Expanded Polypropylene (EPP) is increasingly transforming the automotive industry due to its lightweight, durable, and energy-absorbing properties. Automotive manufacturers are leveraging EPP to reduce vehicle weight, improve fuel efficiency, and enhance crash safety. Its versatility allows seamless integration into bumpers, door panels, and interior components, making it an essential material in modern vehicles.

Beyond structural applications, EPP contributes to sustainability by being fully recyclable and resistant to environmental stressors. Its excellent thermal and acoustic insulation enhances passenger comfort while maintaining performance under extreme conditions. As automakers prioritize efficiency and safety, EPP is becoming a preferred choice for innovative, reliable, and eco-friendly automotive solutions worldwide.

Can EPP Be Used in an Automotive System?

Expanded Polypropylene (EPP) is widely used in automotive systems due to its lightweight, durable, and energy-absorbing properties. It improves safety, efficiency, and sustainability in modern vehicles. EPP is ideal for both structural and interior components, offering versatility while enhancing overall vehicle performance.

- Customizable Designs: Its moldable nature allows complex shapes and sizes, enabling designers to create innovative, functional automotive components efficiently and cost-effectively.

- Bumpers and Crash Absorption: EPP effectively absorbs impact energy during collisions, reducing damage and protecting passengers, making vehicles safer while lowering repair costs.

- Interior Components: Lightweight and flexible, EPP is used in dashboards, seat cores, and door panels, enhancing comfort, reducing weight, and improving fuel efficiency.

- Thermal and Acoustic Insulation: EPP provides excellent heat and sound insulation, ensuring a quieter, more comfortable cabin while maintaining durability in extreme temperatures.

- Eco-Friendly and Recyclable: EPP is fully recyclable, resistant to chemicals, and environmentally friendly, aligning with automotive industry goals for sustainability and reduced carbon footprint.

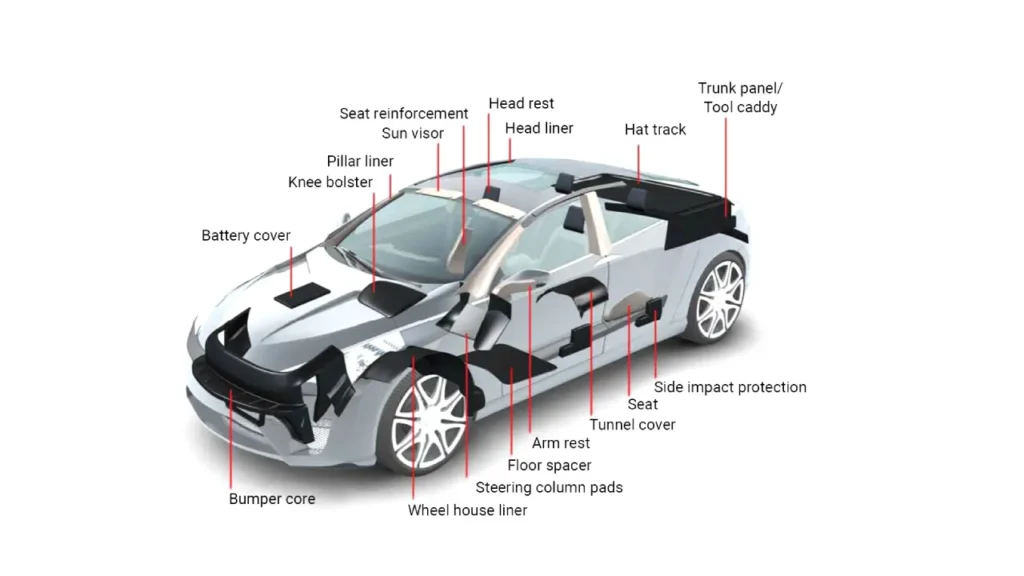

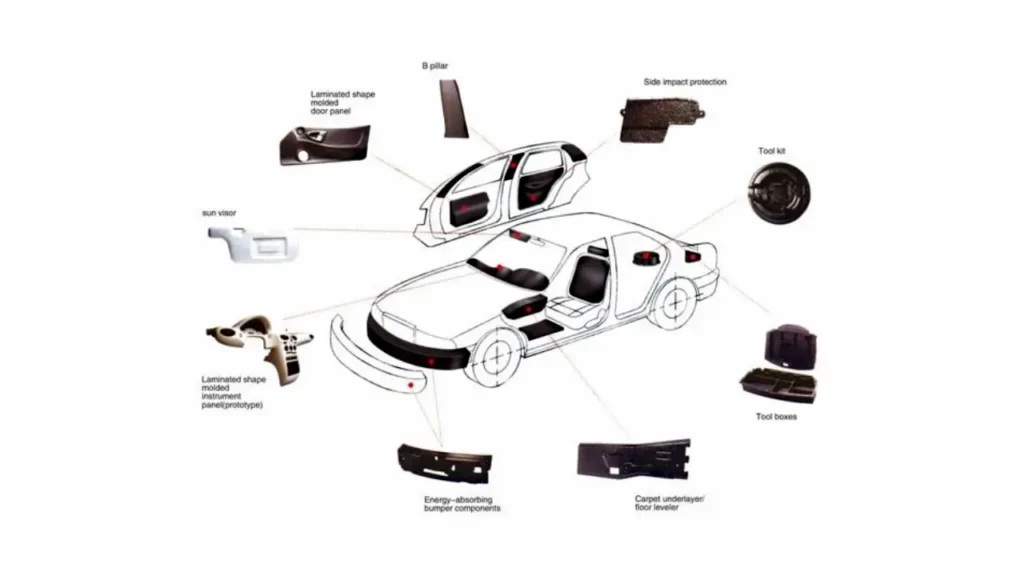

What EPP Can Be Molded for the Automotive System?

Expanded Polypropylene (EPP) is highly versatile and can be molded into various automotive components to improve safety, reduce weight, and enhance comfort. Its energy-absorbing and lightweight properties make it ideal for both structural and interior applications, supporting innovative designs while maintaining durability and efficiency in vehicles.

Bumpers and Impact Protection

EPP is widely used for bumpers and impact-absorbing elements. Its cellular structure effectively dissipates energy during collisions, reducing damage to vehicles and injuries to passengers. This makes EPP a reliable material for safety-critical components.

In addition, EPP molds allow for consistent thickness and precise shapes, ensuring that bumpers meet stringent automotive safety standards. The material’s resilience also ensures long-term performance under repeated impacts without deformation or degradation.

Door Panels and Interior Components

EPP is ideal for door panels, dashboards, and seat cores. Its lightweight nature contributes to overall vehicle weight reduction, improving fuel efficiency and handling performance. It also provides structural support where needed.

Moreover, EPP’s moldability allows designers to create complex, ergonomic shapes for enhanced passenger comfort. Its durability ensures components maintain their form and functionality over time, even under daily stress and vibration.

Thermal and Acoustic Insulation

EPP provides excellent thermal insulation, helping maintain cabin temperature and reducing HVAC load. It also absorbs sound, minimizing road and engine noise for a quieter ride.

The material’s ability to combine insulation with lightweight properties makes it suitable for multiple layers within automotive interiors. This ensures energy efficiency, passenger comfort, and reduced reliance on heavier materials that increase fuel consumption.

Customizable Components

EPP can be molded into complex, lightweight parts that meet specific automotive design requirements. Custom molds allow manufacturers to optimize both aesthetics and functionality.

Its versatility enables the production of components in various shapes, sizes, and densities, supporting innovative automotive design. This flexibility makes EPP a preferred choice for both prototype development and large-scale manufacturing.

EPP Car Parts

Expanded Polypropylene (EPP) is a foam bead product of this polymer, known for its lightweight nature, exceptional energy absorption, and structural strength. It has become a crucial material in the automotive industry due to its advantageous properties. EPP is highly recyclable, making it an environmentally sound choice for modern vehicle manufacturing.

🚗 EPP in Automotive Manufacturing

EPP’s unique combination of low weight and high performance makes it ideal for improving both the safety and efficiency of vehicles. Its superior ability to cushion impacts helps protect occupants and critical components, while its lightness contributes directly to better fuel economy and reduced emissions.

Automotive Industry EPP Material Integration

We manufacture a diverse range of expanded polypropylene components to enhance vehicle safety and performance. We provide lightweight solutions that significantly reduce overall car weight while maintaining high structural integrity. Our team supplies these precision-molded parts to automotive manufacturers globally, ensuring we offer the most advanced technology for impact absorption and thermal management in modern transportation.

EPP Bumper Core

We manufacture EPP bumper cores that serve as the primary energy absorption layer in the front and rear of vehicles. We provide these high-density foam parts to minimize damage during low-speed collisions and protect critical engine components. We supply durable cores that help manufacturers meet strict pedestrian safety standards and reduce repair costs for car owners.

Our facility produces these cores with high precision to ensure a perfect fit behind the bumper cover. We offer various densities to match specific crash test requirements for different vehicle models. We manufacture these lightweight alternatives to metal reinforcements to help improve fuel economy without sacrificing passenger protection during an accident.

EPP Seat Reinforcement

We provide EPP seat reinforcements that offer essential structural support for both passenger and driver seating systems. We manufacture these lightweight foam inserts to replace heavier steel or plastic frames, reducing the total mass of the interior. We supply these parts to help improve comfort and ergonomics by providing a stable base for seat cushions.

We offer these components with high energy-absorbing properties to enhance safety during rear-end collisions. We manufacture custom shapes that integrate seamlessly with heating elements and electronic seat adjustment sensors. We supply these reinforcements to ensure that automotive seats remain durable and provide consistent support throughout the long service life of the vehicle.

EPP Sun Visor

We manufacture EPP sun visor cores using expanded polypropylene to create a lightweight and impact-safe interior component. We provide these foam parts to replace traditional wire or plastic frames, which can be hazardous during a deployment. We supply these cores with a smooth finish that allows for easy upholstery with fabric or vinyl materials.

We offer these visors to help reduce the weight of the roof assembly and improve the overall center of gravity. We manufacture these parts to include integrated cavities for vanity mirrors and lighting wires. We supply these safe, durable components to ensure that drivers have effective glare protection while maintaining the highest interior safety standards.

EPP Pillar Liner

We provide EPP pillar liners that cover the internal structural supports of the vehicle roof and doors. We manufacture these energy-absorbing pads to protect passenger heads from impacting the metal frame during a side-overturn event. We supply these liners to ensure that the interior cabin remains a safe and well-cushioned environment for all occupants.

We offer these parts in various thicknesses to accommodate different vehicle designs and trim levels. We manufacture these liners to provide additional acoustic insulation, helping to reduce wind and road noise inside the cabin. We supply these components to help manufacturers achieve higher safety ratings while improving the overall quietness of the driving experience.

EPP Knee Bolster

We manufacture EPP knee bolsters that are strategically placed in the lower dashboard area to protect the driver and front passenger. We provide these specialized foam pads to absorb kinetic energy during a frontal collision, preventing serious leg and knee injuries. We supply these critical safety elements to integrate seamlessly with the steering column and glovebox.

We offer these bolsters with specific deformation characteristics to ensure they collapse in a controlled manner upon impact. We manufacture these parts to be extremely lightweight, contributing to the overall mass reduction goals of modern automotive engineering. We supply these safety components to provide reliable protection that supplements the action of the primary airbag systems.

EPP Head Rest

We provide EPP head rest cores that are engineered to prevent whiplash injuries during rear-end impacts. We manufacture these parts using high-performance foam to provide a soft yet supportive cushion for the passenger’s head. We supply these cores with internal reinforcements that allow for secure attachment to the seat back adjustment rails.

We offer various shapes and sizes to match the aesthetic and ergonomic requirements of luxury and economy vehicles alike. We manufacture these foam inserts to be highly durable, ensuring they maintain their shape and protective properties over many years of use. We supply these components to enhance the passive safety features of every seating position in the car.

EPP Head Liner

We manufacture EPP head liners that provide both thermal insulation and acoustic damping for the vehicle roof. We provide these large-format foam panels to create a finished interior surface that is both lightweight and structurally stable. We supply these liners to help maintain a comfortable cabin temperature while significantly reducing external noise levels.

We offer these components with integrated channels for wiring harnesses and side-curtain airbags. We manufacture these parts to be easy to install on the assembly line, reducing production time and costs for the manufacturer. We supply these liners to ensure a premium look and feel for the interior of any modern passenger vehicle.

EPP Hat Track

We provide EPP hat tracks, also known as rear parcel shelves, that are manufactured from durable expanded polypropylene. We manufacture these components to be incredibly light, making them easy for the user to remove or adjust when accessing the trunk. We supply these parts to provide a stable surface for lightweight items behind the rear seats.

We offer these tracks with built-in acoustic properties to help isolate trunk noise from the passenger cabin. We manufacture these parts using 100% recyclable materials, supporting the sustainability goals of the modern automotive industry. We supply these components to provide a functional and aesthetically pleasing finish to the rear of the vehicle interior.

EPP Trunk Panel And Tool Caddy

We manufacture EPP trunk panels and tool caddies that organize and protect the storage area of the vehicle. We provide these custom-molded trays to hold spare tires, jacks, and emergency repair kits securely in place. We supply these lightweight solutions to prevent tools from rattling and to optimize the available luggage space.

We offer these caddies with multiple compartments tailored to specific vehicle tool sets. We manufacture these parts to be moisture-resistant and easy to clean, ensuring the trunk area remains tidy. We supply these components to help manufacturers provide a professional and organized cargo management system for their customers.

EPP Battery Cover

We provide EPP battery covers that offer thermal protection and electrical insulation for both traditional and electric vehicle batteries. We manufacture these housings to maintain stable operating temperatures, which extends battery life and improves performance in cold weather. We supply these covers to protect sensitive power cells from physical impacts and environmental debris.

We offer these components with flame-retardant additives to enhance the safety of the vehicle’s electrical system. We manufacture custom fits for various battery sizes and configurations, ensuring a secure and protective enclosure. We supply these covers to help manage the thermal environment of the engine bay or the under-floor battery pack.

EPP Steering Column Pads

We manufacture EPP steering column pads that provide essential impact protection for the driver’s chest and abdomen. We provide these energy-absorbing foam parts to be installed directly around the steering mechanism. We supply these pads to ensure that the area remains safe in the event of a collision where the driver might contact the dashboard.

We offer these parts with precise cutouts for adjustment levers and electronic controls. We manufacture these pads to be thin yet highly effective at absorbing force, allowing for compact dashboard designs. We supply these components to supplement the safety provided by the steering wheel airbag and improve the overall crashworthiness of the vehicle.

EPP Floor Spacer

We provide EPP floor spacers that are used to level the vehicle floor and provide thermal insulation beneath the carpet. We manufacture these lightweight foam blocks to fill the gaps between the metal chassis and the interior floor mat. We supply these parts to create a comfortable, flat surface for the passengers’ feet while reducing vibrations.

We offer these spacers in custom shapes that fit the unique floor pan of any vehicle model. We manufacture these components to provide an additional layer of sound damping, keeping the cabin quiet during high-speed travel. We supply these parts to help simplify the interior assembly process and reduce the overall weight of the flooring system.

EPP Arm Rest

We manufacture EPP arm rest cores that provide a comfortable and ergonomic surface for passengers. We provide these foam inserts for both center consoles and door panels to enhance the long-distance driving experience. We supply these cores with a durable structure that supports the weight of the arm without deforming over time.

We offer these components with integrated mounting points for cup holders and storage bins. We manufacture these cores to be easily covered with leather or fabric, ensuring a high-end finish for the vehicle interior. We supply these parts to provide a balance of soft-touch comfort and rigid structural support in every seating position.

EPP Tunnel Cover

We provide EPP tunnel covers that insulate the center hump of the vehicle floor from transmission heat and noise. We manufacture these foam shields to fit precisely over the exhaust and drivetrain tunnel. We supply these parts to help keep the passenger cabin cool and quiet, especially in rear-wheel or all-wheel drive vehicles.

We offer these covers with specialized coatings that resist high temperatures and automotive fluids. We manufacture these parts to be extremely lightweight compared to traditional heavy rubber or metal heat shields. We supply these components to improve the thermal efficiency of the climate control system by reducing heat soak into the cabin.

EPP Side Impact Protection

We manufacture EPP side impact protection blocks that are installed inside the door panels to absorb energy during a T-bone collision. We provide these high-density parts to minimize the intrusion of the door into the passenger space. We supply these critical safety components to help vehicles pass the most demanding side-impact crash tests.

We offer these protection blocks in various sizes and shapes to fit the specific internal geometry of the car doors. We manufacture these parts to work in conjunction with side-curtain and seat-mounted airbags. We supply these foam inserts to provide a reliable and lightweight safety barrier that protects the ribs and pelvis of the occupants.

EPP Seat

We provide complete EPP seat structures that revolutionize how automotive seating is designed. We manufacture these large-scale foam components to replace complex multi-part metal assemblies. We supply these lightweight seats to help electric vehicle manufacturers maximize their driving range by significantly reducing the mass of the interior cabin.

We offer these seat frames with built-in ergonomic curves that provide superior support and comfort for passengers. We manufacture these components to be 100% recyclable at the end of the vehicle’s life, supporting circular economy initiatives. We supply these innovative seating solutions to provide a more sustainable and efficient way to build modern car interiors.

EPP Wheel House Liner

We manufacture EPP wheel house liners that protect the vehicle body from road salt, water, and debris. We provide these durable foam panels to serve as an acoustic barrier that dampens the sound of tires on the road. We supply these liners to prevent corrosion and reduce the amount of noise that enters the passenger compartment.

We offer these liners with a textured surface that helps to deflect water and mud effectively. We manufacture these parts to be impact-resistant, ensuring they can withstand the constant bombardment of small stones during travel. We supply these components to help extend the life of the vehicle body while providing a more refined and quiet ride.

🚘 Key Automotive Applications for EPP

EPP’s versatility and performance characteristics enable its use in a wide array of vehicle components, significantly improving passive safety and contributing to overall weight reduction. The material’s capacity to absorb impact energy while maintaining structural integrity is crucial for protecting occupants in crash scenarios.

EPP’s lightweight yet durable nature makes it the ideal material for boot fillers and tool caddies. These components securely organize breakdown equipment and spare parts, contributing to the vehicle’s optimized storage layout while adding minimal weight, thus supporting overall fuel economy targets.

Bumper Core

The core is strategically placed behind the bumper fascia to absorb low-speed impact energy, effectively reducing damage and costly repairs. EPP’s exceptional elasticity allows it to recover its shape after minor collisions, providing consistent long-term protection for the vehicle’s critical front and rear structures and managing crash forces.

Side Impact Protection (SIP)

Integrated into door panels and pillars, EPP foam provides crucial impact absorption to protect occupants during a side collision. Its ability to manage and disperse kinetic forces over a large area significantly reduces the risk of injury from direct contact with the vehicle’s internal structure or intrusion from the side.

Seat Components & Headrests

Used in seat cores, headrests, and knee bolsters, EPP enhances comfort and safety. Its excellent energy-absorbing properties are vital for whiplash protection in rear-end collisions, while its low weight helps reduce the overall mass of the seating system, which aids in vehicle performance.

Trunk Fillers & Tool Trays

EPP’s lightweight yet durable nature makes it the ideal material for boot fillers and tool caddies. These components securely organize breakdown equipment and spare parts, contributing to the vehicle’s optimized storage layout while adding minimal weight, thus supporting overall fuel economy targets.

How EPP Foam Absorbs Impact Energy

The process by which EPP foam absorbs impact energy is highly efficient and dependent on its specialized closed-cell structure. Upon impact, the foam goes through stages of compression, plateauxing the stress to manage the energy effectively, which is vital for occupant safety.

Energy Dissipation as Heat: The kinetic energy absorbed during the cell crushing and material deformation process is not stored entirely; a portion of it is effectively dissipated as minor heat within the foam. This dissipation is key to the foam’s damping ability, quickly reducing the force transmitted, ensuring impact forces stay below critical thresholds for injury.

Cell Wall Elastic Buckling: EPP foam consists of numerous fused, gas-filled polypropylene beads, each containing tiny closed cells. When a force is applied, the cell walls initially undergo elastic buckling and collapse under stress. This initial controlled deformation is the primary mechanism for absorbing the impact’s kinetic energy, reducing the shock felt by the passenger.

Plateau Stress Phase: After initial buckling, the material enters a crucial stress plateau region on the stress-strain curve, where the cells continue to crush and compress significantly. During this phase, EPP absorbs a large amount of energy without a sharp increase in the peak force, protecting the body from forces that could cause injury.

Densification and Recovery: Once the cells are almost completely collapsed, the solid polymer material begins to compress against itself, leading to densification and a rapid spike in stress. Crucially, EPP’s high resilience allows it to largely recover its original form after a minor collision, making it ideal for reusable components like bumper cores.

Conclusion

EPP’s remarkable combination of lightweight design, durability, and energy absorption makes it a game-changer in automotive systems. From safety components to interior parts, it allows manufacturers to optimize performance without compromising passenger protection. Investing in EPP materials ensures vehicles meet modern standards for efficiency, safety, and sustainability.

For businesses and manufacturers looking to integrate EPP solutions, sourcing high-quality molds is crucial. Our Epsole platform provides wholesale EPP molds that guarantee precision, reliability, and cost-effectiveness. With customizable options, we support large-scale production while maintaining consistent quality, enabling automotive innovators to achieve superior results efficiently.

By choosing our wholesale EPP molds, you gain access to industry-leading technology and exceptional material performance. Epsole ensures that your EPP components meet exact specifications for automotive applications, helping you stay competitive and innovate confidently. Elevate your production with molds designed for durability, efficiency, and outstanding performance.