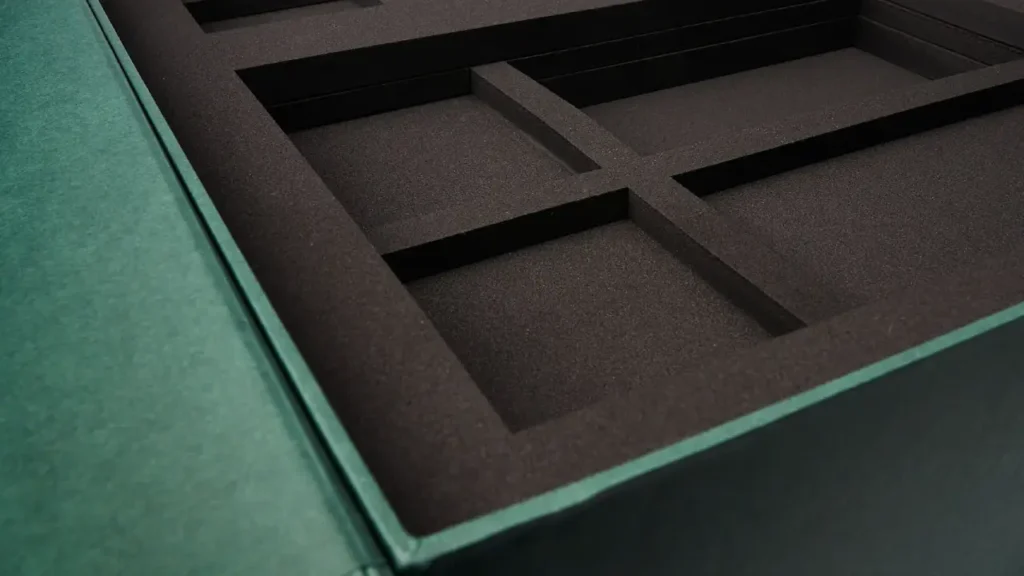

Foam inserts are shaped protective supports designed to hold products securely during storage, packaging, and shipping. They reduce shock, vibration, and abrasion, making them essential for delicate or high-value items. From tools and electronics to medical devices, foam inserts ensure every component stays in place and arrives safely.

Among the many foam options available, EPP and EPS inserts stand out for their balance of protection, weight, and cost. Each material offers unique benefits depending on the product’s fragility, transport environment, and durability needs. Understanding how EPP and EPS differ helps you choose the most reliable solution for your application.

What are Foam Inserts?

Foam inserts are custom-shaped protective pieces designed to secure products during packaging, storage, and shipping. They absorb shocks, limit vibration, and prevent items from shifting or scratching. Used for tools, electronics, medical equipment, and delicate components, foam inserts improve safety, presentation, and overall product protection across a wide range of industries.

EPP Foam Insert Benefits

EPP foam inserts offer durable, lightweight protection designed for repeated use across electronics, tools, automotive parts, and precision devices. Their strength, resilience, and design flexibility make them a dependable packaging choice. By combining superior cushioning with long-term performance, EPP ensures products stay secure, stable, and protected in demanding environments.

- Highly customizable: EPP can be molded into precise shapes and densities to match exact product contours, ensuring tighter fits and better stability. Its design flexibility supports complex layouts, branding elements, and multifunctional packaging structures that enhance product presentation, simplify packing, and improve overall user experience.

- High impact resistance: EPP absorbs repeated shocks and quickly returns to its original shape, preventing damage from drops, vibration, or rough handling. Its rebound strength keeps components stable throughout storage and transport, making it ideal for sensitive or fragile items that require reliable, long-term cushioning performance.

- Lightweight yet strong: EPP reduces overall packaging weight while maintaining impressive structural strength, helping lower shipping costs and improve handling. Its supportive design holds heavy or irregular parts firmly in place, ensuring consistent protection without adding unnecessary bulk or compromising durability throughout repeated use.

- Reusable and long-lasting: EPP withstands multiple handling cycles without cracking, crumbling, or deforming, making it perfect for returnable packaging and equipment cases. Its resilience helps businesses cut waste and reduce replacement expenses while keeping products securely cushioned through countless uses and demanding logistics environments.

- Excellent thermal insulation: EPP protects temperature-sensitive components from heat and cold fluctuations, helping maintain product stability during storage and shipping. This insulation capability supports electronics, automotive parts, and precision devices that require consistent conditions to maintain performance, reduce degradation, and prevent environmental damage.

EPS Foam Insert Benefits

EPS (Expanded Polystyrene) foam inserts provide lightweight yet strong protection for delicate products. They absorb shocks, prevent damage during transport, and are customizable to fit various product shapes. Widely used in electronics, medical equipment, and packaging, EPS inserts combine affordability, durability, and efficiency for safe product handling.

- Moisture Resistance: EPS foam resists moisture and humidity, protecting items from water damage during storage or transport. This feature ensures long-lasting product integrity, especially for electronics and sensitive instruments.

- Lightweight Protection: EPS inserts are extremely light, reducing overall shipping weight while providing strong cushioning to safeguard products. This helps lower transportation costs and ensures delicate items like electronics and glassware remain intact during handling and transit.

- Shock Absorption: EPS foam effectively absorbs impacts from drops or vibrations. Its structure disperses force evenly, minimizing the risk of damage to sensitive components. This makes it ideal for shipping fragile and precision items safely.

- Customizable Design: EPS inserts can be cut or molded to match product shapes precisely. Custom designs ensure snug fits, preventing movement inside packaging, improving protection, and enhancing presentation for retail or gifting purposes.

- Cost-Effective: EPS foam is affordable and widely available, making it an economical solution for protecting products. Bulk production and easy customization reduce packaging costs without compromising safety.

What are EPP and EPS Foam Inserts Used for?

EPP and EPS foam inserts are essential for protecting delicate and high-value items during storage and transportation. Their shock absorption, lightweight nature, and customizable design make them ideal for electronics, medical devices, consumer goods, and industrial components, ensuring products remain safe and intact from manufacturer to end user.

Retail Presentation: Foam inserts enhance product presentation by holding items securely in packaging, creating a professional display. They combine protection and aesthetic appeal, making unboxing a safe and attractive experience for customers.

Electronics Protection: Foam inserts securely hold electronic components such as circuit boards, smartphones, and laptops, preventing movement and reducing risk of damage during shipping. Their custom shapes accommodate various product designs, keeping fragile items safe throughout transit.

Medical Equipment Safety: EPP and EPS inserts protect medical instruments and devices from impacts, vibrations, and shocks. Precision cut designs ensure that sensitive equipment stays secure, maintaining sterility and functionality while reducing the risk of costly damage.

Consumer Goods Packaging: Foam inserts are used to package fragile consumer goods like glassware, cosmetics, and appliances. They offer stability and cushioning, preventing scratches, cracks, or breakage during transportation and storage.

Industrial Component Handling: Heavy or delicate industrial components benefit from foam inserts, which absorb impacts and vibrations during shipping. Customized inserts keep parts in place, minimizing risk of operational delays due to damaged components.

How to Choose EPP and EPS Foam Inserts?

Selecting the right foam inserts is crucial for product safety and cost efficiency. Consider material type, product weight, fragility, and shipping conditions. EPP offers high durability and repeated impact resistance, while EPS is lightweight and affordable. Proper choice ensures maximum protection and optimal packaging performance for your items.

- Budget and Efficiency: Balance cost with protection needs. EPS is more economical and suitable for light-duty packaging, while EPP may cost more but offers higher durability. Select the option that meets safety requirements without overspending.

- Assess Product Fragility: Determine how delicate your items are. Fragile electronics or glassware need inserts with superior shock absorption. Choosing foam that fits snugly around the product minimizes movement, reduces risk of damage, and provides peace of mind during transit.

- Consider Weight and Size: Lighter products may benefit from EPS foam to reduce shipping costs, while heavier or repeatedly handled items may require EPP for durability. Match insert thickness and density to product dimensions for secure and efficient packaging.

- Evaluate Impact Resistance: EPP foam is ideal for repeated impacts or rough handling, providing superior resilience. EPS is suitable for single-use protection. Understanding expected transport conditions helps determine which foam material offers the best long-term protection.

- Customization Options: Choose foam that can be easily molded or cut to fit your product shape. Custom inserts prevent shifting inside packaging, enhance protection, and improve presentation, especially for high-value or fragile items.

Conclusion

Foam inserts play a crucial role in safeguarding products across various industries, offering structured protection that prevents damage during handling and transportation. Whether you’re securing electronics, instruments, or custom-shaped goods, choosing the right material ensures better performance and long-term reliability. EPP and EPS each deliver distinct strengths that match different protective needs.

EPP foam inserts excel with superior impact resistance, long-term durability, and reusability, making them ideal for sensitive or frequently handled products. EPS inserts provide excellent rigidity and cost-effective cushioning for lightweight or single-use packaging. Understanding these differences guides you toward the most efficient protective solution for your business and product requirements.

If you’re ready to enhance your packaging with dependable cushioning, sourcing from a trusted manufacturer makes all the difference. Our Epsole team supplies high-quality wholesale EPP foam inserts and EPS foam inserts tailored to your exact shapes, densities, and protective needs. Partner with us to upgrade your product safety, reduce shipping damage, and streamline your packaging performance.