Foam injection molding plays an important role in modern industrial manufacturing, especially for lightweight and protective components. Among the available materials, EPP and EPS injection stand out for their efficiency, cost control, and adaptability across automotive, packaging, construction, and equipment protection applications.

Although both EPP and EPS rely on foam injection processes, their performance and use cases differ significantly. Understanding their material structures, molding behavior, and functional advantages helps manufacturers choose the right solution for durability, insulation, impact resistance, and long-term production efficiency.

What is Foam Injection?

Foam injection is a manufacturing process used to produce lightweight, molded parts by injecting pre-expanded foam beads into a closed mold. Under heat and pressure, the beads fuse into a solid shape.

This method is widely used with EPP and EPS to create durable, insulated, and impact-resistant industrial components.

- Cost-Effective Production – With efficient molding cycles and minimal material waste, foam injection supports economical mass production. Reusable molds and stable foam materials help manufacturers control costs while maintaining consistent quality across large production volumes.

- Lightweight Structure – Foam injection produces parts with low density and reduced weight without sacrificing strength. This helps lower transportation costs, improves handling efficiency, and supports lightweight design requirements in automotive, packaging, and industrial applications where weight reduction is critical.

- Excellent Impact Absorption – The cellular structure of foam materials absorbs shock and vibration effectively. Foam injection parts protect sensitive products and components during transport or operation, reducing damage risks and extending product lifespan in demanding industrial environments.

- Thermal and Acoustic Insulation – Foam injection creates parts with stable insulating properties. EPS and EPP help control temperature transfer and reduce noise, making the process ideal for insulation panels, protective housings, and equipment requiring thermal or sound management.

- Design Flexibility – Foam injection allows complex shapes, integrated features, and consistent wall thickness. Manufacturers can customize molds to meet specific functional needs, reduce secondary processing, and achieve precise dimensions for industrial and technical applications.

Why Foam Injection?

Foam injection is widely chosen by EPS manufacturers because it delivers lightweight, durable, and cost-efficient components for many industries. By molding foam materials such as EPS and EPP under controlled heat and pressure, this process creates parts with reliable structure, consistent quality, and excellent functional performance for packaging, automotive, insulation, and industrial uses.

Cost-Effective Production – Efficient molding cycles and minimal material waste support economical large-scale manufacturing. Foam injection helps manufacturers maintain stable quality, reduce overall production costs, and achieve consistent output across high-volume production runs.

Lightweight Performance – Foam injection significantly reduces part weight while maintaining structural strength. This helps lower transportation costs, improves handling efficiency, and supports lightweight design goals in industries where reduced mass directly improves overall system performance.

Superior Impact Protection – The cellular structure of foam absorbs shocks and vibrations effectively. Foam injection parts protect products and components during handling and operation, reducing damage, minimizing replacement costs, and improving safety in demanding environments.

Design Flexibility – Foam injection allows complex shapes, integrated features, and uniform wall thickness. Custom molds make it possible to meet specific functional requirements, reduce secondary processing, and achieve precise, repeatable dimensions.

Thermal and Acoustic Insulation – Foam injection materials provide effective insulation against heat and noise. This makes them suitable for insulation panels, protective housings, and industrial applications where temperature control and sound reduction are important.

EPS Foam Injection Molding

EPS foam injection molding is a specialized manufacturing process used to create lightweight, rigid foam parts with consistent structure and insulation performance. By injecting pre-expanded polystyrene beads into a sealed mold and applying heat, the beads fuse into precise shapes. This process is widely used in packaging, construction, appliances, and industrial insulation applications where efficiency and dimensional stability are essential.

- Recyclable and Resource-Efficient – EPS foam is recyclable and uses minimal raw material to achieve volume. Foam injection molding reduces waste and supports sustainable production practices, making EPS a practical option for manufacturers aiming to balance performance, cost control, and environmental responsibility.

- Outstanding Thermal Insulation – EPS foam injection molding produces closed-cell structures that effectively reduce heat transfer. This makes EPS parts ideal for insulation panels, cold-chain packaging, and building materials, helping maintain stable temperatures while improving overall energy efficiency in industrial and commercial applications.

- Lightweight and Rigid Structure – EPS components offer an excellent balance between low weight and structural rigidity. The molded parts are easy to handle, transport, and install, reducing labor effort while maintaining shape integrity and load-bearing capability in packaging, construction, and protective applications.

- Cost-Efficient Mass Production – EPS foam injection molding supports high-volume manufacturing with consistent results. The process uses economical raw materials, short molding cycles, and reusable molds, allowing manufacturers to reduce unit costs while maintaining reliable output quality across large production runs.

- Precise Shape and Dimensional Stability – The controlled molding environment ensures accurate dimensions and uniform density throughout the part. EPS foam injection molding minimizes deformation and shrinkage, enabling tight tolerances and reliable fit for technical components and custom industrial designs.

EPP Foam Injection Molding

EPP foam injection molding is a specialized manufacturing process used to create lightweight, resilient foam parts by injecting expanded polypropylene beads into a closed mold. Through controlled heat and pressure, the beads fuse into a durable structure. This process is widely used in automotive, electronics, packaging, and industrial applications where impact resistance, reusability, and dimensional stability are essential.

- Reusable and Sustainable Solution – EPP foam parts are durable and reusable, supporting multiple use cycles without performance loss. The material is recyclable, helping reduce waste and supporting sustainability goals while maintaining reliable protection and functionality in industrial and packaging applications.

- Outstanding Impact Resistance – EPP foam injection molding produces parts that absorb energy and recover their shape after impact. This makes them ideal for protective components, reducing damage during transport or use. The material’s resilience helps extend product life and improves safety in demanding industrial environments.

- Lightweight Yet Strong Design – EPP parts combine low weight with high mechanical strength. This balance supports efficient handling, lowers transportation costs, and contributes to overall system weight reduction. Industries such as automotive benefit from improved fuel efficiency and easier assembly through lightweight EPP components.

- Thermal and Chemical Stability – EPP foam offers stable performance across a wide temperature range and resists many chemicals. Injection-molded EPP parts maintain shape and function under harsh conditions, making them suitable for long-term industrial use, including automotive battery protection and technical equipment housings.

- Design Flexibility and Precision – EPP foam injection molding supports complex geometries, integrated features, and consistent wall thickness. Custom molds allow precise shaping, reduce the need for secondary processing, and ensure repeatable quality for large-scale production of tailored industrial components.

Foam Injection Molding Machine

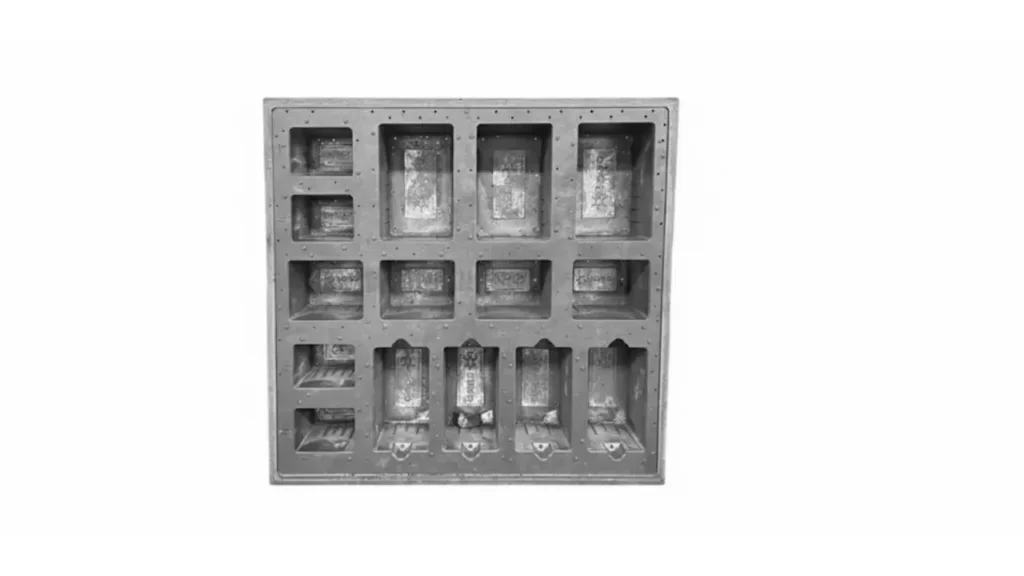

A foam injection molding machine is used to produce lightweight foam parts by shaping expanded beads or foam materials under heat and pressure. It supports stable, repeatable production for EPP and EPS components in packaging, automotive, insulation, and industrial applications.

Different machine types are designed to match material characteristics, output volume, and part complexity.

- Custom Foam Injection Molding Machine – Custom-built EPP foam injection molding machines are tailored to specific product designs, mold sizes, and output requirements. They support special foam materials, unique part geometries, and specialized industrial applications. Custom solutions help manufacturers optimize space, energy use, and overall production efficiency.

- EPP Foam Injection Molding Machine – This foam injection molding machine is designed specifically for expanded polypropylene processing. It provides precise temperature and pressure control to ensure bead fusion and resilience. EPP machines support complex shapes, consistent density, and high-cycle production for automotive, battery protection, and reusable packaging parts.

- EPS Foam Injection Molding Machine – EPS foam injection molding machines are optimized for expanded polystyrene beads and insulation-focused products. They offer efficient steam heating, uniform bead expansion, and accurate molding. These machines are widely used for thermal insulation panels, packaging inserts, and construction components requiring lightweight structure.

- Automatic Foam Injection Molding Machine – Fully automatic foam injection molding machines integrate feeding, molding, cooling, and demolding functions. They reduce labor requirements, improve cycle consistency, and support high-volume production. Automation helps maintain stable quality, increase efficiency, and lower operating costs in large-scale foam molding operations.

- Semi-Automatic Foam Injection Molding Machine – Semi-automatic foam injection molding machines combine manual operation with automated control systems. They are suitable for flexible production environments, smaller batch sizes, and custom foam parts. This type offers cost control, easier operation, and adaptability for manufacturers with changing production needs.

Why Choose Our EPS and EPP Foam?

Choosing the right foam material directly impacts product performance, cost control, and long-term reliability. Our EPS and EPP foam solutions are engineered to meet industrial demands across packaging, automotive, insulation, and protective applications. We focus on stable material quality, consistent molding performance, and practical benefits that support efficient production and dependable end-use results.

- Flexible Customization Options – We support custom densities, shapes, and mold designs. Our EPS and EPP foam can be tailored to specific applications, allowing manufacturers to achieve precise fit, optimized performance, and efficient production workflows.

- Reliable Material Quality – Our EPS and EPP foam deliver consistent density, strength, and structure. This ensures uniform molding results, predictable performance, and reduced defect rates, helping manufacturers maintain stable output and dependable product quality.

- Excellent Protection Performance – Both EPS and EPP provide strong impact absorption and cushioning. EPP offers superior resilience and recovery, while EPS delivers effective shock resistance, protecting products and components during handling, storage, and transportation.

- Lightweight and Cost Efficient – The low density of EPS and EPP reduces material usage and transportation costs. Lightweight parts improve handling efficiency and support economical mass production without compromising functional performance.

- Thermal and Insulation Benefits – EPS excels in thermal insulation, while EPP provides stable thermal performance across a wider temperature range. These properties make our foam suitable for construction, packaging, and industrial applications requiring temperature control.

Conclusion

Choosing between EPP and EPS injection depends on the specific requirements of industrial parts, including strength, resilience, and reuse needs. EPP offers excellent impact recovery and durability, while EPS provides stable insulation and lightweight structure. Evaluating application demands ensures the foam injection process delivers consistent performance and cost efficiency.

From automotive components to protective packaging and industrial insulation, both EPP and EPS injection molding remain essential manufacturing methods. Matching the right foam material with reliable molding equipment improves production accuracy, reduces waste, and supports scalable output for growing industrial demands across global markets.

To achieve stable and efficient foam injection production, dependable molding equipment is critical. You can get wholesale EPP molding machines and EPS molding machines from our Epsole, designed for precision, productivity, and long-term industrial operation. The right machinery helps maximize material performance and supports consistent, high-volume manufacturing results.