We manufacture versatile EPS foam boards designed to meet the rigorous demands of factory environments. These materials offer exceptional durability and thermal resistance for various machinery. By choosing our specialized products, we provide your facility with reliable protection that withstands heavy impact while maintaining consistent temperature control for sensitive processes.

We offer advanced insulation options that streamline your industrial operations. Our team produces lightweight yet sturdy components that fit seamlessly into complex equipment layouts. We supply these solutions to help reduce energy waste and improve safety standards across your production line, ensuring long term performance in challenging settings.

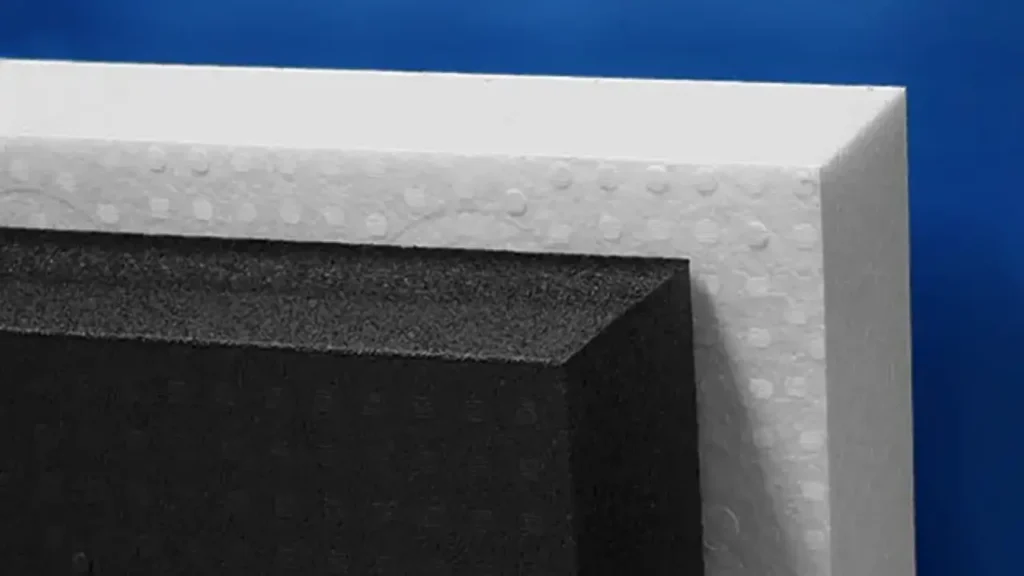

What is EPP Insulation?

EPP insulation, or Expanded Polypropylene insulation, is a lightweight foam material known for durability, thermal stability, and impact resistance. It provides reliable heat and sound insulation while maintaining shape under stress.

EPP is moisture resistant, reusable, and recyclable, making it suitable for automotive, construction, packaging, and industrial insulation applications.

EPP Insulation Benefits

EPP insulation offers a smart balance of performance, durability, and sustainability across many industries. Thanks to its unique foam structure, it delivers dependable thermal and acoustic insulation while staying lightweight and tough. These benefits make EPP insulation a practical choice for long-term use in demanding environments.

- Environmentally friendly solution: EPP is reusable and fully recyclable, helping reduce waste, extend product life cycles, and support sustainable manufacturing and insulation practices.

- Excellent thermal insulation: EPP insulation effectively reduces heat transfer, helping maintain stable temperatures in both hot and cold conditions by trapping air within its closed-cell structure, improving energy efficiency in buildings, vehicles, and equipment over time.

- Strong impact and shape recovery: EPP absorbs repeated impacts and returns to its original shape without cracking, making it ideal for applications where insulation must also protect components from vibration, shocks, and ongoing mechanical stress.

- Lightweight yet durable material: EPP combines low weight with long service life, adding minimal load while delivering reliable strength, which is especially valuable in automotive and transport applications focused on efficiency.

- Moisture and chemical resistance: EPP resists water, oils, and many chemicals, ensuring stable insulation performance in humid or harsh environments while reducing risks of degradation or mold growth.

EPP Applications in Insulation

EPP insulation is widely used across industries where lightweight structure, durability, and thermal stability matter. Its ability to insulate, absorb impact, and resist moisture makes it suitable for both technical and everyday applications. From transportation to construction, EPP helps improve energy efficiency, protect components, and extend product service life.

Electronic device insulation: EPP provides thermal management and shock protection for electronic housings, helping maintain stable operating temperatures while safeguarding internal components.

Automotive thermal insulation: EPP is used in vehicle doors, roofs, and engine compartments to reduce heat transfer, dampen noise, and protect sensitive components from vibration while supporting vehicle lightweight design and fuel efficiency.

HVAC duct insulation: EPP panels and molded parts help maintain air temperature inside ventilation systems, reducing energy loss, limiting condensation, and improving overall system efficiency in residential and commercial buildings.

Building wall insulation: EPP insulation boards provide thermal and acoustic barriers in walls, helping regulate indoor temperatures, improve comfort, and reduce energy consumption in both residential and industrial structures.

Roof insulation systems: EPP is applied beneath roofing layers to minimize heat gain and loss, resist moisture penetration, and maintain stable insulation performance under changing weather conditions.

Floor insulation solutions: EPP insulation is used under flooring systems to reduce heat loss, improve sound insulation, and provide cushioning that enhances walking comfort and structural durability.

Industrial equipment insulation: EPP protects machinery and equipment by maintaining operating temperatures, reducing vibration impact, and shielding sensitive parts from environmental exposure and mechanical stress.

Cold chain packaging insulation: EPP containers and liners help maintain consistent temperatures during storage and transport of temperature-sensitive goods, supporting food, pharmaceutical, and medical logistics.

Appliance insulation components: EPP is used in refrigerators, freezers, and water heaters to improve thermal efficiency, reduce energy consumption, and enhance product durability.

Pipe and conduit insulation: EPP molded covers insulate pipes and conduits, limiting heat loss or gain, preventing condensation, and protecting lines from external impacts.

How to Know if EPP is Soundproof?

Determining if EPP is soundproof involves understanding its acoustic properties and testing methods. EPP foam is designed to absorb and dampen sound, but its effectiveness depends on thickness, density, and application. Evaluating these factors helps ensure optimal noise reduction for walls, panels, or industrial uses where sound control is essential.

- Compare with other insulation materials: Benchmarking EPP against materials like mineral wool or polyurethane foam provides context for its soundproofing performance. This helps decide if EPP alone is sufficient or if combined solutions are needed for maximum noise reduction.

- Check noise reduction coefficient (NRC): The NRC measures how much sound a material absorbs. Higher values indicate better absorption. Testing EPP in controlled conditions helps quantify its ability to reduce echoes, reverberation, and background noise in rooms or machinery enclosures.

- Assess material thickness and density: Thicker and denser EPP panels typically absorb more sound. Evaluating these physical characteristics ensures the foam provides sufficient acoustic insulation for the intended environment, whether for walls, ceilings, or protective enclosures.

- Perform practical sound tests: Real-world testing using sound meters or decibel meters helps determine EPP’s performance in actual conditions. Comparing measurements before and after installation reveals its effectiveness in reducing unwanted noise.

- Consider application method: EPP’s soundproofing efficiency depends on how it’s installed—loose panels, laminated layers, or molded components. Proper placement and coverage enhance absorption and prevent gaps where sound could pass through.

Why Choose Our EPP Materials?

Choosing the right EPP materials ensures long-lasting performance, durability, and efficiency across various applications. Our EPP products combine lightweight design, impact resistance, and thermal stability, making them ideal for automotive, construction, packaging, and industrial uses. We focus on quality, customization, and sustainability to meet the specific needs of our clients.

Environmentally responsible: Our EPP materials are recyclable and reusable, supporting sustainable practices while minimizing waste, reducing environmental impact, and promoting a circular economy without compromising quality or performance.

Exceptional durability: Our EPP materials withstand repeated impacts, stress, and deformation without losing shape or performance, ensuring long-term reliability in demanding environments such as automotive parts, industrial components, and protective packaging solutions.

Lightweight design: Our EPP foam is low in weight yet structurally strong, reducing overall product load, improving energy efficiency in vehicles and machinery, and making handling and installation easier without compromising strength.

Thermal and acoustic insulation: Our EPP materials provide excellent heat and sound insulation, helping maintain stable temperatures, reduce energy consumption, and minimize noise, making them perfect for building, transportation, and electronic applications.

Customizable solutions: We offer tailored EPP products in various shapes, densities, and sizes, allowing clients to meet specific requirements for performance, aesthetics, or application constraints, ensuring optimal functionality and integration.

Conclusion

We provide comprehensive support for all your manufacturing needs through our expert engineering team. By utilizing our specialized foam technology, we supply the market with superior alternatives to traditional materials. We ensure that every board meets strict performance criteria to help your business achieve better operational results and maintain a competitive edge in your specific industry.

We manufacture a wide range of custom options to suit unique project requirements. Whether you need standard sizes or specific shapes, we offer the flexibility to create the perfect fit. Our facility uses modern techniques to produce reliable products that meet global standards, making us a trusted partner for companies looking to upgrade their current thermal management systems.

We invite you to purchase wholesale EPP materials or EPP molds from Epsole today. We supply premium resources at scale to support your growth and production goals. Our team is ready to assist you with technical specifications and bulk orders, ensuring we provide the best possible value for your investment in durable industrial foam technology.