In the intricate world of industrial systems and machinery, there exists a critical component that often goes unnoticed yet plays a pivotal role in ensuring safety, efficiency, and reliability: the relief valve. As industries evolve and technologies advance, the importance of relief valves in safeguarding equipment, personnel, and the environment cannot be overstated.

In this blog post, we embark on a journey to unravel the mysteries surrounding relief valves, exploring their purpose, functions, and significance across various industries and applications. From preventing overpressure situations to protecting against equipment failures, relief valves serve as silent guardians, silently working in the background to maintain operational integrity and mitigate risks.

What Is Pressure Relief Valve

A pressure relief valve (PRV) is a crucial safety device designed to protect equipment, systems, and personnel from the dangers of overpressure conditions. Operating across various industries and applications, PRVs serve as essential safeguards, ensuring that pressure within a system remains within safe limits.

Types of Pressure Relief Valves (PRVs)

Direct-Acting Pressure Relief Valves

Direct-acting pressure relief valves (PRVs) are the simplest type of relief valves. They operate without any auxiliary source of power. Instead, they rely solely on a mechanical spring to exert force against the pressure of the fluid in the system. When the system pressure exceeds the spring force, the valve opens to release excess pressure. Once the pressure drops back to a safe level, the spring closes the valve.

Characteristics:

- Simple Design: These valves are straightforward in their construction and operation, making them easy to maintain.

- Cost-Effective: Generally less expensive due to their simplicity.

- Suitable for Low Flow Rates: Best used in systems with lower flow requirements.

Pilot-Operated Pressure Relief Valves

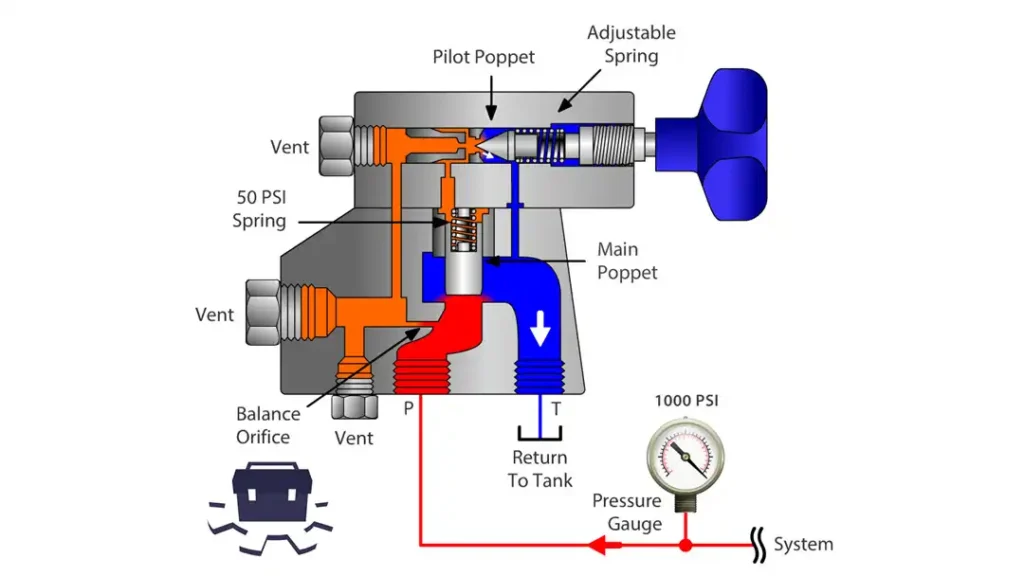

Pilot-operated PRVs use system pressure to help control the opening and closing of the valve. These valves have a smaller pilot valve that senses the system pressure. When the pressure exceeds a predetermined level, the pilot valve opens, allowing pressure to act on the main valve piston, which then opens to release excess pressure.

Characteristics:

- High Accuracy: Provides precise control over the pressure at which the valve opens.

- Stable Operation: Less affected by back pressure and fluctuations in the system.

- Suitable for High Pressure and Flow: Ideal for systems with higher pressure and flow requirements.

Spring-Loaded Safety Relief Valves

Spring-loaded safety relief valves are a common type of safety valve. They use a spring mechanism to hold the valve closed against the pressure of the fluid. When the system pressure exceeds the force exerted by the spring, the valve opens to release the excess pressure.

Characteristics:

- Adjustable Set Point: The pressure at which the valve opens can be adjusted by changing the tension on the spring.

- Robust Design: Suitable for a wide range of applications and pressures.

- Manual Reset: Some designs require manual resetting after activation.

Balanced Bellows Safety Relief Valves

Balanced bellows safety relief valves are designed to mitigate the effects of back pressure on valve performance. They incorporate a bellows assembly that balances out the back pressure, ensuring consistent operation regardless of variations in the outlet pressure.

Characteristics:

- Back Pressure Compensation: Provides stable performance in systems with varying back pressure.

- Corrosion Protection: The bellows can protect the spring and other components from corrosive process fluids.

- High Sensitivity: More responsive to pressure changes than some other designs.

Thermal Relief Valves

Thermal relief valves are specifically designed to protect against excessive pressure caused by thermal expansion in closed systems. They automatically release small amounts of fluid when the temperature and pressure rise beyond safe limits.

Characteristics:

- Temperature-Sensitive: Opens in response to temperature-induced pressure increases.

- Small Size: Generally compact and designed for smaller pressure relief needs.

- Specialized Application: Used in systems like piping networks, storage tanks, and heat exchangers.

Vacuum Relief Valves

Vacuum relief valves prevent vacuum conditions within a system, which could lead to equipment collapse or operational failure. They allow air to enter the system when the internal pressure drops below atmospheric pressure.

Characteristics:

- Prevents Vacuum Conditions: Essential for systems that can experience negative pressure.

- Protective Function: Helps prevent damage to tanks, vessels, and pipelines.

- Automatic Operation: Operates automatically without external power sources.

Conventional Relief Valves

Conventional relief valves are standard relief valves that open in response to excessive system pressure. They are designed without additional features like bellows or pilot operation.

Characteristics:

- Simple Operation: Opens directly in response to pressure.

- Versatile: Suitable for many different applications.

- Cost-Effective: Generally less expensive than more specialized valves.

Pressure and Vacuum Relief Valves

These valves are designed to protect systems from both overpressure and vacuum conditions. They can relieve pressure in both directions, ensuring system stability under varying conditions.

Characteristics:

- Dual Function: Provides protection against both overpressure and vacuum.

- Versatile Application: Ideal for storage tanks and vessels exposed to fluctuating pressures.

- Reliability: Ensures consistent performance under different conditions.

Purpose of Pressure Relief Valve

Pressure relief valves (PRVs) are critical components in many industrial and commercial systems. Their primary purpose is to protect equipment and personnel by ensuring that pressure within a system does not exceed safe limits. Here’s a detailed explanation of the various roles and functions of PRVs:

Protection Against Overpressure

The fundamental purpose of a PRV is to prevent overpressure conditions within a system. Overpressure can occur due to a variety of reasons, including equipment failure, blockages, or sudden changes in temperature. When the system pressure exceeds the design limit, the PRV opens to release the excess pressure, thereby preventing potential damage or catastrophic failure.

Safety of Personnel

Overpressure conditions can pose significant risks to personnel working in or around the equipment. High-pressure failures can lead to explosions, the release of hazardous substances, or other dangerous situations. PRVs help mitigate these risks by maintaining the pressure within safe levels, ensuring a safer working environment.

Protection of Equipment

Overpressure can cause severe damage to equipment such as pipes, tanks, and machinery. This damage can result in costly repairs, downtime, and loss of productivity. PRVs help protect this equipment by relieving excess pressure and preventing damage, thereby extending the lifespan of the system components and reducing maintenance costs.

Maintaining System Integrity

In systems where pressure is a critical operational parameter, maintaining consistent pressure levels is essential for proper functioning. PRVs ensure that pressure fluctuations do not adversely affect the system’s performance, thereby maintaining operational integrity and efficiency.

Compliance with Regulatory Standards

Many industries are subject to strict safety regulations that mandate the use of PRVs. These regulations are designed to protect workers, the public, and the environment from the dangers associated with overpressure. By installing and maintaining PRVs, companies can ensure compliance with these regulations and avoid potential legal and financial penalties.

Environmental Protection

In industries dealing with hazardous or toxic substances, overpressure can lead to leaks or spills that may harm the environment. PRVs help prevent such incidents by safely venting excess pressure and reducing the risk of uncontrolled releases.

Prevention of Product Loss

In many processes, maintaining pressure is crucial to prevent the loss of valuable products. For example, in the chemical and petrochemical industries, the release of overpressure can result in the loss of raw materials or finished products. PRVs help to minimize such losses by controlling the pressure within the system.

Ensuring Process Continuity

Uncontrolled pressure spikes can cause operational interruptions and unplanned shutdowns. PRVs play a crucial role in ensuring process continuity by maintaining pressure within acceptable limits, thus avoiding disruptions and ensuring smooth and continuous operations.

Cost Savings

While PRVs are a relatively small investment compared to the cost of the equipment they protect, their role in preventing overpressure damage can lead to significant cost savings. By avoiding damage, reducing downtime, and minimizing the risk of accidents, PRVs contribute to the overall cost efficiency of industrial operations.

Application in Various Industries

PRVs are used across a wide range of industries, each with specific requirements and standards. Some common applications include:

- Oil and Gas: Protecting pipelines, storage tanks, and processing equipment.

- Chemical Processing: Ensuring safe operations in reactors, distillation columns, and storage vessels.

- Power Generation: Maintaining pressure control in boilers, steam lines, and turbines.

- Water and Wastewater: Preventing overpressure in treatment plants and distribution systems.

- Pharmaceutical: Ensuring the integrity of processing equipment and containment systems.

Pressure Relief Valve Function

Pressure relief valves (PRVs) serve a crucial function in various industrial and commercial settings, ensuring the safe and efficient operation of equipment and systems. Let’s delve deeper into the specific functions and mechanisms of PRVs:

Overpressure Prevention

The primary function of a pressure relief valve is to prevent overpressure conditions within a system. When the pressure surpasses safe operating limits due to factors like equipment malfunction, blockages, or temperature fluctuations, the PRV activates to release excess pressure. By doing so, it protects the system from potential damage and maintains operational safety.

Pressure Regulation

PRVs also contribute to pressure regulation within a system. They help maintain pressure at optimal levels by opening and closing as needed to release or control the flow of fluid. This ensures that the system operates within its designed parameters, enhancing efficiency and performance.

Safety Assurance

One of the critical functions of PRVs is to assure the safety of personnel and assets. By preventing overpressure situations that could lead to equipment failure, leaks, or explosions, PRVs help create a safer working environment. This protects both employees and the surrounding infrastructure from potential harm or damage.

Equipment Protection

PRVs play a vital role in safeguarding equipment and machinery from the adverse effects of excessive pressure. High pressure can cause stress, fatigue, and damage to components, leading to premature failure or breakdowns. By relieving pressure before it reaches dangerous levels, PRVs extend the lifespan of equipment and reduce maintenance costs.

Environmental Protection

In industries dealing with hazardous substances, PRVs help prevent environmental contamination by controlling pressure and minimizing the risk of leaks or spills. By releasing excess pressure safely, PRVs mitigate the potential impact on surrounding ecosystems and communities, promoting environmental stewardship.

Process Optimization

By regulating pressure and preventing overpressure incidents, PRVs contribute to process optimization and efficiency. Maintaining consistent pressure levels ensures smooth and continuous operation of systems, minimizing downtime and maximizing productivity. This leads to improved throughput, quality, and profitability.

Compliance with Regulations

Many industries are subject to regulations and standards governing pressure safety and equipment operation. PRVs play a critical role in ensuring compliance with these requirements by providing reliable pressure relief mechanisms. By adhering to regulatory guidelines, organizations demonstrate their commitment to safety and legal compliance.

Function of Pressure Relief Valve in Hydraulic System

Pressure relief valves (PRVs) are essential components in hydraulic systems, serving several critical functions to ensure safe and efficient operation. Here’s a detailed look at the various roles and mechanisms of PRVs within hydraulic systems:

Maintaining System Pressure

Preventing Overpressure

The primary function of a PRV in a hydraulic system is to prevent overpressure. Hydraulic systems operate under high pressure to transmit power effectively. If the pressure exceeds the system’s design limits due to factors such as pump malfunctions or load changes, the PRV opens to release the excess pressure. This prevents potential damage to the system components, such as pumps, cylinders, and hoses.

Regulating Operating Pressure

PRVs help maintain the operating pressure within the desired range. By opening at a predetermined pressure, they ensure that the hydraulic system does not exceed safe levels, thus maintaining the efficiency and reliability of the operation. This regulation is crucial for the consistent performance of hydraulic equipment.

Protecting System Components

Safety of Hydraulic Components

Hydraulic systems consist of various components, including pumps, actuators, valves, and hoses, all of which can be damaged by excessive pressure. A PRV protects these components by relieving pressure when it becomes too high, thereby extending the lifespan of the equipment and reducing maintenance costs.

Preventing System Failures

High-pressure spikes can cause catastrophic failures in hydraulic systems, leading to costly repairs and downtime. PRVs act as a safety mechanism to prevent such failures by ensuring that pressure levels remain within safe limits, thereby avoiding sudden breakdowns and operational interruptions.

Enhancing Operational Safety

Ensuring Personnel Safety

Overpressure conditions can pose significant risks to personnel operating or working near hydraulic systems. By preventing these conditions, PRVs enhance workplace safety, protecting employees from potential injuries caused by equipment failures or fluid bursts.

Conclusion

In conclusion, the purpose of relief valves cannot be overstated in ensuring the safety, integrity, and efficiency of industrial systems. These critical components play a vital role in protecting equipment, personnel, and the environment by preventing overpressure conditions. By understanding the importance of relief valves and implementing them effectively, industries can mitigate risks, comply with regulations, and safeguard their operations.

As you explore the significance of relief valves in your industry, we invite you to consider partnering with us for your pressure relief valve needs. With our wide range of high-quality products and expertise in the field, we are committed to providing reliable solutions tailored to your specific requirements. Welcome to get wholesale pressure relief valves from us at any time, ensuring the safety and performance of your systems.