Expanded polystyrene (EPS), a ubiquitous material in packaging and insulation, begins its journey as tiny polymer beads. This blog post delves into the intricate process of EPS manufacturing, unraveling the steps that transform these beads into the lightweight, versatile foam we encounter daily. We’ll explore the science behind pre-expansion, molding, and the factors that dictate the final product’s properties.

From the precise application of steam to the careful control of density, EPS production is a fascinating blend of chemistry and engineering. Join us as we demystify the manufacturing process, shedding light on how this seemingly simple material is created. This exploration will provide a deeper understanding of EPS’s applications and its role in various industries.

What Is Expanded Polystyrene

Expanded Polystyrene, or EPS, is a type of plastic foam widely used for packaging, insulation, and various other applications. Its unique properties – lightweight, affordable, and excellent insulation – make it a popular choice for manufacturers and consumers alike.

History of EPS

EPS has a rich history dating back to the 1940s. The first commercial production of EPS started in the United States, with the material being used for a variety of applications, particularly for packaging delicate items. Today, EPS is produced all over the world and plays a significant role in various industries.

How is Expanded Polystyrene Manufactured

Here are the steps of the eps manufacturing process in the following

Step 1: Styrene Monomer Production

Before we delve into the creation of Expanded Polystyrene (EPS), let’s take a step back and discuss the production of the primary raw material: Styrene monomer.

Styrene monomer is a colorless, liquid hydrocarbon derived from petroleum. It is produced through the dehydrogenation of ethylbenzene, a process that involves removing hydrogen atoms and producing styrene monomer and hydrogen gas.

Step 2: EPS Beads Preparation

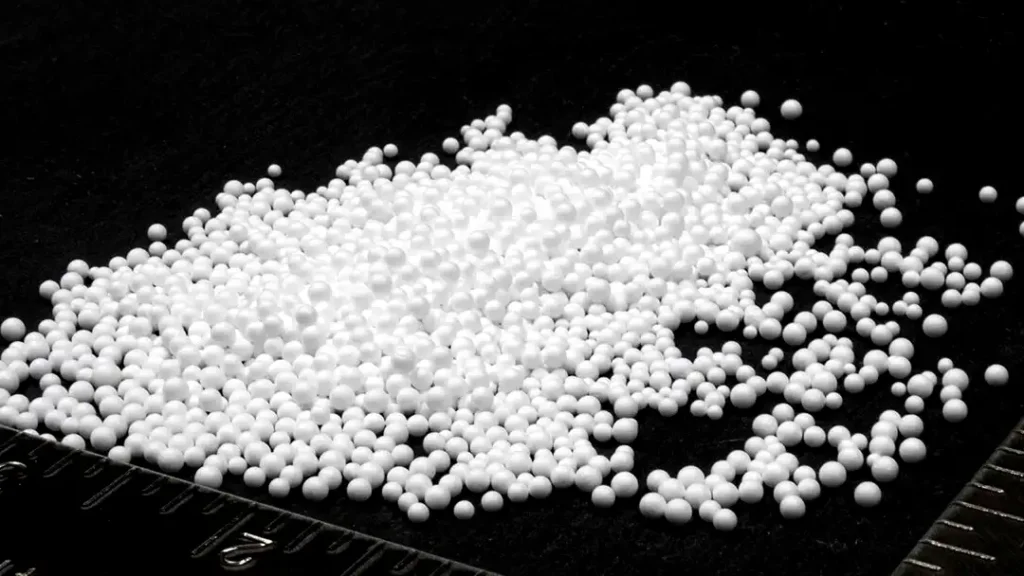

The styrene monomer is then converted into solidified beads through a polymerization process, which involves heating the styrene monomer along with a free radical initiator like benzoyl peroxide. As the reaction progresses, solid polystyrene beads are produced. These beads serve as the base for creating EPS.

Step 3: Foaming and Expanding

The transformation of the solid polystyrene beads into EPS involves the addition of expanders and heat. The expanding process creates the unique cell structure responsible for EPS’s lightweight yet strong properties.

Here are two different methods to expand polystyrene material.

Method 1. Chemical Expansion

In chemical expansion, the polystyrene beads are mixed with a blow agent such as pentane or isobutane. As these expanders evaporate, they produce bubbles within the beads, expanding them and creating a dense network of interconnected cells.

Method 2. Mechanical Expansion

Mechanical expansion involves forcing steam into the hot, pre-expanded beads. The steam creates additional cells within the pre-expanded beads, further expanding the material. After expansion, the EPS is cooled, cut, and shaped as needed.

Step 4: Shaping and Cutting

EPS can be formed into various shapes through processes such as injection molding or compression molding, where the hot, pre-expanded beads are melted and transformed into the desired shape. Once the EPS has cooled and hardened, it is cut and trimmed to the required size and appearance using such techniques as sawing, milling, or die-cutting.

Step 5: Additives

Additives are often employed during EPS manufacturing to enhance its properties. For example, flame retardants can be added to improve EPS’s fire resistance, while blow agents are essential for the expansion process itself.

These steps provide a high-level overview of the process involved in the production of Expanded Polystyrene. In the following sections, we’ll delve deeper into various aspects of EPS, including applications, environmental impact, and sustainable alternatives. Stay tuned!

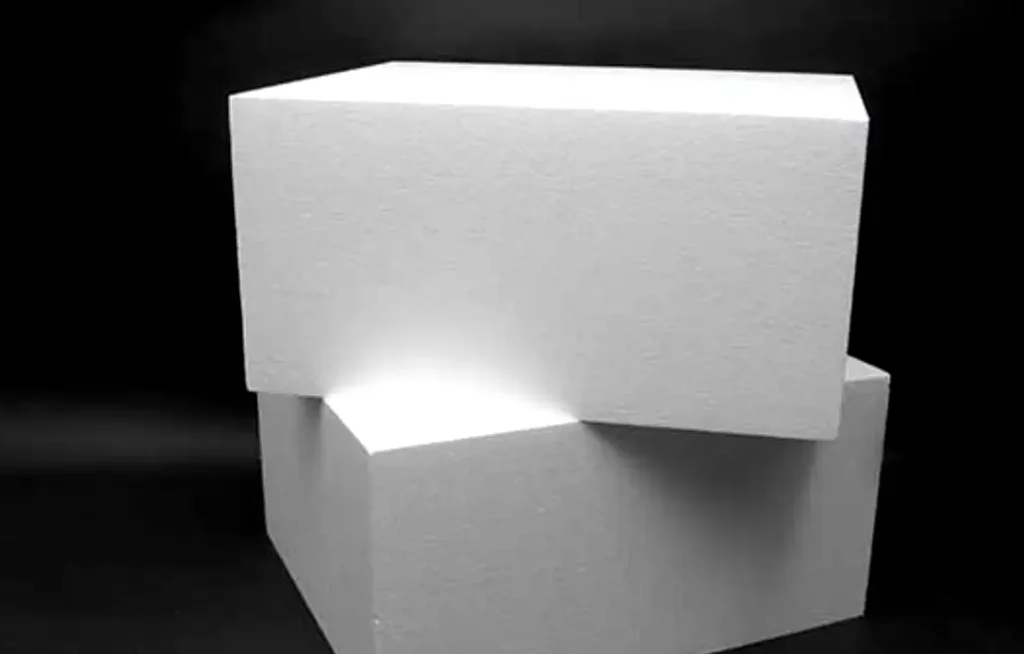

How to Make EPS Foam Blocks

Creating EPS foam blocks involves a series of carefully controlled steps, transforming small polymer beads into large, lightweight blocks. This process is essential for producing materials used in construction, packaging, and various other applications. Here’s a detailed breakdown of the process.

Step 1: Pre-Expansion of EPS Beads

The initial stage involves pre-expanding raw EPS beads. These beads, containing a blowing agent, are exposed to steam within a pre-expander. This heat causes the blowing agent, typically pentane, to vaporize, resulting in a significant increase in the volume of the beads. The degree of expansion is carefully controlled by adjusting steam temperature, pressure, and residence time within the pre-expander, directly impacting the final density of the EPS blocks.

After pre-expansion, the beads, now significantly larger and lighter, are cooled and stabilized. This stabilization period allows the expanded structure to solidify and prevents further expansion. The pre-expanded beads, often referred to as “prepuff,” are then stored in silos or bins, ready for the subsequent molding process. The consistency and uniformity of the pre-expanded beads are critical for achieving uniform density and quality in the final EPS foam blocks.

Step 2: Molding the EPS Blocks

The pre-expanded beads are then transferred to a block molding machine. Within the mold, more steam is applied, causing the pre-expanded beads to fuse together and fill the mold cavity. This fusion process creates a solid block of EPS foam. The mold’s size and shape determine the dimensions of the final EPS block, allowing for the production of various sizes and shapes based on specific application requirements.

The molding process requires precise control of steam parameters and molding cycle times to ensure uniform fusion and density throughout the block. After the molding cycle is complete, the block is cooled, allowing the EPS to solidify and stabilize. This cooling process is crucial for preventing deformation and ensuring the block maintains its desired shape and dimensions. The cooled block is then ejected from the mold and prepared for further processing.

Step 3: Cutting and Shaping the EPS Blocks

Once the EPS blocks are molded and cooled, they are typically cut and shaped to meet specific size and shape requirements. This process is often performed using hot wire cutters or CNC cutting machines. These tools allow for precise and efficient cutting of the EPS blocks, enabling the production of various shapes and sizes, from simple rectangular blocks to complex custom designs.

The cutting and shaping process is essential for tailoring the EPS blocks to their intended applications. For example, in construction, EPS blocks may be cut into specific sizes for insulation panels or structural components. In packaging, they may be shaped to fit and protect delicate products. The precision of the cutting process ensures that the final EPS components meet the required specifications and tolerances.

Step 4: Quality Control and Finishing

After cutting and shaping, the EPS blocks undergo quality control checks to ensure they meet the required specifications. These checks may include dimensional accuracy, density measurements, and visual inspections. Any blocks that do not meet the quality standards are rejected or reworked.

Finally, the finished EPS blocks may undergo additional finishing processes, such as surface treatments or lamination, depending on their intended application. These finishing processes can enhance the blocks’ performance, durability, and aesthetic appeal. The finished EPS blocks are then packaged and prepared for distribution to customers.

Shaping and Cutting of EPS

Injection Molding

Injection molding is a common method for producing EPS products with complex shapes. The pre-expanded EPS beads are melted and injected into a mold, where they cool and harden into the desired shape.

Cutting and Trimming

After the EPS has been molded, it is cut and trimmed to the required size and appearance. This can be done using a variety of methods, such as sawing, milling, or die-cutting.

The Role of Additives in EPS

Flame Retardants

To improve the fire resistance of EPS, flame retardants are often added during the manufacturing process. These materials work by slowing down the spread of fire and reducing the amount of heat released when EPS burns.

Blow Agents

Blow agents, such as the ones mentioned earlier, are crucial for the expansion of EPS. They help create the microcellular structure that gives EPS its unique properties.

Conclusion

Expanded polystyrene, or EPS, is a fascinating material with a wide range of applications. From food packaging to insulation, EPS plays a crucial role in many industries. Understanding its manufacturing process, properties, and potential environmental concerns is essential for responsible consumption and production.

FAQs

What is EPS and where is it used?

EPS is a lightweight, closed-cellfoam plastic commonly used as packaging for fragile items, as insulation in buildings, and in various other applications, such as flotation devices, protective cushioning, and craft materials.

What are the advantages of using EPS?

EPS offers numerous advantages, including excellent insulation, lightweight yet sturdy properties, water-resistance, resistance to moisture, and high load-bearing capacity.

What are some environmental concerns with EPS?

Some environmental concerns associated with EPS include waste management due to its low recycling rate, carbon footprint from production and disposal, and potential release of harmful substances during incineration.

What alternatives exist to EPS for food packaging?

Alternatives to EPS for food packaging include pulp molded fiber, biodegradable plastics, and recycled cardboard.

What are some common uses of EPS in construction?

Common uses of EPS in construction include building insulation, cladding, roofing, and floatation devices for buildings during construction. EPS is also used in the production of decorative moldings, paneling, and wall partitions.

-1-300x300.webp)