When contractors and builders are faced with the choice between insulated concrete forms (ICF) and concrete blocks (CMU) for constructing exterior walls, it’s crucial for them to understand the distinctions in wall systems offered by ICF and their advantages over CMU or cinder blocks.

In this article, we delve into ICF VS Concrete Block, aiming to provide clarity for professionals navigating the complexities of exterior wall construction.

What Is ICF?

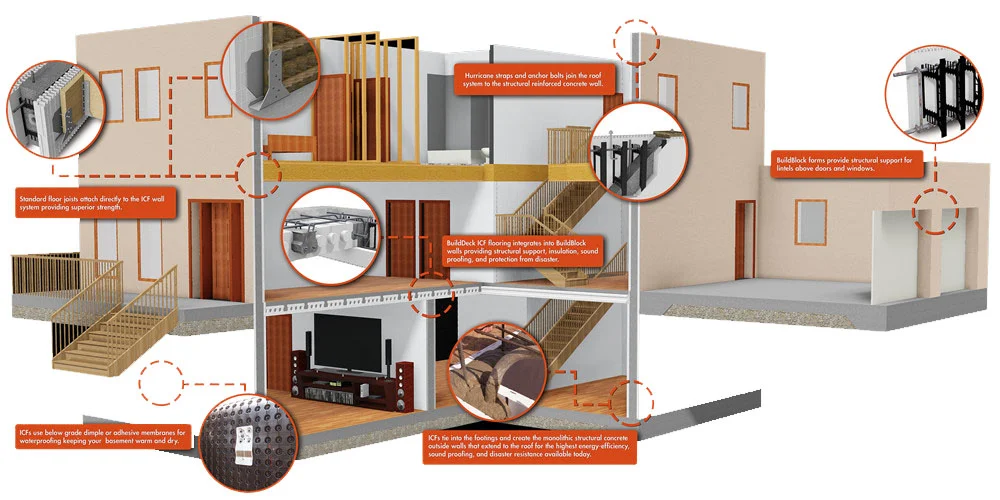

ICF, or Insulated Concrete Forms, comprises hollow foam blocks assembled to form the outer walls of a structure, fortified with steel rebar, and subsequently filled with concrete. This innovative construction method merges Expanded Polystyrene (EPS), a top-tier insulating material, with steel-reinforced concrete, one of the most robust structural building materials available.

What Is Concrete Block?

Concrete block, also known as a concrete masonry unit (CMU), is a standardized building block made of concrete. It is used in construction for building walls, partitions, and other structural elements. Concrete blocks come in various sizes and shapes and are known for their durability, strength, and versatility in construction projects.

Characteristics and Advantages of ICF

Excellent Thermal Insulation: With a continuous layer of insulation material, ICF reduces energy consumption for heating and cooling, leading to lower utility costs and enhanced indoor comfort.

Easy Installation and Customization: ICF is straightforward to install due to its interlocking foam block design and lightweight materials, allowing for quick assembly and transportation. It can also be customized to fit various design requirements, providing flexibility in construction.

Structural Stability and Seismic Resistance: ICF structures are highly stable and resilient against seismic activity, thanks to reinforced concrete and monolithic walls. This ensures durability and safety in high-wind and earthquake-prone regions.

Effective Sound Insulation: ICF walls provide excellent sound insulation, reducing noise transmission between rooms and from external sources. The dense concrete core, combined with foam insulation, creates a sound barrier, enhancing acoustic comfort.

Energy Efficiency and Sustainability: ICF construction promotes energy efficiency by reducing heating and cooling loads, resulting in lower energy consumption and greenhouse gas emissions. Some ICF products use recycled materials, contributing to environmental sustainability and potentially improving indoor air quality.

Characteristics and Advantages of Concrete Block

Structural Strength: Concrete blocks are renowned for their high strength and durability, making them suitable for load-bearing walls and structural elements in buildings.

Fire Resistance: Concrete blocks offer excellent fire resistance, providing enhanced safety by preventing the spread of fires and protecting building occupants.

Design Flexibility: Concrete blocks come in various sizes, shapes, and textures, allowing for versatile design options and architectural styles.

Cost-Effectiveness: Concrete blocks are often cost-effective compared to alternative building materials, considering their longevity and low maintenance requirements.

Resistance to Pests and Rot: Concrete blocks are resistant to pests such as termites and do not rot, ensuring the longevity of buildings and reducing the need for maintenance.

What Are The Advantages Of ICF VS Concrete Block?

Strength of ICF VS Concrete Block

Constructing ICF walls entails assembling interconnected hollow EPS (expanded polystyrene) foam blocks, which interlock to provide continuous insulation throughout the building’s interior and exterior, spanning from the foundation to the roof. Once the insulated concrete forms are reinforced and braced, concrete is poured into the cavities.

This poured-in-place concrete wall system establishes a solid, seamless structural support, significantly enhancing the building’s strength and durability compared to CMU construction. In CMU construction, concrete blocks are laid and bonded together using mortar. To bolster strength, the cells can be filled with concrete, with rebar inserted into every three or four cores.

However, unlike ICF walls, this method does not create a unified concrete system. Consequently, buildings made of concrete blocks lack the same level of strength and structural integrity as those constructed with ICF.

Wind-Resistant: ICF VS Concrete Block

Structures built using insulated concrete forms boast remarkable wind resistance, capable of withstanding winds exceeding 200 mph thanks to their continuous load path. This design ensures that when a building encounters uplift and lateral forces, the load is channeled seamlessly from the roof, walls, and other components down to the foundation and into the ground.

Nudura ICFs are engineered to meet Federal Emergency Management Agency (FEMA) guidelines for safe rooms in storm-prone areas with wind speeds of up to 250 mph. ICF constructions are highly sought after in regions prone to tornadoes and hurricanes due to their exceptional wind resistance.

During Hurricane Michael in 2018, which ravaged Mexico Beach, Florida with wind speeds exceeding 160 mph and a storm surge of 9 to 14 feet, the only beachfront property to withstand the devastation was a residence constructed with Nudura ICFs. This anecdote stands as just one of many testimonials showcasing the tornado and hurricane-resistant qualities of insulated concrete form systems.

Impact-Resistant: ICF VS Concrete Block

ICFs are often preferred in vulnerable areas due to their resilience against extreme weather impacts, withstanding debris speeds exceeding 100 mph, and deflecting damaging projectiles, including splintering wood beams.

The U.S. military mandates ICFs for constructing military buildings and housing to shield occupants from bullets and bomb blasts. Rigorous testing has shown ICF walls endure C4 explosives, with only foam sustaining damage while the concrete structure remains unharmed.

In everyday situations, ICF walls exhibit resilience. For example, when a concrete truck accidentally backed into an ICF structure, only the façade was affected, preserving the building’s structural integrity.

Energy Efficiency Of ICF VS Concrete Block

The energy efficiency of ICF structures stems from the inherent properties of continuous insulation on both sides and the thermal mass of ICF systems, creating an airtight building envelope. This energy conservation leads to reduced operational costs for the end-user, as heating and cooling bills are minimized.

ICFs’ R-values vary depending on the type of insulation and foam thickness, with most systems achieving an R-value greater than 23. Nudura offers solutions with R-values up to R-48.

Concrete blocks typically have an intrinsic R-value ranging from R-4 to R-14, necessitating additional insulation for enhanced energy efficiency. Insulating CMU walls requires an extra step beyond stacking the blocks: the addition of foam insulation.

Cost And Maintenance Of ICF VS Concrete Block

When considering labor, time, and initial material expenses, the construction cost of an ICF building aligns with that of a CMU structure.

Given labor shortages and rising costs, ICF construction offers cost savings during the building phase by requiring fewer workers compared to CMU projects. Constructing CMU walls typically necessitates a team of five to seven workers, whereas ICF walls can be erected by just one trained installer with assistance from a few laborers. Regular ICF training courses ensure a pool of skilled workers proficient in properly bracing, reinforcing forms, and pouring concrete.

Moreover, the assembly of ICF walls consolidates multiple construction processes into one, encompassing insulation, structure, air barrier, vapor retarder, and attachment. This comprehensive system accelerates project completion by streamlining trade coordination, resulting in time and cost savings for all stakeholders.

Achieving comparable durability, energy efficiency, and resilience to an ICF structure with Concrete Blocks would require additional components and steps in CMU construction. These supplementary processes can prolong construction time, increase overall expenses, and heighten the risk of application errors.

Ultimately, the reduced labor and time requirements of ICF construction translate into significant cost savings.

Ease Of ICF Installation VS Concrete Block

Lightweight ICFs offer easy handling and rapid wall construction. The blocks stack effortlessly, interlocking as they are placed and braced for concrete pouring. Skilled workers then pour concrete into the block cores, facilitating swift installation and resulting in a robust, energy-efficient, and disaster-resistant wall that enhances occupant comfort and health.

The simplicity of ICF installation often encourages first-time users to employ them in subsequent projects. In contrast, constructing a concrete masonry wall is a lengthier process, taking twice the time. Concrete Blocks are heavy, leading to increased transportation costs and laborious movement around the job site.

Additionally, CMU construction necessitates the involvement of multiple trades for insulation and wall protection. Framers are required to fur out the walls, followed by insulation installation by a dedicated company. These additional steps extend the project timeline by several days.

Furthermore, CMU buildings typically require the installation of an air and moisture barrier, necessitating the involvement of yet another trade and further delaying the creation of an air- and water-tight building envelope.

Design Advantages Of ICF VS Concrete Block

The robustness and versatility of ICF construction offer limitless design possibilities, adapting to accommodate various sizes, styles, and types of homes or buildings. ICF can be readily tailored to fit custom designs, including curved walls, unique angles, expansive openings, extended ceiling spans, and cathedral ceilings.

Conversely, builders encounter challenges when trying to integrate solid CMU pieces into curved designs. Moreover, ICF structures can achieve any desired exterior finish, catering to a wide range of aesthetic preferences, while CMU buildings typically retain the distinctive look of concrete blocks.

Conclusion

In summary, the comparison between Insulated Concrete Forms (ICF) and Concrete Blocks (CMU) underscores significant differences in construction methods and benefits.

The choice between ICF and Concrete Blocks depends on project-specific needs, budget considerations, and desired outcomes. While both methods have their merits, ICF is favored for those prioritizing energy efficiency, resilience, and ease of installation in exterior wall construction.