We manufacture EPS products for many applications. People often wonder if expanded polystyrene beads are safe. We want to address common concerns about the toxicity of these materials. Our commitment is to supplying safe and reliable polystyrene products. We provide clear facts about the chemical makeup and practical uses of these versatile beads.

We offer EPS raw materials that meet rigorous safety standards. The finished EPS beads are largely inert and safe for general use. Understanding the science behind polystyrene is key. We strive to give you accurate information. We focus on environmental and health aspects of our wholesale EPS products.

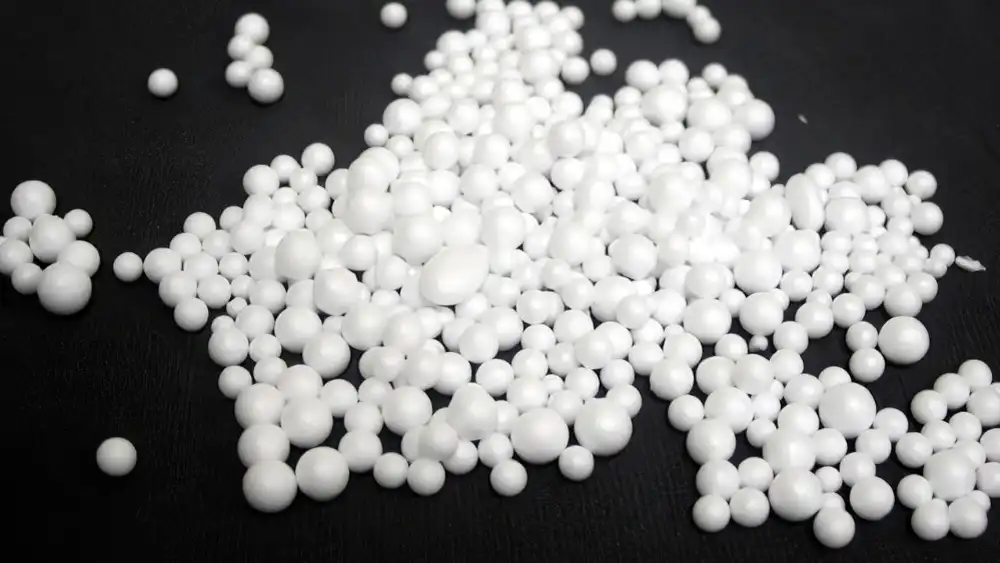

What Are EPS Beads?

Expanded polystyrene (EPS) beads are small plastic particles commonly used in various applications, including packaging, insulation, and crafting. These lightweight beads are favored for their versatility and affordability.

Is EPS Eco-Friendly?

EPS (Expanded Polystyrene) can be a complex material in terms of its environmental impact. While it has certain qualities that might be considered eco-friendly, it also poses challenges.

Pros:

- Lightweight: EPS is extremely lightweight, which means it requires less energy to transport compared to heavier materials. This can reduce fuel consumption and associated emissions during transportation.

- Insulation Properties: EPS is often used as insulation in buildings and packaging due to its excellent thermal insulation properties. This can contribute to energy savings by reducing heating and cooling needs in buildings.

- Recyclability: EPS can be recycled, although the process can be more complicated compared to other materials like paper or aluminum. When properly recycled, EPS can be reused in various applications, reducing the need for virgin materials.

Cons:

- Non-Biodegradable: One of the major drawbacks of EPS is that it is not readily biodegradable. It can persist in the environment for hundreds of years if not properly disposed of, contributing to plastic pollution.

- Resource Intensive: The production of EPS requires the use of fossil fuels and other non-renewable resources. This contributes to greenhouse gas emissions and further depletion of finite resources.

- Waste Management Challenges: EPS is bulky and lightweight, which can make it difficult to manage in waste streams. Improper disposal can lead to littering and environmental pollution.

While EPS has some eco-friendly qualities such as lightweight construction and recyclability, its non-biodegradability and resource-intensive production process present significant environmental challenges. Efforts to improve recycling infrastructure, reduce reliance on fossil fuels in production, and promote alternatives to EPS where possible can help mitigate its environmental impact.

Is EPS Foam Toxic

Expanded Polystyrene (EPS) foam, commonly used in packaging, insulation, and various consumer products, has raised concerns regarding its toxicity and environmental impact. Here are the key points regarding its toxicity:

Health Concerns

- Chemical Composition: EPS foam is made from styrene, a petroleum-based product. Styrene can be a health hazard if inhaled in significant quantities over a long period.

- Exposure During Manufacturing: Workers involved in the production of EPS foam may be exposed to styrene gas, which can cause irritation of the eyes, skin, and respiratory system. Long-term exposure to high levels of styrene has been linked to nervous system effects and possibly increased risk of leukemia and lymphoma.

- Consumer Use: For consumers, the risk is significantly lower. The amount of residual styrene in finished EPS products is typically very low, and under normal conditions of use, there is minimal exposure. However, it is still advised to avoid using EPS foam containers for hot foods and beverages, as heat can cause styrene to leach out.

Environmental Impact

- Non-Biodegradable: EPS foam is not biodegradable and can persist in the environment for hundreds of years, contributing to landfill waste and ocean pollution.

- Toxic Byproducts: When EPS foam is burned, it releases toxic substances, including styrene gas and other harmful compounds, which can be hazardous to both human health and the environment.

Safety Recommendations

- Proper Handling: Avoid using EPS foam products for high-temperature applications, such as hot foods and beverages, to minimize the risk of styrene exposure.

- Disposal and Recycling: Proper disposal and recycling of EPS foam can mitigate some environmental impacts. While not universally accepted, some recycling programs do handle EPS foam.

- Alternatives: Consider using safer and more environmentally friendly alternatives like paper, cardboard, or biodegradable packaging materials.

While EPS foam is not highly toxic under typical consumer use conditions, it poses certain health risks during manufacturing and when exposed to heat. Its environmental impact, primarily due to its persistence and potential to release toxic byproducts when burned, is a significant concern.

EPS Beads Toxicity

Expanded Polystyrene (EPS) beads, like other forms of polystyrene, are generally considered non-toxic under normal conditions of use. However, there are some considerations regarding potential toxicity:

- Chemical Composition: EPS is made from styrene, a synthetic compound derived from petroleum. Styrene monomers are used in the production of EPS, and while they are generally considered safe in their polymerized form (as in EPS), there are concerns about potential health effects associated with exposure to styrene vapors during manufacturing processes.

- Release of Chemicals: While EPS itself is inert and does not leach harmful chemicals under normal conditions, there is potential for the release of toxic substances if EPS is burned. When EPS is incinerated at high temperatures, it can release harmful gases and particulate matter into the air, including styrene, carbon monoxide, and other volatile organic compounds.

- Microplastics: EPS beads, like other plastic materials, can break down over time into smaller particles known as microplastics. These microplastics can absorb and concentrate pollutants from the surrounding environment, potentially posing risks to aquatic organisms if they enter water bodies.

While EPS beads themselves are generally considered non-toxic, there are concerns about potential health and environmental impacts associated with their production, disposal, and breakdown. It’s important to handle and dispose of EPS materials properly to minimize any potential risks to human health and the environment. Recycling EPS whenever possible can help reduce the need for incineration and the release of harmful substances into the environment.

Are EPS Beads Toxic?

Expanded Polystyrene (EPS) beads themselves are generally non-toxic.

EPS is a type of plastic foam made from polystyrene, a polymer composed of carbon and hydrogen atoms. The beads are typically inert and do not contain toxic substances that would pose immediate health risks under normal conditions of use.

However, there are some important considerations:

- Chemical Composition: EPS is derived from styrene, a synthetic compound obtained from petroleum. While styrene monomers are used in the production of EPS, they are polymerized during the manufacturing process, rendering the final EPS beads relatively inert. However, exposure to styrene vapors during manufacturing processes can pose health risks to workers in industrial settings.

- Potential Risks from Ingestion or Inhalation: While EPS beads themselves are not toxic, ingesting or inhaling large quantities of EPS beads could pose choking hazards or respiratory issues, particularly for young children or pets. Proper precautions should be taken to prevent accidental ingestion or inhalation.

- Environmental Impact: EPS beads can contribute to environmental pollution if not properly managed. When disposed of improperly, EPS beads can accumulate in the environment, leading to litter and potential harm to wildlife. Additionally, EPS beads can break down over time into smaller particles known as microplastics, which can have ecological impacts when they enter ecosystems.

EPS beads themselves are not considered toxic, but there are potential risks associated with their production, use, and disposal. Proper handling and disposal practices are important to minimize any potential adverse effects on human health and the environment. Recycling EPS whenever possible can help reduce the environmental impact of EPS beads by diverting them from landfills and reducing the need for new EPS production.

What are EPS beads made of?

EPS beads, or Expanded Polystyrene beads, are mainly composed of polystyrene resin. This resin is a plastic polymer derived from the monomer styrene. During manufacturing, a blowing agent, typically pentane, is incorporated. When steamed, the beads expand; the final product is roughly 98% air and 2% polystyrene.

How do EPS beads impact the environment?

Expanded polystyrene (EPS) beads are not biodegradable and persist for centuries, contributing significantly to plastic pollution. They easily scatter, breaking into microplastics that harm wildlife and ecosystems. Recycling is difficult due to their low density.

Are EPS beads safe for packaging food?

We provide EPS materials for various uses, including packaging. The FDA has historically approved solid polystyrene for direct food contact. However, we advise caution. Heating or microwaving EPS foam can cause trace amounts of styrene monomer to potentially leach into food, especially fatty items. Many regions now restrict this use.

Can EPS beads be recycled?

Yes, Expanded Polystyrene (EPS) beads are fully recyclable. The process typically involves collection, cleaning, and then densification (compaction or melting) to reduce their volume for efficient transport. We take back clean EPS foam scraps and process them into new raw materials or pellets that can be used again in manufacturing new products.

Conclusion

Our focus remains on delivering safe and effective polystyrene products. We assure you the core material of EPS beads, solid polystyrene, is chemically stable and poses minimal risk under normal use. We implement rigorous checks to ensure our EPS raw materials are manufactured to exacting standards. Choosing our products means selecting materials that are reliable and thoroughly vetted for safety.

The versatility of EPS foam in packaging, construction, and insulation is unmatched. We are transparent about the composition of our expanded polystyrene beads. This openness helps customers make informed decisions. We take pride in our production process, which minimizes environmental impact while maximizing product performance and user safety across all applications.

If you are looking to purchase wholesale EPS products, we invite you to connect with our company, epsole. We supply an extensive range of EPS raw materials that are both consistent and certified. Visit our site or contact us to discuss your specific needs for polystyrene beads or finished EPS foam items.