Importing EPS Hot Melting Recycling Machine from China

Revolutionize your recycling process with the EPS Hot Melting Recycling Machine from China! Say goodbye to waste and hello to sustainability. Efficiently transform EPS waste into reusable material. Don’t miss out on this opportunity to enhance your environmental efforts. Contact us now to import your desired EPS hot melting recycle machine and make a lasting impact!

Our EPS Hot Melting Recycling Machine

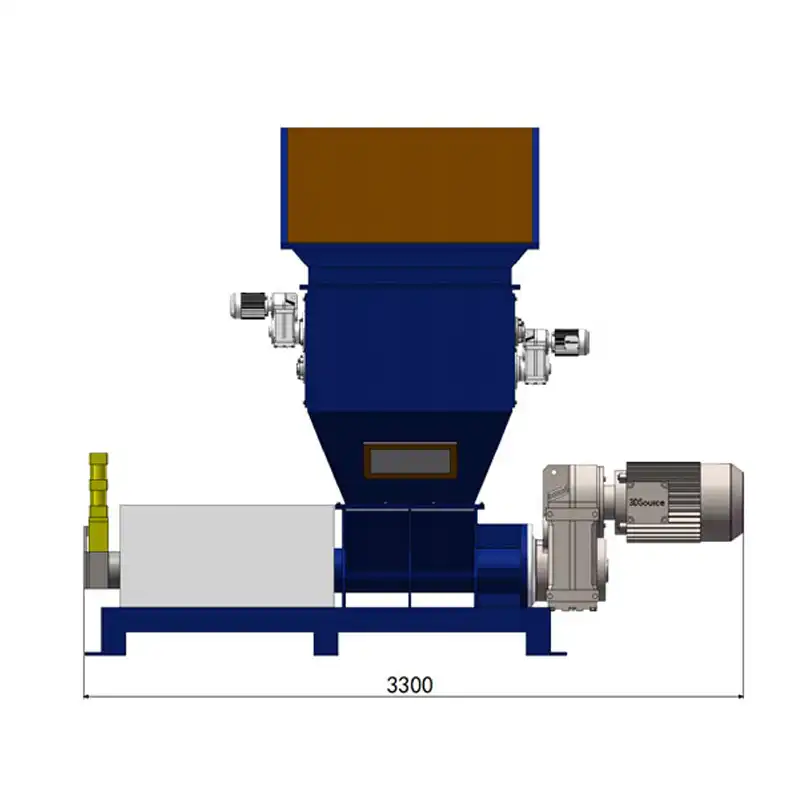

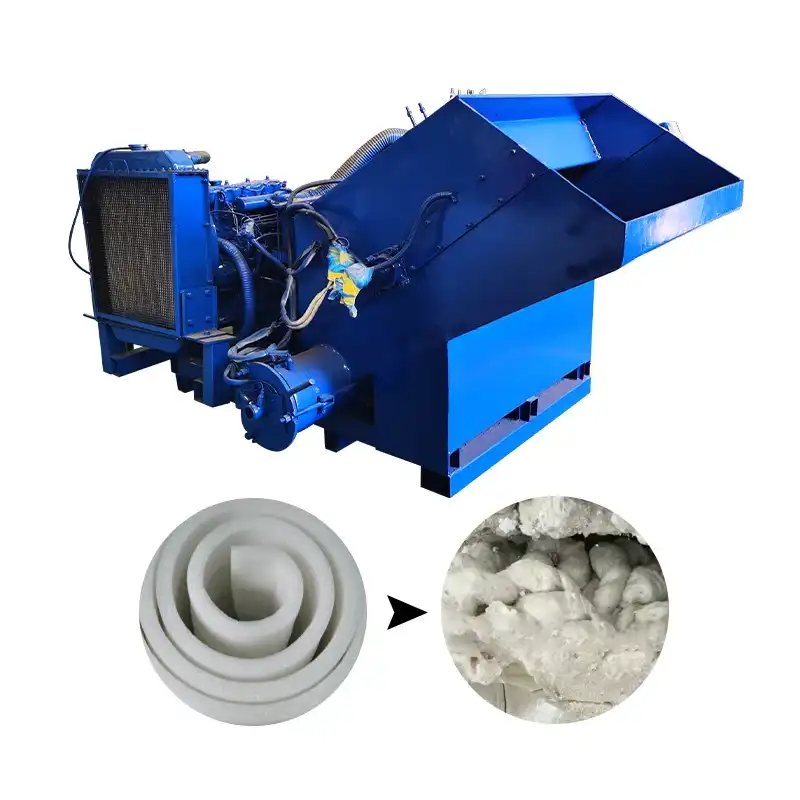

EPS hot melting recycling machine, also named EPS hot melting machine, EPS melting machine, equipped with a crushing mechanism to crush the waste foam.

Upgrade your recycling capabilities with our EPS Hot Melting Recycling Machine from today! Convert EPS waste into reusable material efficiently. Take the first step towards a sustainable future. Contact us today to import your desired EPS hot melting recycling machine and revolutionize your recycling process now.

We are the leading EPS recycling machine factory, to manufacture all qualified EPS hot melting recycling machine with high efficiency and high performance.

-

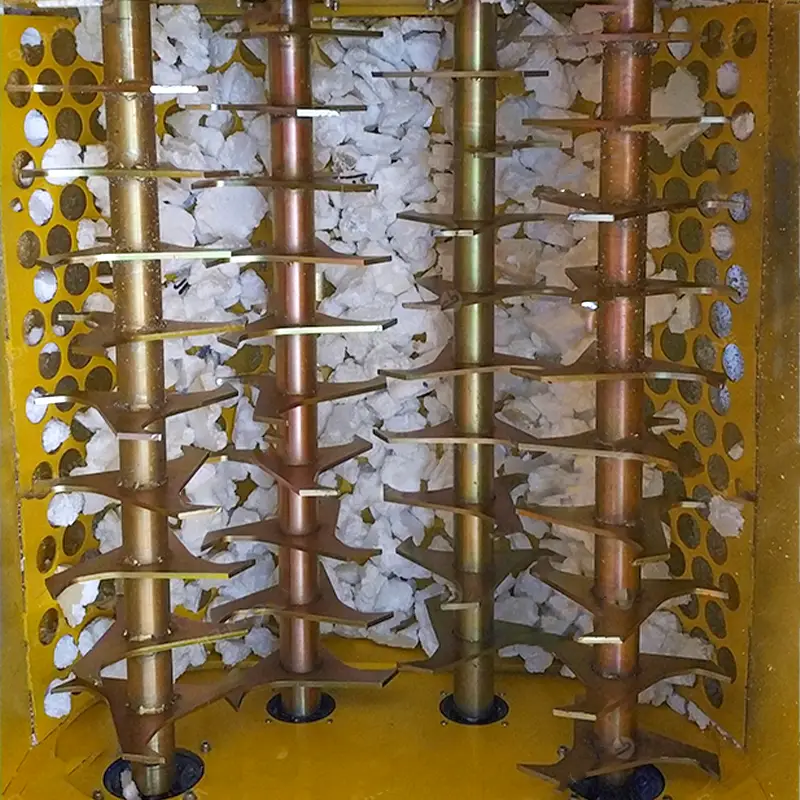

Crushing Mechanism: Efficiently crushes waste foam, facilitating the melting process for easier extrusion.

-

Melting and Extrusion: Melts the crushed foam and extrudes it using screws to create PS blocks, reducing waste volume significantly.

-

Space-saving Design: Greatly compresses the volume of waste foam, saving valuable stacking space.

-

Profitable Output: PS blocks produced can be sold directly on the market, offering a substantial profit margin.

-

Versatile Application: Widely used in foam factories, agricultural trade markets, and waste recycling stations, catering to diverse industrial needs.

Special Features

Powerful Motor

Equipped with a 15KW-class 6 motor and SPB-4 type heavy pulley, ensuring a large torque output for smooth operation.

Precise Temperature Control

Features a two-stage temperature control zone and special screw design, ensuring extruded material is white and clear with minimal smoke and dust, preventing jamming.

Advanced Crushing Design

Incorporates an advanced crushing design with side bearings, significantly reducing foam dust and hopper leakage, improving overall efficiency and cleanliness.

EPS Hot Melting Recycling Machine Applications

Foam Manufacturing Facilities

Ideal for recycling waste foam generated during the manufacturing process, reducing waste and maximizing material utilization.

Packaging Industries

Suitable for recycling foam packaging materials commonly used in shipping and logistics, promoting sustainability and cost-efficiency.

Automotive Industry

Beneficial for recycling foam materials used in vehicle components and packaging, reducing waste and supporting sustainable automotive manufacturing practices.

Furniture Production

Essential for recycling foam cushioning and packaging materials used in furniture manufacturing, minimizing waste and supporting eco-friendly furniture production processes.

Food and Beverage Industry

Valuable for recycling foam packaging materials used for food and beverage products, ensuring sustainable packaging solutions and reducing environmental footprint.

Aerospace and Aviation

Essential for recycling foam materials used in aircraft insulation and packaging, contributing to sustainable practices in the aerospace sector.

Why Choose Our EPS Hot Melting Recycling Machine

-

Simple Operation: Say goodbye to complicated operation process. Our EPS hot melting machine offers easy operation, making recycling a breeze.

-

Space-Saving Design: Tight on space? No problem. Our machine is compact and doesn’t take up much room, allowing you to maximize your workspace.

-

Easy Transportation of Finished Products: With our EPS hot melting machine, transporting finished products is a cinch. Save time and effort with hassle-free transportation.

-

Pollution-Free Operation: Protecting the environment is paramount. Our machine operates without causing pollution, ensuring a cleaner and greener recycling process.

-

Complete Waste Reutilization: Waste plastic doesn’t have to be a burden. Our machine completely reuses waste plastic, turning it into valuable material and generating significant benefits.

FAQs about EPS Hot Melting Recycling Machine

What is an EPS Hot Melting Recycling Machine?

The EPS Hot Melting Recycling Machine is a specialized equipment designed to recycle Expanded Polystyrene (EPS) foam waste by melting it down and extruding it into reusable PS blocks.

How does EPS hot melting recycling machine work?

The machine is equipped with a crushing mechanism to crush the waste foam, which is then melted and extruded using screws to form PS blocks. This process greatly reduces the volume of foam waste and creates reusable material.

What are the key features of the machine?

Some key features include a powerful motor for smooth operation, precise temperature control zones to ensure high-quality output, and an advanced crushing design to minimize dust and leakage.

What are the applications of the EPS Hot Melting Recycling Machine?

The machine has various applications across industries such as foam manufacturing, packaging, construction, electronics, automotive, healthcare, and more.

What are the benefits of using this machine?

Using the EPS Hot Melting Recycling Machine helps businesses reduce waste volume, minimize environmental impact, and generate additional revenue by selling the recycled PS blocks.

Is the machine easy to operate?

Yes, the machine is designed for ease of operation, with simple controls and intuitive mechanisms.

Is the machine environmentally friendly?

Yes, the machine operates without causing pollution and helps prevent secondary pollution of the environment by efficiently recycling EPS foam waste.

What types of foam materials can the machine process?

The EPS Hot Melting Recycling Machine is capable of processing various types of foam materials, including Expanded Polystyrene (EPS), also known as Styrofoam, and similar foam products.

Can the machine be customized to suit specific recycling needs?

Yes, the machine can be customized to accommodate specific requirements, such as volume of foam waste, desired output, and operational preferences, ensuring optimal performance for different applications.

What is the maintenance requirement for the EPS Hot Melting Recycling Machine?

The machine typically requires regular maintenance to ensure smooth operation and longevity. Maintenance tasks may include cleaning, lubrication, and inspection of components. Detailed maintenance instructions and schedules are provided by the manufacturer to facilitate proper upkeep.