EVA and EPP foams are widely used in industries ranging from packaging to sports equipment. While both materials offer lightweight and durable properties, they differ significantly in density, flexibility, and impact resistance. Understanding these differences helps manufacturers, designers, and consumers choose the most suitable foam for specific applications.

EVA foam is known for its softness, cushioning, and easy molding capabilities, making it ideal for footwear, mats, and protective gear. EPP foam, on the other hand, provides higher resilience, energy absorption, and long-term durability, making it suitable for automotive parts, packaging, and robust sports equipment. Choosing the right foam is crucial for performance and cost-efficiency.

What is EVA Foam?

EVA (Ethylene-Vinyl Acetate) foam is a lightweight, flexible, and soft material commonly used in various industries. It offers excellent cushioning, shock absorption, and ease of molding, making it ideal for products requiring comfort, protection, or impact resistance.

EVA foam Applications:

- Toys & Crafts – Lightweight and easy to cut or shape, EVA foam is popular in educational toys, DIY crafts, and creative projects, providing safe and versatile material for children and hobbyists.

- Footwear & Insoles – EVA foam is widely used in shoes and insoles to provide superior cushioning, reduce foot fatigue, and improve overall comfort during daily activities and athletic performance.

- Exercise Mats & Yoga Equipment – It is ideal for yoga mats, gym flooring, and exercise pads, offering a soft, non-slip surface that absorbs impact and protects joints during workouts.

- Protective Gear & Packaging – EVA foam is used in helmets, padding, and packaging materials to absorb shocks, protect fragile items, and prevent injuries during transport or recreational activities.

What is EPP Foam?

EPP (Expanded Polypropylene) foam is a lightweight, durable, and highly resilient material widely used across various industries. Its excellent energy absorption, flexibility, and resistance to chemicals and moisture make it ideal for products requiring long-lasting performance and safety.

EPP Foam Applications:

- Medical & Rehabilitation Devices – EPP foam is applied in orthotics, cushions, and therapy tools to provide support, comfort, and shock absorption for patients recovering from injuries or requiring mobility assistance.

- Automotive Components – EPP foam is used in car bumpers, headrests, and door panels to absorb impact energy, reduce damage during collisions, and enhance passenger safety without adding excessive weight.

- Packaging Solutions – It provides protective cushioning for fragile goods, electronics, and appliances during shipping, minimizing breakage and ensuring safe transport with lightweight, reusable, and eco-friendly material.

- Sports & Fitness Equipment – EPP foam is used in helmets, exercise mats, and protective gear, offering durability, shock absorption, and comfort for athletes and fitness enthusiasts during intense physical activities.

- Toys & Model Aircraft – Its lightweight yet resilient properties make EPP foam ideal for toy construction, model planes, and drones, providing durability, flexibility, and safe impact absorption during play or flight.

EVA vs EPP Foam

EVA and EPP foams are both lightweight, versatile, and widely used in various industries. While they may appear similar, their properties, applications, and performance differ significantly. Understanding these differences helps you choose the right material for specific products and needs.

1. Density & Weight

EVA foam is generally softer and less dense, making it lightweight and flexible. It is easy to shape and mold, which is ideal for comfort-focused applications like mats, shoes, and protective gear.

EPP foam, however, has a higher resilience and slightly higher density, allowing it to absorb impact better. Despite being lightweight, it retains its shape and provides long-term durability, suitable for automotive, packaging, and structural applications.

2. Flexibility & Resilience

EVA foam offers excellent flexibility and cushioning, making it ideal for products requiring soft support and comfort. It compresses easily and recovers slowly, providing a gentle feel under pressure.

EPP foam is highly resilient and returns to its original shape quickly after compression. This makes it suitable for high-impact uses where repeated stress or shock absorption is needed without deforming permanently.

3. Impact Absorption

EVA provides moderate impact absorption, sufficient for everyday use in sports mats, shoes, and protective padding. It cushions but may not withstand extreme or repeated high-impact forces over time.

EPP excels in impact absorption, dispersing energy efficiently to protect fragile items, vehicles, or body parts. Its cellular structure maintains performance even after multiple impacts, making it ideal for demanding environments.

4. Durability & Lifespan

EVA foam is durable for standard use but may degrade under harsh conditions such as high heat, UV exposure, or long-term heavy use. It is suitable for products with moderate wear and tear.

EPP foam is extremely durable, resistant to chemicals, moisture, and repeated compression. Its long lifespan makes it perfect for products that require consistent performance, including automotive components, packaging, and long-term fitness equipment.

5. Applications & Usage

EVA foam is commonly used in footwear, yoga mats, protective padding, and light packaging. Its comfort and softness make it ideal for consumer products with moderate stress requirements.

EPP foam is widely used in automotive parts, robust packaging, sports helmets, toys, and medical devices. Its resilience and impact absorption make it suitable for professional-grade and heavy-duty applications.

Here are some differences between EVA and EPP foam in the following:

| Aspect | EVA Foam | EPP Foam |

|---|---|---|

| Density & Weight | Lightweight, soft | Lightweight but resilient |

| Flexibility & Resilience | Highly flexible, compresses slowly | Highly resilient, quick recovery |

| Impact Absorption | Moderate, suitable for everyday use | Excellent, withstands repeated impacts |

| Durability & Lifespan | Moderate, may degrade under harsh conditions | Long-lasting, chemical and moisture-resistant |

| Applications | Footwear, mats, protective padding | Automotive, packaging, helmets, toys |

EVA vs EPE Foam

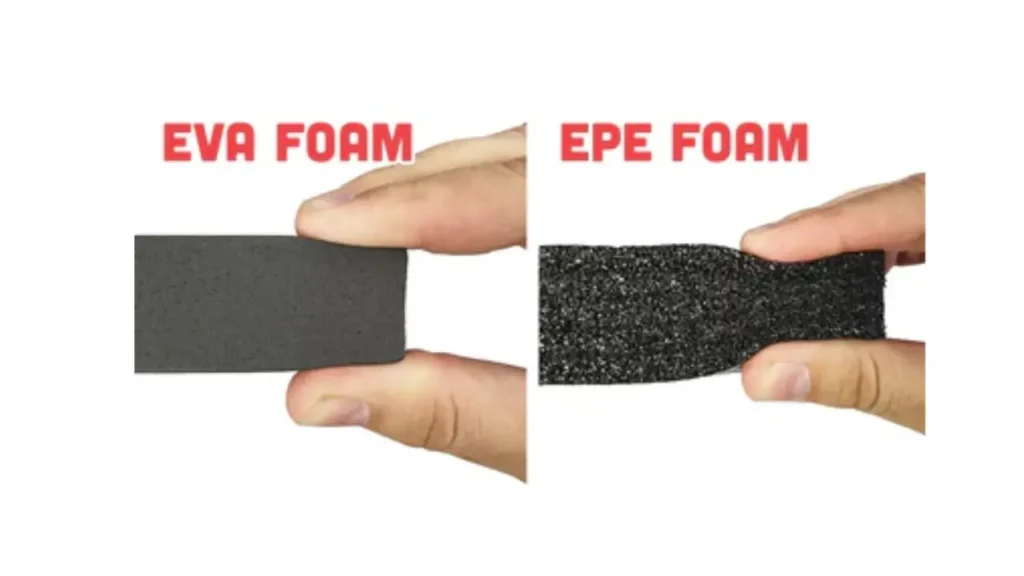

Ethylene-Vinyl Acetate (EVA) and Expanded Polyethylene (EPE) are both closed-cell foams widely used for cushioning and protection, but their performance profiles are distinct. EVA is known for its rubber-like durability and excellent rebound, making it suitable for long-term use and high-impact applications.

EPE, on the other hand, is significantly lighter and more cost-effective, often favored for general packaging and single-use applications. Choosing the right one depends entirely on your project’s specific needs for shock absorption, strength, and longevity.

Key Differences

- Thermal Properties: EPE foam has better thermal insulating properties (lower thermal conductivity) than EVA. This makes EPE a preferable material for simple insulation in construction or thermal blankets. Conversely, EVA maintains its protective qualities across a wider, more consistent temperature range, making it more reliable for shipping to extreme climate zones.

- Density and Texture: EVA foam has a higher density and a smooth, resilient, rubbery feel. This density gives it a more substantial and premium touch. EPE foam, or “pearl cotton,” has a lower density and feels softer, lighter, and more foamy. This difference is immediately noticeable when handled side-by-side.

- Durability and Resilience: EVA foam is significantly more durable with superior tear and tensile strength. Its excellent rebound means it quickly returns to its original shape after compression, making it ideal for repeated impacts and demanding applications like sports equipment or reusable cases. EPE is less resilient and may retain compression marks from heavy or sharp objects over time.

- Cost and Application: EPE foam is generally more affordable and is the material of choice for cost-effective, general-purpose packaging, void filling, and wrapping of lighter, less fragile goods. EVA foam costs more but is justified for high-value, custom-fit protective inserts where precision, long-term integrity, and robust protection against strong impacts are essential.

How to Choose EVA and EPP Foam?

Choosing between EVA and EPP foam depends on the intended application, desired durability, flexibility, and impact absorption. Understanding the material properties ensures optimal performance, cost-efficiency, and user satisfaction. Selecting the right foam enhances product quality, longevity, and effectiveness across industries like fitness, packaging, automotive, and medical devices.

Factors to Consider:

Specific Application Needs – Consider the industry or environment where the foam will be used. EVA suits consumer goods, sports, and fitness, while EPP is ideal for automotive, packaging, protective gear, medical, and technical applications requiring durability and resilience.

Purpose of Use – Determine whether comfort, impact resistance, or durability is the priority. EVA is ideal for soft cushioning and comfort, while EPP excels in high-impact absorption and long-term durability for demanding applications.

Density & Flexibility – Consider the foam’s density and flexibility. EVA offers soft, flexible support suitable for mats or footwear, whereas EPP provides higher resilience, retaining shape under repeated stress and offering superior structural integrity.

Durability Requirements – Assess how long the product needs to last under expected conditions. EVA performs well under moderate use, while EPP withstands harsh environments, repeated impacts, moisture, and chemicals, ensuring longevity for professional or industrial applications.

Production & Cost Efficiency – Evaluate the ease of molding, cutting, and production costs. EVA is easier and cheaper to process for mass-market products, while EPP may involve higher upfront costs but offers long-term value and reduced replacement frequency.

Conclusion

In summary, EVA and EPP foams each bring unique benefits to different applications. EVA is softer and more flexible, ideal for comfort-focused uses, while EPP offers superior resilience and durability for high-impact or structural requirements. Knowing their differences ensures better material selection.

For manufacturers and fitness or sports equipment producers, using the right foam material enhances product quality and customer satisfaction. EPP foam is particularly advantageous when durability, lightweight strength, and energy absorption are priorities. This makes it a preferred choice for demanding applications and professional-grade products.

Get wholesale EPP foam from our Epsole to ensure consistent quality and reliable supply. We provide customized options to meet your production needs, helping you create foam products efficiently, reduce waste, and deliver excellent performance to your customers every time.