures throughout the injection cycle, ensuring consistent product quality and reducing the risk of defects.

Automated Operation: The EPS injection machine features automated functions for injection, cooling, and ejection, streamlining the production process and minimizing manual intervention, thereby improving efficiency and productivity.

Material Handling: Equipped with efficient material handling systems, the machine can handle various types of EPS materials, including expanded polystyrene beads, ensuring versatility in production and accommodating diverse manufacturing requirements.

Energy Efficiency: Our EPS injection machine incorporates energy-saving technologies such as efficient heating elements and insulation, reducing energy consumption and operational costs while also contributing to environmental sustainability.

EPS Injection Machine Applications

Packaging Materials

EPS injection machines are commonly used in the production of packaging materials such as foam trays, containers, and protective packaging inserts. These lightweight and versatile products provide excellent cushioning and protection for a wide range of items during shipping and storage.

Insulation Panel

EPS injection machines are utilized to manufacture EPS insulation panels used in construction applications. These panels offer superior thermal insulation properties, helping to reduce energy consumption and maintain comfortable indoor temperatures. EPS insulation panels are widely used in residential, commercial, and industrial buildings.

Decorative Items

EPS injection machines are also employed to create decorative items such as architectural moldings, signage, sculptures, and themed props. EPS's lightweight nature, combined with the ability to achieve intricate designs, makes it an ideal material for producing decorative elements used in various industries, including event planning, retail, and entertainment.

Why Choose Our EPS Injection Machine

Superior Quality: Our EPS injection machine is built with precision engineering and high-quality materials, ensuring durability, reliability, and consistent performance over time. You can trust our machine to deliver top-notch results with every mold.

Advanced Technology: Incorporating the latest advancements in injection molding technology, our EPS machine offers cutting-edge features such as precise temperature control, automated operation, and energy-efficient systems. Stay ahead of the curve with our innovative solutions.

Versatility: Whether you’re producing small, intricate parts or large-scale components, our EPS injection machine offers versatility to meet a wide range of manufacturing needs. From custom designs to standardized products, our machine can handle it all.

Efficiency and Productivity: With streamlined processes, automated functions, and optimized energy consumption, our EPS injection machine maximizes efficiency and productivity in your production line. Get more done in less time without compromising on quality.

Comprehensive Support: From installation and training to ongoing maintenance and support, we’re committed to providing comprehensive assistance every step of the way. Our team of experts is here to ensure that your experience with our EPS injection machine is smooth and successful.

FAQs about EPS Injection Machine

What is an EPS injection machine?

An EPS injection machine is a specialized equipment used in the manufacturing process of expanded polystyrene (EPS) products. It injects molten EPS material into molds to create various shapes and forms.

How does an EPS injection machine work?

The EPS injection machine works by heating EPS beads to their melting point and then injecting the molten material into a mold under pressure. After the material cools and solidifies, the mold is opened, and the finished product is ejected.

What types of products can be made with an EPS injection machine?

An EPS injection machine can produce a wide range of products, including packaging materials, insulation panels, construction components, decorative items, and more.

What are the advantages of using an EPS injection machine?

Some advantages of using an EPS injection machine include precise molding capabilities, high production efficiency, versatility in product design, and the ability to create lightweight yet durable products.

How can I choose the right EPS injection machine for my needs?

When selecting an EPS injection machine, consider factors such as production volume, product specifications, required features (such as automation and temperature control), budget, and supplier reputation.

What maintenance is required for an EPS injection machine?

Regular maintenance is essential to ensure the optimal performance of an EPS injection machine. This may include cleaning, lubrication, inspection of components, and calibration of systems. It’s also important to follow manufacturer recommendations for maintenance schedules and procedures.

Can an EPS injection machine be customized for specific production requirements?

Yes, many EPS injection machine manufacturers offer customization options to tailor the machine to specific production needs. This may include modifications to the injection system, mold configuration, control systems, and more.

How can I get support and assistance with my EPS injection machine?

Most EPS injection machine suppliers provide comprehensive support services, including installation assistance, training for operators, troubleshooting guidance, and ongoing technical support. Contact your machine supplier for assistance as needed.