Welcome to the ultimate guide on ICF Block R Value. In this detailed article, we’ll delve deep into the world of Insulated Concrete Form (ICF) blocks, exploring their thermal insulation properties and understanding how they contribute to energy-efficient and sustainable construction practices.

Whether you’re a homeowner, builder, or industry professional, this guide aims to provide you with valuable insights into maximizing the energy performance of your building projects using ICF blocks.

What are ICF Blocks?

ICF blocks, short for Insulated Concrete Form blocks, are innovative building materials designed to enhance the energy efficiency and structural integrity of residential and commercial buildings.

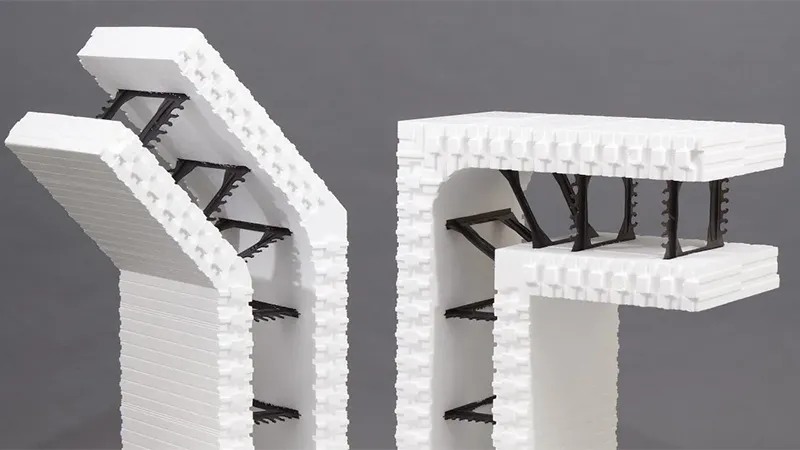

These blocks consist of two layers of expanded polystyrene (EPS) foam connected by webs or ties, forming hollow cores into which concrete is poured. The resulting walls provide exceptional thermal resistance, strength, and durability.

ICF block construction, or Insulated Concrete Form construction, is a modern building technique that combines the strength and durability of concrete with the superior insulation properties of expanded polystyrene (EPS) foam. Here’s a more detailed explanation:

Anatomy of an ICF Block:

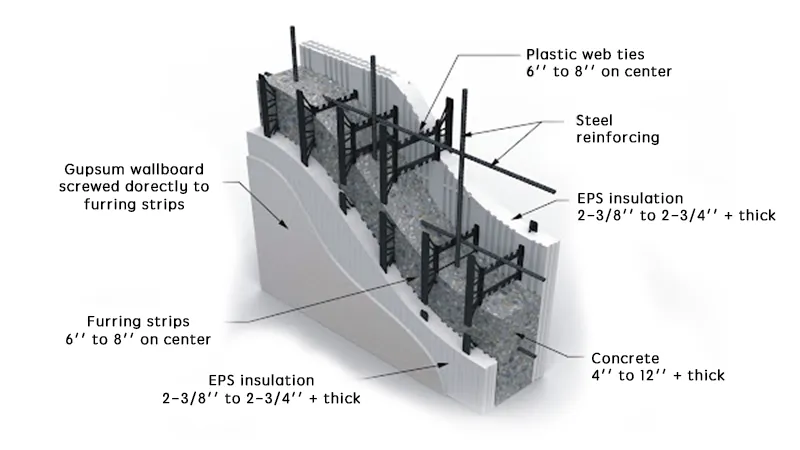

ICF blocks typically consist of two layers of EPS foam panels connected by plastic or metal ties or webs. These panels are molded to have hollow cores into which concrete is poured during the construction process. The EPS foam serves as both a formwork for the concrete and as insulation for the finished wall.

Components of ICF Blocks:

- EPS Foam Layers: Expanded polystyrene foam is a lightweight, rigid, and durable material known for its excellent thermal insulation properties. The foam panels are available in different thicknesses and densities to suit various building requirements.

- Tie or Web System: The ties or webs are structural components that hold the two layers of EPS foam together and provide stability during concrete placement. They also ensure proper alignment and spacing between the foam panels.

- Concrete Core: Once the EPS foam panels are assembled, concrete is poured into the cavities created by the hollow cores. The concrete fills the entire space within the ICF block, forming a solid and robust wall structure.

ICF Block Construction Process:

- Preparation: The site is prepared, and the foundation is laid according to the building plans.

- Placement of ICF Blocks: The ICF blocks are stacked and interlocked to form the walls of the building. The blocks are typically dry-stacked without the need for mortar, making the construction process faster and more efficient.

- Reinforcement: Steel reinforcement bars (rebar) are inserted vertically and horizontally within the ICF walls to enhance structural strength and integrity.

- Concrete Pouring: Once the ICF walls are in place and the reinforcement is installed, concrete is poured into the cavities of the blocks using a pump or chute.

- Curing: After the concrete has been poured, it is left to cure and harden, forming a solid wall structure.

- Finishing: Once the concrete has cured, interior and exterior finishes, such as drywall, siding, or stucco, can be applied to complete the construction process.

Benefits of ICF Block Construction

ICF block construction offers a multitude of benefits, making it a popular choice for builders and homeowners alike.

Here are some of the key advantages:

Superior Insulation: One of the primary benefits of ICF block construction is its exceptional thermal insulation properties. The combination of expanded polystyrene (EPS) foam and concrete creates a continuous barrier against heat transfer, significantly reducing energy consumption for heating and cooling.

Energy Efficiency: By minimizing thermal bridging and air leakage, ICF walls contribute to significant energy savings over the lifespan of a building. This not only reduces utility bills but also lowers carbon emissions, making ICF construction an environmentally sustainable choice.

Structural Strength: ICF walls are inherently strong and durable, providing robust structural support for buildings. The reinforced concrete core offers resistance to various environmental factors such as wind, earthquakes, and fire, enhancing the overall safety and longevity of the structure.

Soundproofing: The dense mass of concrete and the insulation properties of EPS foam combine to create excellent sound insulation. ICF walls effectively dampen noise transmission, resulting in quieter indoor environments and enhanced occupant comfort.

Moisture Resistance: ICF blocks are resistant to moisture infiltration, preventing issues such as mold, mildew, and rot. This helps maintain indoor air quality and prolongs the lifespan of the building materials, reducing maintenance costs over time.

Speed of Construction: ICF block construction is often faster than traditional building methods. The interlocking blocks can be quickly assembled, and the concrete can be poured in a single step, reducing labor and construction time.

Design Flexibility: ICF blocks can be easily cut or shaped to accommodate various architectural designs and building configurations. From curved walls to intricate shapes, ICF construction allows for creative freedom while maintaining energy efficiency and structural integrity.

Environmentally Friendly: ICF construction minimizes construction waste and reduces the use of energy-intensive materials such as wood and steel. Additionally, the energy-efficient nature of ICF buildings helps lower overall energy consumption and greenhouse gas emissions, contributing to a more sustainable built environment.

Factors Affecting ICF Block R Value

Several factors influence the R-value of Insulated Concrete Form (ICF) blocks, determining their effectiveness in providing thermal insulation. Understanding these factors is crucial for optimizing the energy efficiency of buildings constructed using ICF blocks.

Here are the key factors affecting ICF block R-value:

- Material Composition: The type and density of the expanded polystyrene (EPS) foam used in ICF blocks significantly impact their R-value. Higher-density EPS foam typically offers better insulation properties compared to lower-density foam. The thermal conductivity of the EPS foam also plays a critical role in determining the overall thermal resistance of the ICF blocks.

- Wall Thickness: The thickness of the ICF walls directly affects their insulation performance. Thicker walls generally provide higher R-values due to increased insulation material and a greater barrier against heat transfer. Builders can choose between single-layer and double-layer ICF walls, with double-layer walls offering enhanced insulation but requiring additional materials and construction time.

- Installation Quality: The quality of installation greatly influences the thermal performance of ICF walls. Proper installation techniques, including ensuring tight seals and insulation continuity, are essential for maximizing the R-value of ICF blocks. Common installation mistakes, such as gaps or voids in the insulation layer, can compromise the effectiveness of the thermal barrier and lead to energy loss.

ICF Block Material Composition

The material composition of Insulated Concrete Form (ICF) blocks primarily consists of two key components: expanded polystyrene (EPS) foam and concrete. Let’s delve into each of these materials:

Expanded Polystyrene (EPS) Foam:

EPS foam serves as the insulation core of ICF blocks and is renowned for its exceptional thermal insulation properties. It is a lightweight, rigid, and durable material derived from polystyrene beads that have been expanded and molded into foam panels. The EPS foam used in ICF blocks is available in various densities and thicknesses to suit different construction needs.

High-Density EPS Foam:

High-density EPS foam offers greater thermal resistance and insulation performance compared to low-density foam. It consists of tightly packed polystyrene beads, resulting in a denser and more robust material with higher R-values.

Thermal Conductivity:

The thermal conductivity of EPS foam, measured in units of watts per meter-kelvin (W/mK), determines its ability to resist heat flow. Lower thermal conductivity values indicate better insulation properties, as they indicate slower heat transfer through the material.

Concrete Core:

The concrete core of ICF blocks provides structural strength, stability, and durability to the building walls. It is formed by pouring concrete into the cavities created by the EPS foam panels during the construction process. Once cured, the concrete solidifies, forming a solid and robust wall structure that can withstand various environmental conditions.

Reinforcement:

Steel reinforcement bars (rebar) are often inserted vertically and horizontally within the concrete core to enhance structural integrity and resistance to forces such as wind, earthquakes, and impacts.

By combining EPS foam insulation with a concrete core, ICF blocks offer a unique and highly effective building material that provides both thermal insulation and structural support. This composition results in energy-efficient buildings with superior comfort, durability, and resilience.

Calculating the R Value of ICF Blocks

Calculating the R-value of Insulated Concrete Form (ICF) blocks involves understanding the thermal properties of the materials used and applying specific formulas.

Here’s a step-by-step guide to calculating the R-value of ICF walls:

Identify Material Specifications: Gather information about the materials used in the construction of the ICF blocks, including the type and density of the expanded polystyrene (EPS) foam, the thickness of the concrete core, and any additional insulation layers.

Conduct Thermal Conductivity Tests: Measure the thermal conductivity of the EPS foam and other insulation materials used in the ICF blocks. Thermal conductivity, often denoted by the symbol “λ” (lambda), represents the rate at which heat flows through a material. Lower thermal conductivity values indicate better insulation properties.

Apply Formulae for R-value Calculation: Once you have gathered the necessary information, you can use the following formula to calculate the R-value of the ICF walls:R-value = Thickness / Thermal Conductivity

- Thickness: Measure the total thickness of the insulation layer, including the EPS foam and any additional insulation materials.

- Thermal Conductivity: Use the thermal conductivity values obtained from the material specifications to represent the insulating properties of the materials.

Understanding U-Value: In addition to R-value, it’s essential to consider the U-value (or U-factor) of the ICF walls. The U-value represents the overall rate of heat transfer through a structure and takes into account factors such as conduction, convection, and radiation. Lower U-values indicate better thermal performance.

Relationship Between R-value and U-value: The relationship between R-value and U-value is inverse; as R-value increases, U-value decreases, indicating improved insulation and energy efficiency.

Importance of U-value in Building Codes: Many building codes and energy efficiency standards specify maximum allowable U-values for different building components, including walls, roofs, and windows.

By calculating and understanding the R-value and U-value of ICF walls, builders and designers can make informed decisions to optimize the energy efficiency and thermal performance of their buildings.

R Value Calculation Methodology

Calculating the R-value of Insulated Concrete Form (ICF) walls involves a systematic methodology to ensure accurate results.

Here’s a step-by-step guide to the R-value calculation process:

Identify Material Specifications:

Begin by gathering detailed information about the materials used in the construction of the ICF walls. This includes the type and density of the expanded polystyrene (EPS) foam, the thickness of the concrete core, and any additional insulation layers or coatings applied to the walls.

Determine Thermal Conductivity:

Thermal conductivity (λ) is a critical parameter that quantifies the rate of heat transfer through a material. For each component of the ICF wall (such as EPS foam, concrete, and additional insulation layers), determine the thermal conductivity value. This information is typically provided by the manufacturer or can be obtained through material testing.

Calculate Resistance for Each Layer:

The R-value of each layer of the ICF wall is calculated using the formula:R-value = Thickness / Thermal Conductivity

- Thickness: Measure the thickness of each insulation layer, including the EPS foam, additional insulation materials, and concrete.Thermal Conductivity: Use the thermal conductivity values determined in step 2.

Summation of Resistances: Once you have calculated the resistance for each layer, sum up the individual resistances to obtain the total R-value of the ICF wall. This total R-value represents the overall thermal resistance of the entire wall assembly.

Understanding U-Value: While R-value quantifies the resistance to heat flow, U-value (or U-factor) represents the overall rate of heat transfer through a structure. The relationship between R-value and U-value is inverse; as R-value increases, U-value decreases, indicating improved insulation performance.

Calculation of U-Value: The U-value of the ICF wall can be calculated by taking the reciprocal of the total R-value:U-value = 1 / R-value

Interpretation: Lower U-values indicate better thermal insulation and energy efficiency.

By following this methodology and considering both R-value and U-value, builders and designers can accurately assess the thermal performance of ICF walls and make informed decisions to optimize energy efficiency in building design and construction.

Enhancing ICF Block R Value

Enhancing the R-value of Insulated Concrete Form (ICF) blocks is essential for maximizing their thermal insulation properties and improving energy efficiency in buildings.

Here are several strategies to enhance the R-value of ICF blocks:

Supplementary Insulation Techniques:

Adding supplementary insulation techniques can further increase the thermal resistance of ICF walls. These techniques include:

Exterior Insulation Finishing System (EIFS):

EIFS involves applying a continuous layer of insulation, typically expanded polystyrene (EPS) foam, to the exterior surface of the ICF walls. This additional layer of insulation improves the overall thermal performance of the building envelope.

Interior Insulation Options:

Interior insulation materials, such as rigid foam boards or spray foam insulation, can be installed on the inner surface of the ICF walls to enhance their R-value. This approach is particularly useful in retrofitting existing buildings or achieving higher insulation levels in colder climates.

Thermal Bridging Mitigation:

Thermal bridging occurs when heat bypasses the insulation layer through structural elements, such as metal ties or studs, reducing the overall effectiveness of the insulation. Mitigating thermal bridging can help improve the R-value of ICF walls. Strategies to minimize thermal bridging include:

Utilizing Thermal Breaks:

Installing thermal breaks, such as insulating sheathing or foam gaskets, between structural elements and the ICF walls can interrupt the flow of heat and enhance insulation performance.

Proper Placement of Structural Elements:

Careful planning and design consideration for the placement of structural elements, such as window and door openings, can minimize thermal bridging and optimize the thermal performance of the ICF walls.

Optimizing Wall Thickness:

Increasing the thickness of ICF walls can enhance their R-value by providing additional insulation material and reducing thermal bridging. Builders can choose between single-layer and double-layer ICF walls, with double-layer walls offering higher insulation levels and improved thermal performance. However, it’s essential to balance the benefits of increased insulation with cost and construction considerations.

Utilizing High-Density EPS Foam:

Choosing high-density EPS foam for ICF block construction can improve the R-value of the walls. High-density EPS foam has smaller, more tightly packed beads, resulting in better thermal insulation properties compared to lower-density foam. This upgrade in insulation material can contribute to enhanced energy efficiency and comfort in buildings.

ICF Block R Value in Sustainable Construction

In sustainable construction, the R-value of Insulated Concrete Form (ICF) blocks plays a crucial role in enhancing energy efficiency and reducing environmental impact.

Here’s how ICF block R-value contributes to sustainable construction practices:

Energy Savings Potential:

ICF blocks provide superior thermal insulation, resulting in reduced heating and cooling loads for buildings. By minimizing heat transfer through walls, ICF construction helps lower energy consumption and utility costs. This energy savings potential not only benefits building owners but also reduces reliance on fossil fuels and decreases greenhouse gas emissions associated with energy production.

Economic and Environmental Benefits:

The energy-efficient properties of ICF blocks translate into economic savings over the lifespan of a building. Lower energy bills and reduced maintenance costs contribute to long-term affordability and financial viability. Additionally, by reducing energy consumption and carbon emissions, ICF construction supports environmental conservation efforts, mitigates climate change impacts, and fosters sustainable development practices.

LEED Certification and ICF Blocks:

Leadership in Energy and Environmental Design (LEED) certification is a widely recognized green building rating system that rewards environmentally responsible construction practices. ICF construction can contribute to earning LEED credits in categories such as Energy and Atmosphere and Indoor Environmental Quality. Meeting LEED criteria for energy efficiency demonstrates a commitment to sustainability and may qualify buildings for tax incentives, rebates, and other financial incentives.

Indoor Environmental Quality:

In addition to energy efficiency, ICF construction enhances indoor environmental quality by minimizing air infiltration and maintaining consistent indoor temperatures. The airtight construction of ICF walls reduces drafts, allergens, and pollutants, creating healthier and more comfortable living and working environments for occupants. Improved indoor air quality contributes to occupant health and well-being, aligning with sustainable building principles.

Lifecycle Assessment:

Sustainable construction practices consider the entire lifecycle of a building, from materials sourcing and construction to operation and eventual demolition or renovation. ICF blocks, with their durable construction and long lifespan, offer sustainable solutions that withstand the test of time. Their high R-value and energy-saving benefits contribute to overall lifecycle efficiency, reducing resource consumption and waste generation over the building’s lifetime.

FAQs

Are ICF blocks suitable for both residential and commercial construction projects?

Yes, ICF blocks are versatile and can be used in various types of buildings, including single-family homes, multi-story residences, commercial structures, and institutional facilities.

How do I maintain the structural integrity of ICF walls during construction?

Proper bracing and alignment during concrete placement, as well as adherence to manufacturer’s guidelines, are essential for ensuring the structural integrity of ICF walls.

Can ICF blocks be customized to accommodate specific architectural designs?

Yes, ICF blocks can be easily cut or shaped to meet specific design requirements, allowing for the creation of curved or angled walls with ease.

Are there any limitations to the use of ICF blocks in regions with extreme climates?

While ICF blocks perform well in most climates, additional insulation or design considerations may be necessary in areas with extremely high or low temperatures to optimize energy efficiency.

How do I choose the right type of ICF block for my project?

Factors such as desired R value, building code requirements, budget constraints, and project specifications should be considered when selecting the appropriate type of ICF block for a construction project.

Can ICF blocks contribute to improved indoor air quality?

Yes, ICF construction minimizes the infiltration of outdoor pollutants and allergens, resulting in healthier indoor environments for occupants.

Conclusion

In conclusion, understanding the significance of ICF Block R Value is crucial for achieving optimal energy efficiency and sustainability in construction projects. By harnessing the exceptional insulation properties of ICF blocks, builders and homeowners can create comfortable, environmentally responsible buildings that stand the test of time.

Whether you’re aiming to reduce energy costs, minimize carbon emissions, or enhance occupant comfort, incorporating ICF blocks into your construction plans can yield significant benefits for both the present and the future.