Expanded polystyrene fill, often abbreviated as EPS fill, is a versatile material with numerous applications across industries. From packaging to construction, its lightweight and insulating properties make it invaluable.

In this detailed guide, we dive into the world of expanded polystyrene fill, exploring its uses, benefits, and environmental considerations.

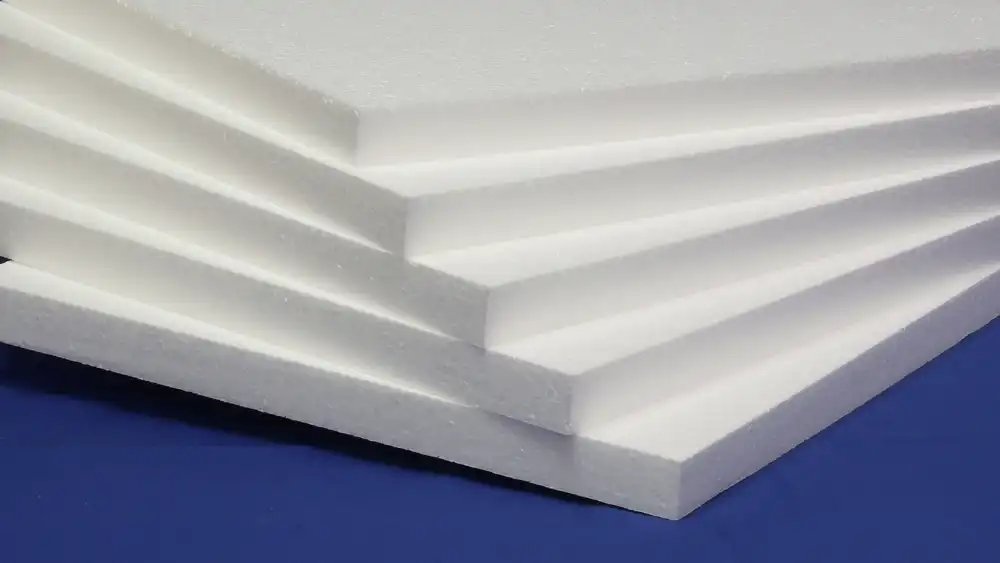

What Is Expanded Polystyrene Fill

Expanded polystyrene fill, commonly known as EPS fill, is a lightweight and durable material used in various applications. It is created by expanding polystyrene beads through a molding process, resulting in a versatile product that finds utility in diverse industries.

Expanded polystyrene fill is widely utilized for its excellent insulating properties, making it an ideal choice for packaging fragile items, insulating buildings, and even creating lightweight sculptures.

What Is The Material of EPS Filling?

The material used for EPS filling is expanded polystyrene (EPS).

EPS is a lightweight, rigid plastic foam derived from polystyrene beads. EPS is formed into various shapes and sizes through a process involving the expansion of these beads, making it suitable for insulation, packaging, and other applications.

Its unique cellular structure provides excellent thermal insulation and shock absorption properties, making it a popular choice in industries requiring protective packaging and building insulation.

What Is EPS Filling?

EPS filling stands for Expanded Polystyrene Filling. It’s the lightweight, airy material commonly found inside bean bag chairs.

What is it made of?

EPS filling is made from polystyrene granules that have been expanded into small, white beads. These beads are incredibly light yet surprisingly supportive, making them perfect for creating a comfortable and moldable seating experience.

Key characteristics of EPS filling:

- Lightweight: Easy to handle and move around.

- Supportive: Provides good support for your body.

- Moldable: Conforms to your body shape.

- Affordable: Generally a budget-friendly option.

While EPS filling is widely used and considered safe, some people prefer alternative fillings like memory foam or microbeads for different comfort preferences or environmental concerns.

EPS Filling Gun

An EPS filling gun is a specialized tool designed to efficiently fill products with expanded polystyrene (EPS) beads. It’s commonly used in industries that rely on EPS as a filling material, such as:

- Furniture manufacturing: For bean bag chairs, cushions, and other soft furnishings.

- Packaging: For protective packaging materials.

- Insulation: For filling insulation panels.

How does EPS filling gun work?

The gun typically has a hopper to hold the EPS beads and a mechanism to propel them into the filling product. Some models may have additional features like adjustable flow control or vacuum capabilities.

Key benefits of using an EPS filling gun:

- Speed: Quickly fills products with consistent amounts of EPS.

- Efficiency: Reduces labor costs and time spent on filling.

- Accuracy: Precise control over the amount of filling.

The Benefits of Expanded Polystyrene Fill

Expanded polystyrene fill offers a multitude of benefits across various industries:

1. Superior Insulation: Expanded polystyrene fill provides outstanding thermal insulation, helping to maintain consistent temperatures in packaging and construction applications.

2. Lightweight Nature: Being lightweight, EPS fill reduces transportation costs and facilitates ease of handling, especially in packaging.

3. Shock Absorption: Its cushioning properties make it an excellent choice for protecting delicate items during shipping and handling.

4. Versatility: EPS fill can be molded into various shapes and sizes, making it adaptable to different packaging and construction requirements.

5. Cost-Effectiveness: Due to its lightweight nature and ease of production, expanded polystyrene fill offers a cost-effective solution for insulation and packaging needs.

6. Durability: Despite its lightweight structure, EPS fill is remarkably durable, providing long-lasting protection for packaged goods and maintaining structural integrity in construction applications.

7. Moisture Resistance: Expanded polystyrene fill exhibits resistance to moisture, preventing water absorption and maintaining its insulating properties even in humid environments.

8. Environmental Sustainability: With increasing focus on sustainability, EPS fill manufacturers are developing eco-friendly options that are recyclable and contribute to reducing environmental impact.

Applications of Expanded Polystyrene Fill

Expanded polystyrene fill finds application in a wide range of industries due to its versatility and beneficial properties:

1. Packaging: Expanded polystyrene fill is extensively used in the packaging industry to protect fragile items during transportation. Its shock-absorbing capabilities ensure that delicate products remain intact even during rough handling and shipping.

2. Construction: In the construction sector, expanded polystyrene fill is employed for insulation purposes. It fills cavities in walls and roofs, providing thermal efficiency and structural support. Additionally, its lightweight nature reduces the overall weight of construction materials, making it easier to handle and transport.

3. Insulation: Expanded polystyrene fill serves as an excellent insulating material in various applications. Whether it’s insulating pipes, floors, or walls, EPS fill helps maintain optimal temperatures and reduces energy consumption, contributing to energy efficiency in buildings.

4. Void Filling: In industrial applications, EPS fill is used for void filling and cushioning. It fills empty spaces in containers or packages, preventing movement and minimizing the risk of damage during transit.

5. Art and Sculpture: Artists and sculptors appreciate the lightweight and moldable nature of expanded polystyrene fill. It serves as a versatile medium for creating intricate sculptures, stage props, and art installations. Its ease of shaping allows for the realization of complex designs with precision.

6. Marine Applications: Due to its buoyancy and resistance to water absorption, EPS fill is utilized in marine applications. It serves as flotation material for docks, buoys, and floating platforms, providing stability and support in aquatic environments.

7. Landscaping: In landscaping projects, expanded polystyrene fill is used to create artificial hills, terrain contours, and decorative features. Its lightweight properties make it easy to sculpt and shape, allowing for the realization of creative landscape designs.

8. Geofoam: Geofoam, a specialized form of expanded polystyrene fill, is employed in civil engineering projects such as road construction and slope stabilization. Its lightweight nature reduces soil pressure and minimizes settlement, offering an effective solution for infrastructure development.

Environmental Considerations

While expanded polystyrene fill offers numerous benefits, it’s essential to address its environmental impact:

1. Recyclability:

EPS fill can be recycled into various products, reducing its environmental footprint. Many recycling facilities accept expanded polystyrene for processing.

2. Biodegradability:

While traditional polystyrene takes hundreds of years to decompose, innovative biodegradable options are emerging, mitigating environmental concerns.

3. Environmental Awareness:

Businesses and consumers are increasingly opting for eco-friendly alternatives, driving the demand for sustainable packaging and construction materials.

FAQs

What is expanded polystyrene fill used for?

Expanded polystyrene fill is utilized for insulation, packaging, and artistic endeavors due to its lightweight and insulating properties.

Is expanded polystyrene fill recyclable?

Yes, expanded polystyrene fill can be recycled into various products, contributing to a more sustainable waste management system.

How does expanded polystyrene fill benefit the packaging industry?

Expanded polystyrene fill provides excellent cushioning and shock absorption, ensuring the safe transportation of delicate items.

Are there any environmental concerns associated with expanded polystyrene fill?

While expanded polystyrene fill is recyclable, its disposal can contribute to environmental pollution if not managed properly.

Can expanded polystyrene fill be used for construction purposes?

Yes, expanded polystyrene fill is commonly used for insulation in construction, offering thermal efficiency and structural support.

What are the alternatives to expanded polystyrene fill?

Biodegradable options and sustainable materials are emerging as alternatives to traditional expanded polystyrene fill, catering to environmentally conscious consumers.

Conclusion: Embracing Innovation for a Sustainable Future

Expanded polystyrene fill remains a valuable material in various industries, offering unparalleled insulation and versatility. As businesses and consumers prioritize sustainability, the development of eco-friendly alternatives continues to evolve. By embracing innovation and conscious consumption, we can pave the way for a more sustainable future.