Importing EPS Foam Block Machine from China

Are you in need of an EPS foam recycling machine for your project? Epsole, a top EPS machine manufacturer based in China, can provide you with a high-quality machine tailored to your specifications. Feel free to reach out to us for a quote and further information.

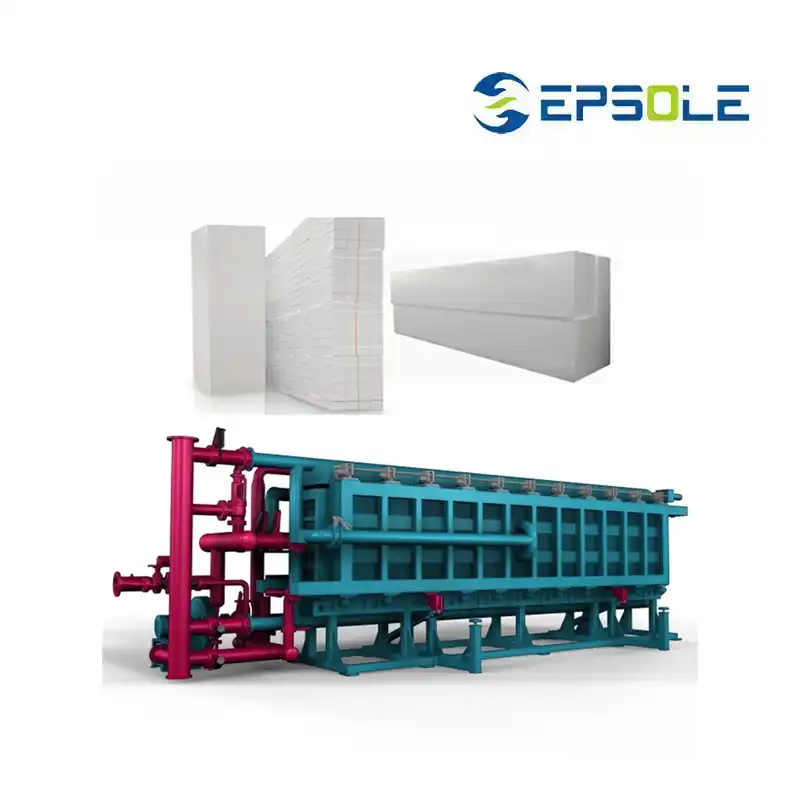

Our EPS Foam Block Machine

EPS foam block machine, also related to EPS foam moulding machine, EPS foam recycling machine, is a machine designed to foam EPS blocks.

Efficiency: EPS foam block machines can produce large volumes of foam blocks quickly and efficiently, helping businesses meet demand and increase productivity.

Cost-effectiveness: These machines streamline the production process, reducing labor costs and minimizing material waste, thus improving overall cost-effectiveness.

Customization: With adjustable settings and molds, EPS foam block machines allow for the production of foam blocks in various sizes, densities, and shapes, catering to specific customer requirements.

Insulation properties: EPS foam blocks produced by these machines are excellent insulators, providing thermal insulation for buildings and reducing energy consumption for heating and cooling.

Lightweight: EPS foam blocks are lightweight yet sturdy, making them easy to handle during transportation and installation, reducing logistical complexities and costs.

EPS Foam Block Machine Applications

Packaging

EPS foam blocks are widely used for packaging fragile items such as electronics, appliances, glassware, and furniture. The lightweight and shock-absorbing properties of EPS foam make it an ideal choice for protecting goods during shipping and handling.

Construction

EPS foam blocks are used in construction for insulation, filling voids, and creating lightweight structural elements. They are commonly used in insulated concrete forms (ICFs), insulated panels, and roof insulation systems to improve energy efficiency and thermal performance of buildings.

Insulation

EPS foam blocks are used as insulation material in a wide range of applications, including walls, roofs, floors, and refrigeration units. The low thermal conductivity of EPS foam helps to reduce heat transfer, improve energy efficiency, and maintain comfortable indoor temperatures.

Why Choose Our EPS Recycling Machine

Efficiency: Our EPS recycling machine is designed for maximum efficiency, ensuring rapid processing of expanded polystyrene (EPS) waste into reusable materials. With advanced technology and innovative features, our machine streamlines the recycling process, saving you time and resources.

Versatility: Our EPS recycling machine is versatile and capable of handling various types of EPS waste, including packaging materials, insulation boards, and foam products. Whether you’re recycling EPS from construction sites, manufacturing facilities, or retail operations, our machine delivers consistent and reliable performance.

Quality Output: We prioritize the quality of recycled EPS materials produced by our machine. Through precision engineering and high-quality components, we ensure that the recycled EPS meets industry standards and customer expectations. You can trust our machine to deliver superior recycled materials for your specific applications.

Sustainability: Choosing our EPS recycling machine demonstrates your commitment to sustainability and environmental responsibility. By recycling EPS waste with our machine, you contribute to the reduction of plastic pollution, conserve natural resources, and promote a circular economy. Together, we can make a positive impact on the planet.

Support and Service: When you choose our EPS recycling machine, you gain access to dedicated support and service from our team of experts. From installation and training to maintenance and troubleshooting, we’re here to help you maximize the performance and longevity of your recycling equipment.

FAQs

What is an EPS recycling machine?

An EPS recycling machine is a specialized piece of equipment designed to process and recycle expanded polystyrene (EPS) foam waste into reusable materials. It typically involves crushing, melting, and densifying EPS foam to reduce its volume and facilitate recycling.

How does an EPS recycling machine work?

EPS recycling machines work by first breaking down EPS foam waste into smaller pieces through a crushing mechanism. The crushed EPS is then melted and densified using heat and pressure, transforming it into denser blocks or pellets that can be reused in various applications.

What types of EPS waste can be recycled with an EPS recycling machine?

EPS recycling machines can process various types of EPS waste, including packaging materials, insulation boards, foam packaging, and manufacturing scraps. They are versatile and adaptable to different forms of EPS foam waste.

What are the benefits of using an EPS recycling machine?

Using an EPS recycling machine offers several benefits, including reducing EPS waste sent to landfills, conserving natural resources, lowering carbon emissions, and promoting sustainability. It also helps businesses save on waste disposal costs and enhances their environmental stewardship.

Is EPS recycling environmentally friendly?

Yes, EPS recycling is environmentally friendly because it diverts EPS waste from landfills, where it can take up valuable space and contribute to pollution. Recycling EPS reduces the need for virgin EPS production, conserving energy and resources in the process.

Are EPS recycling machines easy to operate?

Most modern EPS recycling machines are designed with user-friendly interfaces and intuitive controls, making them relatively easy to operate. However, proper training and maintenance are essential to ensure optimal performance and safety.

Can recycled EPS materials be used in new products?

Yes, recycled EPS materials produced by EPS recycling machines can be used in various applications, including packaging, insulation, construction materials, and consumer products. Recycled EPS offers similar performance characteristics to virgin EPS while reducing environmental impact.

What is the lifespan of an EPS recycling machine?

The lifespan of an EPS recycling machine depends on factors such as usage, maintenance, and quality of components. With regular maintenance and proper care, EPS recycling machines can last for many years, providing a reliable and sustainable solution for EPS waste management.

Is EPS recycling economically viable?

Yes, EPS recycling can be economically viable, especially when considering the cost savings from reduced waste disposal fees and potential revenue generation from selling recycled EPS materials. Investing in an EPS recycling machine can lead to long-term financial benefits for businesses and municipalities.

Are there any regulations or standards for EPS recycling?

Yes, many regions have regulations and standards in place to promote EPS recycling and reduce EPS waste. These may include mandates for recycling certain types of EPS materials, requirements for recycling facilities to meet certain environmental standards, and incentives for businesses to implement EPS recycling programs. It’s essential to be aware of and comply with relevant regulations and standards when engaging in EPS recycling activities.