Selecting the correct EPS filling gun is crucial for optimizing your production line’s efficiency and product quality. The right choice can dramatically improve fill accuracy, reduce cycle times, and minimize material waste. This guide will help you navigate the various types of guns available, ensuring you choose the one that best suits your specific molding applications and operational goals.

From manual to fully automated systems, the technology behind EPS filling guns has evolved to meet diverse manufacturing demands. Understanding the key features, such as nozzle design, flow control, and durability, is essential. We’ll explore these factors to provide you with the knowledge needed to make a strategic investment for a more productive and profitable operation.

What is EPS Filling Gun?

An EPS (Expanded Polystyrene) filling gun, also known as an EPS injector or filler, is a specialized tool used in the manufacturing of expanded polystyrene foam products. Its primary function is to precisely and efficiently dispense pre-expanded EPS beads from a hopper into a mold.

By controlling the flow of the beads, the gun ensures even distribution within the mold, which is a critical step for producing consistent, high-quality foam products used for various applications like packaging and insulation. The use of a filling gun automates and streamlines what would otherwise be a slow and inconsistent manual process, thereby increasing production speed, reducing labor costs, and minimizing material waste.

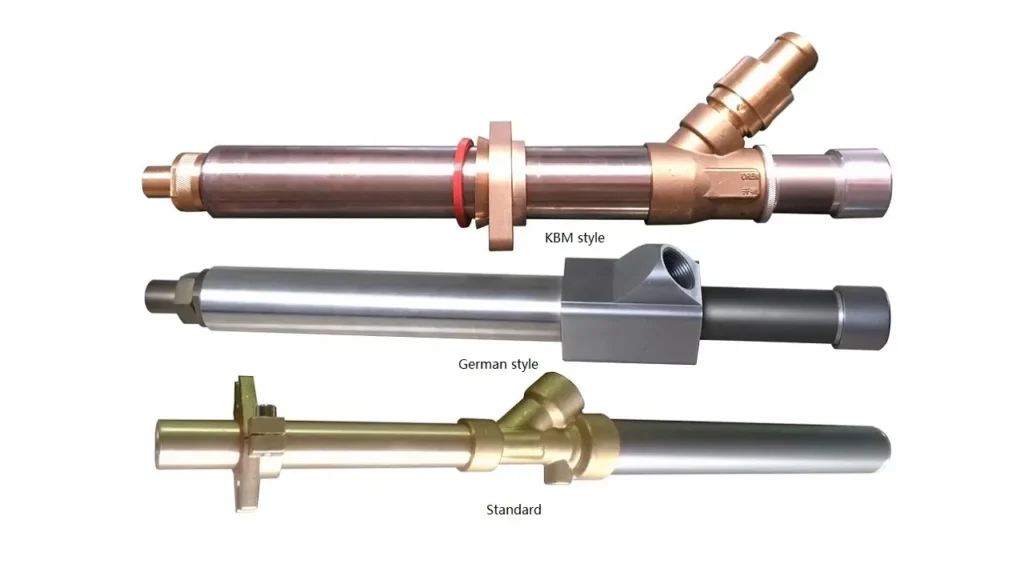

EPS Filling Gun Types

Different types of EPS filling guns are designed to meet the diverse needs of the expanded polystyrene molding industry. Choosing the right one is essential for optimizing production speed, ensuring consistent product quality, and maximizing operational efficiency. The primary variations relate to their design, mechanism, and level of precision, which in turn affect their suitability for specific applications.

Germany Style EPS Filling Gun

The Germany-style EPS filling gun is a high-precision tool known for its robust construction and advanced design. Engineered for efficiency, it often features a unique valve mechanism that provides exceptional control over the flow of EPS beads, ensuring a consistent and uniform fill. Its durability makes it a popular choice for large-scale industrial operations where reliability and minimal downtime are paramount. This type is particularly well-suited for intricate molds and applications requiring very accurate material placement.

This style of filling gun is built with high-quality, corrosion-resistant materials to withstand demanding production environments. Its design typically allows for easy maintenance and quick disassembly, reducing the time needed for cleaning and repairs. Many models feature ergonomic grips and a balanced weight distribution, which improves operator comfort and reduces fatigue during long production shifts. The Germany-style gun is valued for its contribution to superior product quality and enhanced operational efficiency.

KBM Style EPS Filling Gun

The KBM style EPS filling gun is renowned for its straightforward design and ease of use. It is a popular choice for both new and experienced operators due to its simple yet effective functionality. This type of gun often incorporates a single, reliable valve system that ensures a steady and predictable flow of EPS beads. Its basic construction makes it less prone to mechanical failures, contributing to a stable and consistent production process.

This style is a versatile option for a wide range of molding applications, from simple packaging to more complex insulation products. The KBM style is praised for its affordability and low maintenance requirements, making it an excellent investment for small to medium-sized enterprises. Its robust build and intuitive operation allow for quick training and seamless integration into existing production lines, providing a dependable solution for everyday EPS molding tasks.

Standard EPS Filling Gun

The standard EPS filling gun represents a baseline design that balances functionality with cost-effectiveness. Characterized by its conventional structure, this gun typically features a simple on/off valve for controlling the bead flow. It is widely used across the industry for general-purpose applications where precise flow control is less critical than speed and volume. This type is an accessible entry point for companies beginning to automate their EPS molding processes.

While it may lack some of the advanced features of specialized models, the standard filling gun is celebrated for its reliability and broad applicability. Its no-frills design minimizes potential points of failure, ensuring long-term performance with minimal upkeep. This gun is ideal for high-volume production of straightforward EPS products like blocks and sheets, where its efficiency and dependable operation can significantly boost output.

EPS Filling Gun Applications

An EPS filling gun is a fundamental tool used across various industries for the precise and efficient injection of expanded polystyrene (EPS) beads into molds or cavities. This process is essential for creating a wide range of foam products with consistent density and quality.

The main applications of these guns are found in manufacturing, packaging, and construction, where the unique properties of EPS—such as its lightweight nature, excellent insulation, and cushioning—are highly valued. By automating the filling process, the guns ensure uniform distribution, which is crucial for product performance and structural integrity.

- Molding: Used with EPS shape molding machines to produce a vast array of foam products, including cups, plates, decorative items, and components for products like helmets.

- Packaging: Creating custom-fit foam packaging to protect fragile items like electronics, appliances, and glassware during transport.

- Insulation: Producing foam panels and blocks for walls, roofs, and floors to enhance thermal insulation and energy efficiency in buildings.

- Construction: Manufacturing lightweight yet strong construction materials such as insulated concrete forms (ICFs) and structural insulated panels (SIPs) that provide both structural support and insulation.

How to Choose the Right EPS Filling Guns

Choosing the right EPS filling gun is a critical decision that impacts your production efficiency and final product quality. The ideal gun should align with your specific manufacturing needs, from the complexity of your molds to your desired production speed. Consider the following key factors when making your selection:

- Compatibility: Ensure the gun is compatible with your existing EPS molding machine and the specific type and size of EPS beads you are using.

- Nozzle Type and Design: The shape and number of nozzles determine how evenly the beads are distributed. Multi-nozzle designs are ideal for large, complex molds, while single nozzles are better for smaller, simpler shapes.

- Flow Control and Precision: Look for a gun that offers precise control over the bead flow to prevent overfilling or inconsistent density, which can compromise product quality.

- Durability and Materials: The gun’s construction should be robust enough to withstand continuous industrial use. Guns made from high-quality metals are more durable and have a longer service life.

- Ergonomics and Ease of Use: A lightweight and well-balanced gun reduces operator fatigue, especially during long production runs. Easy maintenance and cleaning are also vital for minimizing downtime.

Conclusion

Choosing the right EPS filling gun is a pivotal decision that directly impacts the performance and profitability of your production line. As we’ve explored, each type offers distinct advantages, from the precise control of single-head guns to the high-speed efficiency of multi-nozzle systems. By carefully assessing your specific needs—including mold complexity, production volume, and automation level—you can select a gun that ensures optimal material usage and consistent, high-quality output.

Investing in a superior filling gun is a long-term strategy for operational excellence. It not only streamlines your molding process but also reduces maintenance costs and downtime, providing a significant return on investment. The correct gun becomes a core component of a lean manufacturing process, helping you meet production targets and maintain a competitive edge in the market.

For a wide selection of high-quality wholesale EPS filling guns designed for various industrial applications, visit our website. At Epsole, we offer reliable, durable, and technologically advanced solutions to enhance your production efficiency. Partner with us to find the perfect filling gun to optimize your operations and achieve consistent, exceptional results.