Expanded Polypropylene (EPP) and Expanded Polyolefin (EPO) are both closed-cell bead foams utilized in various applications, yet they possess distinct characteristics. While both offer lightweighting and energy absorption, their base polymers and manufacturing processes lead to differences in properties like stiffness, impact resistance, and temperature performance. Understanding these nuances is key to selecting the optimal material for a specific need.

This blog post will delve into the comparative analysis of EPP and EPO foams, highlighting their key differences in terms of material properties, typical applications, and performance characteristics. By exploring these distinctions, you’ll gain a clearer understanding of when to choose one over the other for your engineering and design requirements.

What is EPP Foam?

EPP foam, short for Expanded Polypropylene, is a highly adaptable closed-cell bead foam renowned for its exceptional properties. These include outstanding energy absorption, resilience to multiple impacts, effective thermal insulation, buoyancy, and resistance to water and chemicals. Additionally, EPP boasts an exceptionally high strength-to-weight ratio and is 100% recyclable, making it a sustainable choice.

It can be manufactured in a wide range of densities, from 15 to 200 grams per liter, which are then transformed through molding into densities ranging from 18 to 260 grams per liter. The steam chest molding process fuses individual beads into the final product form, resulting in a sturdy yet lightweight structure.

EPP Foam Manufacturing Process

The manufacturing process of EPP (Expanded Polypropylene) involves several steps to achieve the desired foam product:

Alright, here’s the revised response with “Step” prepended to each subtitle:

Expanded Polypropylene (EPP) foam’s exceptional properties are a direct result of its carefully controlled manufacturing process. This multi-stage process transforms raw polypropylene resin into the lightweight, resilient material we see in countless applications. Understanding each step provides insight into how EPP achieves its unique characteristics.

Step 1: Pre-Expansion

The initial stage involves the pre-expansion of raw polypropylene resin beads. These small pellets are introduced into a pre-expander, a vessel where they are exposed to steam and air. This causes the blowing agent, typically pentane, contained within the beads to vaporize, leading the polypropylene to soften and expand significantly. The degree of expansion is carefully controlled at this stage to achieve the desired density of the final EPP foam.

Step 2: Conditioning

Following pre-expansion, the EPP beads undergo a conditioning or maturation phase. This typically occurs in large silos where the expanded beads are allowed to cool and stabilize. During this time, air diffuses into the closed cells created during pre-expansion, and any residual blowing agent dissipates. This conditioning process is crucial for ensuring the dimensional stability and consistent properties of the final molded EPP parts.

Step 3: Molding

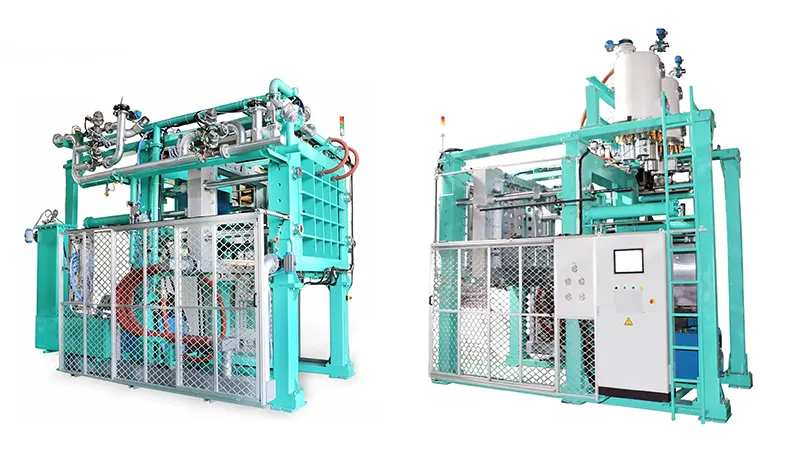

The conditioned EPP beads are then transferred to a molding machine. Within the mold, the pre-expanded beads are subjected to further steam heating and pressure. This causes the beads to expand further and fuse together, conforming to the shape of the mold cavity. The steam pressure and cycle times are precisely controlled to ensure proper fusion and the desired density and structural integrity of the molded EPP part.

Step 4: Cooling and Demolding

After the molding cycle is complete, the mold is cooled, typically with water. This solidifies the EPP foam into the final shape. Once sufficiently cooled, the mold opens, and the finished EPP part is ejected. The cooling process is critical for ensuring the part retains its shape and dimensional accuracy.

Step 5: Post-Processing (Optional)

Depending on the specific application, the molded EPP parts may undergo post-processing steps. These can include trimming excess material, surface finishing, or assembly with other components. For example, automotive bumper cores might be combined with outer shells and mounting hardware. These final steps ensure the EPP product meets the exact requirements of its intended use.

What is EPO Foam?

EPO foam, short for Expanded Polystyrene Polyethylene blend, is a unique copolymer resulting from a special polymerization process. It comprises 30% polyethylene and 70% polystyrene, making its composition and structure distinct.

Expanded Polyolefin (EPO) foam is a lightweight, closed-cell foam material used in various applications, particularly in the manufacturing of model aircraft, UAVs (unmanned aerial vehicles), and other hobbyist projects. It’s a type of thermoplastic foam that offers excellent strength-to-weight ratio, buoyancy, thermal insulation, and resistance to water and chemicals.

What is the Process of EPO Foam Production?

The production of Expanded Polyolefin (EPO) foam is a multi-step process that transforms raw plastic beads into a resilient, lightweight, and versatile material. It combines the properties of two distinct polymers to create a unique foam with superior characteristics, making it suitable for a wide range of applications.

Step 1: Material Blending and Impregnation

The process begins by blending two primary polymers: expandable polystyrene (EPS) and polyethylene (PE). These raw plastic beads are mixed together with a blowing agent, typically pentane. The beads are then subjected to heat and pressure, which allows the blowing agent to be absorbed, or impregnated, into the polymer mixture.

This blending and impregnation step is fundamental to the final product’s performance. By combining the rigidity of polystyrene with the flexibility of polyethylene, the process creates a unique raw material. The absorbed blowing agent will later be crucial for the expansion of the beads during subsequent steps.

Step 2: Pre-expansion

The impregnated beads are then fed into a pre-expander vessel. Here, they are exposed to steam, which heats the beads and vaporizes the blowing agent within them. This causes the beads to expand significantly, creating small, lightweight foam pellets.

Controlling the temperature and steam pressure in this stage is key to achieving the desired density of the final foam product. The pre-expanded beads, now much larger and less dense, are cooled and allowed to “rest” so that the internal pressure equalizes before the final molding stage.

Step 3: Molding and Fusion

The pre-expanded beads are then placed into a mold that has the shape of the desired final product. More steam is introduced into the mold, causing the beads to expand further and fuse together. The heat and pressure from the steam bond the beads into a single, cohesive foam part.

This final molding step gives the EPO foam its definitive shape and structural integrity. After the beads have fully fused, the mold is cooled to solidify the foam. The finished part is then ejected and may undergo further post-processing like trimming or surface finishing.

EPP vs EPO Foam

Composition

EPP foam is a homopolymer, meaning it is made exclusively from expanded polypropylene beads. This single-polymer structure gives EPP its consistent material properties and makes it easy to recycle, as there are no other polymers mixed in.

EPO foam is a copolymer blend, typically combining expanded polystyrene (EPS) with polyethylene (PE). This unique fusion of two different plastics creates a material that balances the rigidity of EPS with the flexibility of PE, resulting in a hybrid foam.

Durability and Flexibility

EPP is known for its exceptional elasticity and high-impact resilience. The foam has a “memory” quality, allowing it to absorb multiple impacts and return to its original shape without permanent deformation. This makes it ideal for repeated use.

EPO, while durable, is more rigid and prone to permanent creasing or cracking upon a heavy impact. It performs well in single-impact scenarios but can become brittle under repeated stress. Its structure is less elastic than EPP.

Weight and Density

EPP foam typically has a lower density and is lighter for a given volume. Its lightweight nature, combined with its strength, is a key advantage for applications where reducing overall weight is crucial without sacrificing protection.

EPO foam is generally denser than EPP, giving it a slightly more solid and firm feel. This increased density contributes to its greater rigidity and makes it a good choice for products requiring a balance between weight and structural integrity.

Manufacturing Process

The production of EPP involves the use of steam chest molding to fuse individual polypropylene beads together. This process creates a single, unified structure with a distinct beaded appearance that is characteristic of the material.

EPO is manufactured through a special polymerization process that blends the two different polymers together before expansion. This fusion creates a more uniform, fine-celled structure, which contributes to its smoother surface finish.

Common Applications

EPP is widely used in demanding, high-performance applications. Its primary uses include automotive components like bumper cores and passenger safety parts, as well as in reusable packaging, and specialized sports equipment.

EPO is very popular in the hobby and recreational markets, especially for creating models like remote-control airplanes. Its rigidity and ease of molding also make it a common choice for disposable packaging and product cushioning.

| Aspect | EPP (Expanded Polypropylene) | EPO (Expanded Polyolefin) |

| Composition | Pure polypropylene | Blend of polystyrene and polyethylene |

| Durability | Excellent, absorbs multiple impacts | Good, but prone to creasing |

| Flexibility | Highly elastic with shape memory | More rigid and less flexible |

| Density | Generally lower | Slightly higher |

| Primary Use | High-performance, reusable items | Hobby models, disposable packaging |

EPP Applications

EPP foam is widely utilized in sectors that demand high performance and exceptional durability. Its ability to absorb multiple impacts without permanent deformation makes it a top choice for safety and resilience. Key applications include:

- HVAC and heating components: EPP’s excellent resistance to chemicals and its ability to maintain structural integrity across a wide temperature range make it suitable for various components within heating and air conditioning systems.

- Automotive components: EPP is extensively used for energy-absorbing bumper cores and other vital passenger safety parts, significantly enhancing vehicle crash protection and occupant safety through its incredible resilience.

- Reusable packaging: Due to its ability to withstand repeated impacts and return to its original shape, EPP is an excellent choice for durable, reusable packaging containers and inserts that protect goods during transit.

- Specialized sports equipment: Its superior shock absorption and lightweight nature make it a preferred material for protective padding and inserts in high-impact sports helmets and other safety gear.

- Structural and insulating materials: The combination of a high strength-to-weight ratio and excellent thermal insulation properties makes EPP a very valuable material for lightweight structural and insulating applications in construction.

EPP Application of Car Parts:

EPP molded parts play a crucial role across various industries, notably in automotive manufacturing. Their exceptional energy-absorbing characteristics enhance passive safety measures and offer enhanced protection for vehicle occupants. This makes them ideal for producing components like fenders, headrests, and other impact-absorbing elements.

Another advantage lies in the lightweight nature of EPP, contributing to reduced fuel consumption and promoting eco-friendliness in cars. Furthermore, the ability to achieve precise shapes makes EPP versatile in applications such as sun visors, paneling, or custom toolboxes designed to accommodate breakdown sets efficiently.

EPP Parts for Electronic Equipment:

With the trend towards larger TVs, traditional EPS packaging is no longer sufficient to ensure their safe transportation. As a result, EPP cushions have emerged as the preferred packaging material for large TVs.

The EPP Electrostatic Discharge Protection (ESDP) grade offers enhanced protection against electrostatic discharge, featuring a permanent surface resistance of less than 10^7 ohms. This property promotes rapid static decay, effectively shielding against sparking and other electrical hazards during transit.

EPP Thermo Box:

Whether you’re in the restaurant industry, catering business, or food retail sector, the EPP box offers tailored solutions for every sector’s needs. Additionally, our practical recreational boxes are perfect for private use, whether for shopping trips or camping adventures.

The EPP box excels in insulation, featuring a high-stacking rim with special knobs and reinforced corners that guarantee a secure fit for the lid. This ensures safe transportation and optimal insulation for hot, cold, and fresh food items. Moreover, its sturdy yet lightweight construction makes it a durable and convenient choice for various applications.

EPP Sport & Leisure:

EPP has been used to make; climbing, skiing, horse riding, skateboarding, surfing, baseball, and cycling helmets, ski boot insoles, body boards, swimming floats, body protection, shin pads, bicycle rims, exercise/yoga rolls, and more.

EPP Pallets and Plank:

Direct production of EPP beads offers a substantial reduction in material costs and provides a viable alternative to EPS pallets. These beads enable goods to be loaded with weights of up to 3000kg. Additionally, EPP planks are lighter yet stronger, offering superior product protection using less material. Prototyping is also feasible to ensure the product aligns perfectly with your requirements.

Why Are Most RC Airplanes Made Out of EPO Foam?

EPO foam has found widespread use in RC airplanes due to its lightweight nature, exceptional durability, and impressive impact resistance. Its ability to withstand crashes and rough landings surpasses that of many other materials commonly used in RC aircraft construction. Another advantage of EPO foam is its ease of repair using CA glue, making maintenance straightforward for hobbyists.

Although EPO foam may show signs of wear, such as scuffing, it remains resilient and can be easily restored with paint or other touch-up materials, maintaining its aesthetic appeal. These qualities, coupled with its balanced combination of durability and weight, make EPO foam a preferred choice among RC enthusiasts for constructing reliable and long-lasting aircraft models.

Related: EPS vs EPP Foam: What Are Differences Between Them?

Conclusion

In summary, the choice between EPP and EPO depends on the specific needs of your project. If you require a material that can withstand multiple, high-force impacts and maintain its structural integrity,

EPP is the superior choice. Its high resilience and durability make it a long-term, reusable solution. Conversely, if your application prioritizes a lightweight, more rigid structure for single-use or less-demanding scenarios, EPO is a cost-effective alternative.

Ready to find the perfect foam for your project? Get wholesale EPP material and related products from Epsole. Our EPP foam is designed for superior performance and durability, ensuring your products are protected and built to last.