Understanding what to use to cut foam board is essential for anyone tackling DIY projects, crafting, or professional tasks involving this versatile material. Achieving clean and precise cuts can be challenging without the right tools and techniques.

This article delves into the best methods for cutting foam board, highlighting the most effective tools and practices to ensure smooth, accurate results. Whether one is a seasoned professional or a beginner, mastering the right approach to cutting foam board can significantly enhance the quality and efficiency of their work.

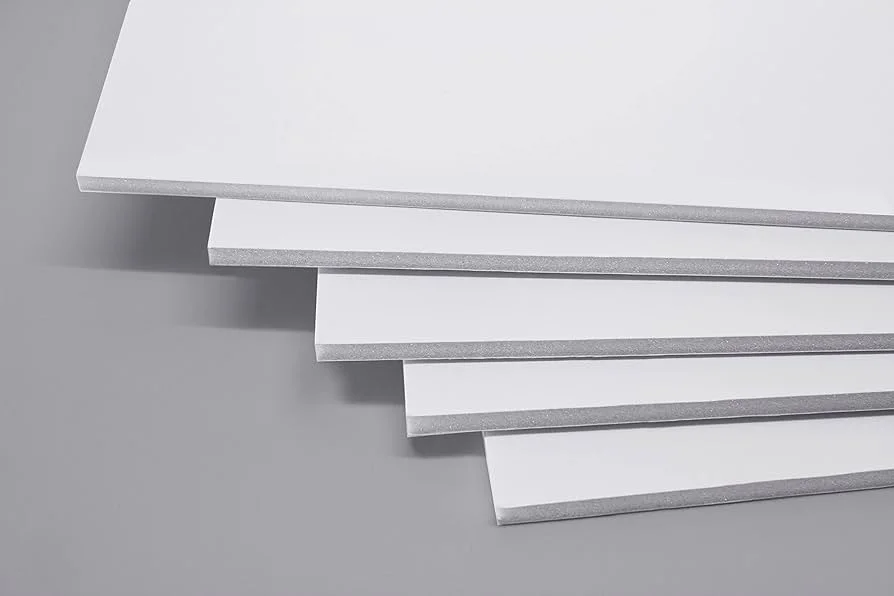

What Is Foam Board?

Composition And Characteristics Of Foam Board

Foam board, also known as foam core, is made up of a lightweight, rigid foam center sandwiched between two outer layers of paper or plastic. This composition gives it both strength and flexibility, making it easy to work with while maintaining its structural integrity. The foam core is typically made from polystyrene or polyurethane, providing excellent insulation properties and a smooth surface ideal for various applications.

Common EPS Foam Uses And Applications

Foam board is incredibly versatile and finds use in a wide range of projects. It is commonly used for mounting photographs and artwork, creating architectural models, crafting displays, and even as a lightweight backing for presentations. In the construction industry, foam board serves as an efficient insulation material, enhancing energy efficiency in buildings. Its ease of cutting and shaping makes it a favorite among hobbyists and professionals alike.

Why Cutting Foam Board Properly Is Crucial?

Cutting foam board properly is essential to ensure clean, precise edges that enhance the overall appearance and functionality of your project. Incorrect cutting can result in jagged edges, damaged surfaces, and wasted materials, undermining the quality of your work.

Proper cutting techniques also help maintain the structural integrity of the foam board, ensuring it stays intact and serves its intended purpose effectively. By mastering the right tools and methods, you can achieve professional-looking results every time.

Benefits Of Using Foam Board

Lightweight

Foam board is remarkably lightweight, making it easy to transport, handle, and work with. Despite its light weight, it offers a sturdy and rigid structure, ideal for projects that require both durability and ease of use. Whether you’re mounting artwork or creating models, the lightness of foam board ensures convenience without compromising on strength.

Cost-Effective

Foam board is a budget-friendly material, making it an excellent choice for both personal and professional projects. Its affordability does not sacrifice quality, allowing you to achieve high-quality results without breaking the bank. From crafting to construction, foam board provides an economical solution that meets a wide range of needs.

Print-Friendly

Foam board’s smooth and even surface is perfect for printing, ensuring sharp and vibrant images. It can easily accommodate various printing methods, making it ideal for signage, displays, and presentations. The print-friendly nature of foam board allows for professional-grade visuals, enhancing the overall appeal of your projects.

Adhesive

Foam board works well with a variety of adhesives, making it versatile for different applications. Whether you’re mounting photos, attaching elements for a display, or constructing models, the board’s compatibility with adhesives ensures a secure and lasting bond. This feature enhances the durability and functionality of your creations.

What To Use To Cut Foam Board: Best Tool To Cut Foam Board

Flatbed Die-Cutters

For large-scale signmakers, a flatbed die-cutter is the ideal solution for all foam cutting projects. This machine is specifically designed to handle foam board, delivering clean, precise results with high accuracy. When comparing rotary to flatbed die-cutting, the flatbed option is superior for foam boards, as it excels with sheet materials. Additionally, it’s versatile enough to cut other materials, such as acrylic sheets.

.webp)

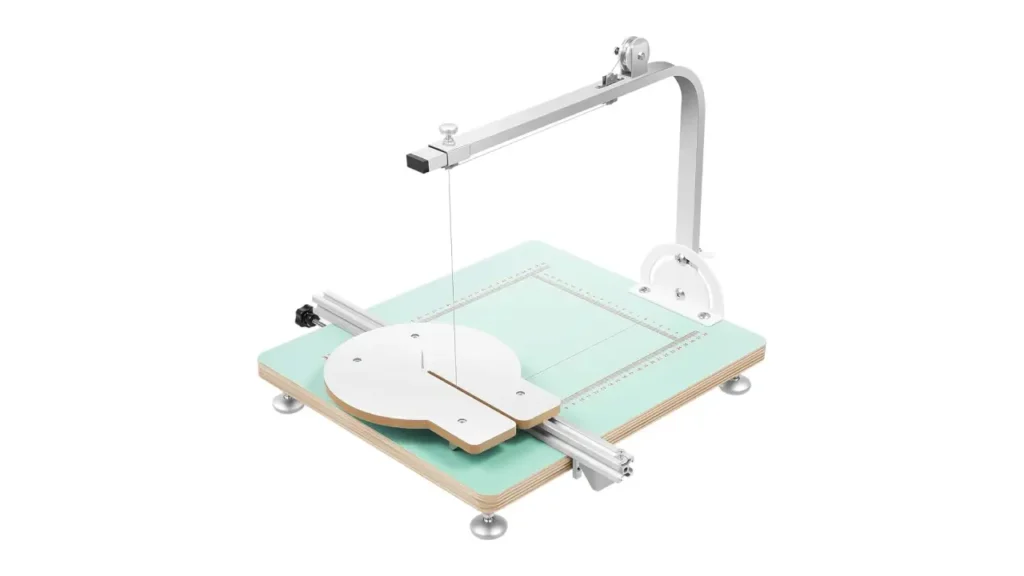

Hot Wire Cutters

Hot wire cutters operate by passing an electric current through a thin wire, which heats up to a high temperature. You guide this heated wire through the foam board, melting and slicing through it with ease. The heat allows for smooth and precise cuts, making it simple to follow intricate patterns and shapes without applying much physical effort.

Hot wire cutters offer several benefits, such as creating clean, smooth edges with minimal mess and allowing for intricate cuts that are hard to achieve with other tools. They are also relatively quiet and easy to use once set up. However, there are some drawbacks: they require careful handling to avoid burns, they can be more expensive than other cutting tools, and they often need a power source, limiting their portability.

Foam Cutting Saw

A foam cutting saw is equipped with a long, thin serrated blade designed to effortlessly slice through thick foam boards. Powered by electricity, it offers a swift cutting process, reducing manual labor significantly. The saw’s design ensures precision and consistency in cuts, making it suitable for both straight lines and intricate shapes.

Using a foam cutting saw provides several benefits, such as saving time and effort when working with large volumes of foam. It enables quick and uniform cuts, enhancing efficiency in various projects. However, these saws can be expensive to purchase and maintain. Additionally, they tend to create a fair amount of debris and require careful handling to avoid accidents or messy workspaces.

Table Saw

A table saw is a stationary woodworking tool equipped with a circular blade mounted on an arbor, powered by an electric motor. It features a flat table surface with an adjustable fence that guides material through the blade for precise cuts. The blade can be tilted to make bevel cuts, and some models include safety features like blade guards and riving knives.

Using a table saw offers numerous benefits, such as its ability to make accurate and repeatable cuts in various materials, including wood, plastic, and foam board. It’s versatile, allowing for adjustments in blade height and angle to accommodate different cutting needs.

However, table saws can be large and require adequate space for operation and storage. They also pose safety risks due to the exposed blade and powerful motor, necessitating caution and proper safety gear during use.

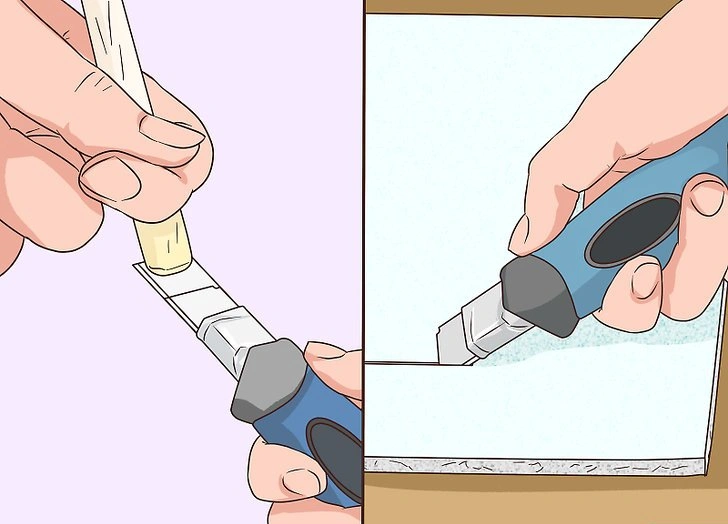

Utility Knife

Utility knives come in various types, including retractable blade knives, snap-off blade knives, and fixed blade knives. Retractable blade knives allow you to adjust the blade length for different cutting depths. Snap-off blade knives feature segmented blades that can be snapped off to reveal a fresh cutting edge. Fixed blade knives have a sturdy, non-retractable blade ideal for heavy-duty cutting tasks.

Utility knives offer versatility and convenience for a wide range of cutting tasks, from precise detail work to cutting through thicker materials like foam board. They are compact and portable, fitting easily into tool belts or pockets.

However, their thin blades may require frequent replacement, and they may not be suitable for cutting very thick or dense materials. Additionally, care must be taken during use to avoid accidents due to their sharp blades.

How To Cut Foam Board?

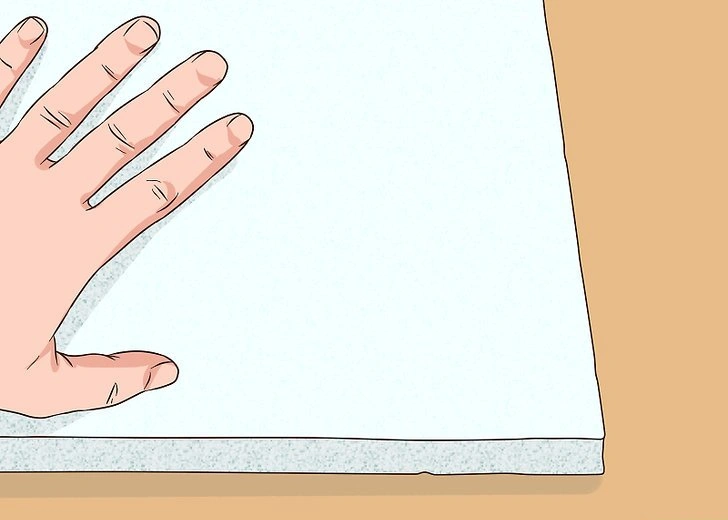

Cutting foam board cleanly requires the right tools, steady technique, and proper preparation. Whether you are working with EPS, XPS, or rigid insulation boards, accurate cuts help ensure tight joints, better insulation performance, and a professional finish.

Following the correct steps also reduces material waste and prevents crumbling or uneven edges.

Cutting Foam Manual

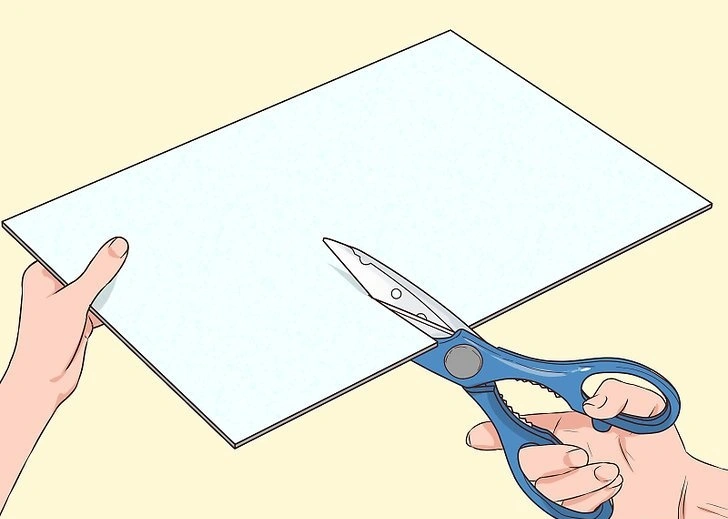

Step 1. Use scissors to cut through soft foam

For thin or flexible foam, use a pair of heavy-duty scissors. You can cut both curves and straight lines, but it’s helpful to lightly sketch your design on the foam with a permanent marker before starting. Make long, smooth cuts to avoid choppy edges in the foam.

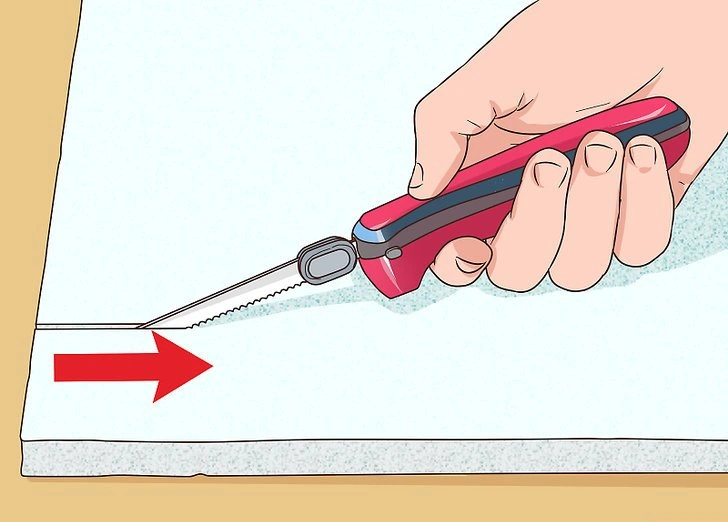

Step 2. Wax a blade to cut foam efficiently

For basic straight cuts, select a blade with a comfortable handle, such as a utility knife, old kitchen knife, bread knife, or box cutter. Rub a white candle along the blade before slicing through the foam; the wax helps the blade glide smoothly. Simple blades work best with soft or thin foam. If the blade starts to snag, reapply the candle wax.

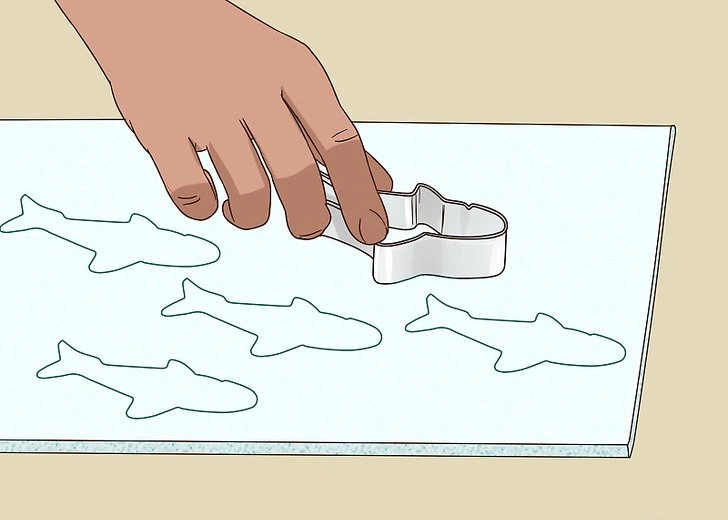

Step 3. Use cookie cutters to cut foam

For soft or rigid foam up to 1/2-inch (12 mm) thick, lay the foam flat on your work surface. Choose a metal cookie cutter in your desired shape and press it evenly through the foam until it cuts all the way through. You may need to push against the foam to pop the cut piece out.

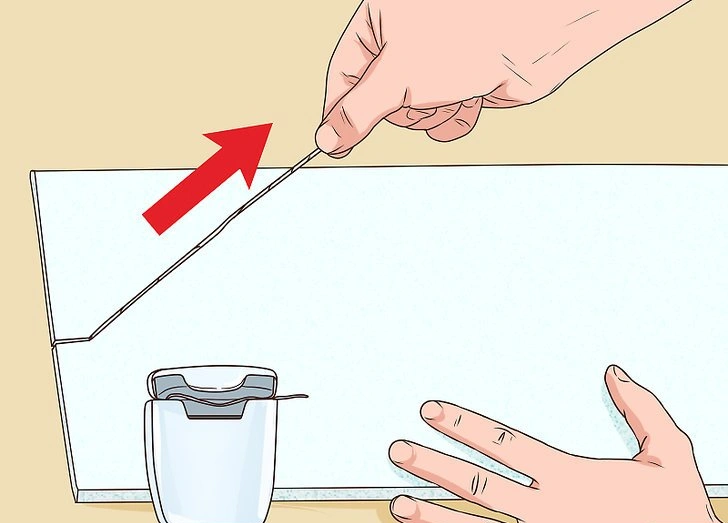

Step 4. Slice through foam using dental floss

For cutting thin foam sheets, use a long strand of dental floss. Place the floss on your work surface and lay the foam sheet on top, aligning the floss with your desired cutting line. Hold the foam with one hand and pull the end of the floss towards you with the other hand. Dental floss is ideal for straight cuts. For clean cuts on multiple sheets, slice them individually.

Using Electric Tools

Step 1. Secure the foam to your work surface if necessary

With a stationary foam saw, you can move the foam while cutting. However, if using an electric knife or wire cutter, it’s important to prevent the foam from moving. You can hold the foam with one hand, secure it with clamps, or place it in a vise. Ensure the portion of foam you are cutting extends away from the clamps or vise to provide adequate cutting space.

Step 2. Wear protective gear

Always exercise caution and wear eye protection when using electric cutting tools. If the cutting process produces fine foam dust, wear a face mask to avoid inhaling it.

Step 3. Use an electric knife

To cut through thick or stiff foam (up to 4 to 10 cm thick), stack the foam pieces together. Plug in the electric knife and turn it on before touching it to the foam. Use the thinnest blade for straight or curved cuts. Move slowly through the foam to achieve a clean cut. If you’re cutting very soft foam, avoid applying downward pressure while cutting, as this can make it harder to cut and cause the blade to deviate from the desired cutting line.

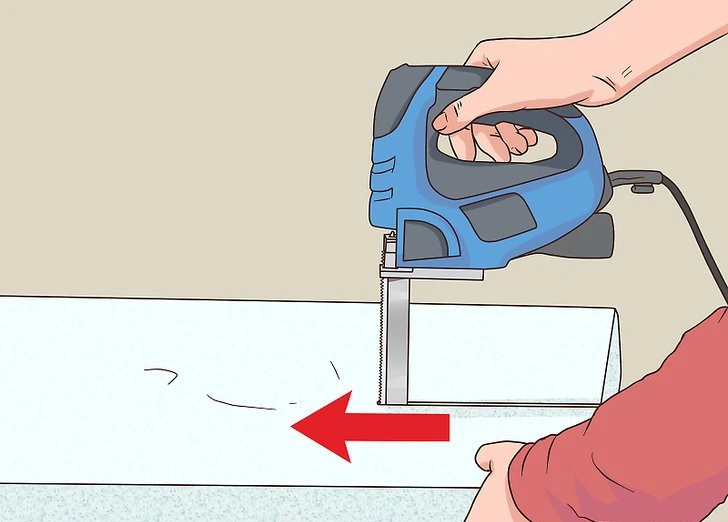

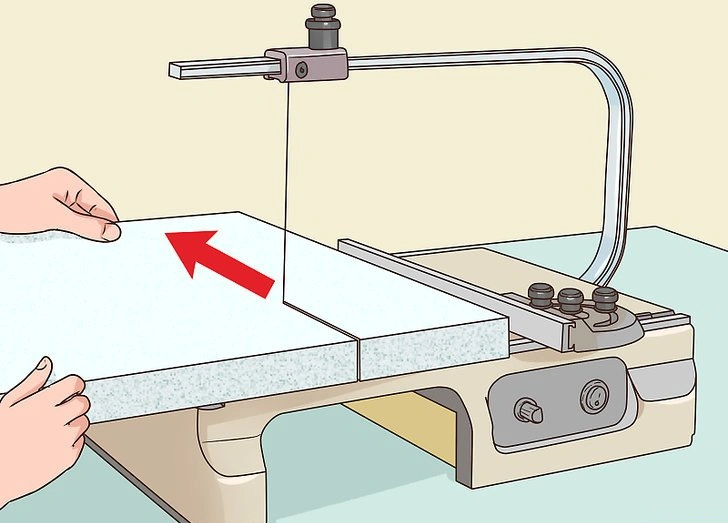

Step 4. Cut foam with a saw

If you frequently cut foam, consider investing in a foam cutting saw. This saw comes with a base that sits on your work surface, with a vertically running blade. You hold and move the foam against the blade to make your cuts. If you prefer to hold the foam and move the saw, you can remove the base on most foam saws or use a common jigsaw for thinner foam boards.

Step 5. Heat a wire cutter to slice through foam

Plug in a small wire cutter until the wire heats up. Be cautious not to touch the wire directly. Guide the foam through the blade to create straight, seamless cuts. For intricate designs like waves, curves, or circles, a hot wire foam cutting table might be ideal. When purchasing a hot wire cutter, you can choose the thickness of the blade, which dictates the foam thickness it can handle.

Conlusion

In conclusion, selecting the appropriate tools and techniques for cutting foam board is crucial for achieving professional results. Whether opting for utility knives, hot wire cutters, or electric saws, each method offers unique benefits tailored to different project demands.

It’s essential to consider factors such as foam thickness, desired cuts, and safety precautions when choosing your cutting approach. By mastering these techniques, one can ensure efficient, precise cuts that enhance the quality and effectiveness of foam board projects.

1. What’s the best way to cut foam board?

The best method depends on the thickness and type of foam board. For straight cuts, use a utility knife or a sharp blade with a straightedge. For intricate designs, consider a hot wire cutter or a fine-toothed saw.

2. What to use to cut foam?

Depending on the type and thickness of foam, utility knives, hot wire cutters, electric knives, or even scissors can be effective tools. Choose based on the project’s requirements for precision and ease of use.

3. What is the best way to cut upholstery foam?

Upholstery foam is best cut with an electric knife or a serrated bread knife for clean, smooth edges. Electric scissors or a rotary cutter with a sharp blade can also work well.

4. What is the best way to cut memory foam?

Memory foam can be cut using an electric knife, sharp utility knife, or serrated knife. Ensure the blade is long enough to cut through the thickness in one pass for smooth results.

5. What is the best way to cut high-density foam?

High-density foam is dense and requires a sharp blade for cutting. A utility knife with a strong, straight edge or an electric knife is recommended for clean cuts without jagged edges.

6. What is the best way to cut foam core board?

Foam core board can be cut with a sharp utility knife or a hot wire cutter for precise edges. Ensure the blade is sharp to prevent tearing the foam core layers.

7. What is the best tool to cut foam?

The best tool depends on the type of foam and the desired cut. Utility knives are versatile, while electric knives offer efficiency. Hot wire cutters are ideal for precision, and saws work well for thicker foams.

8. What Cricut blade cuts craft foam?

Cricut machines offer fine-point blades suitable for cutting craft foam. Ensure the blade is sharp and set the correct cutting depth according to the foam’s thickness for precise results.