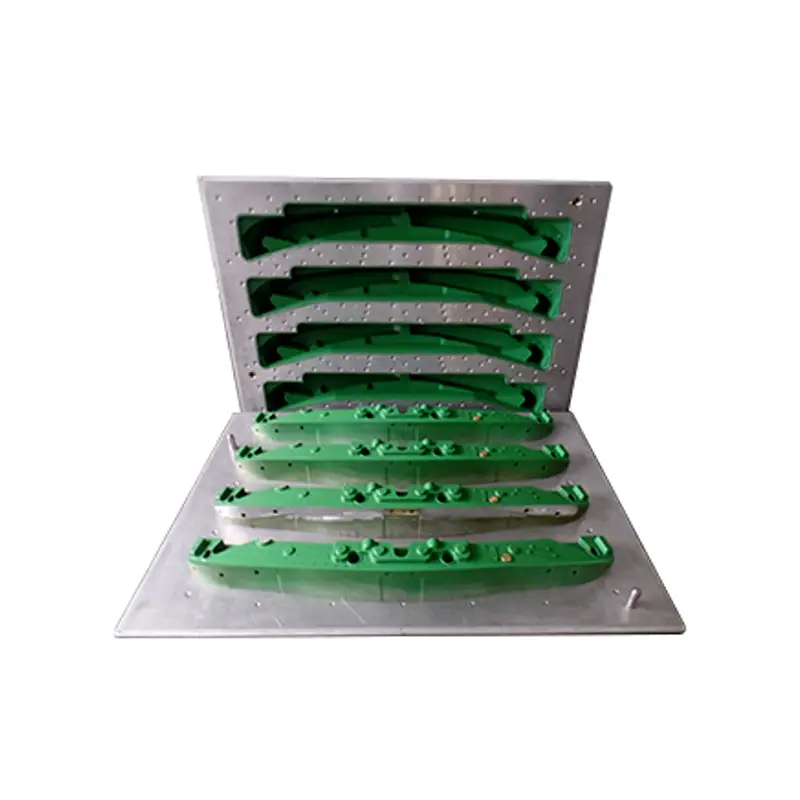

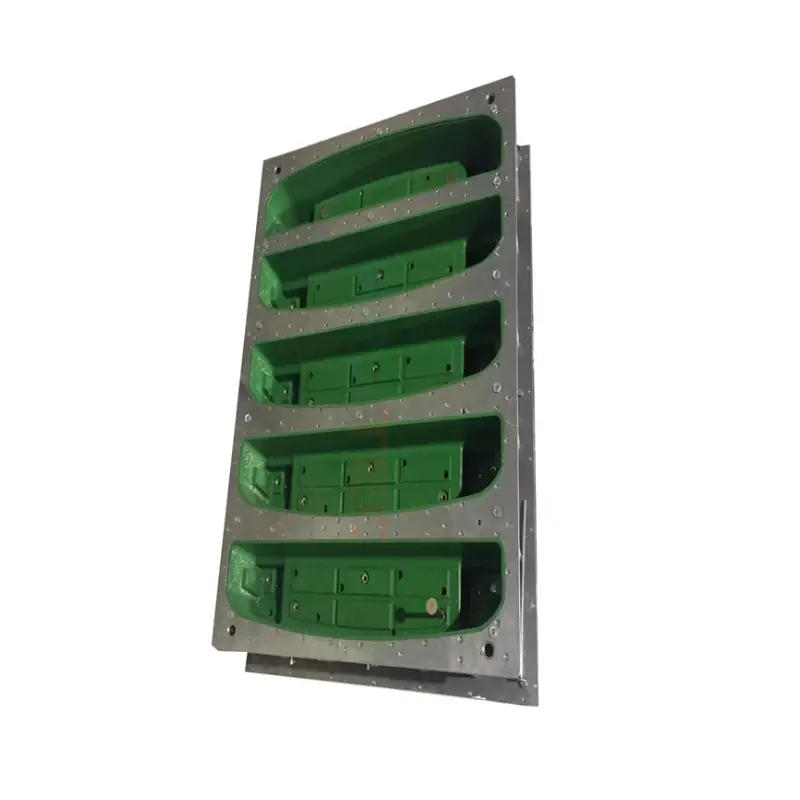

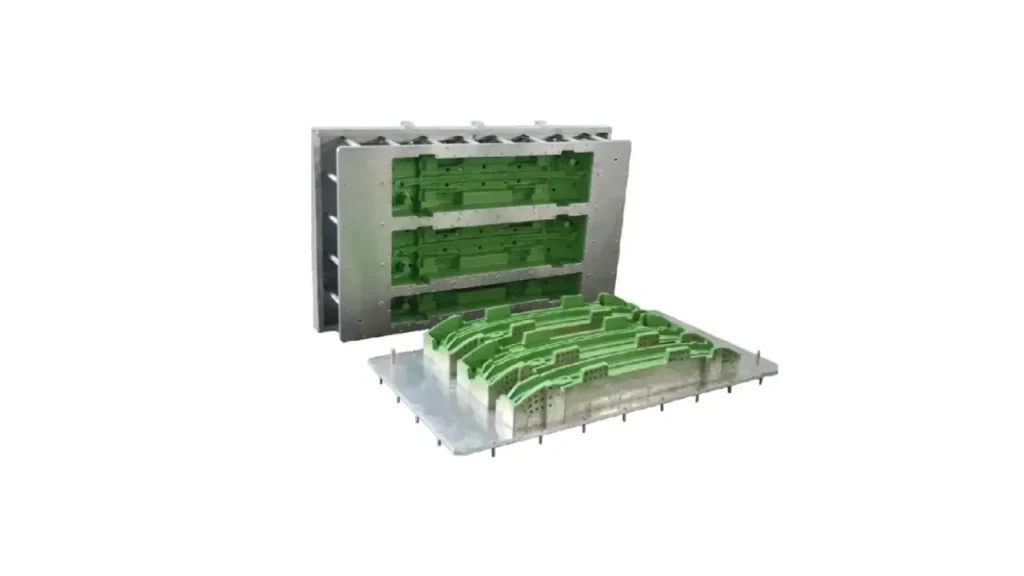

Custom EPP Bumper Mold from China

We specialize in creating custom EPP bumper molds tailored to your exact specifications. Utilizing advanced technology and high-grade aluminum, our molds are engineered for precision, durability, and a non-stick finish. This ensures a fast and efficient production cycle, enabling you to manufacture lightweight, high-performance EPP bumpers that meet stringent automotive safety and design standards.

Get EPP Bumper Mold Wholesale

Precision Engineering: Our molds are meticulously designed and manufactured using advanced CNC machining to ensure perfect dimensional accuracy. This guarantees that every EPP bumper produced will meet your exact specifications and automotive industry standards.

High-Grade Materials: We use only premium aluminum and surface treatments to construct our molds. This not only makes them durable and resistant to wear but also ensures excellent heat conductivity, allowing for faster and more consistent molding cycles.

Optimal Performance: The unique design of our molds, including optimized cooling channels and a smooth surface finish, prevents material sticking and ensures a consistent foam density. This results in lightweight yet highly impact-resistant EPP bumpers.

Cost-Effective Solution: By streamlining the molding process and reducing waste, our molds help you achieve greater production efficiency. This leads to lower operational costs and a better return on investment over the long term.

Comprehensive Customization: We work closely with you to create a mold that fits your specific needs. From complex geometries to integrated features, we can design a custom solution that perfectly aligns with your product vision and manufacturing requirements.

Exceptional Durability and Longevity We offer molds built with superior materials ensuring an extended operational life and resistance to wear.

Precision Engineering for Perfect Fit We supply molds built to tight tolerances, guaranteeing every EPP bumper produced has a flawless, precise fit.

Optimized Thermal Efficiency in Production Our molds feature advanced design for rapid heating and cooling cycles, decreasing molding time and maximizing output efficiency.

Cost-Effective and Reliable Manufacturing We manufacture EPP molds for minimal maintenance and maximum uptime, leading to lower operational costs and consistent results.

Customize Your Desired EPP Bumper Mold

Size and Shape

We can customize the size and shape of your EPP bumper mold to match any vehicle model or design. Whether you require a standard front bumper or a complex, multi-component rear bumper, we precision-engineer the mold to your exact CAD specifications, ensuring perfect fit and finish for your final product.

Core and Cavity Design

We can tailor the core and cavity design to achieve specific material density and part features. By adjusting the mold’s internal structure and draft angles, we ensure optimal material flow and a consistent product density. This allows us to produce bumpers with a precise balance of lightweight properties and impact absorption.

Cooling and Venting Systems

We can optimize the cooling and venting systems within the mold to enhance production efficiency. By strategically placing cooling channels, we reduce cycle times and prevent material overheating. We also design an effective venting system to eliminate gas traps, resulting in a flawless, void-free finished product.

Surface Finish and Coatings

We can apply various surface finishes and coatings to the mold to improve part release and durability. A non-stick coating minimizes sticking and simplifies the demolding process, while a textured finish can be added to create specific patterns directly on the EPP bumper, saving you a separate post-processing step.

EPP foam bumper Functions

Energy Absorption: Their cellular structure absorbs and dissipates kinetic energy during a collision, protecting vehicle occupants.

Lightweighting: The material’s low density reduces vehicle weight, improving fuel efficiency and lowering emissions.

Multi-Impact Resilience: EPP foam returns to its original shape after an impact, making it ideal for absorbing energy in low-speed collisions.

Pedestrian Safety: Its flexible nature reduces the severity of injuries in the event of an impact with a pedestrian.

Temperature Resistance: The material functions reliably across a wide range of temperatures, ensuring consistent performance.

EPP bumper applications

Front and Rear Bumpers: EPP foam is the primary material for bumper cores, where it absorbs crash energy in low-speed collisions and protects vehicle occupants. Its multi-impact resilience saves on repair costs.

Side Impact Protection: EPP foam is strategically placed within door panels and pillars to absorb energy during a side collision. This helps to protect occupants by reducing the force of the impact.

Headrests and Seating: EPP is used in headrests and seat inserts to enhance occupant safety and comfort. It provides excellent energy absorption to cushion impacts and a lightweight structure to reduce vehicle weight.

Trunk and Storage Organizers: Due to its lightweight, durability, and ability to be molded into complex shapes, EPP foam is perfect for creating custom-fit tool pods, trunk organizers, and storage compartments.

EPP bumper for technical molded parts

EPP (Expanded Polypropylene) foam‘s unique properties make it ideal for a variety of technical molded parts, not just bumpers.

Integrated Features: EPP can be molded to include built-in features like snap-fit connectors, simplifying assembly and reducing the need for separate parts.

Variable Density: A single EPP part can be molded with different densities in specific areas. This allows for enhanced impact resistance where needed, and a lighter structure elsewhere for weight savings.

Hybrid Parts: EPP can be molded around metal inserts, creating stronger, hybrid components. This allows for integrated mounting points and structural reinforcements.

Thermal and Acoustic Insulation: EPP foam is a great insulator. It can be used to create parts that reduce noise and regulate temperature within a vehicle’s interior.

Complex Shapes: The material’s moldability allows for intricate and complex shapes, giving designers the freedom to create innovative components that fit perfectly and optimize performance.

How to Use EPP Mold for Car Bumper

Using an EPP mold for car bumper production is a multi-step process that requires precision and the right equipment.

Design and Engineering: The process begins with designing the mold based on the car’s bumper specifications. We use advanced software to create a 3D model, ensuring the mold’s shape, cooling channels, and venting systems are optimized for efficient production and perfect part quality.

Mold Manufacturing: The designed mold is then manufactured from high-grade aluminum using precision CNC machining. This ensures the mold cavity is perfectly accurate. The mold surface is also treated to prevent material sticking and to ensure easy demolding.

Pre-Expansion of Beads: Raw EPP beads are pre-expanded in a separate machine using steam. This makes the beads expand and prepare them for the molding process. The density of the final bumper is controlled during this step by adjusting the expansion ratio.

Steam Molding Process: The pre-expanded beads are injected into the closed aluminum mold. High-pressure steam is then introduced into the mold cavity. This heat and pressure cause the beads to fuse together, forming the solid EPP bumper shape.

Cooling and Demolding: After the EPP has fused, the mold is rapidly cooled with circulating water. Once cooled, the mold opens, and the finished EPP bumper is ejected. The lightweight and durable part is now ready for a vehicle’s assembly line.

EPP Bumper Mold FAQs

what is EPP bumber?

An EPP bumper, or more accurately an EPP bumper core, is the energy-absorbing component located behind the outer plastic bumper cover on a vehicle. It is made from Expanded Polypropylene (EPP) foam, a lightweight, closed-cell foam material.

what is EPP bumper used for?

EPP (Expanded Polypropylene) is a versatile, lightweight, and highly resilient foam material primarily used in the automotive industry. Its unique properties make it ideal for a variety of critical applications beyond just the external bumper.

Here’s what EPP is used for:

Bumper Cores: This is the most common use. The EPP foam core is the primary component for absorbing impact energy in low-speed collisions. It’s designed to compress and then return to its original shape, which helps prevent damage to the vehicle’s body and reduces repair costs.

Side Impact Protection: EPP is strategically placed within door panels and pillars to absorb energy during a side-on collision. This helps protect occupants by reducing the force of the impact.

Headrests and Seating: EPP foam is used in the cores of headrests and various seating components. Its energy-absorbing properties help protect occupants from whiplash and other injuries in a crash, while its lightweight nature contributes to the overall weight reduction of the vehicle.

Tool Trays and Storage: Due to its ability to be molded into complex, custom shapes, EPP foam is perfect for creating lightweight and durable tool trays, trunk organizers, and other storage compartments that fit perfectly within the vehicle’s interior.

Acoustic and Thermal Insulation: EPP’s cellular structure provides excellent thermal and acoustic insulation. It’s used in various vehicle parts to reduce noise and vibrations, creating a quieter and more comfortable ride. In electric vehicles, it’s also used to protect and insulate battery packs from extreme temperatures.

how to mold EPP bumpers?

Molding EPP (Expanded Polypropylene) bumpers is a specialized process that transforms small plastic beads into a finished, lightweight, and highly durable component. The process, known as steam chest molding, involves several key steps:

1. Pre-Expansion

The process starts with raw polypropylene beads. These beads are placed in a special vessel called a pre-expander, where they are exposed to high-pressure steam. The heat causes a blowing agent within the beads to vaporize, making the beads expand significantly, much like popcorn. This step dramatically increases their volume and reduces their density.

2. Conditioning (Aging)

After pre-expansion, the beads are not yet stable. They are stored in large silos for a period of several hours to a few days. During this “aging” phase, air diffuses into the closed-cell structure of the beads, replacing the blowing agent and stabilizing their internal pressure. This is a critical step to ensure the beads can be properly molded later.

3. Molding

This is the core of the process. The conditioned EPP beads are pneumatically transferred into an aluminum mold cavity that is precisely shaped to the final bumper design. The mold is then closed, and high-pressure steam is injected into the cavity. This steam causes the beads to undergo a secondary expansion and their surfaces to become tacky. The combination of heat and pressure forces the beads to fuse together, forming a single, solid, and homogeneous EPP foam part.

4. Cooling and Demolding

After the steam molding phase, the mold is cooled, typically by circulating cold water through integrated channels. This step solidifies the EPP foam, allowing it to hold its shape. Once the part has cooled and stabilized, the mold is opened and the finished EPP bumper is ejected.

5. Post-Processing

The final part may undergo some post-processing steps. This can include trimming any excess material (known as “flash”), and sometimes drilling, cutting, or adding inserts for final assembly. The molded EPP bumper is then ready to be integrated into the vehicle’s assembly line, usually placed behind the painted plastic bumper fascia.

Why to choose our mold EPP bumpers?

We manufacture molded EPP bumpers that provide superior impact protection and lightweight performance, making them an excellent choice for modern product design. We offer these components with exceptional energy absorption capabilities, critical for safeguarding sensitive equipment and improving product durability.

This commitment to advanced material science ensures our bumpers deliver reliable, long-lasting safety.

Exceptional Impact Protection We supply EPP bumpers with outstanding shock-absorbing properties. This material structure allows them to quickly dissipate energy from impacts, protecting the internal and external components of your products from damage. We guarantee a high degree of safety and structural integrity under stress.

Significant Weight Reduction We provide lightweight EPP solutions that contribute to overall product efficiency. The material’s low density means you get robust protection without the added bulk. This weight advantage is particularly crucial for applications in automotive, drones, and portable equipment where minimizing mass is vital.

Superior Thermal Insulation We offer EPP bumpers that naturally possess excellent thermal insulation characteristics. This property is beneficial in applications requiring temperature stability, helping to maintain performance across a wider range of operating conditions. We ensure your product’s internal environment remains protected from external heat or cold.

Chemical and Water Resistance We manufacture durable EPP bumpers that exhibit strong resistance to many common chemicals and water. This inherent robustness makes our components suitable for harsh or outdoor environments, ensuring the bumpers maintain their structural and protective qualities over their lifespan.