Maintaining your EPS mould is crucial for continuous, effective production. We provide practices that shield your investment from wear and tear, ensuring every cycle meets your exacting standards. Proper care minimizes downtime and keeps your manufacturing process running smoothly and efficiently.

We supply these moulds as foundational tools for your business. Neglecting them can lead to defects and costly repairs. We offer these vital maintenance steps to help you achieve the best performance and longevity from your EPS equipment, securing your production quality.

What are EPS Moulds?

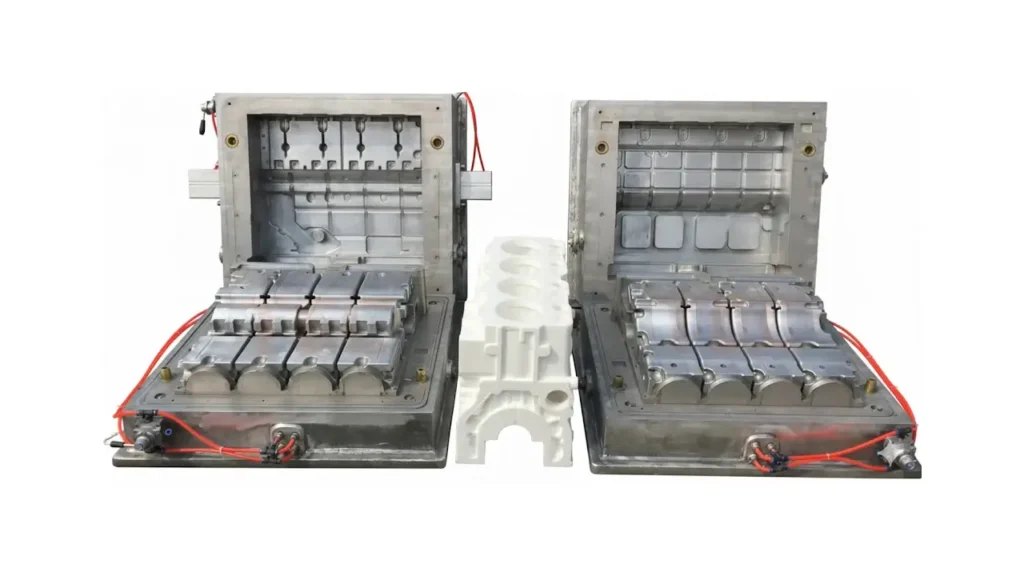

EPS moulds are specialized tools we manufacture for creating shapes from Expanded Polystyrene. We provide these moulds to inject steam, causing EPS beads to expand and fuse into the desired product form. They are crucial for producing lightweight, insulating items, and packaging solutions with precise dimensions and excellent consistency.

Types of EPS Moulds

We manufacture various types of EPS moulds, each precisely engineered to serve specific industry demands, from simple forms to complex, technical components. Understanding the distinctions ensures you select the correct tooling for your production needs, guaranteeing optimal results. We supply molds for different applications and production scales.

EPS Block Molds: We supply block molds that produce large, rectangular EPS foam blocks. These blocks are subsequently cut using hot wire techniques into sheets or varied custom shapes. This method offers versatility for insulation, geofoam, and architectural elements, maximizing material utilization and flexibility.

EPS Packaging Molds: We offer these molds to create custom protective solutions for diverse products, including electronics, cold chain logistics, and fragile goods. They are designed for superior shock absorption and lightweight structure, ensuring secure transit and minimal shipping costs, which helps protect the item.

EPS Insulation Panel Molds: We provide specialized tooling for constructing large panels used in the building and construction sectors. These moulds feature precise dimensions and often include interlocking profiles. They ensure high thermal efficiency and ease of installation, contributing to energy-saving structures and meeting code requirements.

How to Maintain EPS Mould?

Proper maintenance is fundamental to ensuring your EPS moulds deliver optimal, consistent performance and maximum longevity. We provide simple, actionable tips that prevent common issues, reduce the need for unscheduled repairs, and maintain the structural integrity of your tooling. Regular care is key to protecting this valuable manufacturing asset.

Optimal Storage Practices We suggest storing unused moulds in a clean, dry, and temperature-controlled environment. Coating the mould surfaces with a rust inhibitor is critical before storage to prevent corrosion, especially on polished areas. Proper storage protects the mould from dust and humidity damage, preserving its readiness for production.

Routine Cleaning After Use We advise cleaning all residual EPS beads and debris from the mould cavities and vents immediately after each production cycle. This prevents material buildup and blockages which can affect part quality. Using high-pressure water or dry ice blasting is effective for maintaining the mould’s precise surface finish.

Thorough Inspection and Lubrication We recommend frequent visual checks for signs of wear, pitting, or damaged sealing strips. Apply high-temperature, compatible grease to all moving components, such as ejector pins and guide rails. This lubrication minimizes friction, ensuring all moving parts operate smoothly and preventing premature wear and tear.

Conclusion

By consistently following the preventative care and cleaning tips we have supplied, you are ensuring your EPS mould maintains its structural integrity and casting precision. This rigorous approach reduces the frequency of unexpected failures and the need for expensive component replacements. We enable maximum operational efficiency, which protects your bottom line.

We understand that your EPS mould is a significant asset. Our guidance is designed to transform routine upkeep into a strategic practice that significantly extends the mould’s service life. We help you preserve the mould’s fine details and smooth surfaces, ensuring a consistent finish and reliable performance for years to come.

For high-performing, durable EPS moulds, we invite you to explore the extensive selection we manufacture. We offer complete tooling solutions built to the highest specifications for various applications. Visit our epsole to get wholesale EPS mould options that will seamlessly integrate with your maintained equipment.