When it comes to selecting the right type of foam for various applications, understanding the differences between Expanded Polystyrene (EPS) and Expanded Polypropylene (EPP) is crucial.

Both EPS and EPP foams are widely used in packaging, insulation, and automotive industries due to their lightweight and protective properties. However, they differ significantly in terms of characteristics and applications.

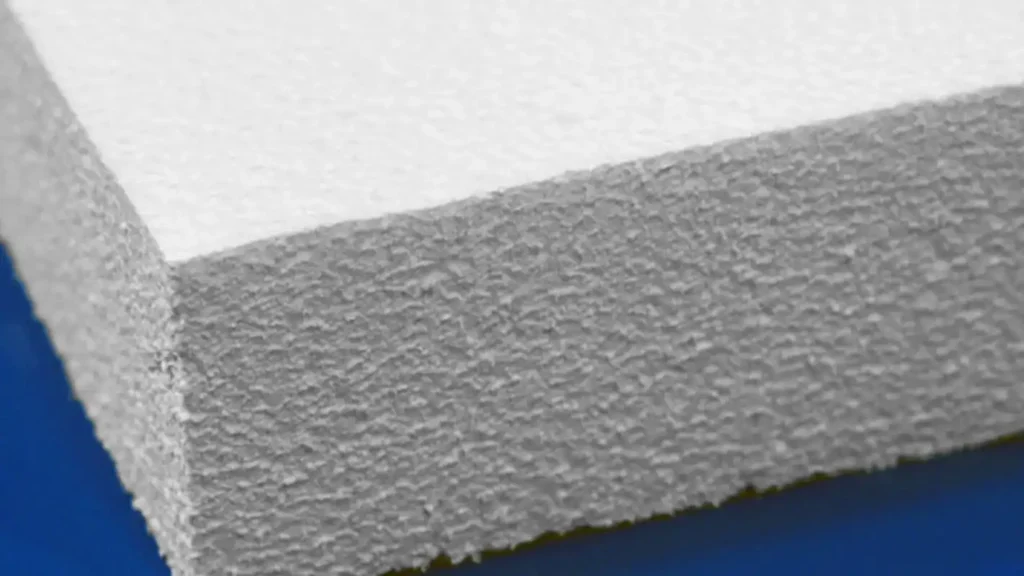

What is EPS Foam?

EPS foam, or Expanded Polystyrene, is a lightweight, rigid, and durable foam commonly used in packaging, insulation, and construction. Made by expanding polystyrene beads with steam, EPS foam offers excellent thermal insulation, shock absorption, and moisture resistance, making it ideal for protecting products and maintaining energy efficiency in various industrial and consumer applications.

- Applications Across Industries: EPS foam is used in packaging, building insulation, automotive parts, and decorative products. Its versatility, low weight, and performance make it a preferred material for industries that need reliable, cost-effective, and easily moldable foam solutions.

- Composition and Structure: EPS foam consists of tiny polystyrene beads fused together to form a rigid, closed-cell structure. This composition provides strength while remaining lightweight, making it easy to handle, cut, and shape for packaging, construction panels, or protective inserts in transportation applications.

- Thermal Insulation Properties: EPS foam has excellent thermal insulation capabilities due to trapped air in its structure. It slows heat transfer, reducing energy consumption in buildings, refrigeration, and shipping applications. Proper use enhances energy efficiency while maintaining consistent internal temperatures.

- Shock Absorption and Protection: The lightweight, resilient structure of EPS foam provides cushioning for fragile items during shipping. Its ability to absorb impacts reduces the risk of damage to electronics, glass, or other sensitive products, making it widely used in protective packaging solutions.

- Moisture and Chemical Resistance: EPS foam resists water absorption and is chemically stable, preventing degradation when exposed to moisture or mild chemicals. This property makes it suitable for insulation, food packaging, and construction applications where durability and longevity are critical.

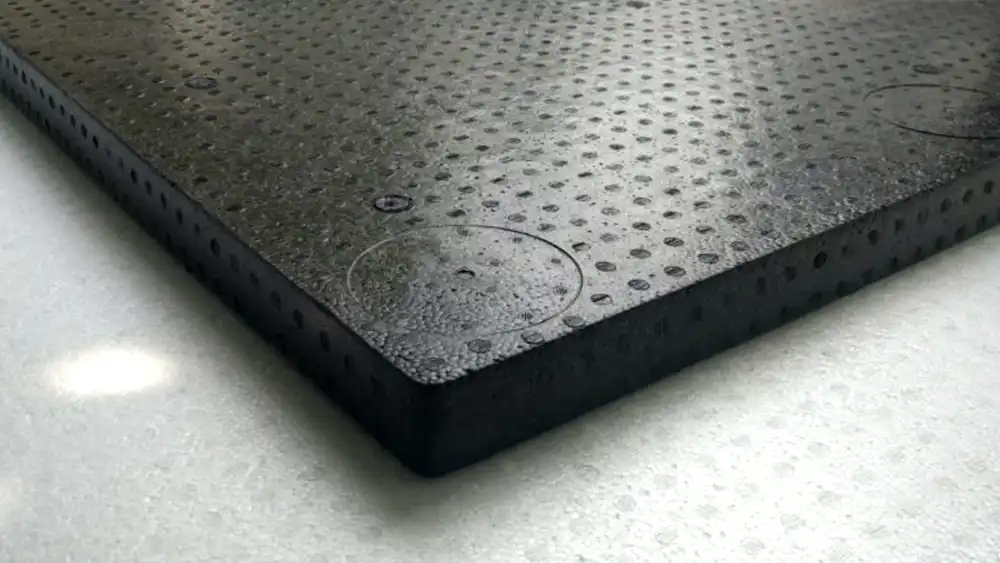

What is EPP Foam?

EPP foam, or Expanded Polypropylene, is a lightweight, flexible, and highly durable foam used in automotive, packaging, and industrial applications. Known for its excellent impact resistance, resilience, and thermal insulation, EPP foam can be molded or cut into complex shapes, making it ideal for protective components, reusable packaging, and energy-absorbing structures in various industries.

- Applications Across Industries: EPP foam is widely used in automotive parts, reusable transport trays, protective packaging, and insulation components. Its versatility, durability, and ability to be molded or cut into custom shapes make it a preferred material for demanding industrial applications.

- Composition and Structure: EPP foam is made by expanding polypropylene beads into a resilient, closed-cell structure. This gives it high elasticity, lightweight characteristics, and durability, allowing it to absorb impacts, maintain shape, and withstand repeated compression without permanent deformation.

- Impact Resistance and Shock Absorption: EPP foam excels at absorbing energy from impacts, making it ideal for automotive crash components, protective packaging, and sports equipment. Its ability to return to its original shape after compression ensures long-lasting protection and performance.

- Thermal and Chemical Resistance: EPP foam offers good thermal insulation and resists moisture and many chemicals. This makes it suitable for temperature-sensitive applications, packaging, and environments where foam must remain stable under exposure to heat, humidity, or mild chemicals.

- Lightweight and Durable: The low density of EPP foam reduces overall weight while maintaining structural integrity. Its combination of lightness, flexibility, and strength allows for easy handling, transport, and use in products that require both cushioning and durability.

EPS vs EPP Foam

EPS and EPP foams are lightweight, durable materials widely used in packaging, automotive, and insulation applications. While both are made from expanded polymer beads, they differ in flexibility, impact resistance, and thermal properties. Understanding these differences helps manufacturers choose the best material for specific applications, balancing cost, performance, and durability.

Material Composition

EPS foam is made from expanded polystyrene beads fused into a rigid, closed-cell structure, giving it lightweight and insulating properties. EPP foam, by contrast, is made from polypropylene beads, forming a more flexible and resilient structure, capable of withstanding repeated compression without losing shape.

The choice of composition affects performance in real-world applications. EPS is ideal for single-use packaging, insulation panels, and low-impact protective components. EPP’s flexibility makes it perfect for automotive energy absorbers, reusable packaging, and industrial components that require repeated impact resistance.

Impact Resistance

EPS foam provides moderate impact absorption but can crack or deform under repeated stress, making it suitable for one-time use packaging or cushioning. EPP foam excels in repeated impact absorption, returning to its original shape even after heavy compression, making it durable for long-term or reusable applications.

For applications where repeated shocks or vibrations occur, EPP is the better choice. EPS is cost-effective and sufficient when occasional impact protection is needed, but it lacks the resilience and longevity of EPP in demanding industrial and automotive environments.

Thermal Insulation

EPS offers excellent thermal insulation due to its rigid, closed-cell structure, making it widely used in building panels, food containers, and cold-chain packaging. Its insulating properties reduce energy consumption and maintain stable temperatures efficiently.

EPP foam also provides thermal resistance but is slightly less insulating than EPS. However, its ability to deform without breaking makes it more suitable in applications requiring both thermal performance and durability, such as automotive insulation panels or reusable food trays.

Flexibility and Reusability

EPS foam is rigid and can easily break under bending or repeated compression, limiting its reusability. Its rigidity is ideal for static applications but not suitable for parts that require repeated handling or reshaping.

EPP foam is highly flexible and elastic, making it ideal for reusable products. It can endure repeated impacts, bending, and compression without permanent deformation. This makes EPP the material of choice for automotive crash components, reusable packaging, and industrial cushioning systems.

Cost and Manufacturing Considerations

EPS foam is generally less expensive and easier to manufacture in large blocks or sheets. It’s cost-effective for disposable applications or products that require large volumes of lightweight foam.

EPP foam is more expensive due to its complex manufacturing process and higher performance characteristics. While initial costs are higher, EPP’s durability, reusability, and resilience often reduce long-term replacement costs, providing better value for high-performance applications.

Here are some differences between EPS foam and EPP foam as follows:

| Properties | EPS Foam | EPP Foam |

|---|---|---|

| Density | Higher density | Lower density |

| Strength | Less resilient | More resilient |

| Flexibility | More rigid | More flexible |

| Impact Resistance | Lower impact resistance | Higher impact resistance |

| Thermal Conductivity | Low thermal conductivity | Moderate thermal conductivity |

| Temperature Resistance | Susceptible to high temperatures | Maintains integrity across a wider temperature range |

| Cost | Generally more cost-effective | Typically more expensive |

| Recyclability | Can be recycled but less common | Recyclable and reusable |

Applications of EPS and EPP Foam

EPS and EPP foams are widely used across multiple industries due to their lightweight, durable, and insulating properties. While EPS excels in rigid, protective, and thermal applications, EPP is preferred for flexible, reusable, and impact-resistant products. Understanding their distinct applications helps manufacturers select the best foam type for packaging, automotive, construction, and industrial uses.

Packaging Solutions

EPS foam is commonly used for disposable packaging, protecting electronics, glass, and fragile items during shipping. Its rigid structure absorbs shocks, prevents damage, and reduces transportation risks, making it a cost-effective solution for single-use protective packaging.

EPP foam is ideal for reusable packaging, such as transport trays and protective inserts. Its elasticity allows repeated impacts without damage, making it suitable for automotive parts, heavy equipment components, and industrial supply chains where durability and repeated use are essential.

Automotive Components

EPS foam is often used in car headrests, dashboard panels, and insulation parts that require light cushioning and structural support. Its lightweight and thermal insulation properties help improve vehicle efficiency and comfort.

EPP foam is widely applied in energy-absorbing components like bumpers, crash structures, and seating cores. Its high resilience and ability to withstand repeated impacts make it ideal for safety-critical automotive applications, protecting passengers while maintaining shape and performance over time.

Construction and Insulation

EPS foam is extensively used in building insulation, wall panels, and roof boards. Its excellent thermal resistance helps reduce energy consumption and maintain stable indoor temperatures, making it a popular choice for both residential and commercial construction.

EPP foam can also be used in construction for lightweight panels, vibration damping, and reusable modular components. Its flexibility and durability make it suitable for applications requiring repeated handling, impact resistance, and long-term performance under variable conditions.

Consumer Goods and Sports Equipment

EPS foam is found in disposable cups, coolers, and packaging for household appliances. Its lightweight and insulating properties provide practical, cost-effective solutions for everyday consumer products.

EPP foam is used in helmets, sports padding, and protective gear. Its ability to absorb repeated impacts while maintaining elasticity ensures safety, comfort, and long-term durability, making it preferred for high-performance or safety-focused consumer products.

Industrial Applications

EPS foam supports temporary protective solutions, shipping inserts, and insulation for temperature-sensitive materials in industrial processes. It is cost-effective for large-scale, single-use applications where rigid protection is needed.

EPP foam is used in reusable trays, pallets, and vibration-damping inserts for machinery and electronics. Its impact resistance, flexibility, and durability make it ideal for repeated industrial use, reducing replacement costs and improving operational efficiency.

Here are some uses of EPS and EPP foam in the following:

| Aspect | EPS Foam | EPP Foam |

|---|---|---|

| Packaging Solutions | Single-use protective packaging | Reusable and durable packaging |

| Automotive Components | Cushions, insulation panels | Crash absorption, energy-absorbing |

| Construction & Insulation | Wall panels, roof boards | Lightweight panels, vibration damping |

| Consumer Goods & Sports | Cups, coolers, appliance protection | Helmets, sports padding, protective gear |

| Industrial Applications | Shipping inserts, insulation | Reusable trays, pallets, machine protection |

How to Choose EPS and EPP?

Choosing between EPS and EPP foam depends on the specific requirements of your project, including impact resistance, flexibility, thermal insulation, and production volume. Evaluating the performance, cost, and application needs of each foam type ensures the most suitable material is selected, improving durability, efficiency, and overall product quality in automotive, packaging, construction, or industrial uses.

Application Requirements: Consider industry-specific needs such as automotive crash absorption, packaging protection, construction insulation, or consumer safety products. Matching the foam type to performance, weight, and handling requirements ensures optimal functionality and avoids material wastage or failure in critical applications.

Consider Impact Resistance: Determine the level of shock absorption needed. EPS foam is suitable for one-time impact protection, such as disposable packaging, while EPP foam can handle repeated impacts, making it ideal for automotive components, reusable packaging, and protective equipment. Choosing the correct material prevents damage and ensures long-term reliability.

Evaluate Flexibility and Reusability: EPS foam is rigid and can easily break under stress, making it better for single-use applications. EPP foam’s flexibility allows repeated compression without deformation, making it suitable for reusable trays, energy-absorbing automotive parts, and long-lasting industrial components where durability is critical.

Assess Thermal Insulation Needs: EPS foam provides excellent thermal insulation for building panels, food packaging, or temperature-sensitive shipments. EPP foam also offers thermal resistance but with added durability and impact resistance, making it suitable for applications where insulation must be combined with repeated use or structural support.

Production Volume and Cost: EPS foam is cost-effective and easy to manufacture in large blocks or sheets, suitable for mass-produced or disposable items. EPP foam is more expensive initially, but its durability and reusability reduce long-term costs, providing better value for high-performance or repeated-use applications.

Conclusion

Choosing the right foam material depends on your project requirements, production volume, and desired performance. EPS foam is cost-effective and suitable for disposable or single-use applications, while EPP foam offers superior resilience, flexibility, and reusability for demanding industrial and automotive uses. Understanding these differences ensures optimal product performance.

For businesses seeking reliable foam materials, sourcing the right supplier is key. We provide wholesale EPS foam and EPP foam tailored for various applications, from packaging and insulation to automotive and industrial components. Our products ensure consistent quality, durability, and performance for both single-use and reusable solutions.

Investing in the proper foam type and supplier helps reduce costs, improve product protection, and enhance operational efficiency. By choosing EPS or EPP foam from our wholesale offerings, manufacturers gain high-performance materials designed to meet diverse application needs and long-term usage requirements.