Welcome to the comprehensive guide on shaping EPS foam. Whether you’re a beginner or an experienced artisan, mastering the art of sculpting foam opens endless creative possibilities. From crafting props for theater productions to creating stunning sculptures, EPS foam is a versatile material.

In this guide, we’ll delve into the intricacies of shaping EPS foam, exploring various techniques and tools to help you unleash your creativity.

What is EPS Foam?

EPS foam, short for Expanded Polystyrene foam, is a lightweight and rigid material commonly used in packaging, insulation, and crafting. Composed of polystyrene beads expanded with steam, EPS foam exhibits excellent thermal insulation properties.

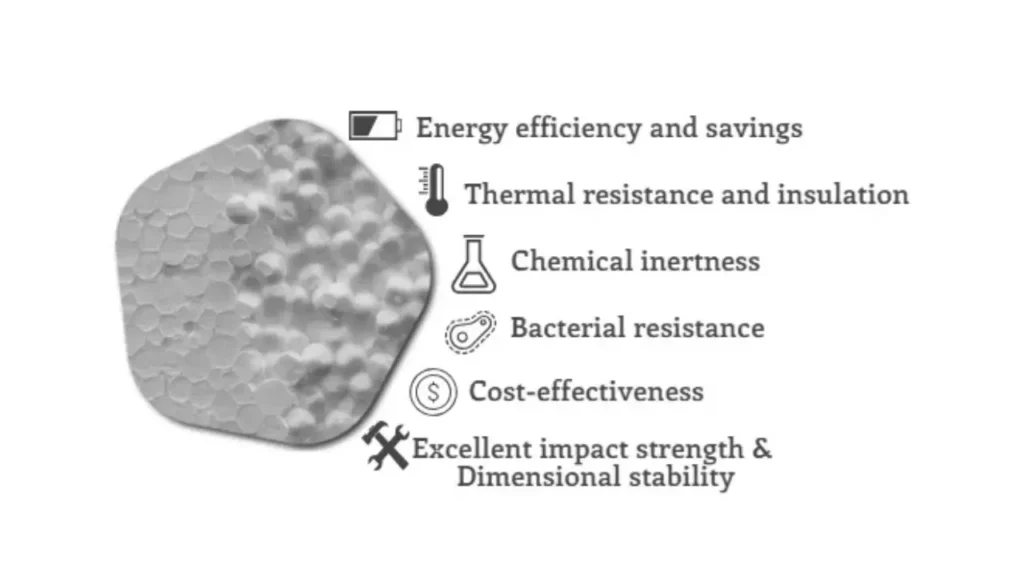

Properties of EPS Foam

We supply and manufacture advanced EPS foam solutions, ensuring exceptional performance across various sectors. Our product is widely used in construction and protective packaging due to its outstanding cellular structure and material integrity. We offer this highly efficient material as a reliably strong and cost-effective choice for insulating structures and protecting goods.

Excellent Impact Strength And Dimensional Stability: We provide EPS foam engineered with high shock absorption capabilities, which is essential for protective cushioning. Its dimensional stability ensures the material retains its precise shape and size across fluctuations in temperature or moisture. This guarantees a sturdy and reliable structural performance.

Energy Efficiency And Savings: We provide EPS foam that is crucial for building energy efficiency. Its excellent thermal performance significantly reduces a structure’s heating and cooling requirements. We help clients achieve notable long-term energy savings and lower utility costs because the foam’s barrier minimizes heat exchange through walls and roofs.

Thermal Resistance And Insulation: We offer superior thermal resistance thanks to the closed-cell composition of the material, which traps air. This structure acts as a dependable insulation layer that maintains stable interior temperatures effectively. This low thermal conductivity ensures we supply a material that delivers consistent, lasting thermal performance.

Chemical Inertness: We ensure our EPS foam is chemically inert, meaning it remains stable when exposed to most common construction chemicals. This resistance prevents degradation or unwanted reactions over time, allowing for safe integration with various building envelope materials. We supply a durable product with a long, maintenance-free service life.

Bacterial Resistance: We manufacture a product that is inherently resistant to mold, mildew, and fungal growth. The material is non-nutritive and has a low water absorption rate, preventing it from supporting microorganisms. This property is key to supplying solutions that help maintain healthier and cleaner indoor environments.

Cost-Effectiveness: We offer EPS foam as an economically sensible solution for projects of any size. Its lightweight nature significantly lowers transportation and labor expenses on the job site. The foam’s durability combined with the resultant energy savings contributes to a low overall lifecycle cost for the end-user.

Benefits of Shaping EPS Foam

Shaping EPS foam offers a myriad of benefits that make it a preferred choice for various applications:

Versatility: EPS foam is highly versatile, lending itself to a wide range of projects and applications. Whether you’re crafting intricate sculptures, architectural models, or lightweight props for theater productions, EPS foam provides a versatile canvas for creativity.

Lightweight: One of the most significant advantages of EPS foam is its lightweight nature. Unlike traditional materials like wood or metal, EPS foam allows for the creation of large-scale structures without adding significant weight. This makes it ideal for projects where weight is a concern, such as stage sets or event decorations.

Ease of Manipulation: EPS foam is easy to manipulate, making it suitable for artists and craftsmen of all skill levels. Whether you’re a beginner or an experienced artisan, shaping EPS foam requires minimal effort and expertise. Its lightweight and forgiving nature allow for easy cutting, carving, and shaping to achieve desired designs.

Cost-Effectiveness: Compared to other materials like wood or metal, EPS foam is highly cost-effective. It’s readily available and affordable, making it an economical choice for both hobbyists and professionals alike. Additionally, its lightweight properties can result in cost savings during transportation and installation.

Insulation Properties: In addition to its creative benefits, EPS foam also boasts excellent thermal insulation properties. Its closed-cell structure provides effective insulation against heat transfer, making it ideal for use in packaging and construction applications where thermal efficiency is essential.

Durability: Despite its lightweight and airy appearance, EPS foam is surprisingly durable. It can withstand a wide range of environmental conditions, including moisture, mold, and mildew, ensuring longevity in various applications. Additionally, EPS foam is resistant to rot and decay, making it suitable for both indoor and outdoor use.

Tools for Shaping EPS Foam

We provide various EPS foam products that often require cutting and shaping for final application in architecture or design. To achieve precise, clean results, specific tools are necessary for working with this lightweight material. We ensure professionals and hobbyists can work the foam efficiently using both thermal-based and mechanical cutting methods. The right equipment is key to reducing waste and guaranteeing optimal finish.

CNC Automated Cutting Systems We employ CNC cutting systems for large-volume, complex foam fabrication. These computer-controlled machines use multiple hot wires or routers to follow precise digital paths, ensuring high accuracy and repeatability. We manufacture custom packaging inserts and large architectural elements with supreme efficiency using this advanced equipment.

Hot Wire Cutters We supply specialized thermal cutters that use an electrically heated wire to melt and slice through the foam. This method offers unparalleled precision and creates a remarkably smooth, sealed edge without generating dusty waste. This tool is ideal for quickly producing custom architectural moldings and straight EPS foam sheets.

Hot Knives We offer specialized hot knives designed to cut complex shapes and carve details into thick foam blocks. The heated blade easily glides through the material, which helps in defining grooves and internal voids. This thermal tool minimizes friction and delivers clean cuts, making it a valuable asset for sculptors and insulation installers.

Serrated Knives And Hand Saws We recommend using sharp, fine-toothed serrated blades, like a bread knife or hand saw, for basic manual cuts. These tools are effective for slicing insulation panels into required sizes for installation. While quick, they can produce static-prone foam dust, so we advise working in a well-ventilated area for cleanliness.

Abrasive Tools And Rasps We recommend using tools like surform rasps and varying grits of sandpaper for refining and smoothing surfaces. These abrasive tools allow users to remove small amounts of material to achieve curved or detailed profiles after initial cuts. This technique provides the final, detailed shape for intricate EPS foam sculptures and prototypes.

How to Shape EPS Foam?

Safety Precautions: Always wear safety goggles and a dust mask when working with EPS foam to protect yourself from airborne particles and fumes generated during cutting and shaping processes. Additionally, work in a well-ventilated area to minimize exposure to fumes.

Shaping EPS foam involves several techniques and tools to achieve desired designs effectively.

Here’s a step-by-step guide on how to shape EPS foam:

Prepare Your Workspace: Start by setting up a clean and well-ventilated workspace. Ensure you have ample room to maneuver and work comfortably.

Gather Your Tools: Collect the necessary tools for shaping EPS foam, including a hot wire cutter, foam rasp, sanding blocks, heat gun or oven (for heat molding), and safety equipment such as safety goggles and a dust mask.

Design Your Project: Before you begin shaping the EPS foam, have a clear idea of the design or shape you want to create. Sketch out your design on paper or create a digital mockup to serve as a reference.

Cutting with a Hot Wire Cutter: If you need to make straight cuts or shape large pieces of EPS foam, use a hot wire cutter. Turn on the cutter and carefully guide it along the lines of your design, allowing the heat to melt through the foam smoothly.

Carving with a Foam Rasp: For more intricate details or shaping curved surfaces, use a foam rasp. Gently carve away excess foam, working in small, controlled movements to achieve the desired shape and texture.

Sculpting: Sculpting involves shaping EPS foam into three-dimensional objects. Use a combination of cutting, carving, and shaping techniques to bring your design to life, focusing on creating smooth transitions and realistic textures.

Heat Molding (Optional): If you need to reshape or bend the foam, you can use heat molding. Apply heat to the desired area using a heat gun or by placing the foam in a preheated oven. Once the foam becomes pliable, carefully mold it into the desired shape and hold it in place until it cools and sets.

Refine and Smooth: After shaping the EPS foam, use sanding blocks to refine rough edges and smooth out any imperfections. Start with coarse sandpaper to remove any large bumps or uneven areas, then gradually switch to finer grits for a polished finish.

Finishing Touches: Once you’re satisfied with the shape and texture of the EPS foam, you can add finishing touches such as painting, sealing, or embellishing with other materials to enhance the appearance and durability of your project.

Techniques for Shaping EPS Foam

Carving

Carving is a fundamental technique for shaping EPS foam. Using a hot wire cutter or foam rasp, carve away excess foam to create desired shapes and forms.

Sculpting

Sculpting involves shaping EPS foam into three-dimensional objects. Whether crafting figurines or architectural models, sculpting allows for intricate detailing and realistic textures.

Heat Molding

Heat molding is a technique that involves applying heat to EPS foam to reshape it. By heating the foam with a heat gun or oven, it becomes malleable, allowing for bending and shaping into desired forms.

Tips for Working with EPS Foam

Work in a Well-Ventilated Area

When shaping EPS foam, ensure adequate ventilation to prevent inhalation of fumes produced during cutting and shaping processes.

Use Safety Equipment

Wear safety goggles and a dust mask to protect yourself from airborne particles and fumes generated during foam sculpting.

Practice Patience

Mastering the art of shaping EPS foam takes time and practice. Be patient with yourself and embrace the learning process.

Common Mistakes to Avoid

Applying Too Much Heat

Excessive heat can cause EPS foam to melt or deform irreversibly. Use caution when heat molding and ensure even distribution of heat.

Neglecting Surface Preparation

Failing to properly prepare the surface of EPS foam can result in adhesion issues when painting or applying finishes. Always sand and prime the foam before adding decorative elements.

Overcomplicating Designs

Keep designs simple and manageable, especially when starting out. Overly intricate designs can be challenging to execute with EPS foam.

FAQs

How do I shape EPS foam without a hot wire cutter?

You can use handheld tools like utility knives or serrated blades to carve EPS foam manually. While it may require more effort, it’s still achievable with patience and precision.

Can EPS foam be recycled?

Yes, EPS foam is recyclable. Many recycling facilities accept EPS foam for processing into new products, reducing environmental impact.

What types of projects can I create with shaped EPS foam?

The possibilities are endless! You can create anything from cosplay costumes and props to architectural models and themed décor.

Is EPS foam suitable for outdoor use?

While EPS foam is not inherently weatherproof, it can be coated with sealants or paints to enhance durability and weather resistance.

How do I achieve smooth finishes on EPS foam?

Sanding is key to achieving smooth finishes on EPS foam. Start with coarse sandpaper to remove rough edges, then gradually switch to finer grits for a polished surface.

Can EPS foam be painted?

Yes, EPS foam can be painted with acrylic or latex paints. However, it’s essential to prime the foam beforehand to ensure proper adhesion and prevent paint from being absorbed unevenly.

Conclusion

Mastering the art of shaping EPS foam opens a world of creative possibilities. Armed with the right tools, techniques, and tips, you can bring your imagination to life and create stunning works of art. Whether you’re a hobbyist or a professional crafter, shaping EPS foam allows you to unleash your creativity and craft intricate designs with ease.