EPP Foam Blocks

EPP foam blocks are lightweight, durable, and versatile solutions for packaging, automotive, construction, and sports. Our EPP blocks offer superior cushioning, impact absorption, and insulation. Crafted for performance and sustainability, they are 100% recyclable.

Get EPP Foam Blocks Wholesale

- Exceptional Durability and Reusability: Crafted from expanded polypropylene, these blocks withstand repeated use and impacts without losing their integrity, offering a cost-effective and sustainable solution.

- Superior Protection and Cushioning: Their unique closed-cell structure provides excellent shock absorption and cushioning, safeguarding delicate items during transport or use in protective applications.

- Lightweight and Easy to Handle: Despite their robustness, Epp foam blocks are remarkably lightweight, making them easy to maneuver, install, and integrate into various applications.

- Versatile and Customizable: Available in various densities, sizes, and shapes, Epp foam blocks can be easily customized to meet specific project requirements across diverse industries, from packaging to construction and beyond.

wholesale EPP foam block

As a leading wholesale supplier of EPP foam blocks, we offer a diverse range of high-quality, durable, and lightweight solutions. Our blocks provide exceptional cushioning and impact protection for various applications. Benefit from competitive pricing and reliable supply for your business needs. Contact us today for a quote!

EPP foam blocks for RC planes

Our EPP foam blocks for RC planes offer the ideal balance of lightweight durability and impact resistance. Perfect for building custom wings, fuselages, and other components, our high-quality foam ensures both structural integrity and excellent crash resilience for your любимые модели. Explore the possibilities for your next build!

EPP foam blocks for kids toy

We craft safe and engaging EPP foam blocks perfect for kids’ play! Lightweight, soft, and durable, our blocks encourage creativity, building, and imaginative fun. Non-toxic and easy to clean, they’re ideal for toddlers and young children. Explore our range of colors and sizes for endless playtime possibilities!

interlocking EPP foam blocks for building

As an EPP foam manufacturer, we can produce interlocking EPP foam blocks, we provide innovative and safe building materials for various applications. Our lightweight yet durable blocks are perfect for creating modular structures, play areas, and more. Enjoy easy assembly, excellent impact absorption, and endless design possibilities with our high-quality EPP foam solutions. Contact us for wholesale inquiries!

custom EPP foam block sheet

We specialize in creating custom EPP foam block sheets tailored to your exact specifications. Our advanced cutting and shaping capabilities allow us to produce unique sizes, thicknesses, and intricate designs. Benefit from our expertise in providing lightweight, durable, and protective foam solutions for your specific applications. Get a custom quote today!

custom shaped EPP foam blocks

We offer custom shaped EPP foam blocks to meet your exact design needs. Utilizing advanced molding and CNC cutting, we manufacture components with precise dimensions and excellent impact absorption. Our blocks are lightweight, highly durable, and ideal for automotive parts or protective packaging inserts. We provide specialized solutions ensuring optimal performance and material consistency for every unique requirement.

wholesale EPP blocks with various sizes

We offer wholesale EPP blocks in a wide range of sizes and densities. Our bulk supply is perfect for EPP manufacturers needing versatile foam material for large-scale production. We provide reliable inventory for applications like soundproofing, safety padding, and custom component fabrication. We ensure consistent quality and ready availability of EPP to meet your business’s significant demands.

educational EPP foam blocks

We offer educational EPP foam blocks designed for safe, hands-on learning in schools and daycare settings. These blocks are lightweight, easy to handle, and provide an excellent medium for developing motor skills and spatial reasoning. We supply sets that are durable and non-toxic, supporting the creation of engaging, large-scale structures. They promote collaborative play and imaginative design in a safe environment.

EPP foam building blocks

We offer EPP foam building blocks perfect for educational and recreational uses. They are lightweight, yet possess excellent impact absorption and multiple-impact resistance for safe play. We supply non-toxic, durable blocks that encourage creativity and spatial skill development in children. These blocks are also recyclable and highly resistant to moisture, supporting a clean learning environment.

EPP high density exercise blocks

We offer EPP high density exercise blocks for superior support and stability in yoga and Pilates. These foam blocks provide firm, reliable cushioning to improve alignment and deepen your stretches safely. We manufacture them to be exceptionally durable, resisting wear and tear even with frequent, heavy use. Our lightweight blocks are an essential tool for enhancing flexibility and muscle recovery for all fitness levels.

custom shaped EPP blocks for kids

We offer custom shaped EPP blocks specifically made for children’s imaginative play areas. Our blocks are lightweight, soft, and possess superior durability, ensuring a safe and long-lasting toy. We provide non-toxic, easy-to-clean shapes that encourage creative building, motor skill development, and collaborative play. We manufacture various designs, from animals to modular components, for endless fun and educational activities.

wine EPP foam box for fragile objects

We offer wine EPP foam boxes specifically designed to protect fragile objects during transport. The material’s superior shock absorption prevents breakage and safeguards valuable contents. We supply lightweight, recyclable containers that provide reliable thermal insulation against temperature fluctuations. These boxes ensure your bottles arrive intact, preserving the integrity and value of your product with confidence.

triangle hollow EPP foam yoga blocks

We offer triangle hollow EPP foam yoga blocks for advanced practice and stability. This unique shape helps deepen stretches and achieve proper alignment in challenging poses like Triangle Pose. We supply a product that is high density, yet lightweight and comfortable for joints. The hollow design often includes a removable roller for targeted muscle release, making it a versatile fitness tool.

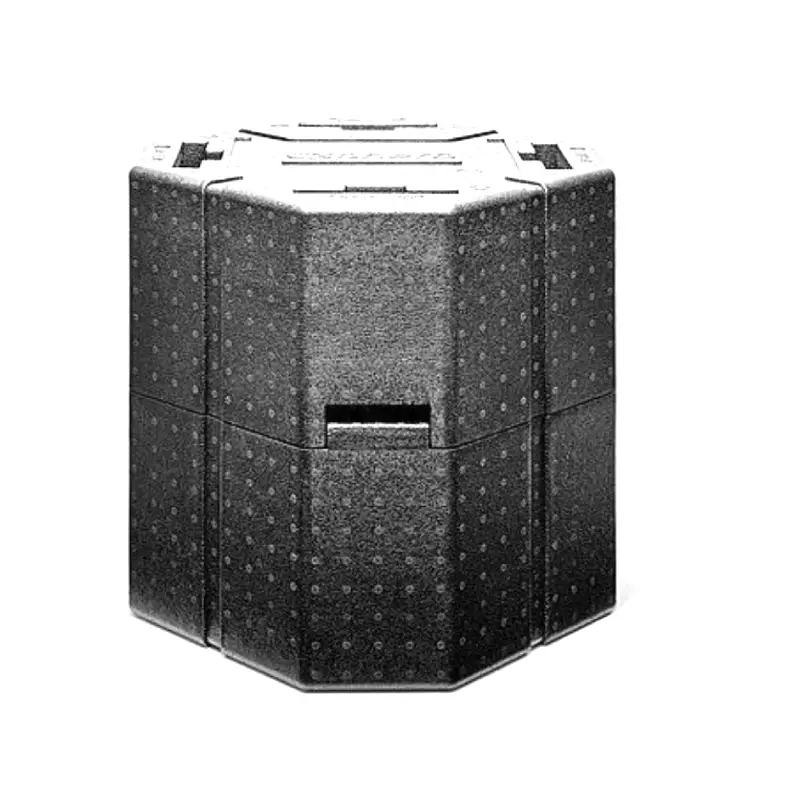

hexahedron EPP foam block

We offer hexahedron EPP foam blocks that are precisely molded for various industrial and consumer uses. These cubical components provide exceptional impact absorption and stability. We supply these lightweight blocks for applications like protective packaging, void fillers, and insulation for HVAC systems. Our products ensure consistent dimensions and material strength for reliable, durable performance in critical applications.

EPP toy building blocks

EPP toy building blocks, we offer lightweight, safe, and durable solutions for creative play. Made from eco-friendly EPP material, they’re soft to touch, impact resistant, and easy to clean. Ideal for kids’ education, kindergartens, and family play, supporting imagination, motor skills, and safe fun.

EPP foam brick blocks

We offer EPP foam brick blocks designed for lightweight construction, packaging, insulation, and protective applications. These blocks deliver excellent impact resistance, thermal stability, moisture tolerance, and recyclability. Custom sizes, densities, and colors are available, supporting OEM projects, efficient logistics, repeated use, and long service life across demanding industrial environments worldwide.

large EPP foam interlock blocks

Large EPP foam interlock blocks provide lightweight strength, shock absorption, and thermal insulation for packaging, construction, and play spaces. We offer customizable sizes, densities, and colors, easy snap-fit assembly, reusable durability, moisture resistance, and eco-friendly performance. Ideal for safe flooring, modular structures, protective shipping, and creative installations, worldwide supply options.

custom shaped EPP foam block

Custom shaped EPP foam blocks deliver lightweight strength, impact resistance, and thermal stability for protective packaging and industrial applications. We offer precision molding, tight tolerances, complex geometries, and consistent density. Ideal for electronics, automotive, medical, and logistics uses, ensuring durability, recyclability, and reliable performance with scalable production and tooling options.

hexagonal EPP foam block

Hexagonal EPP foam blocks we offer combine lightweight strength, shock absorption, and thermal stability for packaging, insulation, and protection needs. Their precise geometry maximizes space efficiency, resists deformation, and supports reuse. Ideal for electronics, instruments, and logistics, they are customizable in size, density, and color to meet diverse industrial requirements.

huge EPP foam block

We offer huge EPP foam blocks designed for large-scale packaging, industrial protection, and custom molding projects. Lightweight yet tough, these blocks deliver excellent shock absorption, thermal insulation, and long-term durability, making them ideal for logistics, construction, automotive components, and protective structural applications worldwide.

FAQs about EPP foam Block

What is EPP foam block?

EPP foam block refers to a solid, typically rectangular or cuboid shape made from Expanded Polypropylene (EPP) foam.

EPP is a closed-cell bead foam known for its high strength-to-weight ratio, excellent energy absorption, and durability. These blocks are lightweight yet robust, offering superior cushioning and impact resistance, along with thermal and sound insulation properties.

Their versatility makes them suitable for a wide array of applications across various industries, including packaging, automotive components, construction, and sports equipment

What is EPP foam block used for?

EPP foam blocks are incredibly versatile due to their unique combination of properties. Their excellent energy absorption and cushioning make them ideal for protective packaging, ensuring fragile items remain safe during transit. In the automotive industry, they are used for impact protection components like bumpers and door panels, contributing to vehicle safety and lightweighting. Their durability and resistance to moisture and chemicals also make them suitable for reusable containers and various industrial applications.

Beyond these core uses, EPP foam blocks find applications in a surprising range of fields. In construction, they can be used for insulation and lightweight structural elements. Their buoyancy makes them useful in aquatic applications and recreational equipment. Additionally, EPP foam blocks are utilized in sports and fitness, for example, as yoga blocks or rollers, providing support and stability. Their moldability also allows for the creation of custom inserts and components for diverse needs.

Here’s a summary of common EPP foam uses:

- Packaging: Protective packaging for electronics, fragile goods, and industrial parts.

- Automotive: Energy-absorbing components like bumpers, headrests, and door panels.

- Construction: Thermal and sound insulation, lightweight structural elements.

- Logistics: Reusable containers and dunnage.

- Sports and Recreation: Yoga blocks, foam rollers, buoyancy aids.

- Industrial: Custom inserts, seals, and gaskets.

How to install EPP foam blocks?

Installing EPP foam blocks is generally a straightforward process, often depending on the specific application. Whether you’re using them for packaging, insulation, or other purposes, the key is to ensure a secure and appropriate fit.

Here’s a general guide outlining common steps involved in installing EPP foam blocks for various applications, keeping in mind that specific project requirements may necessitate adjustments to these instructions.

Preparation and Surface Assessment

Before you begin the installation, it’s crucial to prepare the area where the EPP foam blocks will be placed. This involves ensuring the surface is clean, dry, and free from any debris that could interfere with proper adhesion or placement. For applications requiring adhesive, ensure the surface is compatible with the chosen adhesive. Carefully measure the area to determine the precise number and arrangement of blocks needed, and pre-cut or shape the blocks if necessary for a snug fit.

Adhesive Application (If Applicable)

For applications where the EPP foam blocks need to be adhered to a surface, select an adhesive that is compatible with EPP foam and the substrate material. Apply the adhesive evenly to either the back of the foam block or the surface where it will be installed, following the manufacturer’s instructions for the adhesive. The amount of adhesive needed will depend on the size and weight of the block and the desired level of adhesion. Ensure proper ventilation if using adhesives with strong fumes.

Placement and Alignment

Carefully position the EPP foam block onto the prepared surface, aligning it according to your plan or the specific requirements of the application. Press the block firmly against the surface to ensure good contact with the adhesive, if used. For applications where blocks are interlocking or need to fit tightly together, take extra care during placement to avoid gaps or misalignment. Use appropriate tools, like levels or guides, to ensure accuracy, especially for larger installations.

Securing and Finishing

Depending on the application, additional securing methods might be necessary. This could involve using mechanical fasteners, such as screws or clips, especially for larger or structural applications. Allow sufficient drying or curing time for any adhesives used, as per the manufacturer’s recommendations, before subjecting the installed blocks to stress or load. Inspect the final installation to ensure all blocks are securely in place and the desired outcome is achieved.

Where you can use EPP foam blocks?

The versatility of EPP foam blocks stems from their unique combination of properties, making them suitable for a wide spectrum of applications across numerous industries. Their exceptional energy absorption and cushioning make them a go-to choice for protective packaging, safeguarding delicate electronics, automotive parts, and fragile consumer goods during shipping and handling.

In the automotive sector, EPP foam is integral in creating lightweight yet impact-resistant components like bumpers, headrests, and door panels, contributing to both safety and fuel efficiency. Their durability and resistance to moisture and chemicals also make them ideal for reusable containers, dunnage, and various industrial applications where robust and long-lasting materials are required.

Beyond these common uses, EPP foam blocks find innovative applications in diverse fields. In the construction industry, their insulation properties and lightweight nature make them suitable for thermal and acoustic insulation, as well as lightweight structural elements. Their inherent buoyancy leads to their use in aquatic and recreational equipment, such as flotation devices and pool noodles.

EPP foam’s moldability allows for the creation of custom inserts and components for medical devices, sports equipment like yoga blocks and rollers, and even artistic and model-making endeavors.

Here’s a summary of where EPP foam blocks are commonly used:

- Packaging: Protective packaging for electronics, fragile items, and industrial components.

- Automotive: Bumpers, headrests, door panels, seating components, and interior trim.

- Construction: Thermal and acoustic insulation, lightweight structural elements, void fillers.

- Logistics and Material Handling: Reusable containers, dunnage, and protective inserts.

- Sports and Recreation: Yoga blocks, foam rollers, flotation devices, padding for sports equipment.

- Medical: Positioning aids, orthotic components, and protective packaging for medical devices.

- Industrial: Seals, gaskets, filters, and custom components for machinery.

- Consumer Goods: Appliance packaging, furniture padding, and various household items.

- Arts and Crafts: Model making, sculpting, and DIY projects.