Custom EPP Battery Mold from China

We provide custom EPP battery molds from China, a cost-effective solution for creating lightweight, durable, and shock-absorbent battery housings. Our molds are designed to protect lithium-ion batteries in electric vehicles, drones, and other electronics, ensuring a perfect fit and superior performance.

Get EPP Battery Mold Wholesale

Impact Resistance: EPP is a highly resilient foam that can absorb significant impact energy, protecting delicate battery cells from damage during drops, collisions, or vibrations. This is crucial for applications like electric vehicles and drones.

Lightweight: EPP foam is extremely light, which helps reduce the overall weight of a device. This is particularly important for electric vehicles and drones where minimizing weight can extend range or flight time.

Thermal Insulation: EPP has excellent thermal insulation properties, helping to regulate the temperature of the battery pack. This is important for maintaining optimal battery performance and preventing overheating.

Customizable: EPP molds can be custom-designed to fit any battery shape or size, providing a perfect, snug fit. This ensures maximum protection and efficient use of space within the device.

Customize Your Desired EPP Battery Mold

Shape & Dimensions

We can tailor the mold to match any battery shape, from standard rectangular blocks to complex, irregular forms. This ensures a perfect fit, providing maximum protection and efficient use of space. Our precision engineering guarantees all dimensions, including length, width, and height, are accurate to your specifications.

Material Density

We offer a range of EPP material densities to meet your specific needs. Lower densities provide greater energy absorption and lighter weight, ideal for drones. Higher densities offer enhanced structural rigidity and durability, suitable for heavy-duty applications like electric vehicle battery packs.

Internal Cavities & Features

We can incorporate internal features such as channels for wiring, ventilation holes for thermal management, and specific cavities for connectors or circuit boards. These integrated features streamline the assembly process and create a complete, self-contained protective enclosure for the battery.

Surface Finish & Texture

We customize the mold’s surface to produce your desired final texture on the EPP part. A smooth finish is often chosen for aesthetic purposes, while a textured or patterned surface can enhance grip, reduce friction, or improve heat dissipation.

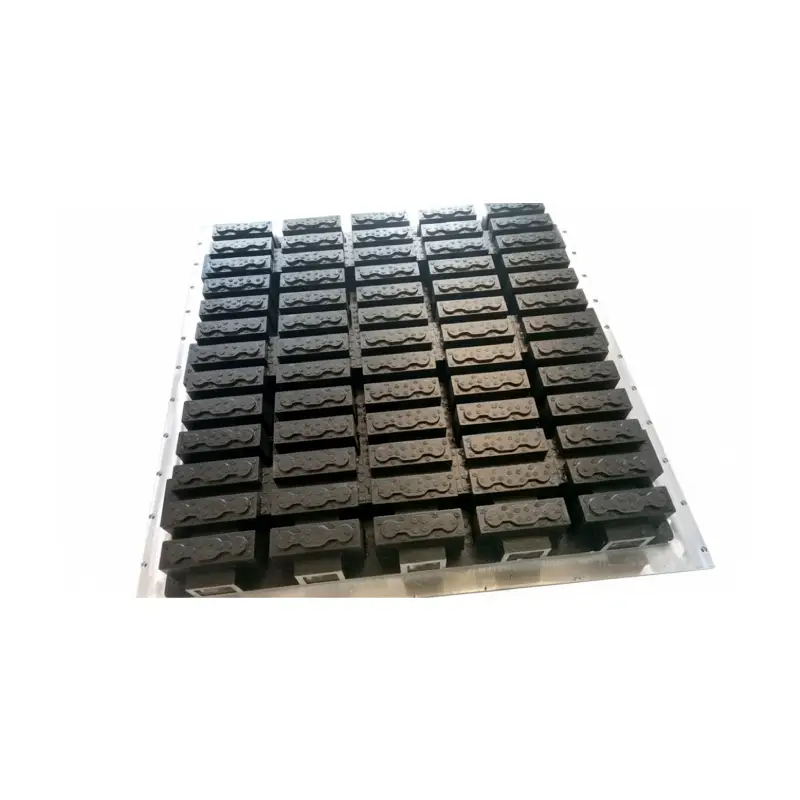

custom EPP battery mold

We are a leading provider of custom EPP battery molds, offering a cost-effective and precise solution for protecting your battery packs. We tailor every mold to your exact specifications, from complex shapes to varying material densities, ensuring superior impact resistance and thermal insulation. Our molds are designed for optimal performance, simplifying assembly and enhancing the durability of batteries for EVs, drones, and other electronics.

EPP battery mold for electric vehicel

We specialize in providing EPP battery molds for electric vehicles, offering a crucial solution for battery protection. Our EPP molds create durable, lightweight, and impact-resistant housings that protect lithium-ion battery packs from external forces and vibrations. We help enhance EV safety and performance by ensuring superior thermal insulation and a perfect fit for every battery design.

EPP battery mould

We are a China-based manufacturer specializing in custom EPP battery molds. Our molds create lightweight, durable, and thermally insulating housings that protect lithium-ion battery packs from impact and temperature fluctuations. We offer comprehensive solutions from design to production, ensuring a perfect fit and superior performance for applications like electric vehicles and drones.

EPP Battery Housing Mold

We offer EPP battery housing mold designed with precision and durability to meet modern energy storage demands. Our molds ensure lightweight strength, high impact resistance, and excellent thermal insulation. With advanced manufacturing techniques, we provide reliable solutions for electric vehicle and energy industries, helping you achieve efficiency, safety, and sustainability in battery housing production.

EPP battery mold for electric vehicles

We offer EPP battery mold for electric vehicles, designed to provide lightweight, durable, and impact-resistant solutions for battery packaging. Our EPP battery molds ensure excellent thermal insulation, high strength, and reliable protection for EV batteries. With precision engineering and customizable options, we deliver energy-efficient, eco-friendly, and cost-effective EPP battery molds tailored to your electric vehicle requirements.

electric vehicle EPP battery mold

We offer electric vehicle EPP battery mold designed for lightweight, durable, and high-performance energy storage solutions. Our molds ensure precise shaping, excellent thermal insulation, and shock absorption to enhance battery safety and efficiency. With advanced manufacturing techniques, we provide reliable, customizable EPP battery molds to meet evolving EV industry demands and sustainable production standards.

EPP battery mold for electric vehicles

We provide EPP battery molds for electric vehicles, designed for maximum protection, durability, and precision. Made from expandable polypropylene, our molds can be customized in size, shape, and design to meet automotive standards. Lightweight yet strong, they ensure safe handling, transportation, and storage of EV batteries, supporting reliable performance and long-term safety.

EPP mold for electric car batteries

We provide EPP molds for electric car batteries, engineered for durability, precision, and safety. Made from expandable polypropylene, our molds can be customized in size, shape, and design to meet automotive specifications. Lightweight yet robust, they protect batteries during manufacturing, transportation, and storage, ensuring long-lasting performance and reliable safety for electric vehicle applications.

EPP battery mold for electric vehicles

We offer EPP battery molds for electric vehicles, designed for precision, durability, and safety. Our molds ensure accurate shaping, lightweight construction, and reliable impact absorption, protecting battery packs during production and operation. Ideal for EV manufacturers, these EPP molds streamline manufacturing, enhance performance, and provide long-lasting, consistent results for both prototype and mass production applications.

EPP battery case mold

We offer EPP battery case molds designed for precision, durability, and lightweight protection. Our molds produce consistent, accurate cases that securely house batteries while absorbing shocks and impacts. Ideal for RC aircraft, drones, and electronic devices, they ensure long-lasting performance, reliable safety, and efficient production, making them perfect for both hobbyists and professional manufacturers.

EPP Battery Mold FAQs

what is EPP battery mold?

An EPP battery mold is a specialized tool used in manufacturing to create protective housings for battery packs, especially those used in electric vehicles, drones, and other electronics. Made from durable materials, the mold is filled with expanded polypropylene (EPP) beads, which are then fused together with steam to form a lightweight, impact-resistant foam casing.

The resulting EPP housing provides crucial protection against physical shock and vibrations, while also offering excellent thermal insulation to help regulate battery temperature and ensure optimal performance.

The EPP mold’s design can be customized to fit a wide range of battery shapes and sizes, making it an essential component for producing safe and efficient battery packs.

what is EPP battery mold used for?

An EPP (Expanded Polypropylene) battery mold is a specialized tool used to produce custom-shaped protective housings for battery packs.

By utilizing the unique properties of EPP, these molds create casings that are integral to the safety, performance, and longevity of batteries in various applications. The process involves steam-fusing EPP beads within the mold’s cavity, resulting in a lightweight, durable, and impact-resistant foam part.

The applications of EPP battery molds include:

Electric Vehicles (EVs): They are essential for creating durable battery casings that protect large lithium-ion packs from impact during collisions and vibrations from the road, while also providing thermal insulation to regulate temperature.

Drones and Robotics: EPP molds produce custom, lightweight enclosures that reduce the overall weight of the device, which is critical for maximizing flight time and operational efficiency.

Medical Equipment: The material’s hygienic and non-toxic properties, along with its ability to be molded into intricate shapes, make it suitable for housing batteries in sensitive medical devices.

Consumer Electronics: EPP molds are used to create custom-fit protective packaging and internal components for electronic devices, ensuring that batteries are securely held and protected from drops and shocks.

Why choose our EPP battery mold?

Choosing our EPP battery molds provides a strategic advantage for your production. We combine cutting-edge technology with extensive industry expertise to deliver molds that are not just tools, but a pathway to superior product quality and manufacturing efficiency. Our molds are meticulously engineered for precision and durability, ensuring a reliable and long-lasting production asset.

Here’s why you should choose us:

Precision Engineering: Our molds are crafted with advanced CNC machining to ensure perfect dimensional accuracy, guaranteeing that every EPP housing fits your battery pack with a perfect, snug fit.

Customization Expertise: We offer a comprehensive customization service, allowing you to specify everything from material density to integrated internal features. This means you get a mold tailored precisely to your product and production needs.

Optimal Production Efficiency: Designed for fast and consistent cycles, our molds feature optimized heating and cooling channels. This reduces cycle times and material waste, leading to a significant increase in your overall production efficiency and a lower cost per part.

Reliable and Durable: We use high-grade aluminum and specialized surface treatments to ensure our molds are durable, resistant to wear, and have excellent thermal conductivity. This guarantees a long service life and consistent, high-quality results.

What temperature is EPP foam molding?

EPP foam molding typically involves a process called steam chest molding, where the temperature is carefully controlled to fuse the EPP beads together.

The mold itself is preheated, and then high-pressure steam is injected to heat the material. This process is crucial because it allows the EPP beads to soften and expand against each other, creating a single, cohesive part.

After the steaming phase, the mold is rapidly cooled to solidify the EPP and “set” the final shape of the product.

Steaming Temperature: The temperature inside the mold during the steaming phase is usually between 140°C and 160°C (284°F and 320°F). This is slightly above the melting point of EPP, which is typically between 160°C and 176°C, allowing the bead surfaces to become tacky and fuse. ♨️

Molding Pressure: To achieve these high temperatures, the steam pressure is carefully controlled, usually ranging from 2.5 to 4.0 bar. The combination of high temperature and pressure ensures the beads fully expand and weld together.

Cooling Phase: After molding, the EPP part is cooled to a demolding temperature of around 70°C to 80°C (158°F to 176°F) before being ejected from the mold. This step is essential to prevent warping and ensure dimensional stability.

Post-Molding: Some EPP parts may require a final drying step in a tempering oven, with temperatures ranging from 60°C to 80°C, to remove any residual moisture and achieve full dimensional stability.