EPP foam, or Expanded Polypropylene, is a versatile material known for its outstanding characteristics. This lightweight yet incredibly durable plastic foam offers a compelling combination of features, making it a popular choice across various industries. This guide explores the key EPP foam properties, focusing specifically on its significant capabilities in insulation and shock absorption.

Understanding how EPP’s unique cellular structure contributes to these benefits is crucial. Its excellent thermal resistance makes it an effective insulator, while its high elasticity and memory effect allow it to absorb multiple impacts without permanent deformation. Discover the science behind these properties and the wide range of applications that capitalize on EPP’s superior performance.

What is EPP?

EPP stands for Expanded Polypropylene, which is a highly versatile, closed-cell thermoplastic foam known for its exceptional combination of light weight, durability, and resilience.

It is manufactured by expanding polypropylene beads and then molding them, resulting in a material with a unique cellular structure that grants it excellent energy absorption capabilities, allowing it to recover its original shape after repeated impacts, along with good thermal insulation properties and resistance to chemicals.

EPP Foam Properties

EPP foam demonstrates excellent thermal insulation properties due to its closed-cell structure, which traps air and limits heat transfer effectively. This makes it an ideal material for applications requiring temperature stability, such as HVAC components or temperature-controlled packaging. Furthermore, its low water absorption ensures its insulating performance remains consistent, even in humid environments, contributing to its overall efficiency and reliability.

Shock Absorption

The material’s defining feature is its outstanding energy absorption and high resilience. EPP can deform significantly upon impact to dissipate kinetic energy, yet it possesses remarkable “shape memory,” allowing it to spring back to its original form, often after multiple impacts. This multi-impact capability makes it superior for safety components like automotive bumpers and durable protective packaging.

Mechanical Strength & Durability

EPP boasts a high strength-to-weight ratio, meaning it is exceptionally strong relative to its light mass. It exhibits good compressive strength and excellent durability, resisting fatigue and permanent deformation under repeated mechanical stress. This inherent toughness allows EPP to serve reliably in demanding industrial applications, replacing heavier, traditional materials without compromising structural integrity or longevity.

Chemical & Environmental Resistance

A significant advantage of EPP is its excellent resistance to various chemicals, oils, and solvents, making it suitable for industrial and specialized environments. Moreover, EPP is 100% recyclable, aligning with sustainability goals. Its robust nature also contributes to a longer product lifecycle, reducing the need for frequent replacements and minimizing environmental impact.

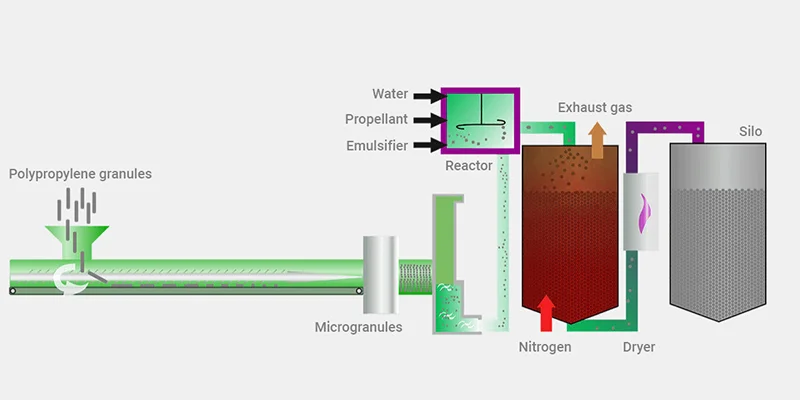

How is EPP Foam Manufactured?

EPP Foam is produced through a molding process that includes expanding and fusing polypropylene beads. Initially, the beads undergo pre-expansion using steam. Subsequently, they’re inserted into a mold, where they undergo heat and pressure treatment.

This process leads to the merging of individual beads, resulting in the formation of a sturdy, lightweight foam structure featuring closed cells. Through molding, a diverse range of shapes and densities of EPP products can be crafted.

Step 1: Raw Material Selection

The initial stage involves carefully selecting premium polypropylene resin as the starting material for the foam. This base polymer is chosen specifically because it inherently possesses the necessary attributes, like lightweight potential and good mechanical stability.

Step 2: Pre-Expansion

Next, the chosen PP beads undergo pre-expansion, where they are treated, typically with steam or a chemical agent. This critical step increases the volume of the beads significantly, preparing them to form the final low-density foam structure required for EPP.

Step 3: Molding

The now-expanded beads are carefully loaded into a precisely engineered mold cavity designed for the final desired part shape. Molds can be constructed from durable materials like aluminum or steel to withstand the subsequent high-pressure molding cycle effectively.

Step 4: Steam Chest Molding

The primary shaping method is steam chest molding, where the closed mold is enveloped by a steam chest. Steam is then injected, acting as the heat source to soften the beads and initiate the final, controlled expansion within the mold confines.

Step 5: Fusion and Shape Formation

The injected steam provides the necessary heat to fuse the expanded beads together into a solid matrix. Internal pressure within the mold forces the material to conform exactly to the cavity’s shape, setting the final density and form.

Step 6: Cooling and Demolding

Once the fusion and shaping are complete, the part must solidify completely to maintain its structure. The mold is actively cooled via water or air circulation before the hardened EPP component is safely removed from the cavity.

Step 7: Trimming and Finishing

After demolding, the raw part often requires refinement to meet exact product standards. Trimming processes are used to cleanly remove any excess material or flashing that formed during the fusion process from the molded component.

Step 8: Additional Processing

Finally, secondary operations tailor the EPP for its intended role, which may include precise cutting, specialized laminating for surface reinforcement, or high-quality painting and printing applications. These steps complete the customization of the part.

What Are the EPP Foam Properties?

EPP Foam, short for Expanded Polypropylene foam, stands as a testament to modern engineering’s ingenuity. Expanded Polypropylene (EPP) is a highly versatile closed-cell foam material known for its exceptional energy absorption, impact resistance, thermal insulation, buoyancy, and recyclability, making it a preferred choice across various industries.

First, Foam Properties the most famous Properties: Insulation and Shock Absorption

EPP Foam Insulation Properties

EPP foam insulation boasts several key features that make it an ideal choice for insulation applications:

Thermal Efficiency: EPP foam insulation provides effective thermal insulation, helping to maintain consistent indoor temperatures and reduce energy consumption.

Durability: It exhibits exceptional durability, retaining its insulation properties even after prolonged exposure to environmental factors.

Lightweight: EPP foam insulation is lightweight, making it easy to handle and install compared to traditional insulation materials.

Moisture Resistance: Its closed-cell structure offers inherent moisture resistance, preventing water absorption and mold growth.

Application of EPP Foam Insulation Properties

Building Insulation

EPP foam insulation is commonly used in residential, commercial, and industrial buildings to improve energy efficiency and comfort. It is installed in walls, roofs, and floors to minimize heat transfer and reduce heating and cooling costs.

Cold Chain Logistics

In the logistics industry, EPP foam insulation plays a vital role in maintaining the integrity of temperature-sensitive products during transit. It is used in packaging and containers to provide thermal insulation and protect perishable goods from temperature fluctuations.

HVAC Systems

EPP foam insulation is also utilized in HVAC (Heating, Ventilation, and Air Conditioning) systems to enhance thermal efficiency and minimize heat loss. It is employed in ductwork, pipes, and equipment enclosures to prevent energy wastage.

EPP Foam Shock Absorption Properties

EPP foam shock absorption properties are characterized by several key features:

Resilience: EPP foam exhibits high resilience, allowing it to return to its original shape after impact, thus maintaining its protective capabilities over multiple impacts.

Energy Absorption: Its cellular structure enables EPP foam to absorb and dissipate kinetic energy, minimizing the risk of damage or injury.

Uniformity: EPP foam provides uniform shock absorption across its entire surface, ensuring consistent protection for the object or individual being safeguarded.

Application of EPP Foam Shock Absorption Properties

Protective Packaging

EPP foam is commonly used in protective packaging applications to safeguard fragile items during transit. Its ability to absorb impact energy helps prevent damage to sensitive electronics, glassware, and other delicate products.

Sports Equipment

In the sports industry, EPP foam is utilized in the manufacturing of helmets, padding, and protective gear. Its shock absorption properties help reduce the risk of head injuries and impact-related trauma during high-impact activities such as cycling, skiing, and contact sports.

Automotive Safety

EPP foam plays a crucial role in automotive safety by providing impact protection in vehicle bumpers, headrests, and interior components. Its ability to absorb energy during collisions helps mitigate the risk of injury to vehicle occupants.

What Else does EPP Foam Properties have?

Chemical Resistance: EPP Foam demonstrates remarkable resistance to a wide array of chemicals, oils, and solvents. This inherent property significantly bolsters its durability and renders it suitable for diverse environmental conditions.

Recyclability: EPP Foam stands as a recyclable material, fostering sustainable and eco-friendly practices. Its recyclability facilitates its reuse across various applications, thereby reducing waste and promoting the principles of a circular economy.

Versatile Processing: EPP Foam boasts the capability of being molded into intricate shapes and sizes with ease. This versatility enables the production of tailored components catering to the distinct requirements of various industries. Furthermore, it can be molded to varying densities and thicknesses, further enhancing its adaptability.

Low Water Absorption: EPP Foam exhibits minimal water absorption characteristics, ensuring consistent dimensional stability even when subjected to moisture. This attribute plays a pivotal role in preventing degradation over time.

UV Resistance: EPP Foam showcases exceptional resistance to ultraviolet (UV) radiation, making it an ideal choice for outdoor applications exposed to prolonged sunlight. This UV resistance enhances its longevity and reliability in outdoor settings.

Conclusion

We’ve thoroughly explored the remarkable characteristics of EPP foam, particularly its superior performance in thermal insulation and impact protection. The material’s lightweight, resilience, and ability to withstand repeated shocks without structural degradation make it invaluable for applications from automotive safety components to protective packaging and HVAC systems.

The unique closed-cell structure of Expanded Polypropylene is the secret to its success, offering exceptional energy absorption and minimal heat transfer. Choosing EPP means investing in a high-performance, durable, and often reusable material. When your project demands the best in structural integrity and protective qualities, EPP is the definitive answer.

Ready to leverage the full potential of EPP foam in your manufacturing or packaging needs? For reliable quality and competitive pricing, you can get wholesale EPP foam from our Epsole. Contact us today to discuss your specific requirements and see how our premium EPP solutions can elevate your product design and performance.