Graphite enhanced polystyrene (GEP), a revolutionary material blending the versatility of polystyrene with the exceptional properties of graphite, has emerged as a cornerstone in modern industry. Its unique composition offers a spectrum of advantages, from enhanced thermal conductivity to improved mechanical strength and beyond.

Let’s delve into the world of GEP, exploring its origins, properties, production process, applications, and environmental impact.

What is Graphite Enhanced Polystyrene (GEP)?

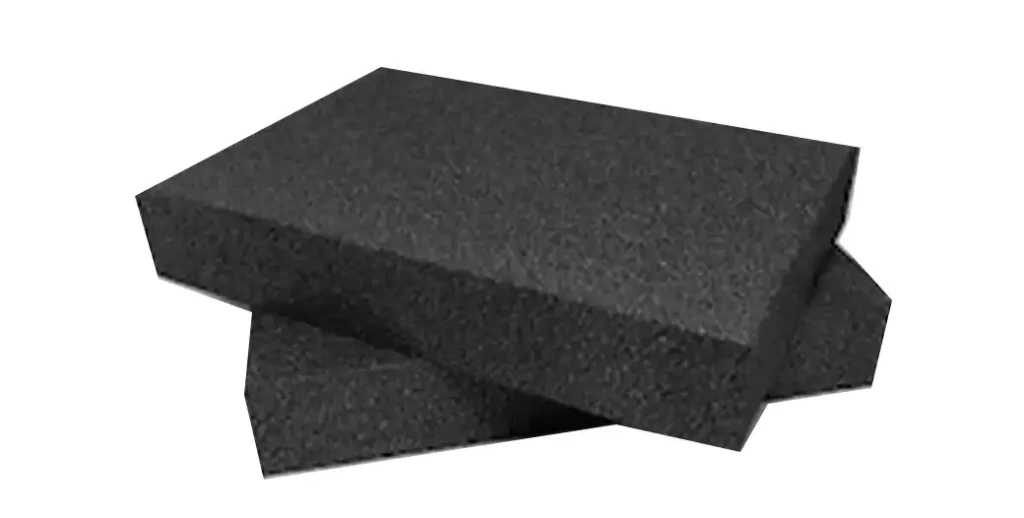

Graphite Enhanced Polystyrene, often abbreviated as GEP, is a composite material comprised of polystyrene infused with graphite particles.

This infusion imparts exceptional thermal, mechanical, and electrical properties to the base polystyrene, making it highly desirable across various industries.

Historical of Graphite Enhanced Polystyrene

The historical background of Graphite Enhanced Polystyrene (GEP) traces back to the late 20th century when there arose a growing demand for materials with enhanced thermal insulation properties and improved mechanical strength. Researchers and scientists began exploring the possibility of creating composite materials that could combine the desirable characteristics of different substances.

The concept of incorporating graphite into polystyrene emerged as a promising avenue for achieving these objectives. Graphite, known for its exceptional thermal conductivity and electrical properties, seemed like an ideal candidate for enhancing the performance of polystyrene, a widely used polymer known for its lightweight nature and versatility.

Early experiments involved blending graphite particles into the polystyrene matrix, aiming to create a composite material that would exhibit superior thermal insulation, mechanical strength, and other desirable properties. Over time, advancements in material science and manufacturing techniques refined the production process, leading to the development of Graphite Enhanced Polystyrene as we know it today.

As the benefits of GEP became increasingly apparent, its adoption spread across various industries, ranging from construction and automotive to electronics and packaging. Today, GEP stands as a testament to the power of innovation and collaboration in addressing the evolving needs of modern industry, offering a sustainable and versatile solution for a wide range of applications.

Graphite Polystyrene Insulation

Graphite Polystyrene Insulation is a composite material composed of expanded polystyrene (EPS) infused with graphite particles. This infusion enhances the material’s thermal conductivity, allowing it to trap and retain heat more effectively than conventional insulation materials. The addition of graphite also strengthens the insulation, making it more durable and resilient to temperature fluctuations and mechanical stress.

Properties of Graphite Enhanced Polystyrene

Thermal Conductivity

One of the standout features of GEP is its exceptional thermal conductivity. By incorporating graphite particles into the polystyrene matrix, heat transfer within the material is significantly enhanced, making it ideal for applications requiring efficient insulation or heat dissipation.

Mechanical Strength

Contrary to conventional wisdom, the addition of graphite to polystyrene does not compromise its mechanical strength. Instead, it reinforces the material, imparting greater structural integrity and durability, thereby expanding its utility across a diverse array of load-bearing applications.

Electrical Conductivity

Graphite’s intrinsic conductivity imparts electrical properties to GEP, making it suitable for applications where static dissipation or electrical insulation is required. This unique combination of electrical characteristics broadens the scope of GEP’s applicability, particularly in electronics manufacturing and packaging solutions.

Chemical Stability

GEP exhibits remarkable chemical stability, rendering it resistant to degradation from exposure to harsh environments or corrosive substances. This inherent resilience ensures the longevity and reliability of GEP-based products in challenging operational conditions.

Graphite Enhanced Polystyrene Production Process

Raw Materials

The production of GEP begins with the procurement of high-quality polystyrene resin and graphite particles. These raw materials form the foundation of the composite material, with their composition and quality exerting a significant influence on the final properties of the product.

Mixing and Blending

In the mixing stage, the polystyrene resin is combined with precisely measured quantities of graphite particles, ensuring uniform dispersion throughout the matrix. This meticulous blending process is critical for achieving consistent performance and desired properties in the final product.

Extrusion and Molding

Once the composite mixture is prepared, it undergoes extrusion and molding processes to form the desired shape and dimensions. These manufacturing techniques allow for the production of GEP components tailored to specific applications, ranging from intricate electronic casings to large-scale construction panels.

Graphite Enhanced Polystyrene Applications

Construction Industry

In the construction sector, GEP finds extensive use in thermal insulation panels, roofing materials, and structural components. Its superior thermal conductivity and mechanical strength make it an ideal choice for enhancing energy efficiency and durability in building projects.

Automotive Sector

Within the automotive industry, GEP is employed in various applications, including interior trim components, engine enclosures, and lightweight structural elements. Its combination of low density, high strength, and thermal stability contributes to improved fuel efficiency and vehicle performance.

Electronics Manufacturing

GEP’s exceptional electrical properties make it indispensable in the realm of electronics manufacturing, where it is utilized in circuit boards, housing enclosures, and heat sinks. Its ability to dissipate heat efficiently ensures the reliability and longevity of electronic devices.

Packaging Solutions

In the packaging industry, GEP offers a sustainable alternative to traditional materials, thanks to its recyclability and reduced environmental impact. It is used in the production of protective packaging, insulating containers, and shock-absorbing materials, safeguarding goods during transit while minimizing waste.

Advantages Over Conventional Polystyrene

Enhanced Thermal Properties

Compared to conventional polystyrene, GEP exhibits superior thermal conductivity, enabling more efficient insulation and heat management in various applications. This translates to reduced energy consumption and enhanced performance across industries.

Increased Durability

The incorporation of graphite particles enhances the mechanical strength and durability of polystyrene, making GEP more resilient to mechanical stress, temperature fluctuations, and chemical exposure. This increased durability extends the service life of GEP-based products, reducing maintenance costs and downtime.

Greater Electrical Conductivity

Unlike standard polystyrene, which is electrically insulating, GEP possesses inherent conductivity due to the presence of graphite. This electrical property makes it suitable for applications requiring static dissipation or electrical grounding, enhancing safety and reliability in electronic systems.

Improved Chemical Resistance

GEP’s chemical stability renders it resistant to degradation from exposure to corrosive substances or environmental contaminants. This robustness makes it well-suited for applications in aggressive industrial environments or harsh operating conditions, where conventional materials may falter.

Environmental Impact

Recyclability

One of the key advantages of GEP is its recyclability, which mitigates the environmental burden associated with traditional polystyrene disposal. By promoting closed-loop recycling systems, GEP contributes to resource conservation and waste reduction, aligning with sustainable manufacturing practices.

Reduction of Carbon Footprint

The production of GEP typically entails lower energy consumption and greenhouse gas emissions compared to alternative materials, owing to its lightweight nature and efficient manufacturing processes. This reduction in carbon footprint underscores GEP’s role as an environmentally responsible choice for eco-conscious industries.

Sustainable Manufacturing Practices

From raw material sourcing to end-of-life disposal, GEP embodies sustainability principles throughout its lifecycle. Manufacturers can minimize their environmental impact by prioritizing renewable resources, optimizing production processes, and promoting circular economy initiatives while maximizing the value proposition of GEP-based products.

FAQs about Graphite Enhanced Polystyrene

What are the primary uses of Graphite Enhanced Polystyrene?

GEP finds applications in various industries, including construction, automotive, electronics, and packaging, where its unique combination of properties offers unparalleled performance and versatility.

How does the production process differ from traditional polystyrene?

The production of GEP involves incorporating graphite particles into the polystyrene matrix, enhancing its thermal, mechanical, and electrical properties. This differs from traditional polystyrene production, which does not involve such additives.

Is GEP environmentally friendly?

Yes, GEP is considered environmentally friendly due to its recyclability and reduced carbon footprint compared to conventional polystyrene. Its sustainable manufacturing practices further contribute to its eco-friendly profile.

Can GEP be recycled?

Yes, GEP is recyclable through conventional plastic recycling processes. Its compatibility with existing recycling infrastructure facilitates the diversion of waste from landfills, promoting resource conservation and circular economy principles.

Are there any safety concerns associated with GEP?

GEP is generally regarded as safe for use in various applications. However, as with any material, proper handling and disposal practices should be observed to minimize potential risks to human health and the environment.

What industries benefit the most from utilizing GEP?

Industries requiring superior thermal insulation, mechanical strength, electrical conductivity, and chemical stability stand to benefit the most from utilizing GEP. This includes sectors such as construction, automotive, electronics, and packaging, among others.

Conclusion

In conclusion, Graphite Enhanced Polystyrene (GEP) represents a paradigm shift in material science, offering a synergistic blend of performance, versatility, and sustainability. From its exceptional thermal properties to its inherent recyclability, GEP continues to redefine the boundaries of innovation across diverse industries. As the demand for efficient, eco-friendly materials grows, GEP stands poised to lead the charge towards a more sustainable future.