Expanded polystyrene (EPS) is a widely used material known for its versatility and lightweight properties. Found in various applications ranging from construction and packaging to insulation, EPS has become a staple in many industries. However, a common question arises among users and professionals alike: Is expanded polystyrene waterproof?

This article delves into the properties of expanded polystyrene, examining its interaction with water, and the benefits and limitations of its use in wet conditions.

What Is Expanded Polystyrene?

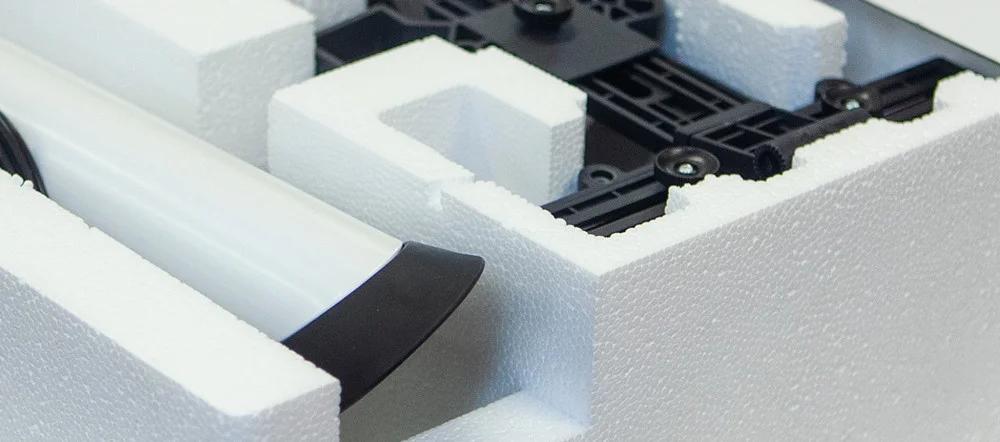

Expanded Polystyrene (EPS) is a lightweight, rigid, closed-cell foam material made from polymerized styrene beads containing dissolved pentane gas. When heated, these beads expand up to 40 times their size, forming a solid foam structure.

EPS is highly versatile, used in construction for insulation, in packaging for protection, and in products like coolers and surfboards due to its excellent thermal insulation, shock absorption, and lightweight nature. Despite being mostly air, EPS is strong and durable, with significant resistance to moisture, compression, and impact.

Environmentally, EPS is 100% recyclable and can be reprocessed into new products, making it sustainable and resource-efficient. Overall, EPS is a functional, adaptable material with broad applications, valued for its insulating properties, durability, and eco-friendliness.

Expanded Polystyrene Waterproof Properties

Expanded Polystyrene (EPS) is often considered water-resistant rather than completely waterproof. Its closed-cell structure helps limit water absorption, making it effective in environments where moisture is a concern, such as foundation and wall insulation.

EPS Waterproof Properties

- Vapor Permeability: While water-resistant, EPS is somewhat permeable to water vapor. This allows the material to “breathe,” meaning it permits the slow diffusion of moisture vapor through its structure, which can be beneficial in managing moisture within building envelopes.

- Closed-Cell Structure: The EPS manufacturing process creates tiny, sealed air pockets within the material. This closed-cell formation is key to its resistance, preventing significant water ingress and maintaining its insulative value even in damp conditions. This makes it a preferred material.

- Low Water Absorption: Due to the material’s inherent nature, EPS exhibits very low water absorption when fully submerged or exposed to high humidity. This crucial property minimizes the increase in weight and the corresponding decrease in thermal performance over its service life.

- Resistance to Freeze-Thaw: Its minimal water absorption helps EPS resist damage from freeze-thaw cycles. Since little water penetrates the structure, there is less volume to expand upon freezing, thereby protecting the foam’s integrity and long-term durability in outdoor applications.

What Makes Expanded Polystyrene Waterproof?

Expanded Polystyrene (EPS) is generally considered highly water-resistant rather than truly waterproof. Its key to resisting moisture lies in its unique manufacturing process, which creates a structure of non-interconnected, closed-cells. This fundamental design is what minimizes water ingress, preserving its insulating properties in wet conditions.

- The Closed-Cell Structure: The manufacturing process uses heat to expand polystyrene beads, creating small, sealed pockets of air. This internal structure is crucial because the non-interconnected cells prevent water from passing through the material’s bulk, acting as physical barriers against moisture penetration.

- The Polystyrene Material: The base polymer, polystyrene, is naturally hydrophobic, meaning it inherently repels water. This molecular characteristic ensures that even the cell walls themselves do not absorb or bond with water molecules, significantly contributing to the foam’s overall resistance to moisture.

- Low Density and Mass: The material’s overall low density means that there is less solid material and more trapped air. This high air content and low mass contribute to its low thermal conductivity, and the minimal solid surface area further restricts the pathways available for water to be absorbed or retained.

- Minimal Water Absorption Rate: When tested, EPS typically demonstrates a very low rate of water absorption, often remaining below 2% by volume, even after prolonged submersion. This low absorption rate is vital for maintaining the material’s structural integrity and its required R-value (thermal resistance) over many years of service.

How Does EPS Interact With Water?

Expanded Polystyrene (EPS) is often described as highly water-resistant due to its inherent material properties and structure, but it is not truly waterproof. Its interaction with water involves minimal liquid absorption while still allowing for the movement of water vapor, which is crucial for building design.

R-Value and Moisture: When EPS absorbs water, its effectiveness as a thermal insulator (R-value) decreases because water is a much better conductor of heat than air. However, studies suggest that its higher vapor permeability allows it to shed or dry out absorbed moisture more effectively over time compared to other rigid foams.

Liquid Water Absorption: EPS has a closed-cell structure, meaning most of the foam’s tiny air pockets are sealed. This design, coupled with the hydrophobic nature of polystyrene, ensures that EPS absorbs only a small amount of liquid water, typically less than 3% by volume, even when submerged for extended periods.

Capillary Movement: While the individual cells are closed, the manufacturing process leaves tiny voids and channels between the fused polystyrene beads. These interstitial spaces can allow liquid water, especially under prolonged contact or pressure, to penetrate and wick into the foam via capillary action, slowly compromising its performance.

Vapor Permeability: EPS is generally considered a vapor-permeable material (a Class III vapor retarder). This means it permits water vapor to slowly diffuse through its structure, a property that can be beneficial for “drying potential” as it allows any moisture that has entered the wall assembly to eventually escape.

Waterproof Expanded Polystyrene Applications

Expanded Polystyrene’s (EPS) high water resistance makes it a vital material in demanding, moisture-prone applications, especially within the construction, civil engineering, and packaging industries. Its ability to repel liquid water while offering high compressive strength ensures long-term performance in wet or submerged conditions.

Below-Grade Foundation Insulation: EPS boards are installed on the exterior of foundation walls and under concrete slabs to provide thermal insulation and an essential moisture barrier. This application helps maintain stable temperatures and prevents water from penetrating the sub-structure, protecting the building envelope.

Flotation Devices and Marine Use: The closed-cell structure and high buoyancy make EPS foam an ideal material for marine applications. It is widely used in constructing dock floats, pontoons, and boat cores, providing reliable, lightweight flotation that resists saturation even after prolonged exposure to water.

Geofoam for Civil Engineering: High-density EPS geofoam blocks are used as an ultra-lightweight fill material in road, bridge, and retaining wall construction. Its low weight minimizes load on soft soils, and its moisture resistance ensures the material’s structural integrity is maintained in groundwater-rich environments.

Protective and Cold-Chain Packaging: EPS is a staple in the cold-chain logistics industry for shipping perishables like seafood and medical supplies. The foam’s thermal insulation and moisture resistance keep contents cold and dry, preventing condensation and bacterial growth during prolonged transport.

Exterior Insulation and Finish Systems (EIFS): In EIFS, EPS serves as the core insulation layer, which is then covered with a waterproof finish. This system utilizes the EPS’s water-repelling properties to provide a continuous, weather-resistant thermal layer for the building’s exterior façade, enhancing durability.

Building And Construction

Foundations and Basements: Waterproof EPS insulation boards are installed below ground level to offer thermal insulation and resist moisture in foundations and basements. This helps in maintaining stable indoor temperatures and prevents water infiltration, safeguarding the structural integrity of the building.

Roofing Systems: EPS panels, coated with waterproof materials, are utilized as insulation layers in roofing systems. These panels not only provide insulation but also act as a barrier against moisture intrusion, thus protecting the building’s interior from water damage. Additionally, by enhancing energy efficiency, they contribute to reduced heating and cooling costs.

Exterior Insulation and Finish Systems (EIFS): Waterproof EPS boards form an integral part of EIFS applications, providing insulation and weatherproofing for building exteriors. These boards offer thermal insulation while effectively shielding the building from external moisture, ensuring durability and enhancing aesthetic appeal.

Packaging

Shipping Containers: Waterproof EPS packaging solutions are employed to safeguard goods during transportation, particularly for items vulnerable to moisture damage like electronics and perishable goods. These containers provide a protective barrier against external moisture, ensuring that the enclosed products arrive at their destination in optimal condition.

Cold Chain Logistics: Waterproof EPS coolers and containers are instrumental in cold chain logistics for transporting temperature-sensitive products. These containers effectively maintain the desired temperature and protect the contents from moisture ingress. By ensuring that the products remain dry throughout the transit, EPS helps preserve their quality and integrity, crucial for industries such as food and pharmaceuticals.

Marine and Aquatic Applications

Boat and Dock Construction: Waterproof EPS foam finds extensive use in constructing boats, docks, and marine structures. Its buoyancy and resistance to water absorption make it an ideal material for these applications. By maintaining buoyancy and structural integrity even when submerged, EPS ensures the durability and stability of marine constructions.

Underwater Insulation: Waterproof EPS panels are utilized as insulating materials in underwater environments, such as subsea pipelines and underwater habitats. In these settings, where protection against water intrusion is critical, waterproof EPS panels provide thermal insulation while preventing moisture ingress. This helps maintain stable temperatures and protects sensitive equipment or habitats from water-related damage.

Conclusion

In summary, while EPS displays water-resistant characteristics owing to its closed-cell structure, it falls short of being entirely waterproof. While suitable for scenarios with occasional moisture exposure, prolonged or consistent water contact can compromise its integrity. Recognizing these limitations is crucial for informed decision-making in diverse applications.

Implementing protective measures like surface treatments can bolster its water resistance when necessary. Overall, understanding these nuances enables prudent use of EPS, balancing its benefits with potential water-related risks.