The demand for rapid and precise EPS patterns is crucial in modern casting. We offer solutions for achieving exceptional surface finishes and tight tolerances on large or complex foam molds. Our high-speed milling capabilities ensure swift production cycles and reduced lead times. We provide the technology to keep your manufacturing process efficient and competitive.

The efficiency of our foam milling process is key to maximizing yield and minimizing material waste. We supply sophisticated CNC machinery designed specifically for optimal EPS cutting performance. This focus on specialized equipment allows us to maintain superior pattern integrity. We guarantee reliable and streamlined pattern processing, meeting the industry’s toughest standards.

What is Foam Milling?

Foam milling is a precision CNC (Computer Numerical Control) machining process. It uses a rotating cutting tool to mechanically remove material from a block of cellular foam, like EPS or polyurethane.

We employ this technique to create complex 3D shapes, detailed prototypes, and accurate molds. It is favored for its ability to produce highly precise parts with excellent surface finishes quickly and efficiently.

EPS Foam Cutting Methods

Expanded Polystyrene (EPS) foam is widely used for insulation, packaging, and custom mold creation, requiring specific cutting methods to ensure clean edges and dimensional accuracy. We employ both manual tools for simple cuts and advanced machinery for complex patterns and mass production. Selecting the right technique is essential for achieving the best results and high efficiency in your foam-based projects.

Choosing an appropriate EPS foam cutting method depends largely on the required shape complexity, volume, and budget constraints. Our cutting processes are optimized to minimize waste and ensure the material integrity of the EPS foam. This provides a reliable foundation for any subsequent manufacturing or construction application.

- Hot Wire Cutting: We offer specialized hot wire cutters that use an electrically heated wire to melt through the EPS foam. This thermal cutting method produces an incredibly smooth, sealed edge with virtually no foam dust or debris. We utilize advanced CNC hot wire machines for precise, repeatable cuts suitable for intricate 2D shapes, custom architectural elements, and large-volume sign making.

- CNC Milling (Routing): We provide CNC milling solutions where a rotating cutting tool, guided by computer control, mechanically removes foam material. This method is essential for creating complex 3D shapes and detailed molds that require high-precision surface finishes and tight tolerances. We guarantee unmatched consistency and can handle projects with the most elaborate design requirements.

- Manual/Blade Cutting: For straight lines, scoring, and simple projects, we use sharp utility knives and foam cutting saws. A fresh, sharp blade is crucial to avoid snagging or crushing the foam cells, which can compromise the cut quality. We recommend this for small-scale, simple cuts where speed and intricate geometry are not the primary concern.

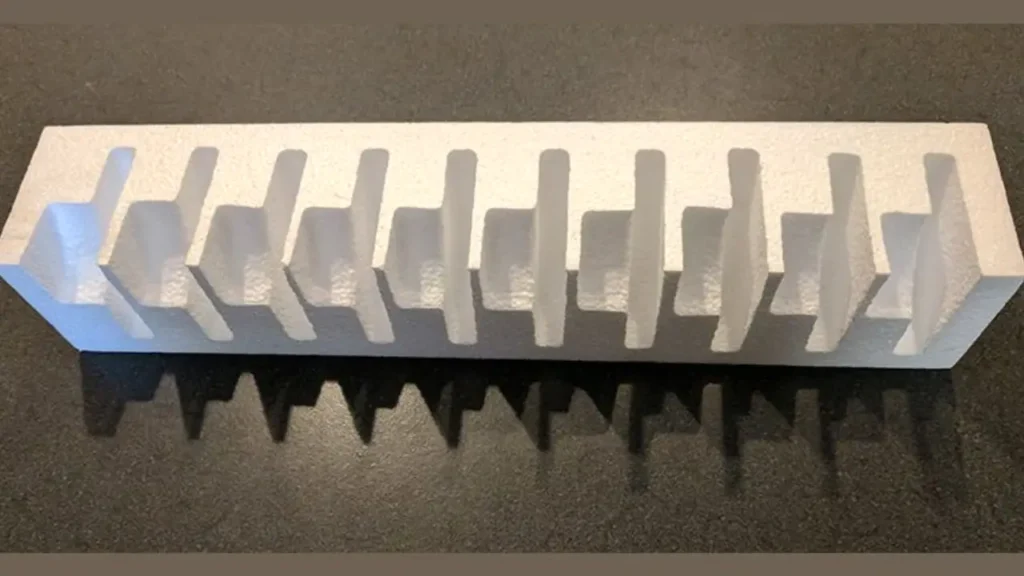

EPS Foam Milling Machine

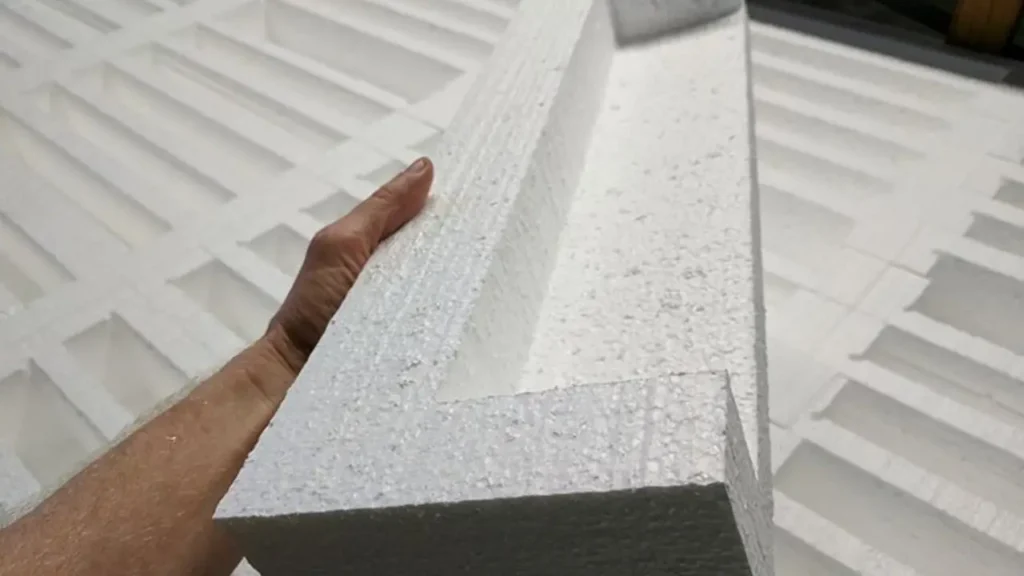

For the precise and efficient production of large or complex foam patterns, the EPS foam milling machine is indispensable. We offer specialized CNC routers that are engineered specifically for cutting Expanded Polystyrene . These machines utilize multi-axis movement and high-speed spindles to carve detailed three-dimensional geometries. We provide the reliable equipment necessary to achieve superior surface quality and accurate dimensions for your molds and prototypes.

We supply a range of EPS foam milling machines tailored to different production scales, from rapid prototyping to high-volume manufacturing. Our machinery is optimized for maximizing material yield and ensuring clean, dust-free operations. By integrating advanced software and robust mechanics, we guarantee a stable, high-performance solution. We ensure consistent pattern creation for the lost foam casting industry.

- Multi-Axis Capability: We provide machines featuring 3, 4, or 5-axis movement capabilities, allowing for the creation of extremely complex, undercut geometries in a single setup. This reduces the need for manual repositioning and eliminates potential errors, which significantly increases both the speed and accuracy of your pattern production. We guarantee enhanced design freedom for your intricate projects.

- Large Work Envelope: We manufacture milling machines with expansive work areas, accommodating oversized EPS blocks and enabling the production of very large foam patterns or multiple smaller patterns simultaneously. This maximum material usage and increased batch capacity improve your overall throughput. We offer solutions that scale directly with your largest project requirements.

- High-Speed Spindle and Tooling: We supply machines equipped with powerful, high-speed spindles optimized for cutting low-density EPS foam without tearing or melting the material. We provide a variety of specialized long-reach tooling designed for deep-carving and complex shapes. This combination ensures faster material removal rates while maintaining a smooth and accurate finish on the foam surface.

How to Use a Foam Milling Machine?

The process of effectively using an EPS foam milling machine requires careful preparation and precise execution to ensure the final foam pattern meets all specifications. We provide a structured approach to help operators master the workflow, from initial design file preparation to the final machining and cleanup. Following these key steps guarantees optimal material utilization and accurate patterns every time.

We ensure that our training emphasizes both safety protocols and operational efficiency. Understanding the machine’s capabilities and limitations is crucial for preventing errors and maximizing machine lifespan. We want our operators to confidently manage material clamping, tool changes, and routine maintenance, leading to consistent, reliable results in your production environment.

Tools Needed

- CNC Foam Milling Machine

- Specialized Foam Milling Bits/Cutters

- CAD/CAM Software

- EPS Foam Block

- Vacuum System (Dust Collection)

- Clamping Fixtures or Vices

Step 1: Prepare the Design and Toolpath

The first step is taking the client’s 3D model and translating it into a language the machine understands using CAM (Computer-Aided Manufacturing) software. We accurately define the cutting strategy, selecting the appropriate tools and setting parameters like feed rate and spindle speed. This toolpath generation is critical, as it dictates the exact motion the cutter will take to carve the pattern.

Once the toolpaths are calculated, we perform a simulation within the software to check for any potential collisions, errors, or unnecessary air cuts. This simulation step is a vital safety and efficiency check that saves time and material. We then export the final, optimized machine instructions, often called G-code, which is ready to be loaded onto the CNC controller.

Step 2: Set Up the Material and Machine

Before machining, we firmly secure the EPS foam block onto the milling bed using vices or a vacuum table to prevent any movement or vibration during cutting. Proper fixturing is essential to maintaining dimensional accuracy and ensuring the safety of the operation. We also confirm the accurate zero-point (origin) for all three axes on the machine.

We then proceed to install the selected cutting tools into the machine’s spindle or tool changer, precisely measuring and registering their lengths into the control system. We perform a final check of all settings, making sure the dust collection system is active and the machine’s environment is clear. This meticulous setup ensures a smooth and uninterrupted milling cycle.

Step 3: Execute the Milling Process

With the G-code loaded and the material secured, we initiate the program, observing the machine’s initial movements closely to confirm correct execution. The machine will then proceed to automatically execute the series of cutting operations, removing material layer by layer to reveal the final pattern. We monitor the machine throughout the process, listening for any unusual sounds or tool vibration.

After the entire program has finished and the spindle has stopped, we carefully remove the newly milled pattern from the work area. We then inspect the part to verify that the surface finish and dimensional tolerances match the original design specifications. We ensure the work area and machine are cleaned of any remaining foam debris, preparing it for the next job.

Conclusion

We’ve explored how advanced CNC technology is transforming EPS pattern creation. The integration of high-speed milling ensures patterns are not only produced quickly but also possess the dimensional accuracy needed for flawless casting results. We are committed to supplying the innovative tools that drive your production forward. We provide the means to achieve consistent quality and operational excellence.

For businesses looking to scale up or introduce more complex designs, investing in a dedicated CNC EPS machine is a strategic move. This equipment is essential for maintaining a competitive advantage through rapid iteration and consistent output. We offer machinery designed for heavy-duty use and long-term reliability. We supply the foundation for your future growth and manufacturing success.

To capitalize on these benefits, we encourage you to get wholesale CNC EPS machine solutions from our epsole. We offer a selection of machinery built for precision, speed, and durability. Our commitment is to provide cost-effective and dependable equipment, backed by our expertise. We supply the best value and technology to enhance your EPS pattern processing capabilities.

-300x300.webp)