Expanded Polystyrene (EPS) foam, commonly known as Styrofoam, is a versatile material used in various industries due to its lightweight nature and excellent insulation properties. However, its widespread use also leads to significant environmental challenges, particularly in terms of disposal.

EPS foam recycling plays a crucial role in addressing these challenges by diverting EPS foam waste from landfills and promoting sustainable waste management practices. By recycling EPS foam, we can reduce pollution, conserve natural resources, and mitigate the environmental impact associated with its disposal.

What Is EPS?

EPS, short for Expandable Polystyrene (PS), is a lightweight, rigid plastic foam material renowned for its exceptional thermal insulation, cushioning, and shock resistance capabilities. With inherent anti-aging properties and waterproof characteristics, EPS is a versatile material extensively utilized in various industries.

Commonly found in food and electronics packaging, EPS provides reliable protection for delicate items during transportation and storage. Its insulation properties also make it a preferred choice in the construction industry, where it serves as an efficient insulating material for walls, roofs, and floors.

The production process involves the expansion of the styrene monomer to create the polymer structure of EPS, resulting in its unique cellular composition. This manufacturing method allows EPS to achieve its desired lightweight and insulating properties while maintaining durability and structural integrity.

Can Expanded Polystyrene Be Recycled?

Yes, Expanded Polystyrene (EPS) can be recycled. While recycling processes for EPS may vary depending on local facilities and capabilities, EPS is a recyclable material that can be processed and reused in various applications.

The recycling process typically involves collecting EPS waste, such as packaging materials or discarded products, and transporting it to recycling facilities. At these facilities, EPS waste is cleaned, shredded, and compacted into densified blocks or pellets. These densified EPS blocks or pellets can then be melted down and formed into new products or reused as raw material for manufacturing.

Recycling EPS helps reduce waste going to landfills, conserves resources, and promotes a circular economy. Many municipalities and recycling centers accept EPS for recycling, so it’s essential to check local recycling guidelines and facilities to determine the best way to recycle EPS in your area.

Why Recycle EPS?

EPS foam recycling plays a crucial role in environmental conservation and waste management. Unlike biodegradable materials, EPS foam can persist in landfills for hundreds of years, releasing harmful chemicals and occupying valuable space. Recycling EPS foam reduces waste accumulation, conserves energy, and minimizes the environmental impact associated with its disposal.

Mechanical Recycling: Shredding and Melting

Mechanical recycling involves shredding EPS foam into smaller pieces, which are then melted and molded into new products. This process helps reduce the volume of EPS foam waste and enables the production of recycled materials for various applications, including packaging and insulation.

Chemical Recycling: Breaking Down Polymers

Chemical recycling utilizes solvents or heat to break down the polymer chains of EPS foam into their constituent molecules. This process allows for the extraction of valuable chemical compounds, which can be used in the production of new materials or energy generation.

Chemical recycling offers a promising solution for addressing the challenges associated with EPS foam recycling, including contamination and degradation.

Pyrolysis: Converting EPS Foam into Energy

Pyrolysis entails heating EPS foam without oxygen, and breaking it down into gases, oils, and char. The products obtained can be used as fuels or raw materials for manufacturing chemicals and various items. Pyrolysis provides an eco-friendly method to turn EPS foam waste into valuable resources, cutting down on its environmental impact.

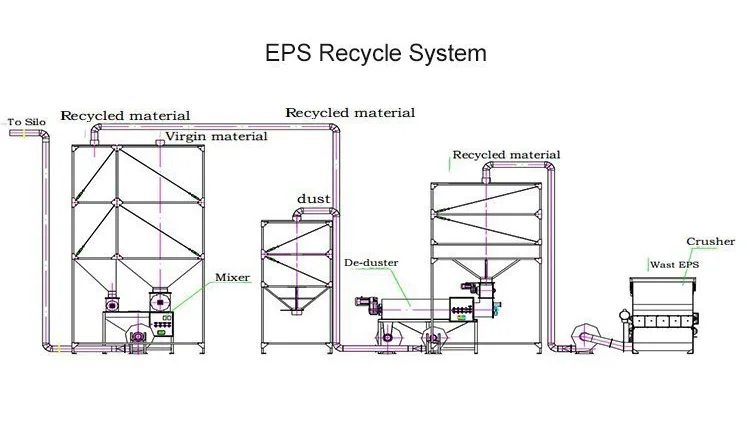

Steps for Mechanical Recovery of EPS foam

- Collection: EPS foam waste is collected from various sources, such as packaging materials, electronic appliances, and construction materials.

- Sorting: The collected EPS foam is sorted to remove any contaminants or non-foam materials, such as labels, tape, or dirt. This step ensures that the recycled material is of high quality.

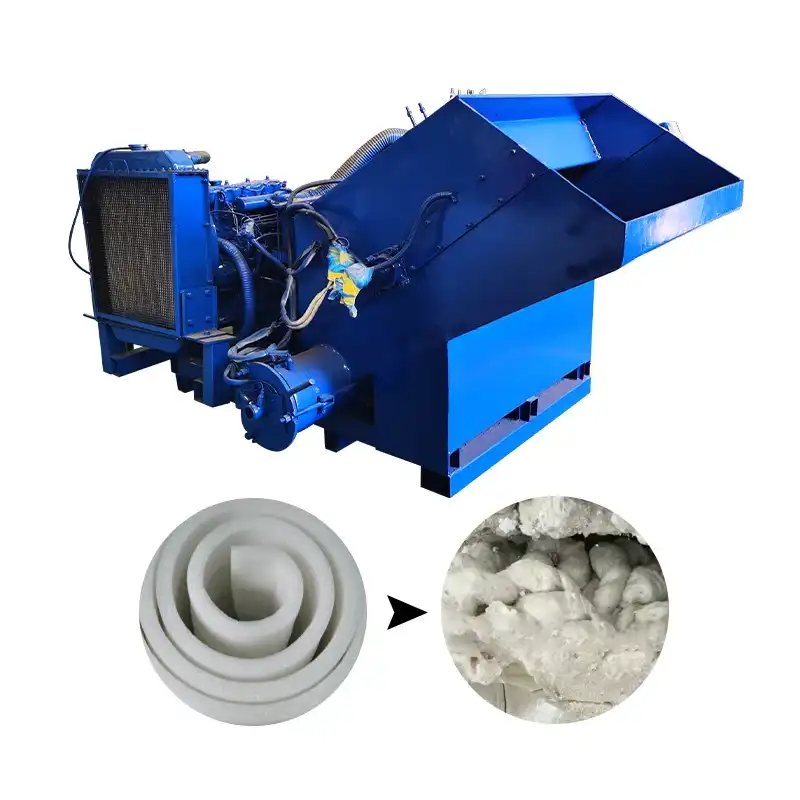

- Shredding or Crushing: The sorted EPS foam is then shredded or crushed into smaller pieces. This process increases the surface area of the material, making it easier to handle in subsequent steps.

- Compacting: The shredded or crushed EPS foam is fed into a compactor machine. This machine applies pressure to compress the foam, reducing its volume significantly. Compacting the EPS foam helps to minimize storage space and transportation costs.

- Melting or Densifying: In some cases, the compacted EPS foam may undergo further processing to melt or densify the material. Melting the EPS foam can transform it into denser blocks or ingots, while densifying involves applying heat and pressure to create solid, dense logs or bricks of recycled material.

- Pelletizing: Alternatively, the melted or densified EPS foam may be pelletized into small pellets or beads. Pelletizing the material can make it easier to handle and transport, as well as facilitate its incorporation into manufacturing processes for new products.

Benefits of EPS Foam Recycling

Waste Reduction: Recycling polystyrene significantly decreases the amount of waste sent to landfills and prevents it from ending up in oceans, contributing to environmental conservation.

Volume Reduction: Polystyrene compactors can compress large quantities of polystyrene, reducing its volume by up to 95%. This not only saves storage space but also makes transportation more efficient.

Space Efficiency: The compacted polystyrene takes up minimal space, making storage and handling more manageable. This can also improve workplace safety by reducing clutter and potential hazards.

Revenue Generation: Recycling polystyrene creates an additional revenue stream for businesses. The market demand for recycled polystyrene blocks provides an opportunity to generate income from what would otherwise be waste material.

Resource Conservation: Recycling polystyrene conserves valuable resources like oil, which is the primary raw material for polystyrene production. This contributes to sustainable resource management and reduces dependence on finite resources.

Carbon Footprint: By recycling polystyrene, the lifecycle of the material is extended, reducing the need for new production from oil-based sources. This leads to a lower carbon footprint and less strain on natural resources.

Environmental Protection: Recycling polystyrene helps protect the environment by reducing pollution, conserving energy, and promoting responsible waste management practices.

How To Recycle EPS Foam?

Collection: EPS foam waste is collected from various sources, including packaging, shipping materials, and consumer products. Recycling centers, waste management companies, and businesses often have collection programs in place to gather EPS foam for recycling.

Sorting: Once collected, EPS foam is sorted based on its type, color, and quality. This step ensures that only clean and uncontaminated EPS foam is processed for recycling, as contaminants can affect the quality of the recycled material.

Compaction or Shredding: After sorting, EPS foam is either compacted or shredded into smaller pieces to reduce its volume and facilitate transportation to recycling facilities. Compaction or shredding helps optimize storage space and transportation efficiency.

Melting and Extrusion: The compacted or shredded EPS foam is then melted down using heat and pressure to form dense blocks or pellets. This process, known as melting and extrusion, transforms the EPS foam into a reusable raw material for manufacturing new products.

Manufacturing New Products: The melted and extruded EPS foam can be used to manufacture a wide range of products, including packaging materials, insulation boards, and even decorative items. By incorporating recycled EPS foam into new products, manufacturers contribute to resource conservation and waste reduction.

How Can You Recycle Polystyrene Properly?

It’s crucial to assess the amount of polystyrene waste generated by your company daily, weekly, and monthly. Once you have a clear understanding of your waste production, you can consider investing in polystyrene compactors.

These compactors offer numerous benefits. Simply load the waste material into the compactor, and it will apply significant pressure to efficiently reduce the volume of polystyrene.

Polystyrene compactors are user-friendly, requiring minimal maintenance, and they can handle both wet and dry polystyrene materials with ease. Once compacted, the polystyrene blocks can be collected and sold to a recycling company of your choice. This not only reduces your company’s carbon footprint but also provides an additional revenue stream, as mentioned earlier.

If you’re interested in learning more about the types of polystyrene compactors available, please click here to get in touch with us today.

Is EPS 100% recyclable?

Certainly! EPS, while not biodegradable, is fully recyclable. However, its recycling poses challenges due to its composition, with 98% being air, making storage and transportation costly.

EPS foam recycling machines help address this by compacting EPS waste, reducing its volume and making transportation more efficient. This process facilitates cost-effective recycling and contributes to sustainability by repurposing EPS into valuable materials.

Is Expanded Polystyrene Foam Recyclable?

Expanded polystyrene foam, commonly known as EPS foam or Styrofoam, is technically recyclable, but the extent of its recyclability depends on various factors, including local recycling capabilities and infrastructure.

EPS foam can be challenging to recycle due to its low density and bulky nature, which makes it economically inefficient to transport and process. However, there are recycling facilities that specialize in handling EPS foam.

Typically, the recycling process involves compacting or densifying the foam into smaller, more manageable blocks or pellets. These densified materials can then be used in various applications, such as manufacturing new foam products or as filler material in construction.

Conclusion

In conclusion, EPS foam recycling is pivotal for addressing environmental challenges associated with its disposal. Through mechanical and chemical processes, EPS waste can be transformed into reusable materials, reducing pollution and conserving resources.

Investing in polystyrene compactors further enhances recycling efficiency and offers additional revenue streams. By embracing EPS foam recycling, we contribute to a cleaner environment and a more sustainable future.