Choosing the right foam material for your project can significantly impact its performance and success. This blog post will delve into the key differences between Expanded Polypropylene (EPP) and Expanded Polyethylene (EPE) foam.

We’ll explore their unique properties, applications, and which material might be the best fit for your specific needs.

What Is EPP

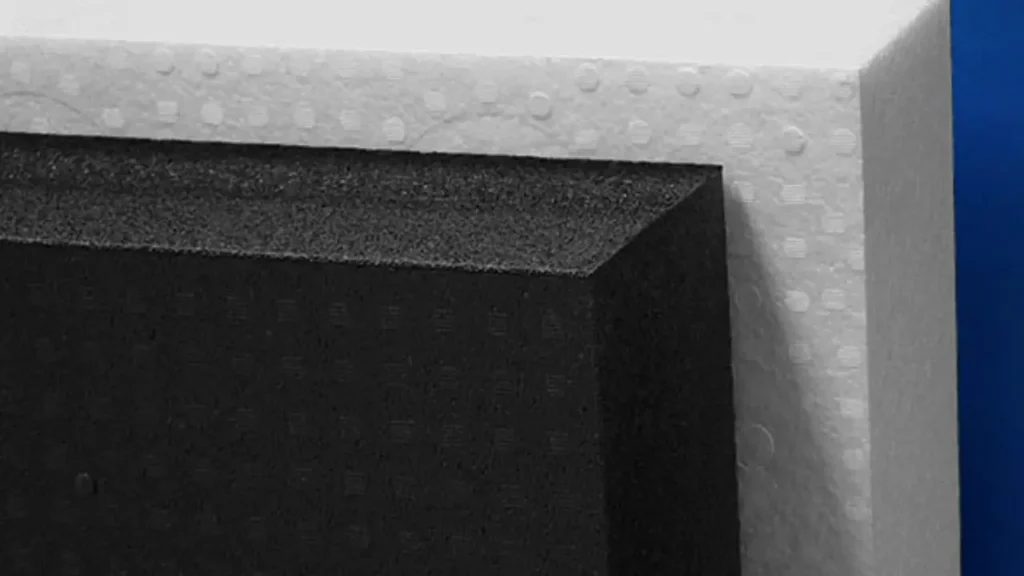

EPP, which stands for Expanded Polypropylene, is a closed-cell foam material known for its exceptional energy absorption, impact resistance, and resilience.

EPP foam material properties include high shock resistance, excellent energy absorption, high resilience, good chemical resistance, and low water absorption. These properties make it suitable for a wide range of applications, from protective packaging and automotive components to sports equipment and thermal insulation.

What Is EPE

Expanded Polyethylene (EPE) foam is a lightweight, closed-cell material created by expanding polyethylene resin. This process introduces gas bubbles into the material, transforming it into a cushion-like foam with excellent shock-absorbing properties.

EPP vs EPE Foam

EPP (Expanded Polypropylene) vs. EPE (Expanded Polyethylene) Foam

Both EPP and EPE are lightweight, closed-cell foams with excellent shock-absorbing properties, but they exhibit distinct characteristics that make them suitable for different applications.

EPP (Expanded Polypropylene)

Production: Manufactured by expanding polypropylene beads with a blowing agent.

Properties:

- Exceptional Impact Resistance: Highly resilient and able to withstand repeated impacts with minimal deformation.

- High Strength-to-Weight Ratio: Strong and durable despite its lightweight nature.

- Excellent Energy Absorption: Effectively dissipates impact energy.

- Good Chemical Resistance: Resistant to many chemicals and solvents.

- Recyclable: Can be easily recycled and reused.

- Temperature Resistance: Withstands a wide range of temperatures.

Applications:

- Sports Equipment: Helmets, protective gear, impact-absorbing pads.

- Automotive: Bumpers, crash pads, interior components.

- Packaging: High-value goods, fragile electronics.

- Marine Applications: Buoyancy aids, flotation devices.

EPE (Expanded Polyethylene)

Production: Manufactured by expanding polyethylene resin.

Properties:

- Good Shock Absorption: Provides effective cushioning and protection.

- Lightweight and Flexible: Easy to shape and mold into various forms.

- Cost-Effective: Generally more affordable than EPP.

- Water and Chemical Resistant: Resistant to moisture and many chemicals.

- Recyclable: Can be recycled and reused.

Applications:

- Packaging: Shipping materials, protective inserts, cushioning for fragile items.

- Construction: Insulation, soundproofing, vibration damping.

- Marine Applications: Buoyancy aids, flotation devices.

- General Cushioning: Furniture padding, floor mats.

Here’s a table showing the key differences between Expanded Polypropylene and Expanded Polyethylene :

| Feature | EPP | EPE |

|---|---|---|

| Material | Expanded Polypropylene | Expanded Polyethylene |

| Density | Generally higher | Generally lower |

| Impact Resistance | Excellent | Good |

| Strength | High | Moderate |

| Flexibility | Less flexible | More flexible |

| Cost | Generally higher | Generally lower |

| Typical Uses | High-performance applications, sports equipment | Packaging, general cushioning |

EPP is the superior choice for applications requiring exceptional impact resistance, high strength, and durability. EPE, while less robust, offers a more cost-effective solution for general cushioning and packaging needs. The optimal choice depends on the specific requirements of the application.

EPP vs EPE, Which One is Better

EPP (Expanded Polypropylene) generally offers superior performance compared to EPE (Expanded Polyethylene) due to its exceptional properties.

- Impact Resistance: EPP significantly surpasses EPE in impact resistance. It can withstand repeated high-impact events with minimal deformation, making it ideal for applications where durability and shock absorption are paramount.

- Strength-to-Weight Ratio: EPP boasts a higher strength-to-weight ratio, meaning it’s stronger and more robust for its weight compared to EPE.

- Energy Absorption: EPP excels at absorbing and dissipating impact energy, providing superior protection in high-impact situations.

However, EPE has its advantages:

- Cost-Effectiveness: EPE is generally more affordable to produce and source than EPP.

- Flexibility: EPE is more flexible and easier to shape and mold into various forms.

In Sum:

Choose EPP when:

- Impact resistance is critical (e.g., sports equipment, automotive parts).

- High strength and durability are required.

- Superior energy absorption is necessary.

Choose EPE when:

- Cost is a primary concern.

- Flexibility and ease of shaping are essential.

- General cushioning and basic shock absorption are sufficient.

Ultimately, the “better” choice depends entirely on the specific application and the priorities of the user.

EPS vs EPP

Expanded Polystyrene (EPS) and Expanded Polypropylene (EPP) are both lightweight foams used in various applications, but they differ significantly in their properties.

EPS, commonly known as Styrofoam, is a widely used, cost-effective material known for its excellent insulation and cushioning properties. It is often used in packaging, insulation, and disposable food containers.

EPP, on the other hand, is a high-performance foam with superior impact resistance, durability, and memory. It is used in high-end applications like sports equipment (helmets, protective gear), automotive components (bumpers), and packaging for high-value goods.

Conclusion

Choosing between EPP and EPE foam depends heavily on the specific application and desired properties. EPP excels in impact resistance, durability, and recyclability, making it ideal for high-performance applications like sports equipment and automotive parts. EPE, while less durable, offers cost-effectiveness and versatility, finding widespread use in packaging and general cushioning.

Consider sourcing from our EPS manufacturer for high-quality, sustainable EPS foam solutions. We offer a wide range of EPS products tailored to your specific needs, including [mention specific products or applications]. Contact us today for a free consultation and discover how our EPS foam can benefit your business.